Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Red Sea Reefer XL 425 - The Upgrade

- Build Thread

- Thread starter Leiph86

- Start date

- Tagged users None

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

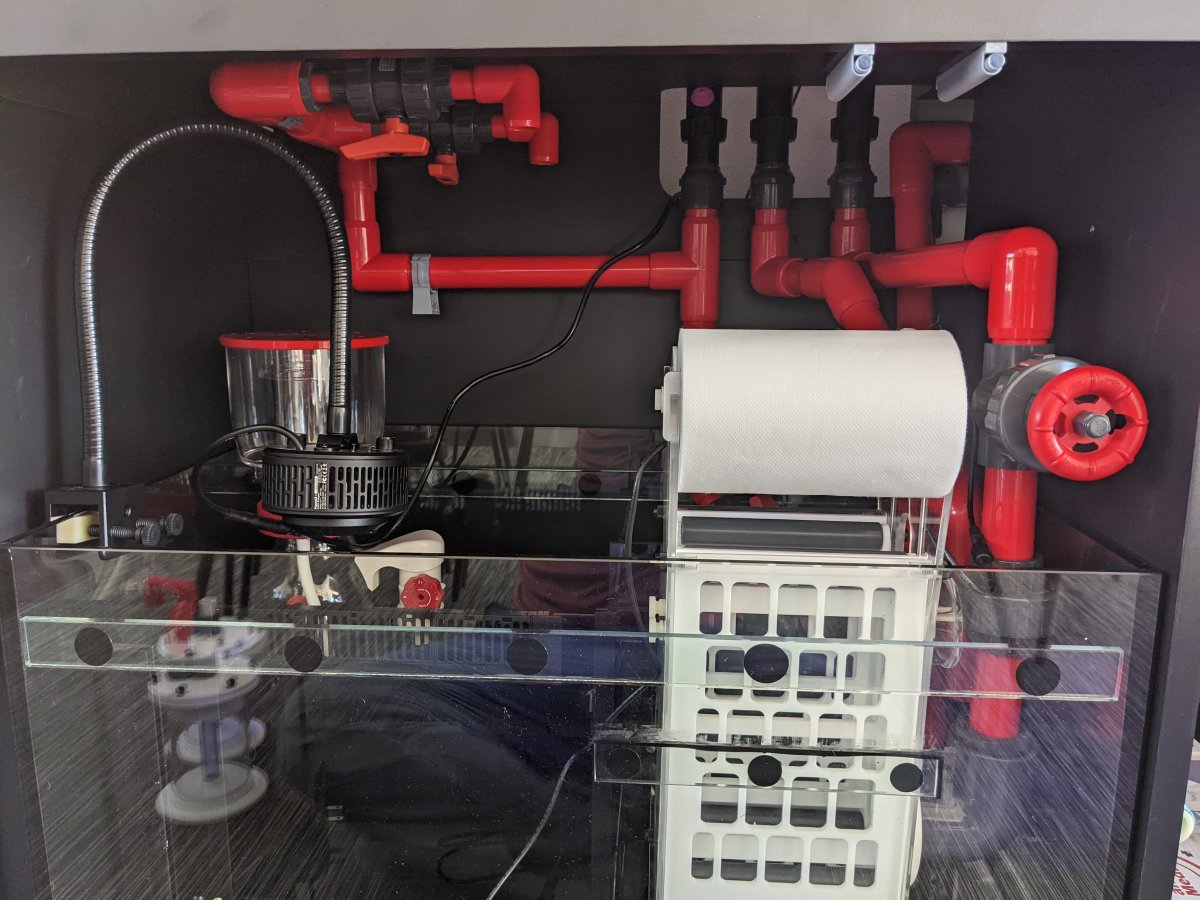

Hey Reef2Reef family - the long awaited final dry fit with some points/issues I faced and how I resolved them:

