- Joined

- Oct 3, 2019

- Messages

- 679

- Reaction score

- 694

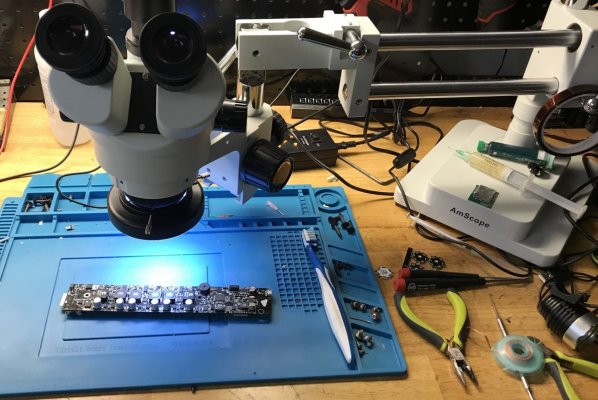

My previous electronic equipment repairs

Radion XR15:

www.reef2reef.com

www.reef2reef.com

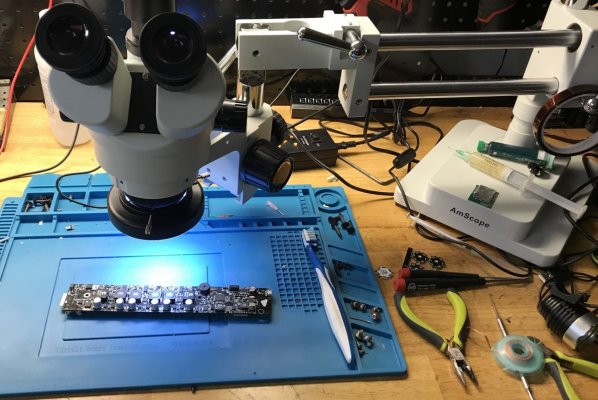

A fellow reefer mailed me their Ecotech Radion for repair service as it's long been out of warranty. The unit turns on briefly before shutting down and the fan is clean and spins perfectly fine.

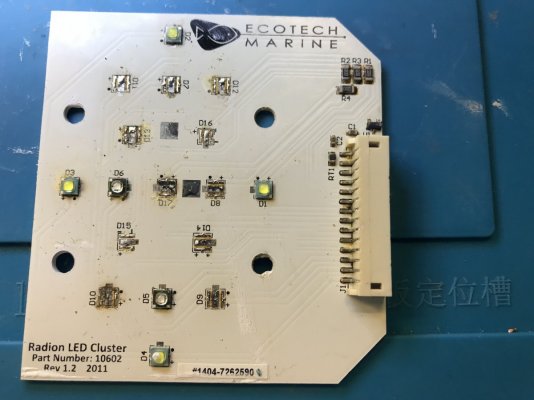

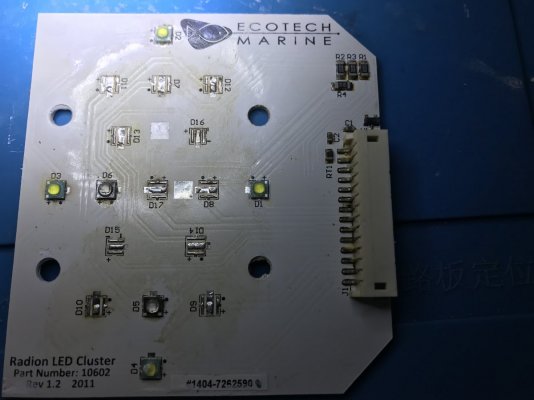

The light appears to be an XR30 Gen 1 with upgraded LED clusters. Let's begin with an initial visual inspection, shall we?

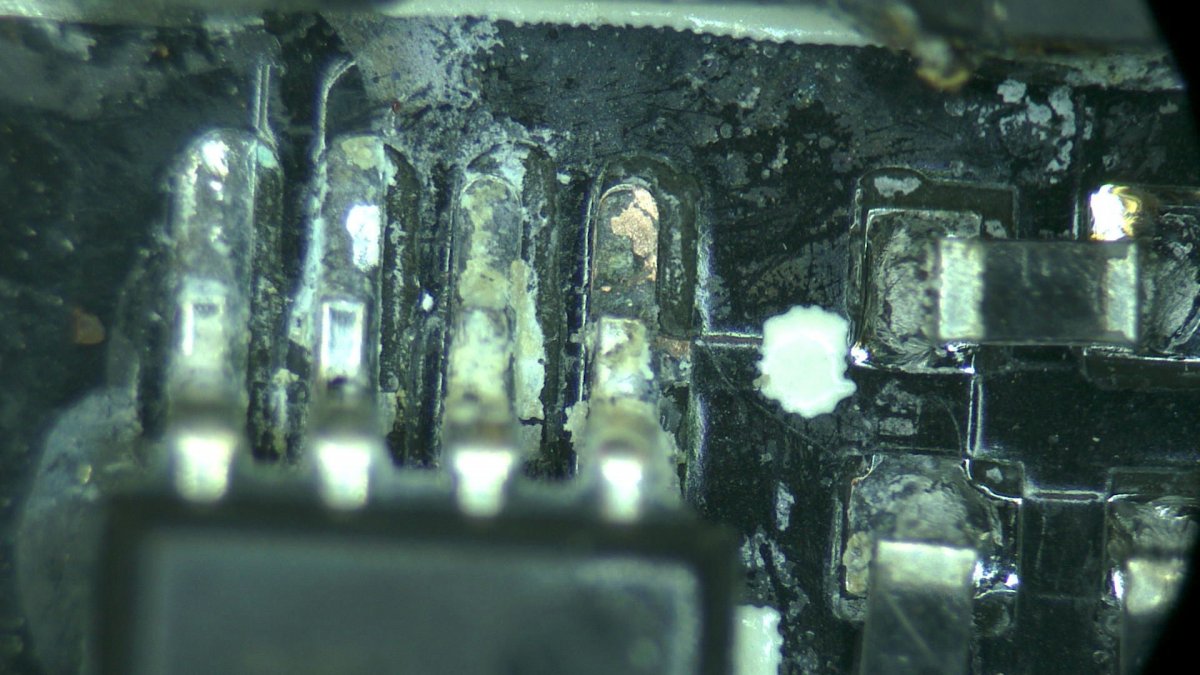

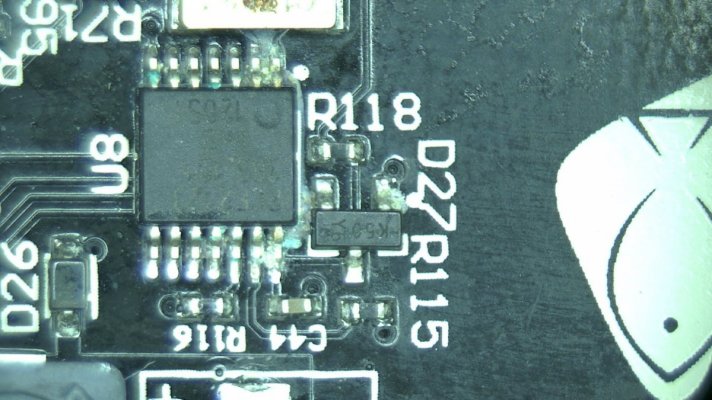

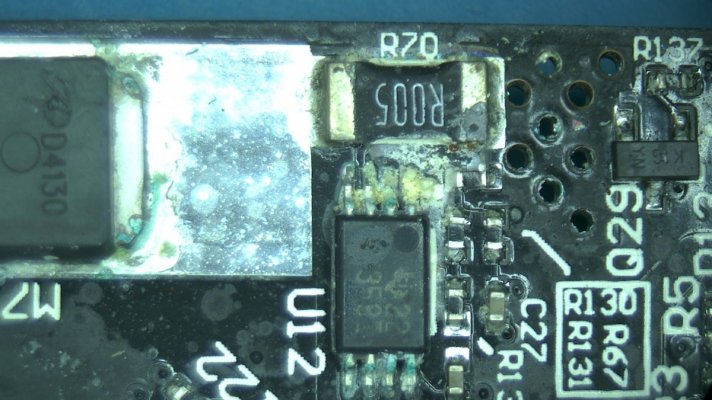

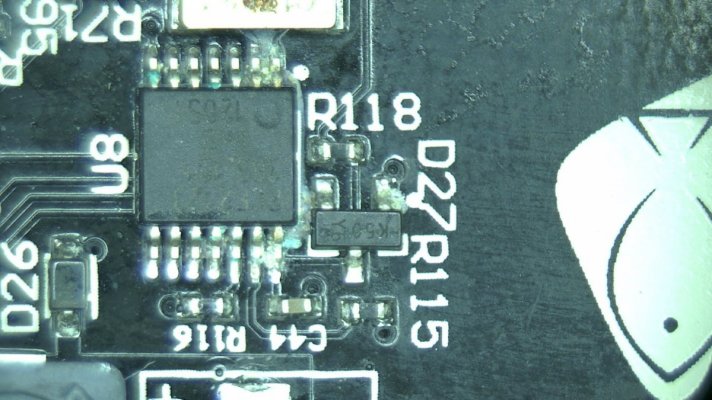

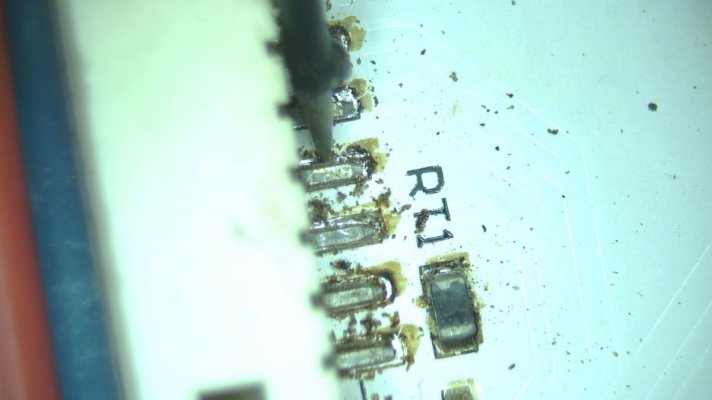

For an older light, one would expect a fair amount of corrosion on the main board. This light is certainly no exception.

