- Joined

- Dec 4, 2018

- Messages

- 184

- Reaction score

- 107

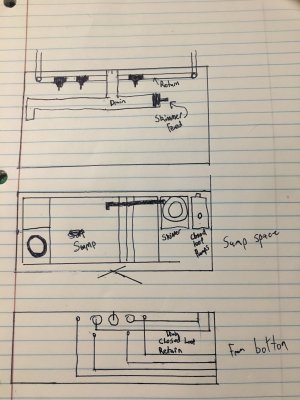

200g system. Vectra m2 for the closed loop, jabao for the return. Plumbed so I can add a 2nd closed loop pump in the future. Recirculating skimmer being fed by the drain. Closed loop plumbing will all run under the tank at the top of the stand to clean up the sump area and keep that out of sight.

currently,

2 x 1.5in drains for the closed loop pumps(didn’t want crazy suction to hopefully keep debree out).

4 x 3/4 returns.

1 drain and 2 returns for each closed loop pump installed.

skimmer calls for 550gph. Return pump is 2500gph. Drain is 1.5in. Hoping to run the skimmer of the drain to avoid abother pump in the stand. And to also allow higher flow in the tank without pushing the full 1800gph through therefugium

currently,

2 x 1.5in drains for the closed loop pumps(didn’t want crazy suction to hopefully keep debree out).

4 x 3/4 returns.

1 drain and 2 returns for each closed loop pump installed.

skimmer calls for 550gph. Return pump is 2500gph. Drain is 1.5in. Hoping to run the skimmer of the drain to avoid abother pump in the stand. And to also allow higher flow in the tank without pushing the full 1800gph through therefugium