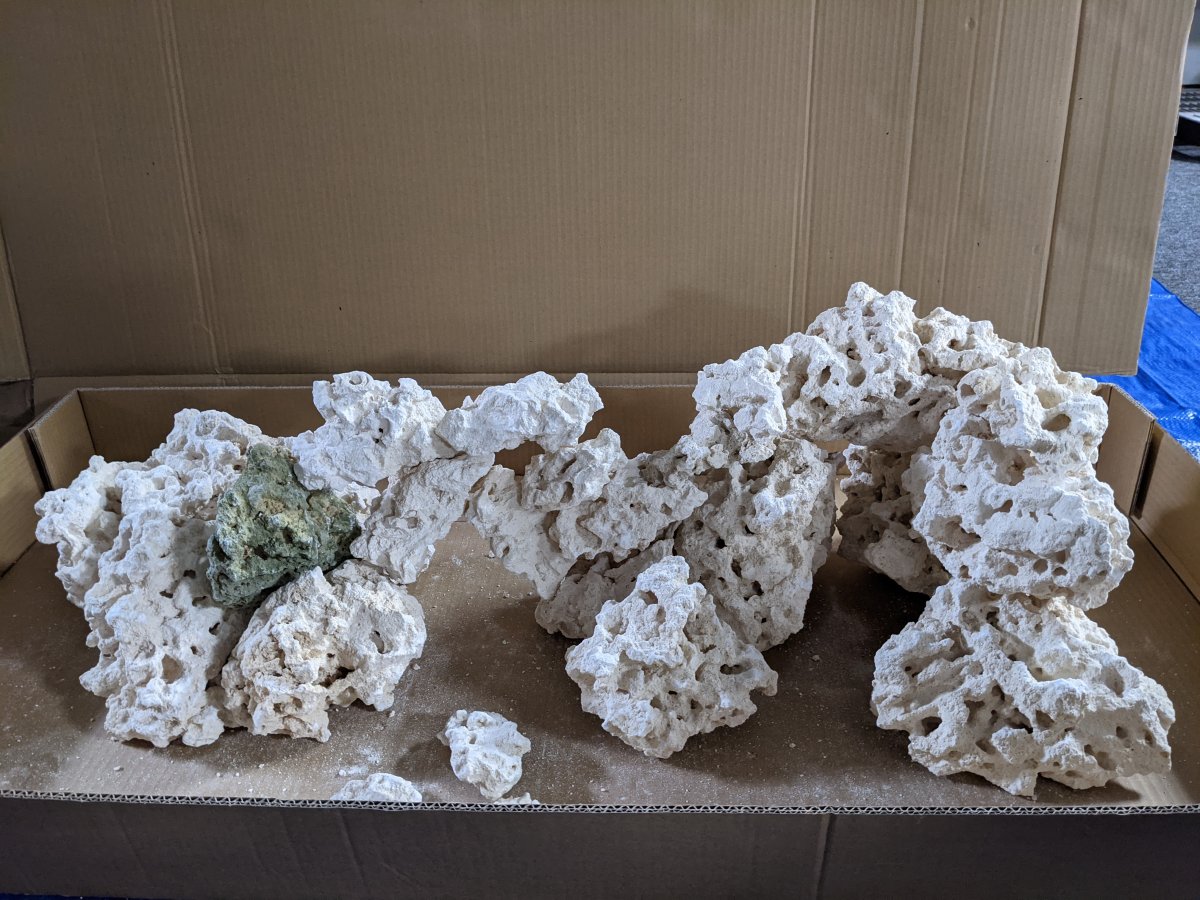

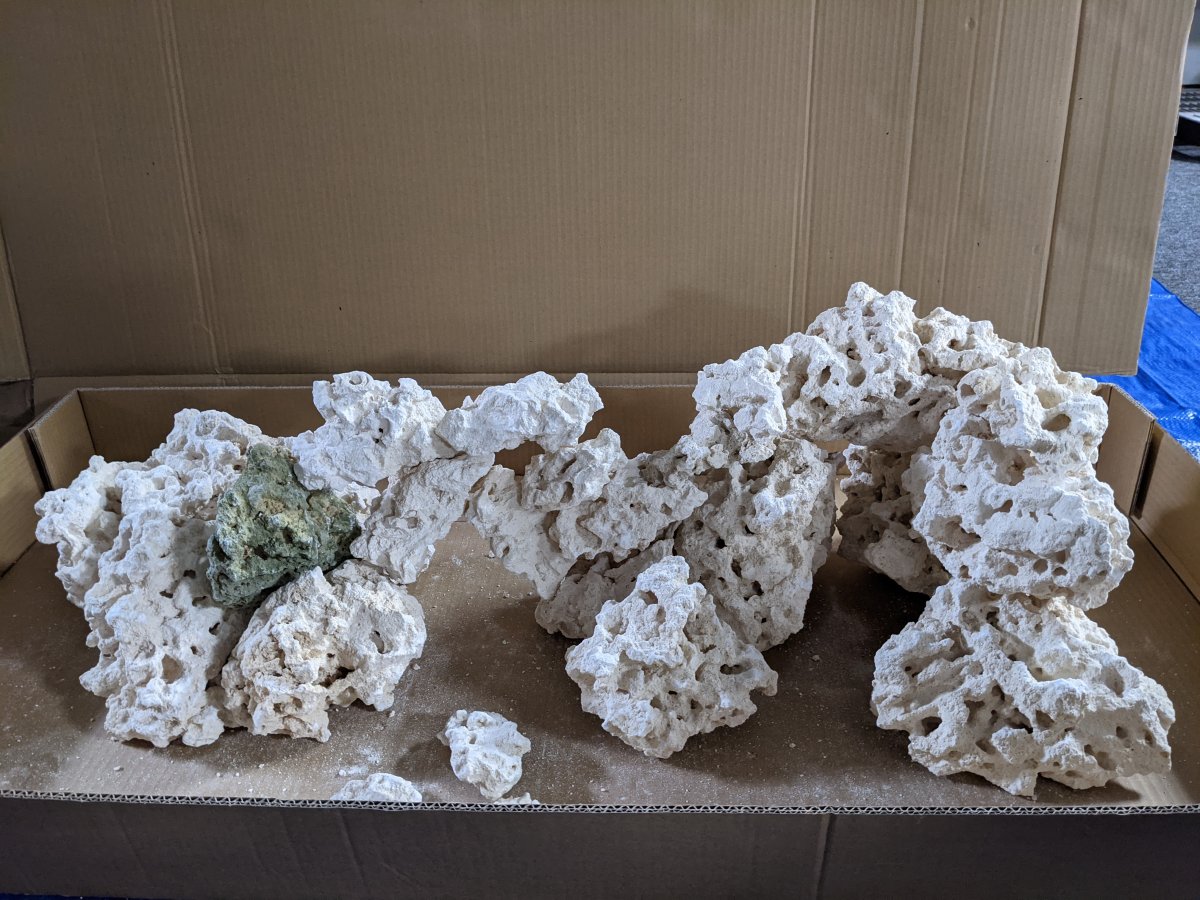

Finally as a side note, my original 20 gallon build I have been battling Dinos (Coolia strain) for almost 2 months and half my corals have bit the dust. Obviously I'm devastated as all the corals were thriving and producing nice growth. I have attempted (not all together at the same time) a blackout, installing a small UV, using DinoX, and even dosing Hydrogen Peroxide to no avail (parameters are all appropriate as well). With the issue of the sand bed contributing much to housing the bacteria I have decided I will for the first time ever have a bare bottom tank. Because of this I will be focusing on using more rock to help establish better biological foot holds for cycling the tank.

https://photos.google.com/photo/AF1QipPUUV36v5mEueX7dF5BpZjVDFzXuEHdbguG3fU

- Unable to install check valve - with the amount of ball valves I feel comfortable with this decision.

- UV Sterilizer installation - Had to install on the 'dry' side of the cabinet and the unit sticks out approximately 2 inches out from the back of the cabinet. I determined this was acceptable since I planned on having a 3" gap between the tank and the wall anyway.

- Bulk Reef Supply corrected the issue related to the wrong return pump I received and I have since received my correct 8k pump and will be using it for now. If I discover flow issues then I will consider an upgrade at that time or split the UV to a separate pump all together.

- I installed a barbed fitting directly to the main return ball valve and will be using a silicone hose to connect the return pump for easier maintenance and reduction of noise.

- The UV White J hooks will be replaced with shorter, gloss black J hooks which I completed the last coat of spray paint on today.

- Final tasks before gluing will be cleaning pipe, cleaning inside of cabinet walls (various smudges and scuffs), adding black caulking to 3 holes that I initially attached the Red Sea clips for holding their stock plumbing to, and testing the return pump orientation with how I currently have the return positioned to.