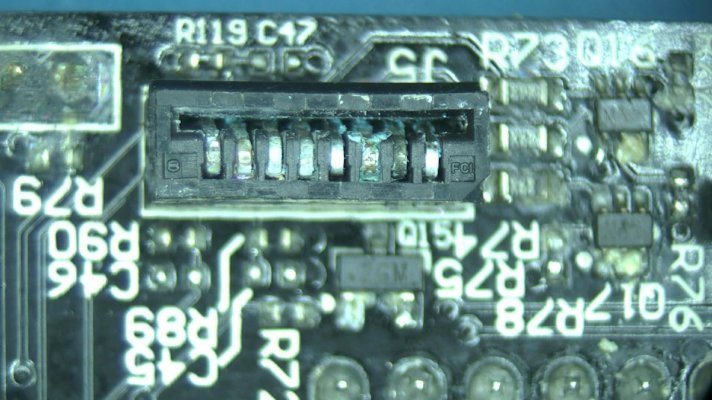

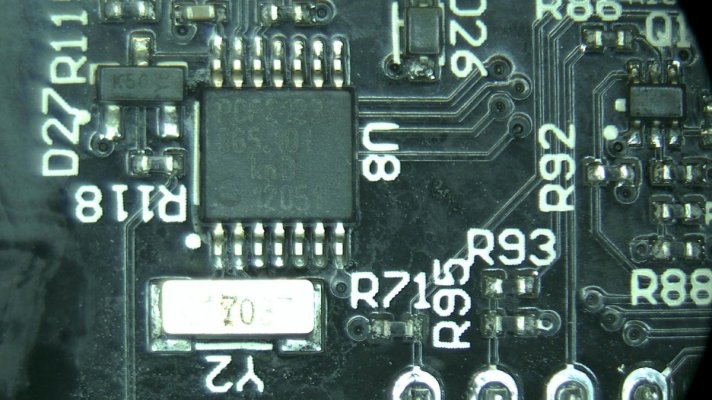

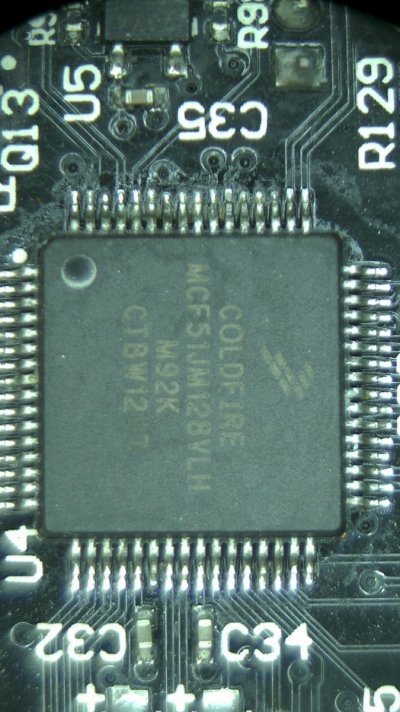

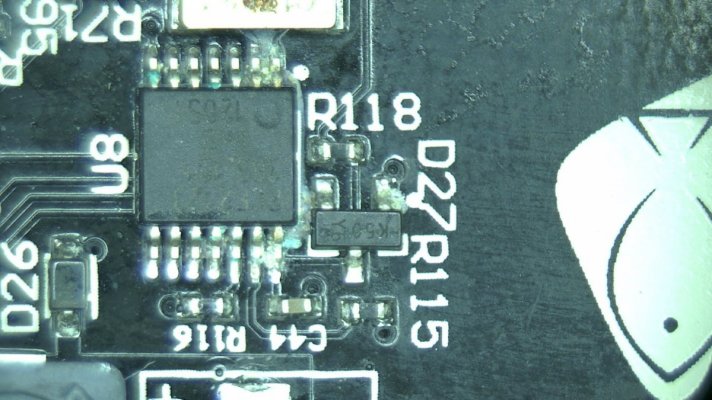

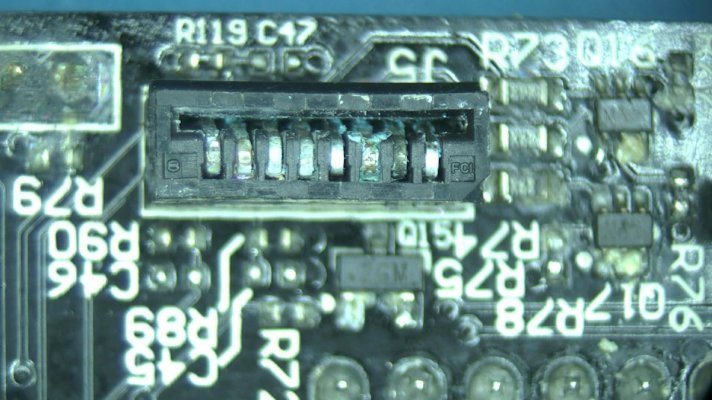

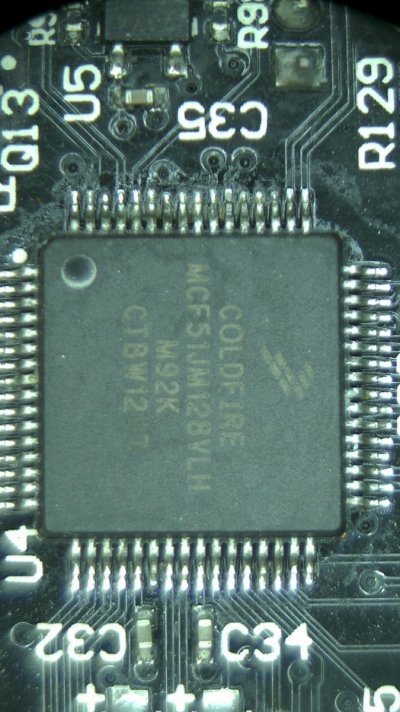

Even the main controller had a quite a bit of corrosion:

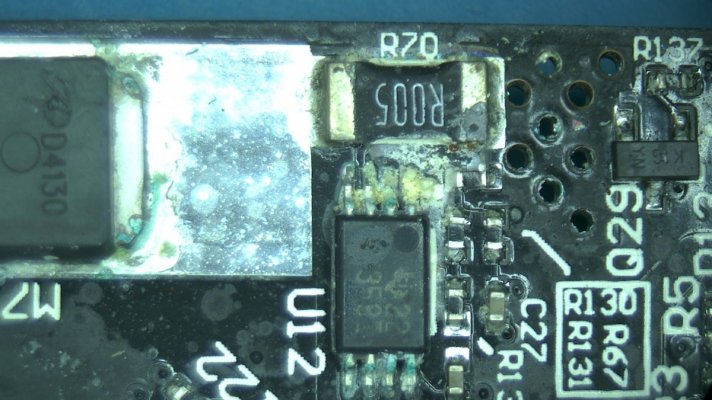

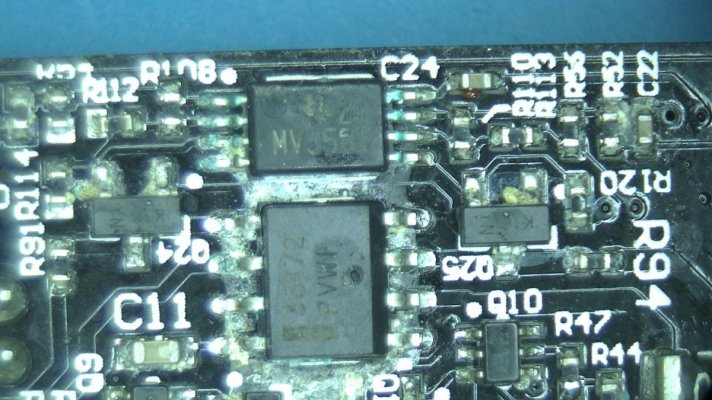

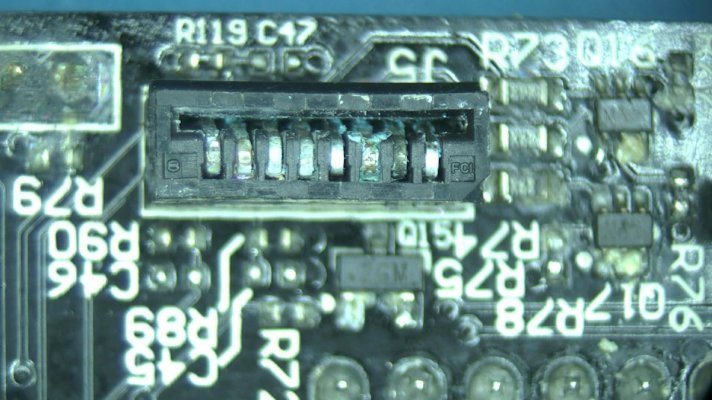

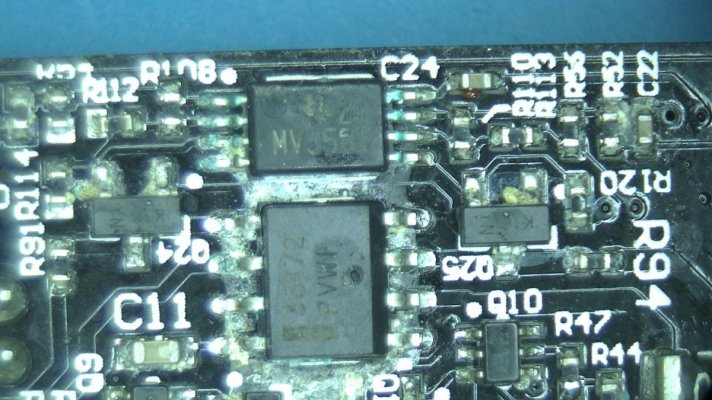

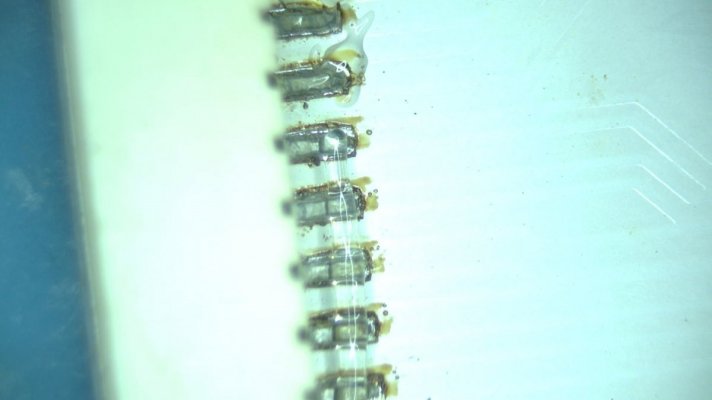

The wireless board was not in a much better shape:

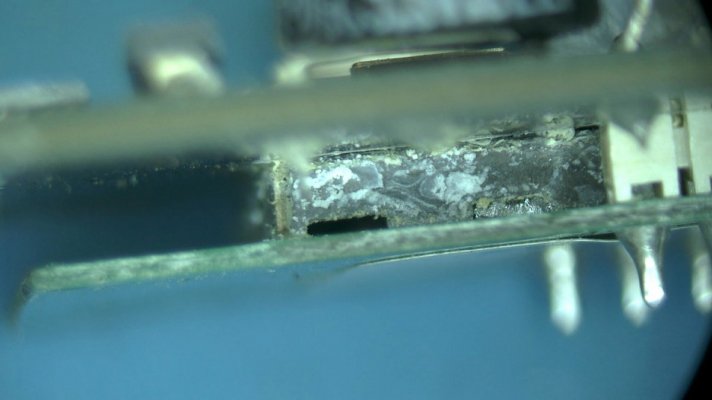

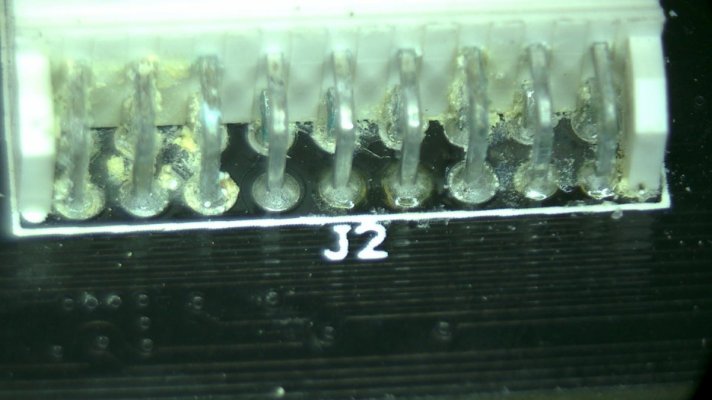

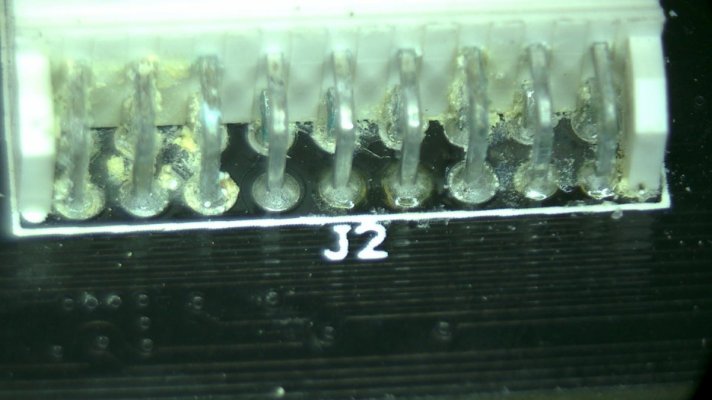

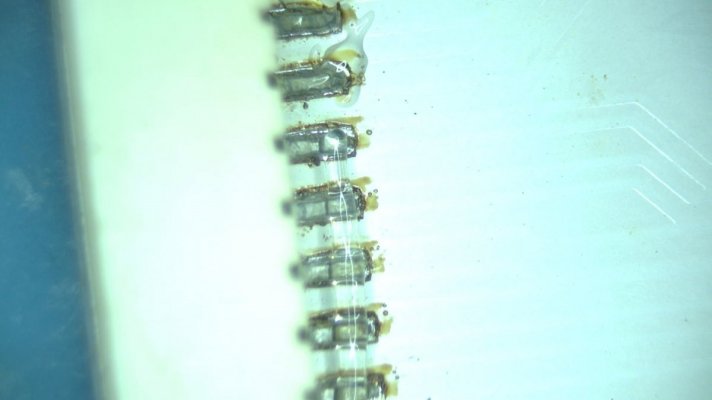

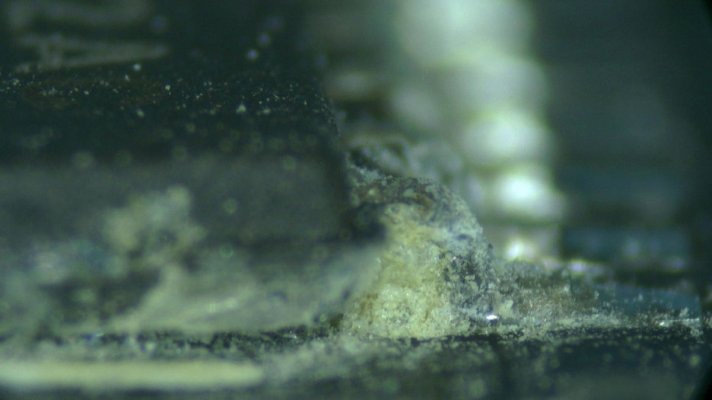

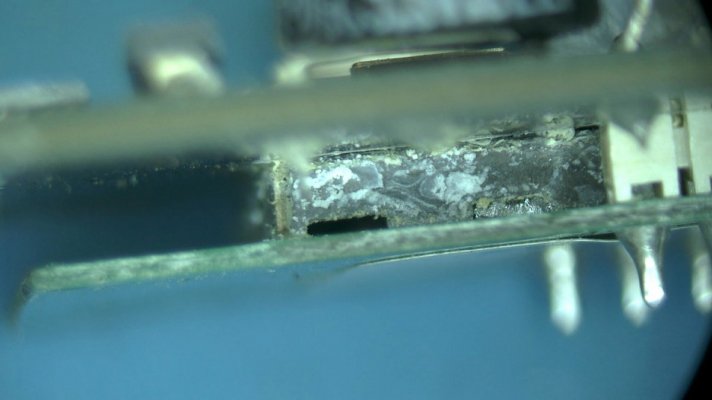

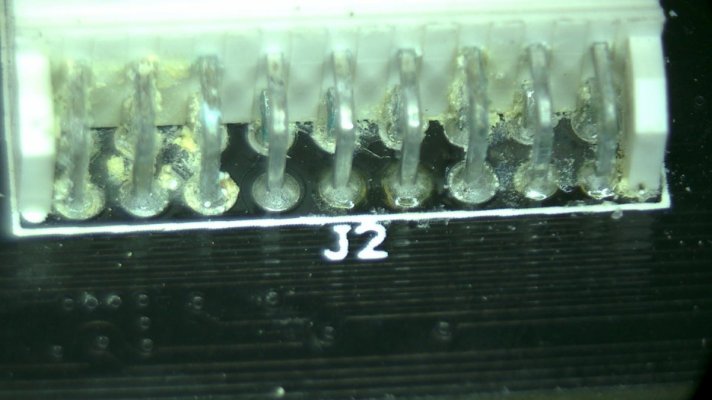

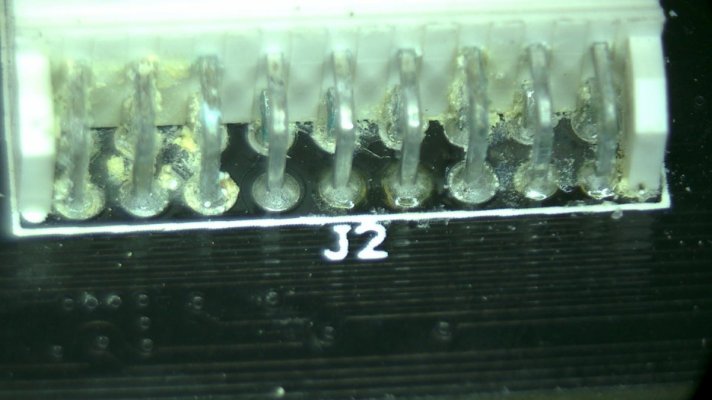

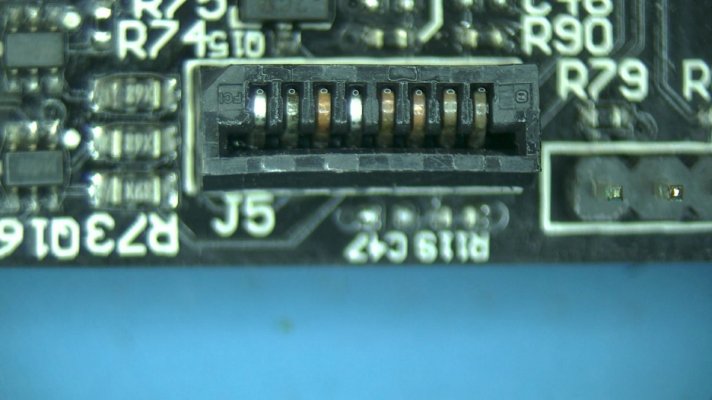

And all connectors were in a rough shape:

Now, all of this corrosion may not have been the primary cause of the failure, but leaving it on the board is going to be asking for trouble later. It's time to give the main board a bath (or two)!