Finally as a side note, my original 20 gallon build I have been battling Dinos (Coolia strain) for almost 2 months and half my corals have bit the dust. Obviously I'm devastated as all the corals were thriving and producing nice growth. I have attempted (not all together at the same time) a blackout, installing a small UV, using DinoX, and even dosing Hydrogen Peroxide to no avail (parameters are all appropriate as well). With the issue of the sand bed contributing much to housing the bacteria I have decided I will for the first time ever have a bare bottom tank. Because of this I will be focusing on using more rock to help establish better biological foot holds for cycling the tank.

https://photos.google.com/photo/AF1QipPUUV36v5mEueX7dF5BpZjVDFzXuEHdbguG3fU

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

Just going to say I am -honored- to even have you look at my build thread! Thank you so much for tons of inspiration and ongoing content! And I still eagerly follow your build!Nice work on the build thread so far! I'm glad you enjoyed my build. Good luck!

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

Looks awesome! Stocking plans?

@Dark_Knightt I think we've already had this conversation lol! Though I'm happy to discuss further if there are new inputs/suggestions on this front from anyone!

A great question - I have a few months or so to figure that out while I finish the set up and cycle. Here is my working list, and I'm open to suggestions or ideas as I know there are fish/corals that I might not be aware of that will work and look great in a mixed reef:

Fish/Inverts:

I'm trying to purchase fish that are easier on the feeding spectrum and on the hardy side as well as not costing an arm and a leg - once the tank is established for at least a year I may consider adding one or two more expensive fish depending on the fish. For now, here is my list:

- Clownfish x2

- Starry Blenny

- Six Line Wrasse

- Royal Gamma

- Yellow Watchman Goby

- Blood Red Fire Shrimp / Peppermint Shrimp

- Tang? See note below...

- Invert Clean Up Crew

- More suggestions welcome here

This is really this will be the first time I want a tang, however, I want to do my proper research to see if there is a smaller adult tang that will work for the 4 foot wide tank (as I know most tanks prefer large swimming spaces).

Corals:

For corals I learned an important lesson with my 20 gallon nano - don't get swept up in the Reef2Reef bidding until after I research what I want. I purchased a number of corals I wasn't prepared to take care of and that were extremely slow growers compared to others. Goals will be primarily photosynthetic corals, but I don't mind if they can have target feeding as a supplement to their 'light diets'. I also want medium to fast growers to fill out the tank (versus lots of little frags that will get crowded). Finally I love movement in the tank, so that's a big factor below.

- Acans and Blasos (some of my favorite LPS)

- Carpet Anemone or Toadstool Leather (just one since I know some can get quite large over time)

- Open Brain Coral

- Candy Cane or Trumpet Corals (undecided here)

- Various Monti's for added depth and natural shelving

- Various colored Birds Nest

- (If bare bottom) - Zoas/GSP for 'carpet' effect

- (If sand) - Zoas on isolated rock islands

Hey quick question ... how many people did you need to move the 425 xl? I see that it’s 170lbs ... do you think 2 people is enough?

In case it’s helpful, I was able to make it work with 2 people for my 425 XL, but it wasn’t light so make sure you and your friend are ready to get a little work out inHey quick question ... how many people did you need to move the 425 xl? I see that it’s 170lbs ... do you think 2 people is enough?

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

I played it safe and had 5 people total - one to open doors and call out steps, and the others to help carry. We had no problems.In case it’s helpful, I was able to make it work with 2 people for my 425 XL, but it wasn’t light so make sure you and your friend are ready to get a little work out in

- Joined

- Nov 2, 2019

- Messages

- 2

- Reaction score

- 0

@Leiph86 Would you mind listing the plumbing pieces you used to convert from the red sea standard. I see you used Red Sea Part #42221, from that point on what fitting/adaptor did you use? From the other users builds you mentioned there are two different possible routes from this Red Sea part and was just wondering why you chose one over the other?

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

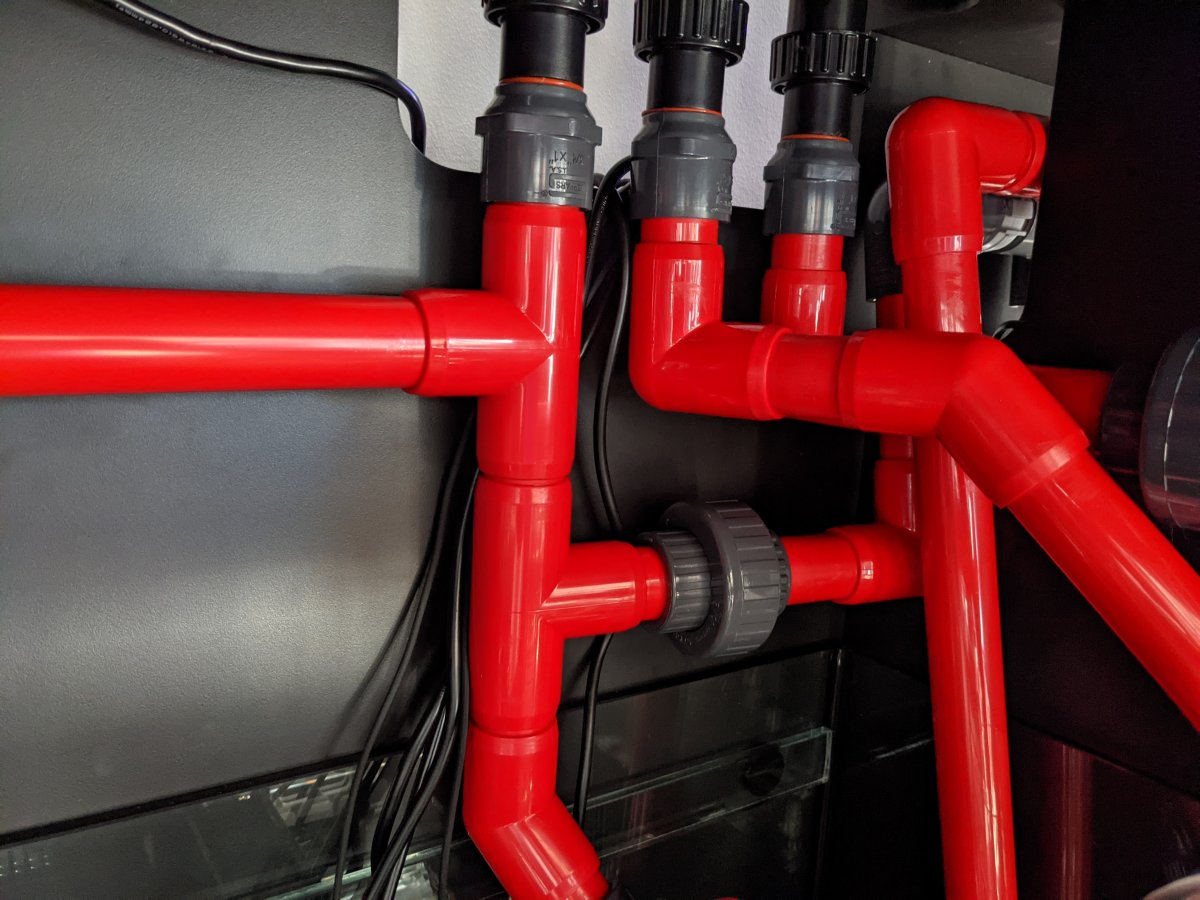

@TrueNorthReef - Thanks for checking out my build. I don't want to take credit for something I used from someone else so see the quote below from @Rudzbrewski 's build - I did the same conversion posted in these photos and used 1" piping throughout my system (the only place reduced down is for the media reactors which are 1/2").@Leiph86 Would you mind listing the plumbing pieces you used to convert from the red sea standard. I see you used Red Sea Part #42221, from that point on what fitting/adaptor did you use? From the other users builds you mentioned there are two different possible routes from this Red Sea part and was just wondering why you chose one over the other?

I'll be doing a tally of all the parts I used for my build with pictures posted of the gluing I did over the weekend later this evening or tomorrow morning.

It wasn’t easy finding a straight answer on which pieces to use to adapt the RS plumbing to standard for the xl425. I messaged RS directly to find out that even though Part 42221 is not listed with the xl425 as a compatible system, the plumbing is the same diameter. Part 42222 is no longer made as 2 pieces that can be unscrewed, so this piece will no longer work.

All you have to do with Part 42221 is remove the barbed attachment by unscrewing it. Then take the O-ring and use it on your 3/4” thread to 1” slip adapter. Finally, use some pink tape on the threads to ensure a tight seal and screw the adapter to the RS piece. I used about 8 layers of tape. I have not tested my plumbing yet, so I will update on any leaks if needed.

Finally, here are the finished pieces that allow you to adapt RS to standard plumbing without any permanent modifications that cannot be undone.

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

While I worked on the tank this weekend I began my aquascape - I really want to achieve a lower section on the left and a higher section on the right due to viewing angles in my home. I also really want to incorporate an arch connecting the two pieces...but I haven't landed on how or exactly from where. The photo below shows me using some smaller pieces to support what would be an arch ideally - so just pretend they aren't there. Finally I want to ensure there is space around the rockwork for 'islands' for any corals I may get that need to be isolated at some point. Let's call the below photo attempt 1 of my vision with more to come shortly. Feedback welcome as always and also curious to see if anyone has built an arch and how they connected it/stabilized it (ie. super glue, acrylic rods, mortar, etc.)...

- Joined

- Jan 22, 2020

- Messages

- 956

- Reaction score

- 1,018

I did a combination of superglue, acrylic rods, and e-marco 400 cement mortar. Super glue and rods to hold the structures general shape and the mortar to really make sure it wasn't going anywhere. Probably went overkill on structural integrity, but acrylic rods are a couple bucks a piece (I think I used 3-4 total because you only need to cut couple inch pieces) and it was way easier to drill into the rock than I expected with the proper (but cheap) drill bit.While I worked on the tank this weekend I began my aquascape - I really want to achieve a lower section on the left and a higher section on the right due to viewing angles in my home. I also really want to incorporate an arch connecting the two pieces...but I haven't landed on how or exactly from where. The photo below shows me using some smaller pieces to support what would be an arch ideally - so just pretend they aren't there. Finally I want to ensure there is space around the rockwork for 'islands' for any corals I may get that need to be isolated at some point. Let's call the below photo attempt 1 of my vision with more to come shortly. Feedback welcome as always and also curious to see if anyone has built an arch and how they connected it/stabilized it (ie. super glue, acrylic rods, mortar, etc.)...

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

I did a combination of superglue, acrylic rods, and e-marco 400 cement mortar. Super glue and rods to hold the structures general shape and the mortar to really make sure it wasn't going anywhere. Probably went overkill on structural integrity, but acrylic rods are a couple bucks a piece (I think I used 3-4 total because you only need to cut couple inch pieces) and it was way easier to drill into the rock than I expected with the proper (but cheap) drill bit.

The only concern I have with gluing everything together is having the ability to 'adjust' aquascape down the road - there have been opportunities with past tanks where having the convenience of simply pulling out one rock from the build (for maintenance, pest removal, fragging, etc.) has been great - however, the con to that is the structure is not as stable and you can't do cool things like arches/overhangs...ugh DECISIONS!

- Joined

- Jan 22, 2020

- Messages

- 956

- Reaction score

- 1,018

There is definitely an advantage to having things arranged and held together without any glue. Based on the aquascape I was going for and the amount I was breaking up the large chunks of rock I knew from the beginning gravity was't going to be on my side.The only concern I have with gluing everything together is having the ability to 'adjust' aquascape down the road - there have been opportunities with past tanks where having the convenience of simply pulling out one rock from the build (for maintenance, pest removal, fragging, etc.) has been great - however, the con to that is the structure is not as stable and you can't do cool things like arches/overhangs...ugh DECISIONS!

You could build and glue together some base areas for stability. Then with strategic placement and drilling add stability with other sections through rods, but not adhere to both sides with glue and make a more stable, but yet still removable peg-hold type system.

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

Sneak peak of a fully assembled tank before I show off final plumbing - can I just say how excited it is to get doors on this stand finally! Ignore the loose cords and boxes, I just couldn't wait until after clean up for this picture  !

!

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

Started trying to play around with the aquascape a little more today and super glue gel by itself (without accelerator since that is out of stock) is nearly impossible to do. Time to order some e-Marco 400 mortar and wait a few more days... ;Rage.

Update: And then I woke up to glue that set over night and rocks were solid. Good thing I didn't plan on ordering the mortar until today! I would say that glue accelerator would make a difference but BRS is sold out!

Update: And then I woke up to glue that set over night and rocks were solid. Good thing I didn't plan on ordering the mortar until today! I would say that glue accelerator would make a difference but BRS is sold out!