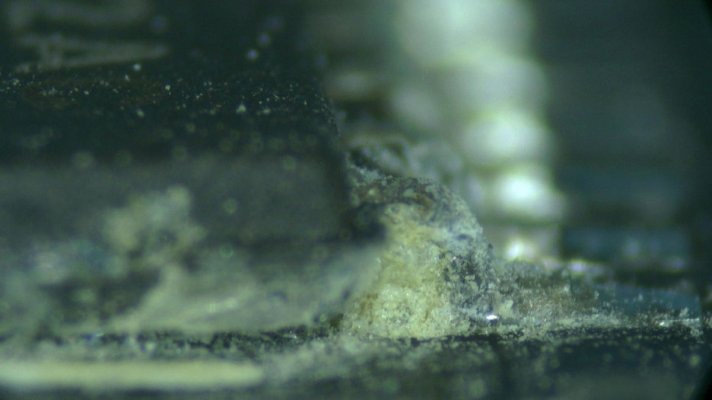

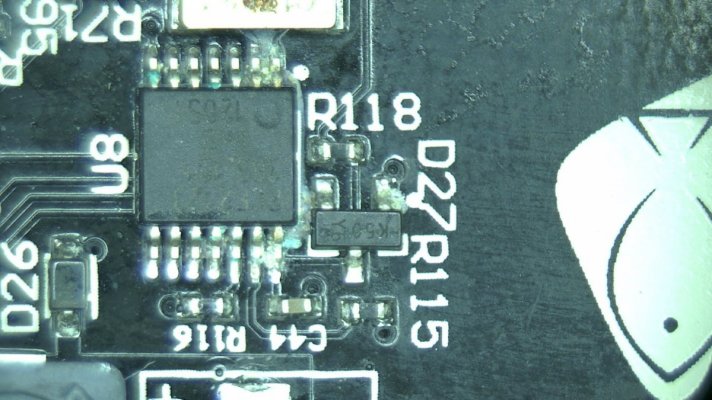

First, the wireless chip needs to come off. We find more corrosion around and under the chip as well:

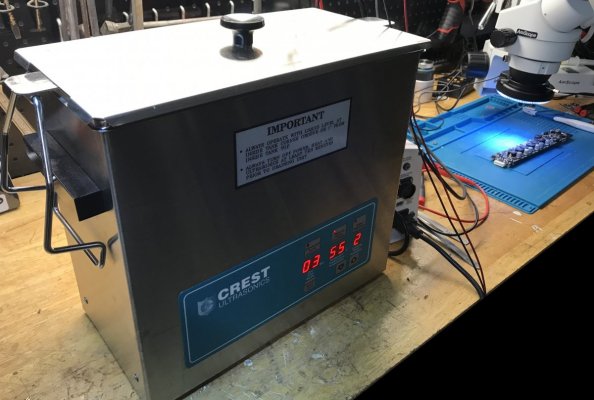

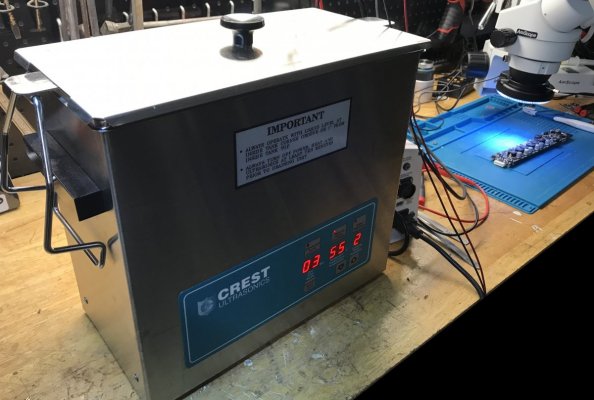

With the wireless module removed, the board is ready for a really good, but gentle ultrasonic cleaning:

And a quick rinse to displace any cleaning solution on the board:

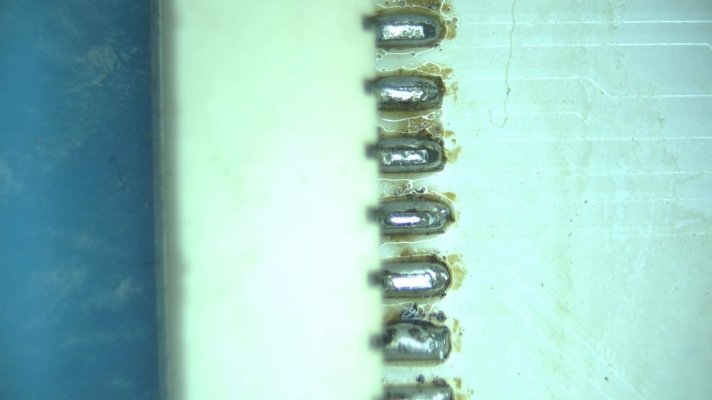

Now let's see if the cleaning made any difference:

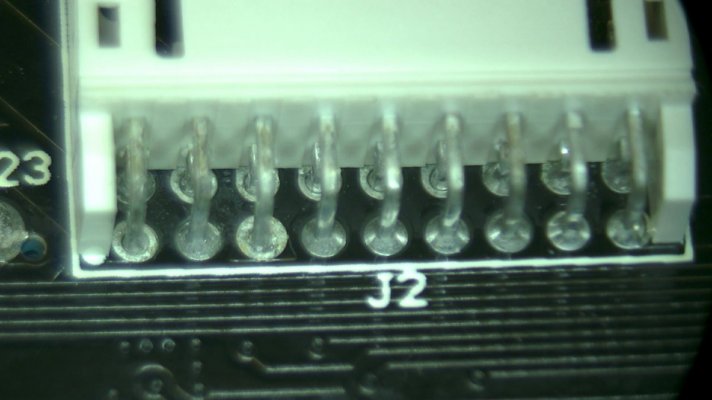

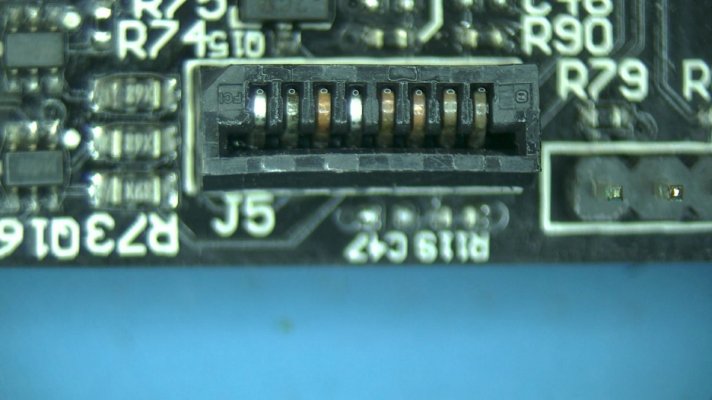

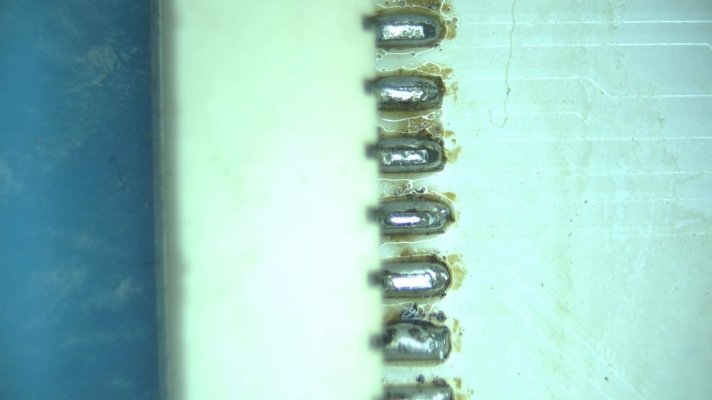

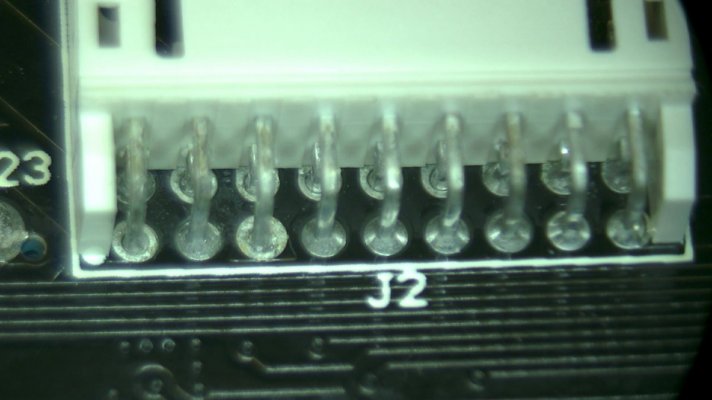

How about connectors:

I'd say, not bad for a quick rinse! But will the light work now? Not a chance. There is a bit more fun ahead!