Last edited:

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

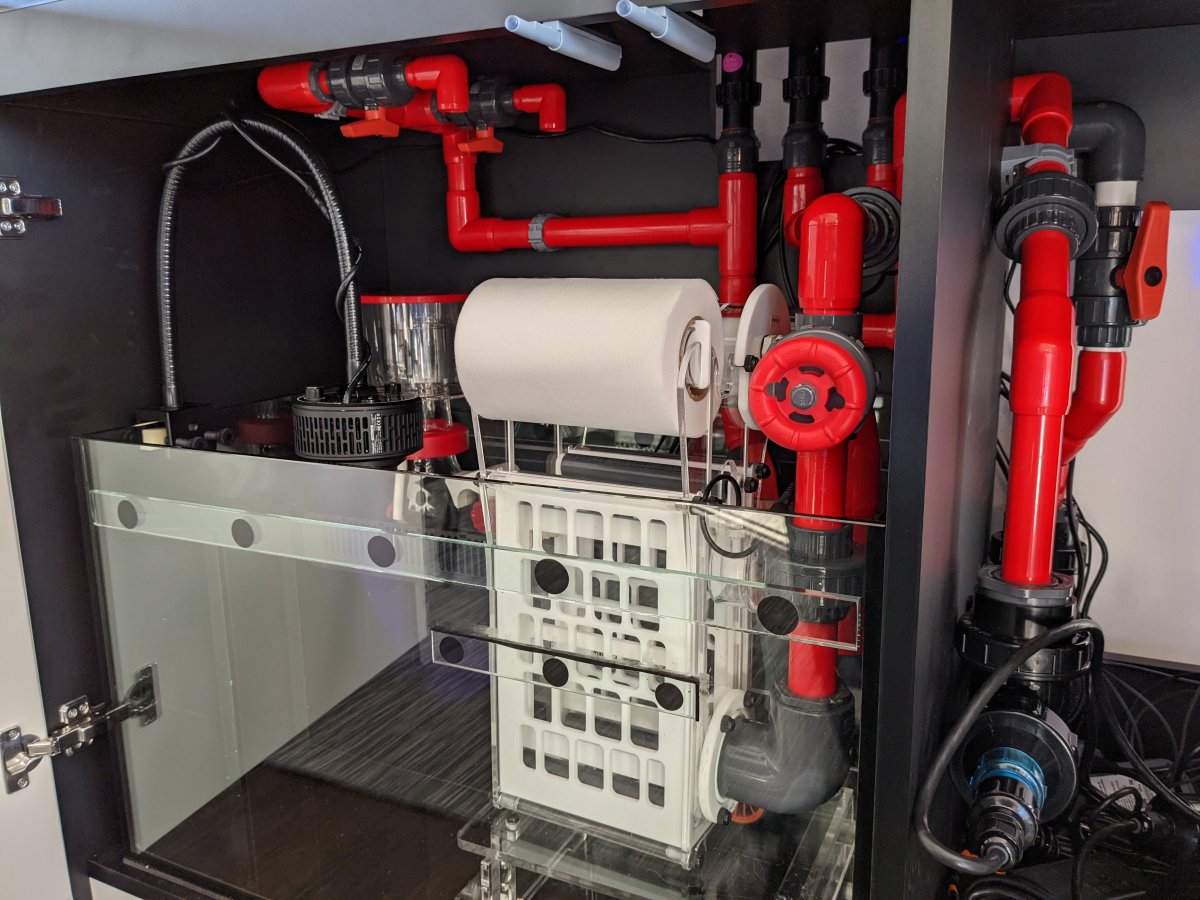

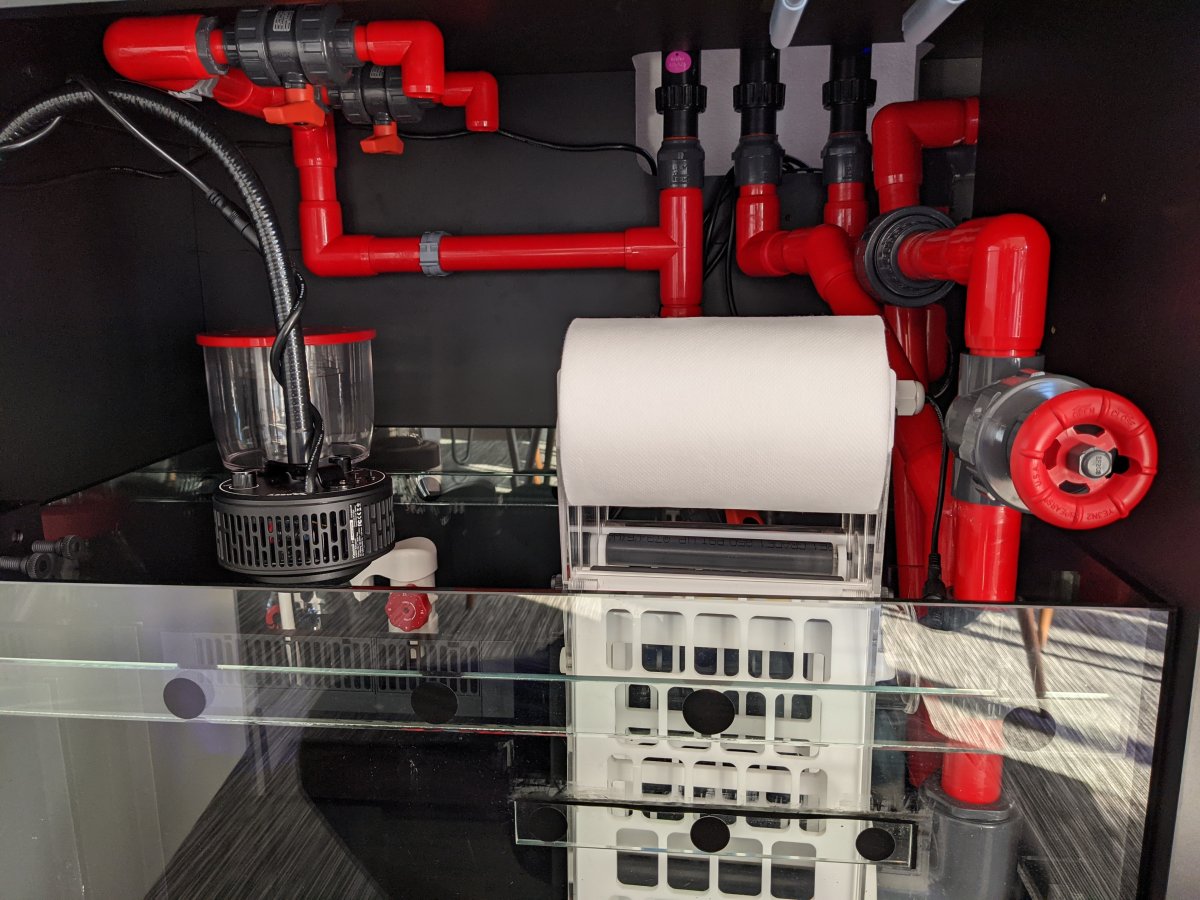

The Build - Plumbing Parts List:

My plumbing used the following parts - the only thing I was short on was about 6 inches of 1" red pipe - I used some standard schedule 40 white pipe on some joints that were not or only slightly visible to compensate for this.

Also a really important thing I learned that not a lot of people talk about - dry fit plumbing does not push in all the way to your fittings - when you use primer and cement your pipes go further into fittings. Either compensate with a little bit extra piping on your dry fit or mark your pipe with a tick mark on where it was with your dry fit. Also, glue one part at a time in sections so you can recut/adjust as necessary.

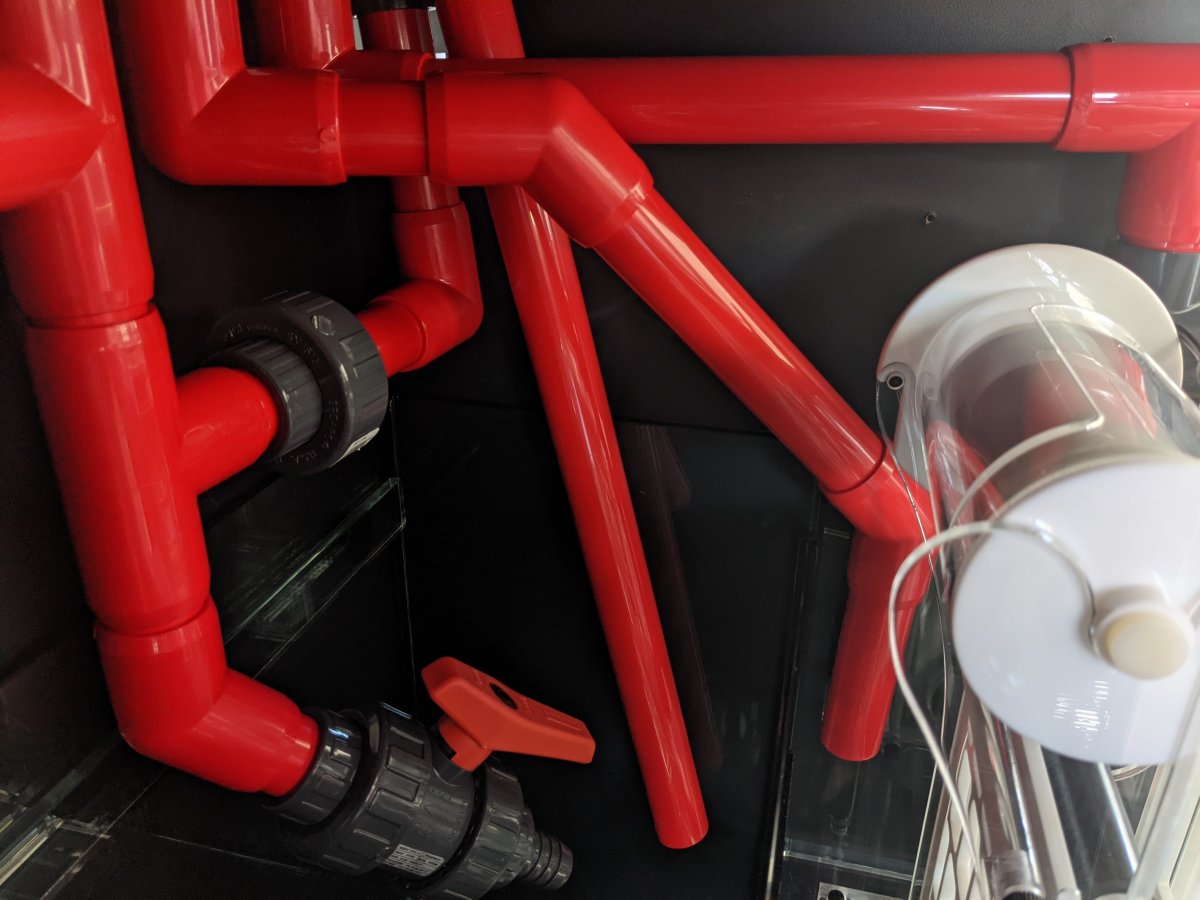

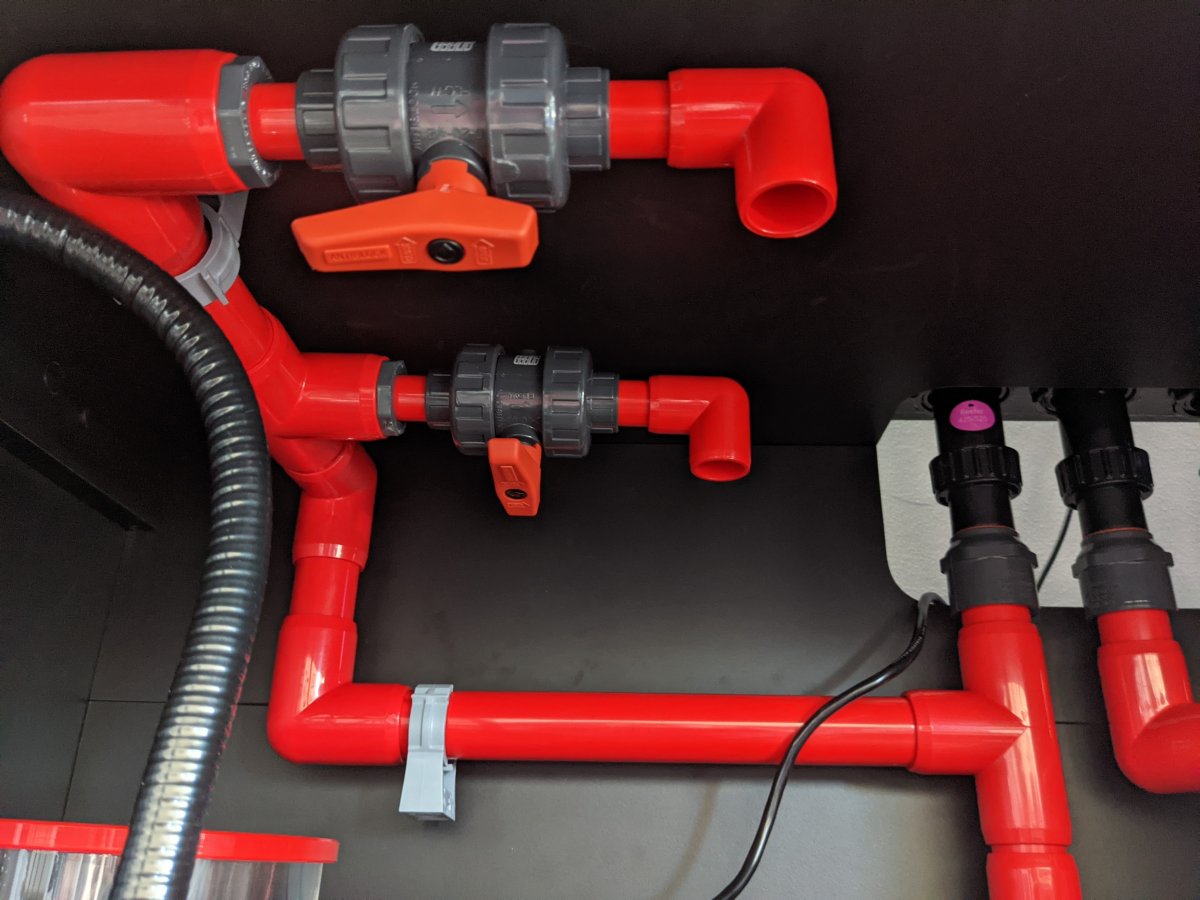