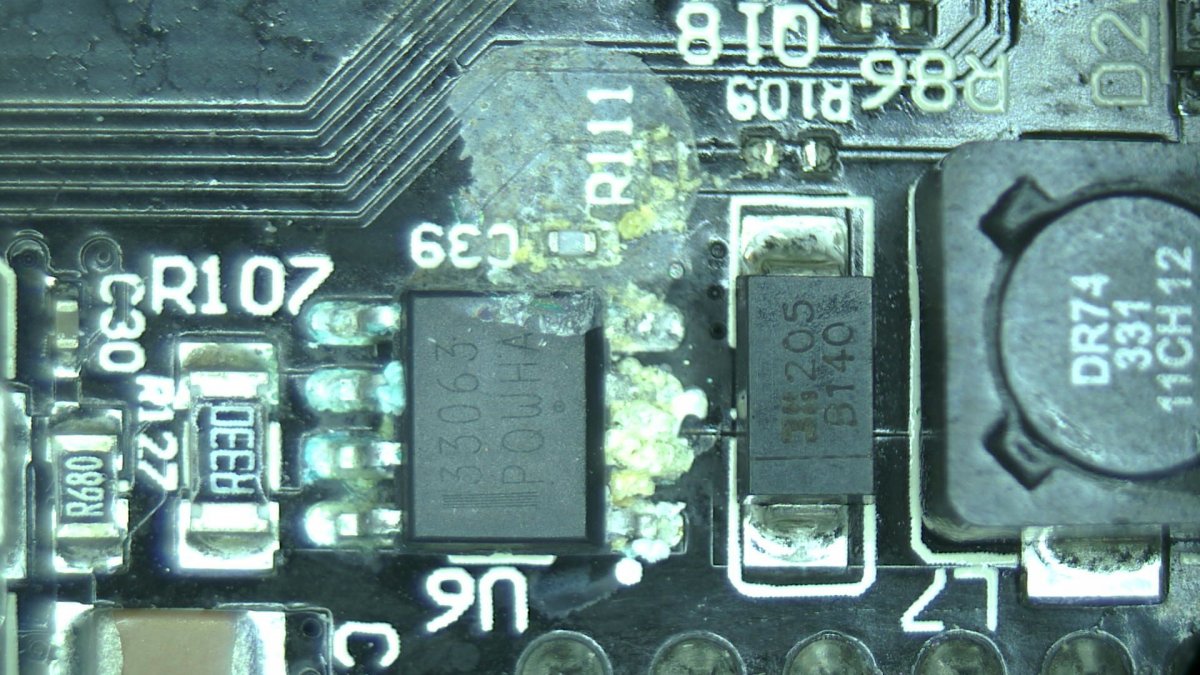

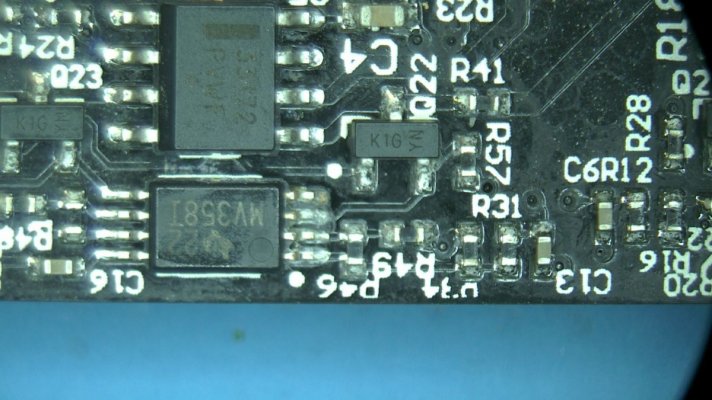

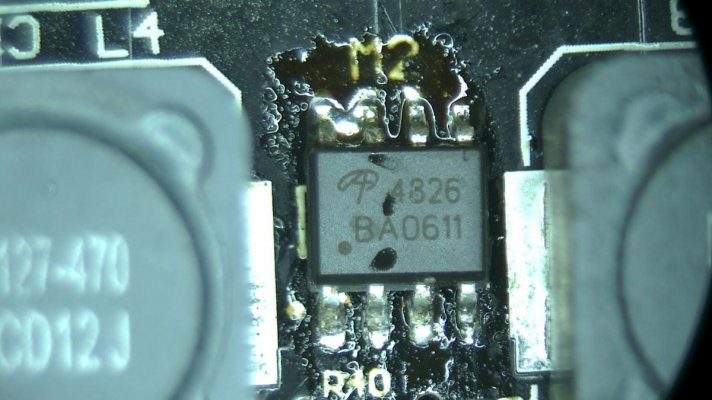

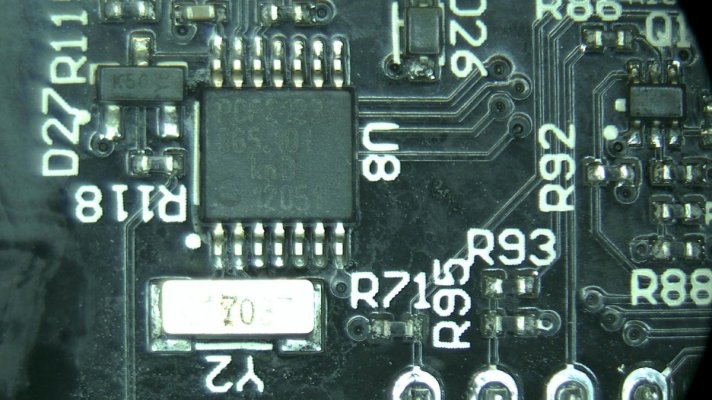

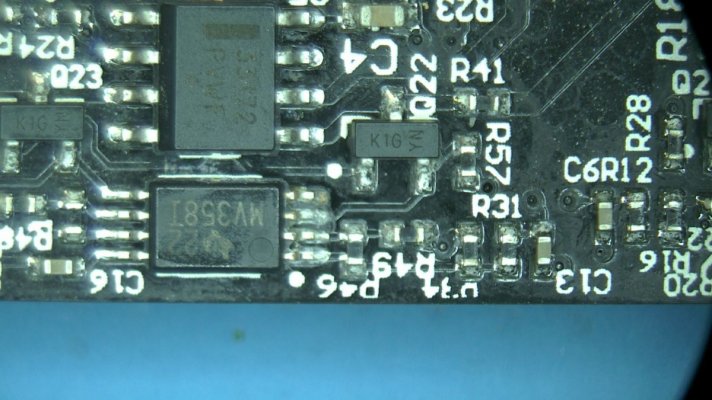

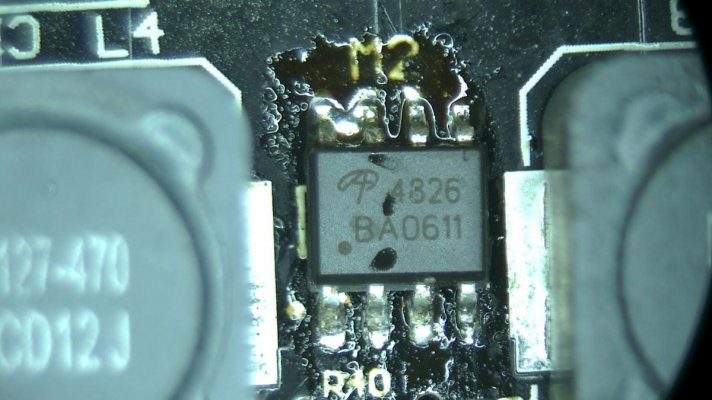

XR30 has 6 channels to control different sets of LEDs. Each channel is handled by a circuit of mosfets, op amps, relays and inductors. To save some space (and money) ecotech is using 3 dual mosfets, one to power two different LED channels. They look like so:

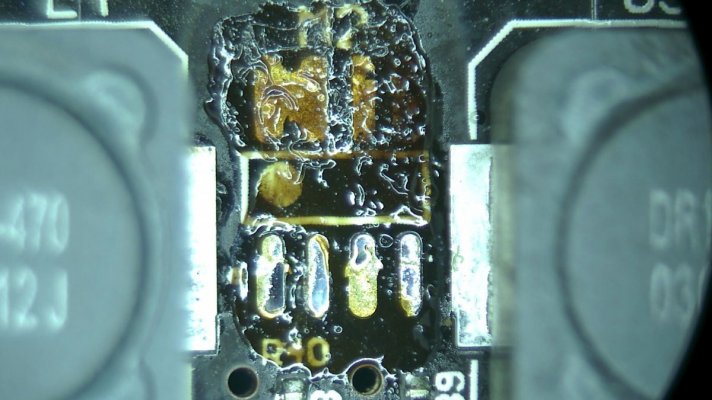

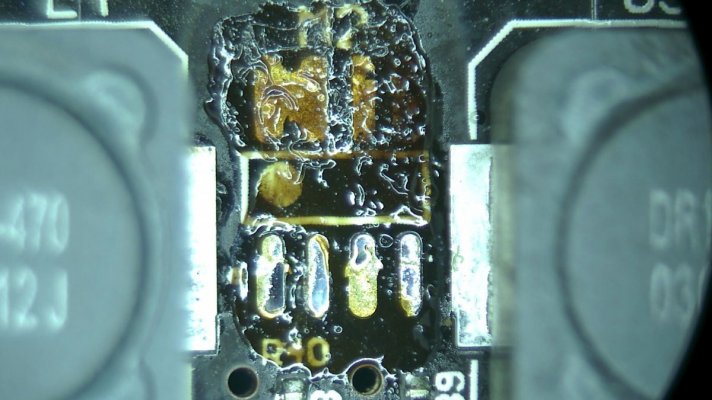

On this board, the middle mosfet shorted on both channels. This means at least 2/6 LED channels won't work unless it's replaced. Let's remove and replace:

With the burned out mosfet replaced, the board is mostly happy again. In fact, it now works perfectly fine with a good known working set of LED clusters.

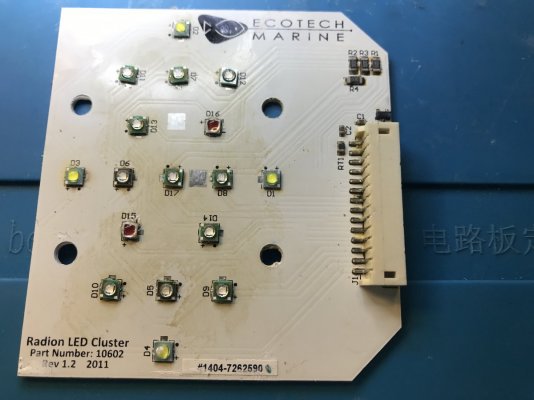

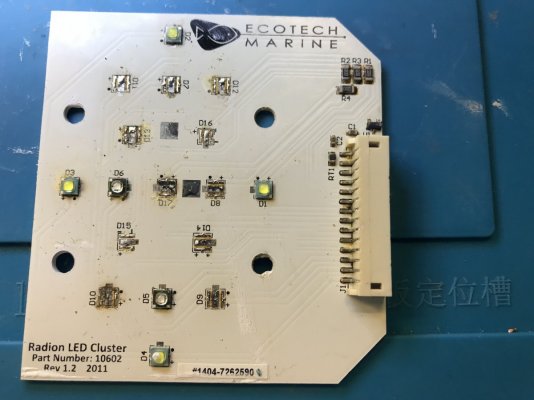

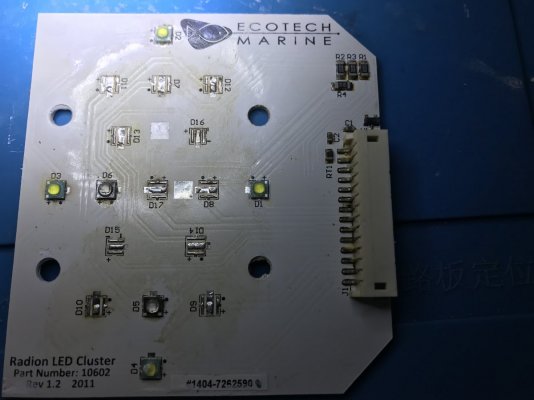

But the lights still won't fully turn on with the original LED lights. Time to examine the clusters. Oh, boy!