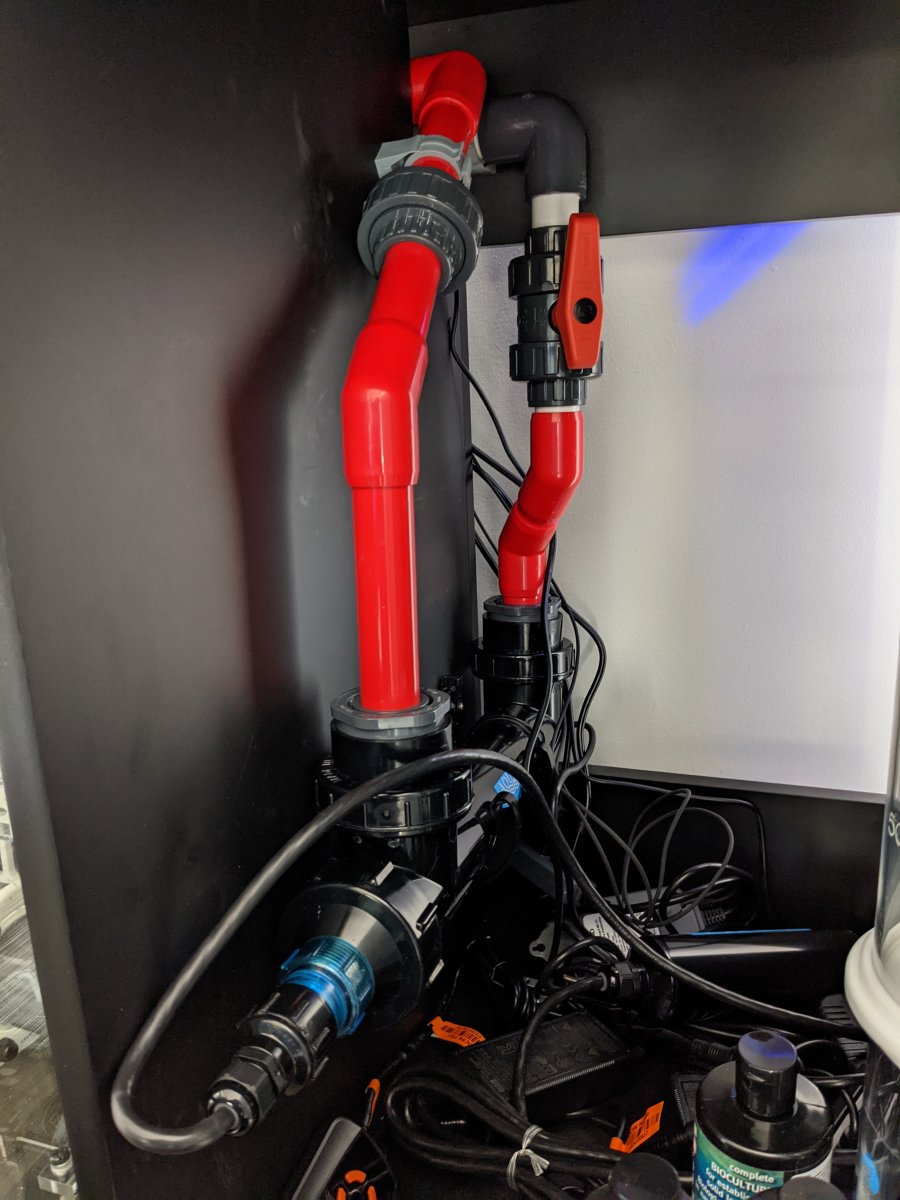

Finally, some updated photos of the final plumbing:

BEHOLD! THE RAT KING'S NEST OF CABLES!...aquascaping gluing and cable management are next...with hopefully a leak test in the coming days! I see the light at the end of the tunnel...to another light...it never really ends...

My plumbing used the following parts - the only thing I was short on was about 6 inches of 1" red pipe - I used some standard schedule 40 white pipe on some joints that were not or only slightly visible to compensate for this.