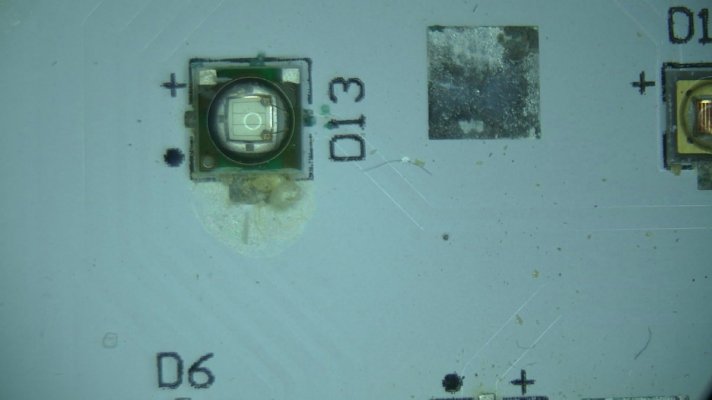

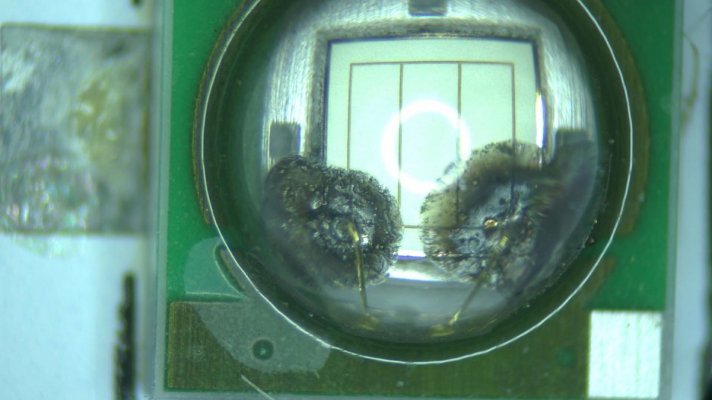

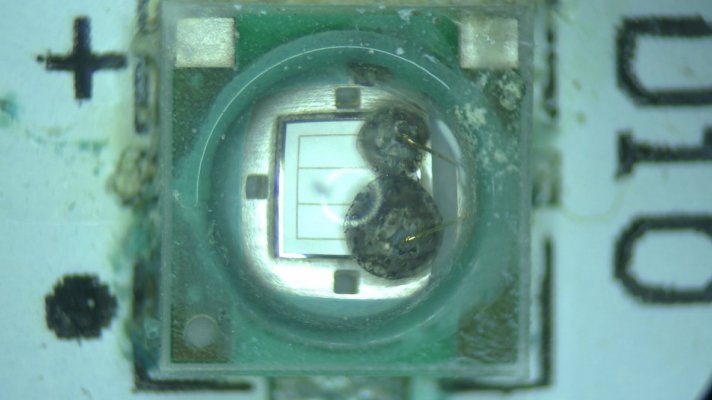

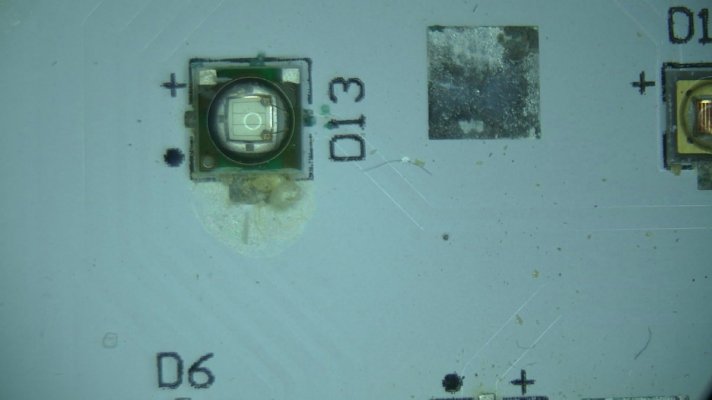

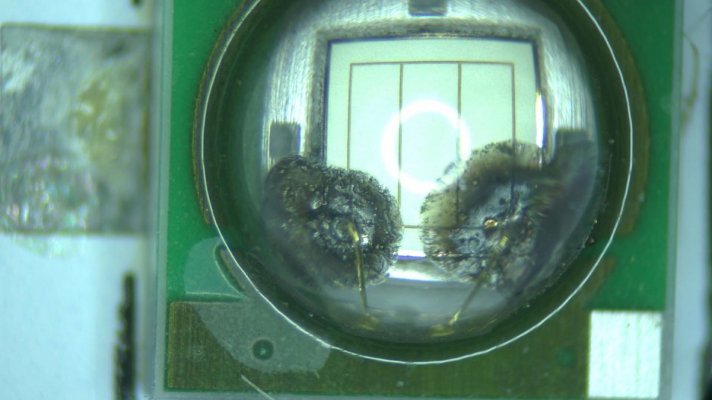

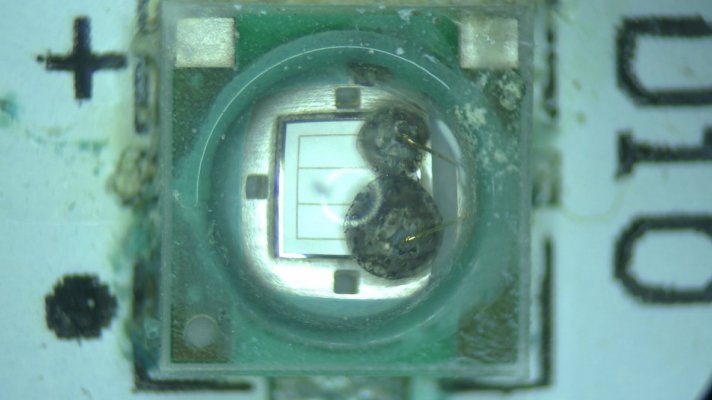

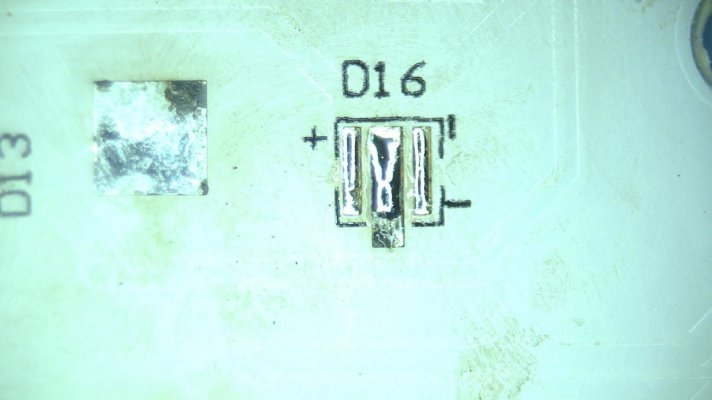

Of the total 32 LEDs across 2 clusters, 19 (!) were burned out or shorted. A typical picture observed:

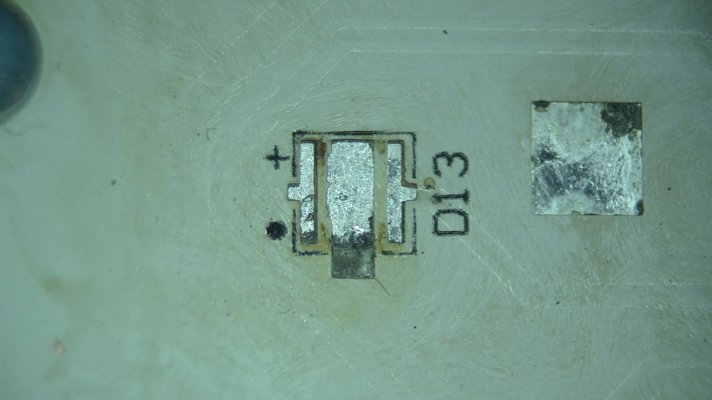

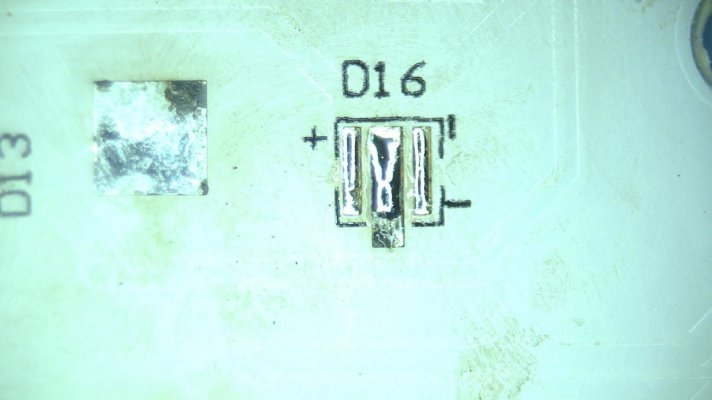

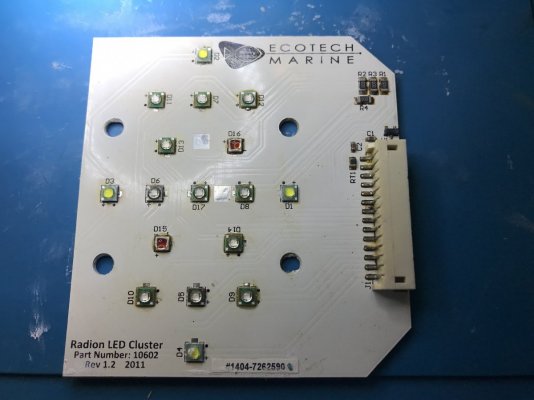

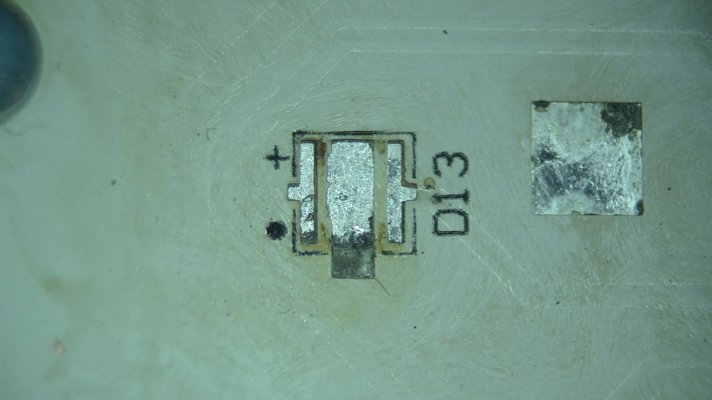

All of them will have to be replaced. There was certainly some corrosion under the LEDs:

But not anything that can't be fixed:

We are ready to do some baking:

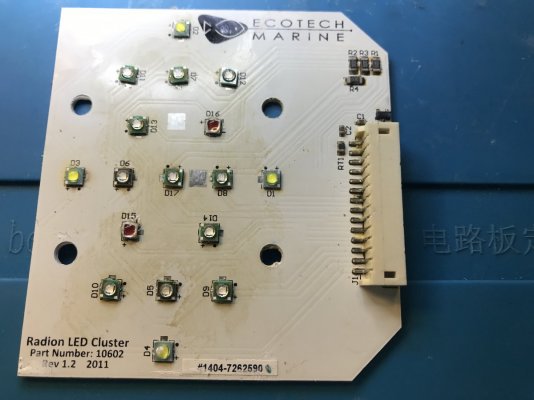

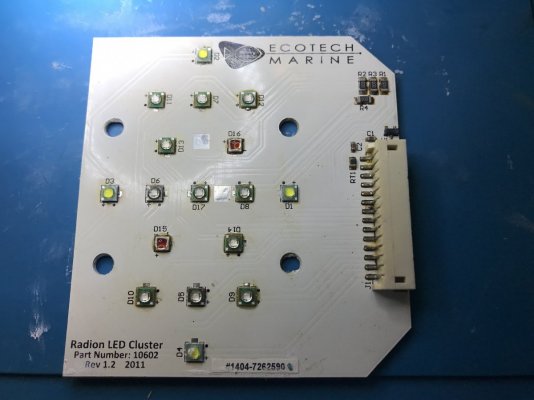

The final product:

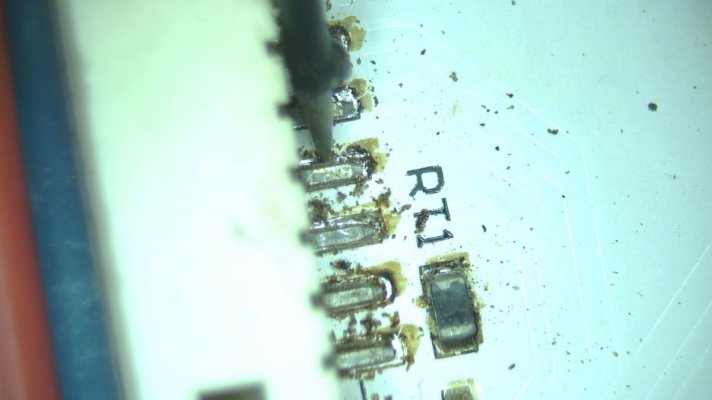

But wait, there is more! After connecting everything together, some LEDs would still not power on. It turns out that the main connector on the cluster has some pins disconnected due to age and corrosion. Here you can see I'm moving the pin with my pick:

We'll clean up and reflow all the pins:

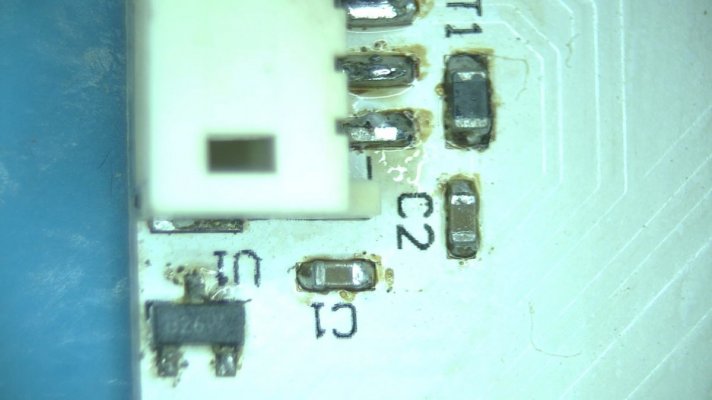

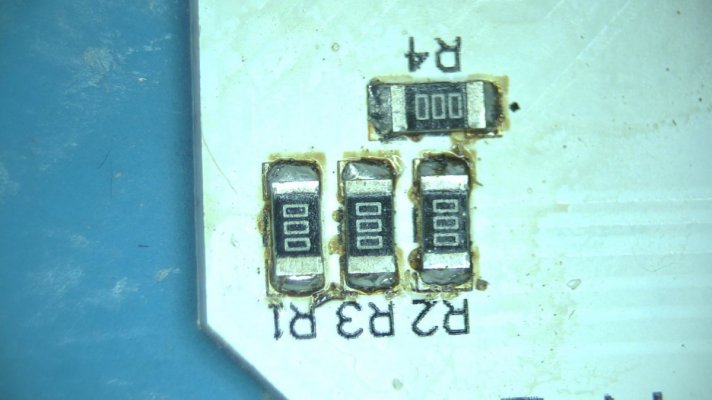

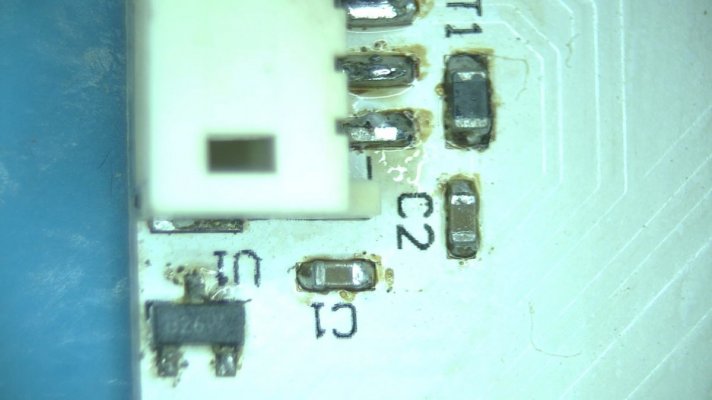

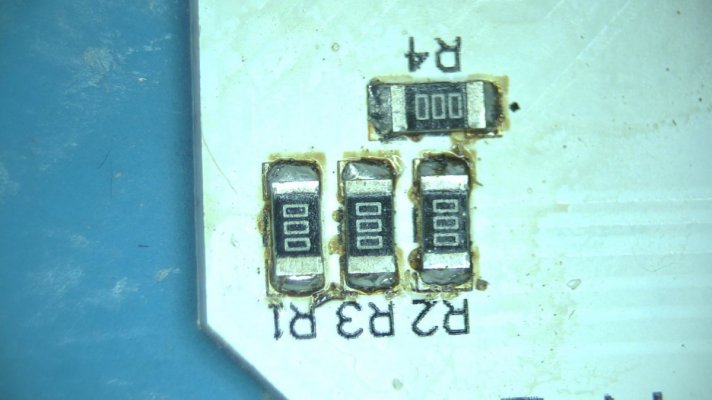

And while we are at it, we might as well touch up any other non LED components on the board:

And with this, the light is working again!

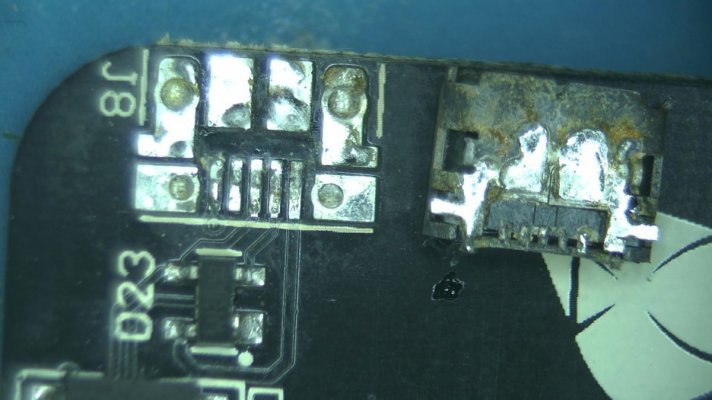

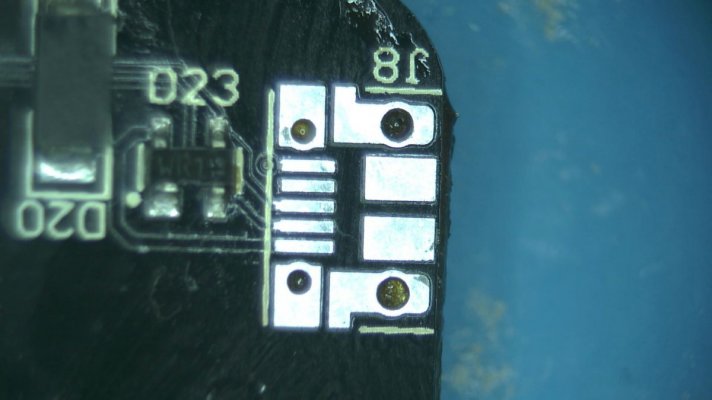

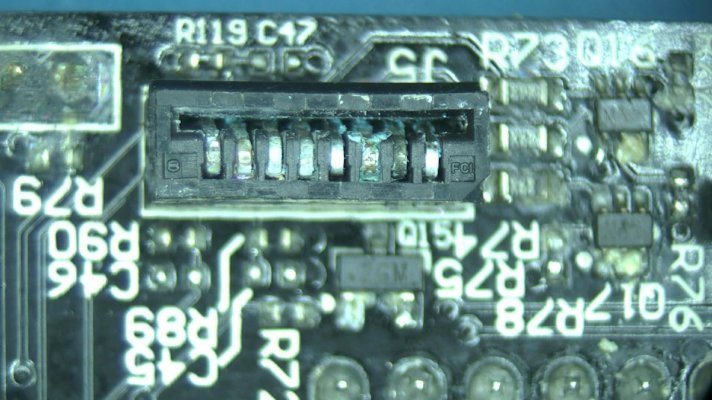

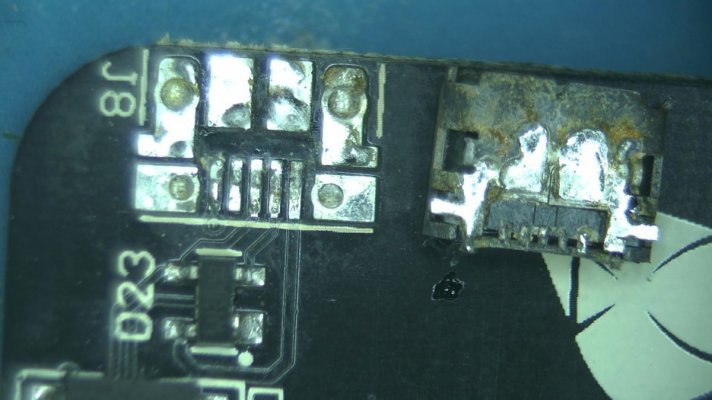

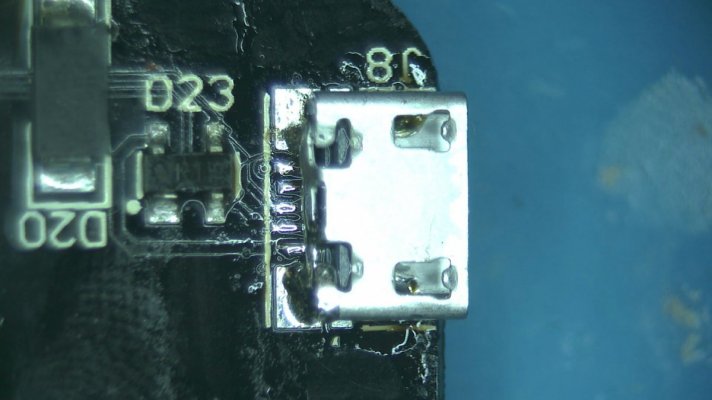

But there is even more! Despite a very good ultrasonic cleaner, the micro USB connector on the main board was corroded to the point it would not make a stable connection. Without the USB, connecting the unit to ecotech live is going to be a problem.

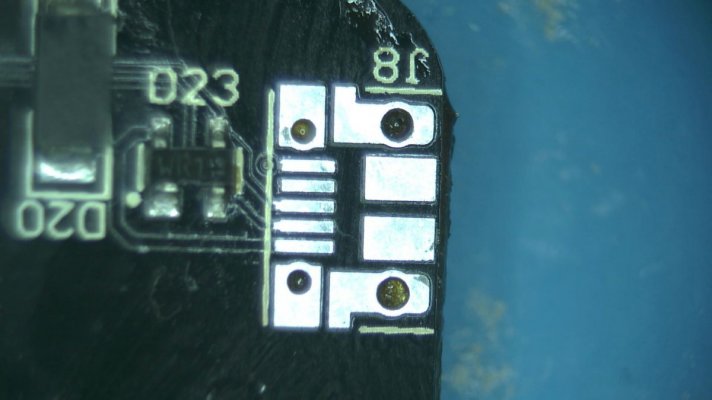

First, we'll remove the bad connector and clean up the pads:

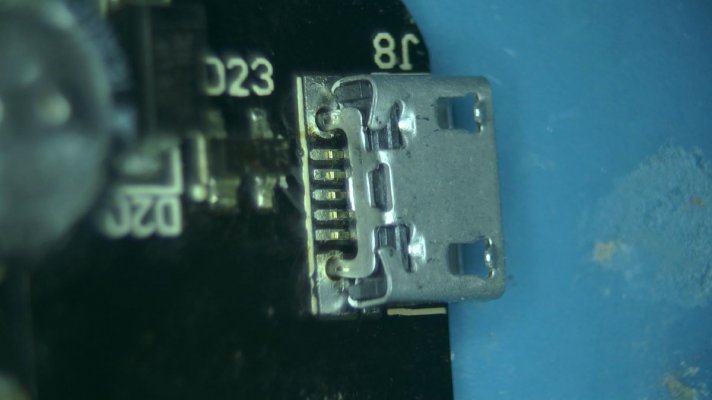

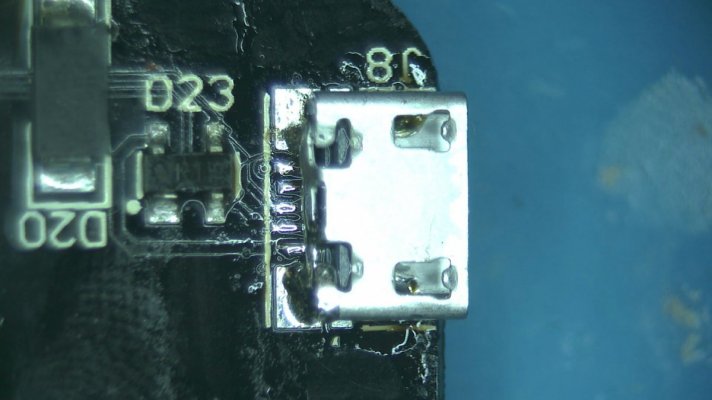

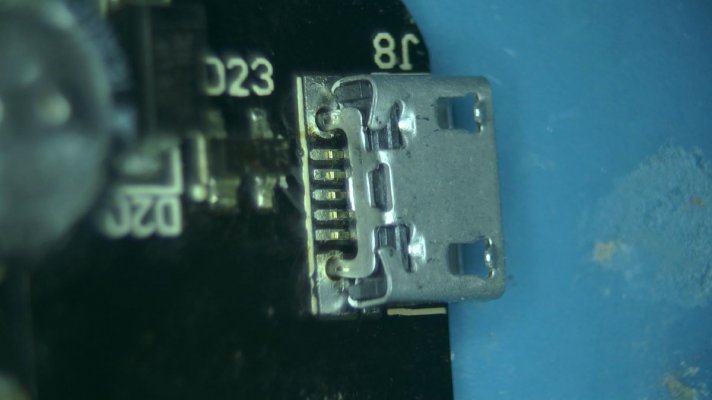

Put a brand new connector in place and solder it in.

And with that, the complete repair of this old radion light is complete. It received many brand new LEDs, the majority of them are newer models with similar specs to the originals. They will provide even more intensity with less power consumption and will last longer. The board was thoroughly cleaned from corrosion and had a mosfet and the USB connector replaced.

Radion XR15:

Radion Lights Board Level Repair

I enjoy an occasional board level repair. It gives me a new angle to this hobby, which is often very heavy on DIY. In this thread I'm going to post some of my more interesting and challenging repairs, picture heavy, including high magnification microscope imagery. Recently, I got ahold of a...

www.reef2reef.com

www.reef2reef.com

A fellow reefer mailed me their Ecotech Radion for repair service as it's long been out of warranty. The unit turns on briefly before shutting down and the fan is clean and spins perfectly fine.

The light appears to be an XR30 Gen 1 with upgraded LED clusters. Let's begin with an initial visual inspection, shall we?

For an older light, one would expect a fair amount of corrosion on the main board. This light is certainly no exception.

Even the main controller had a quite a bit of corrosion:

The wireless board was not in a much better shape:

And all connectors were in a rough shape:

Now, all of this corrosion may not have been the primary cause of the failure, but leaving it on the board is going to be asking for trouble later. It's time to give the main board a bath (or two)!

First, the wireless chip needs to come off. We find more corrosion around and under the chip as well:

With the wireless module removed, the board is ready for a really good, but gentle ultrasonic cleaning:

And a quick rinse to displace any cleaning solution on the board:

Now let's see if the cleaning made any difference:

How about connectors:

I'd say, not bad for a quick rinse! But will the light work now? Not a chance. There is a bit more fun ahead!

XR30 has 6 channels to control different sets of LEDs. Each channel is handled by a circuit of mosfets, op amps, relays and inductors. To save some space (and money) ecotech is using 3 dual mosfets, one to power two different LED channels. They look like so:

On this board, the middle mosfet shorted on both channels. This means at least 2/6 LED channels won't work unless it's replaced. Let's remove and replace:

With the burned out mosfet replaced, the board is mostly happy again. In fact, it now works perfectly fine with a good known working set of LED clusters.

But the lights still won't fully turn on with the original LED lights. Time to examine the clusters. Oh, boy!

Of the total 32 LEDs across 2 clusters, 19 (!) were burned out or shorted. A typical picture observed:

All of them will have to be replaced. There was certainly some corrosion under the LEDs:

But not anything that can't be fixed:

We are ready to do some baking:

The final product:

But wait, there is more! After connecting everything together, some LEDs would still not power on. It turns out that the main connector on the cluster has some pins disconnected due to age and corrosion. Here you can see I'm moving the pin with my pick:

We'll clean up and reflow all the pins:

And while we are at it, we might as well touch up any other non LED components on the board:

And with this, the light is working again!

But there is even more! Despite a very good ultrasonic cleaner, the micro USB connector on the main board was corroded to the point it would not make a stable connection. Without the USB, connecting the unit to ecotech live is going to be a problem.

First, we'll remove the bad connector and clean up the pads:

Put a brand new connector in place and solder it in.

And with that, the complete repair of this old radion light is complete. It received many brand new LEDs, the majority of them are newer models with similar specs to the originals. They will provide even more intensity with less power consumption and will last longer. The board was thoroughly cleaned from corrosion and had a mosfet and the USB connector replaced.