Also a really important thing I learned that not a lot of people talk about - dry fit plumbing does not push in all the way to your fittings - when you use primer and cement your pipes go further into fittings. Either compensate with a little bit extra piping on your dry fit or mark your pipe with a tick mark on where it was with your dry fit. Also, glue one part at a time in sections so you can recut/adjust as necessary.

| Part | Qty Total | Comments |

| Red Sea Part #42221 | 3 | Used to connect to adapters for 1" piping |

| 3/4" Thread to 1" Slip Adapter | 3 | Used for Bulkhead connections with plumbing tape to convert to 1" piping |

| 1" Red Pipe (46" Length) | 3 | |

| 1" 90* Elbow | 11 | |

| 1" 45* Elbow | 6 | |

| 1" T-Fitting | 3 | |

| 1" Gate Valve, Slip x Slip | 1 | Used for main drain (connected to Aquamaxx Fleece Roller Mat) |

| 1" Union, Slip x Slip | 4 | Used throughout for sections that may need to be removed for easier maintenance |

| 1" Ball Valve, Slip x Slip | 2 | Used for Return Pump and UV Sterilizer |

| 1" F Slip to 1.25" M Slip Reducer | 1 | Used to connect 1" Pipe to Aquamaxx Fleece Roller Mat |

| 1/2" Red Pipe (46" Length) | 1 | Used for Aquamaxx Media Reactors |

| 1/2" 90* Elbow | 6 | Used for Aquamaxx Media Reactors |

| 1/2" F Slip to 1/2" M Thread Adapter | 4 | Used for Aquamaxx Media Reactors |

| 1/2" Ball Valve, Slip x Slip | 2 | Used for Aquamaxx Media Reactors |

| 1" F Slip to 1/2" F Thread Reducer | 2 | Used for Aquamaxx Media Reactors |

| 1" F Slip to 2" M Slip Reducer | 2 | Used for Aqua Illumination UV Sterilizer (25w) |

| 1" Pipe Clamps | 4 | Used for support at various extended sections |

| 2" J Hooks (Lowes Hardware) | 2 | Used to mount UV Sterilizer (Lowes specifically as Home Depot's J-Hooks do not work) |

| 1" Pipe Adapter Spigot x Barb | 1 | Used to connect silicone tubing from return pump to return line |

| 1" White Soft Silicone Tubing | 1 | 2 foot section purchased to connect return pump to return line (to allow for errors) |

Finally, some updated photos of the final plumbing:

BEHOLD! THE RAT KING'S NEST OF CABLES!...aquascaping gluing and cable management are next...with hopefully a leak test in the coming days! I see the light at the end of the tunnel...to another light...it never really ends...

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

The Leak Test:

The good news is there is water in the tank and the tank itself has no leaks (always the biggest concern from shipping). On the other hand I discovered two leaks in the plumbing, one very minor and one a little more significant as described and detailed below. The moral of this story is ensure your plumbing is modular and can be removed in sections (as I have done).

Leak 1: Main Return Line Connection to Part #42221 O-Ring Tear

Leak 2: UV Sterilizer to 2" to 1" Reducing Fitting - Multiple drips per 60 seconds

The good news is there is water in the tank and the tank itself has no leaks (always the biggest concern from shipping). On the other hand I discovered two leaks in the plumbing, one very minor and one a little more significant as described and detailed below. The moral of this story is ensure your plumbing is modular and can be removed in sections (as I have done).

Leak 1: Main Return Line Connection to Part #42221 O-Ring Tear

- This leak is due to overtightening in my opinion on this part, a very small drip approximately 1 every 60 seconds was occurring from this connection. I removed this section of the plumbing and discovered a small tear in the O-Ring. I ordered a replacement pack of Red Sea Rings and will be re-assembling once that is received. I also re-ordered a spare part #42221 in the event anything is wrong with that part after installation of replacement o-ring.

Leak 2: UV Sterilizer to 2" to 1" Reducing Fitting - Multiple drips per 60 seconds

- This drip was more significant and was able to produce a pancake sized puddle in 15 minutes. I have read that a good solution would be to use a vacuum to create suction and to re-apply adhesive to the fitting which will get pulled into the joint where air can pass through (I used a primer/cement all in one adhesive). I will be attempting this over the next couple days and will post an update if the fix pans out or not.

Red Sea Reefer XL 425 - The Upgrade

Welcome to my newest build thread for my Red Sea Reefer XL 425 - (if you are looking for my original build thread with my Innovative Marine Nuvo 20 Gallon with custom stand, please use the following link: https://www.reef2reef.com/threads/coming-back-nuvo-20-gallon.699896/). This will be documenting my journey of upgrading my 20 gallon tank to a Red Sea Reefer XL 425 in great detail as well as hopefully a space to foster conversation, innovation, and education (including for myself).

I first would like to shout out those who have inspired this build - as that is usually what leads many of us to take on that ‘bigger and better’ build. There are so many who have inspired me, but specifically these are the all stars for their level of detail and engagement with the community:

- @Rudzbrewski - A newer build thread with an extremely detailed, responsive, and creative approach to some of the same plans I had. Additionally, they give credit to some of the same members I do below for inspiring them.

- @Eight - A Red Sea 250 build that inspired both my 20 gallon with some clever ideas (such as using the Ikea trash can for ATO) and the aesthetic that really vibes with myself and my home.

- @SuncrestReef - Another wonderful detailed thread and active community member that has I’m sure inspired many of us with their build. A very impressive manifold build on this one as well with UV (however, note this is based off the previous sump version).

- @Broadfield - If you haven’t been on this build thread...are you really on Reef2Reef - amazing concepts, customization, and quite the journey. Check it out, you won’t regret it.

Please follow my journey and chime in, ask questions, and allow me the opportunity to see your build as well!

- Honorable Mention - Bulk Reef Supply - These guys really do a lot to educate, inspire, and contribute to the community. Not saying other e-commerce sites do not, but the videos from BRS TV are top notch and have helped to educate me for years - and I appreciate revisiting topics as new information or different understandings unfold. Thanks for making me poor.

not only is intimidating but dang what if something goes wrong then you loose your sump!! I applaoud you for going all the way on it. here is my thing on this system and I've read sooooo many builds cause I want to get one that with a manifold, GFO, carbon canister and the roller mat how easy is to do maintenance. yeah it all looks amazing but when it comes to putting it apart how hard/easy it is??? im still debating whether I get it or not base on the sump size not much room to maneuver, of course you have the right side of cabinet to add piping but I've not seen a build where ppl use the right side to keep open space on sump area..

all of your comments are highly appreciated!!

- Joined

- Jan 15, 2020

- Messages

- 229

- Reaction score

- 225

@Johnsoto25 Yeah - so that's the key - equipment that isn't accessible isn't serviceable in my opinion. I built my plumbing with ways to remove equipment to ensure I can clean and remove/replace components as needed. The main drain has two unions (one before the gate valve and one after to replace the gate valve or maintain the roller mat if needed).not only is intimidating but dang what if something goes wrong then you loose your sump!! I applaoud you for going all the way on it. here is my thing on this system and I've read sooooo many builds cause I want to get one that with a manifold, GFO, carbon canister and the roller mat how easy is to do maintenance. yeah it all looks amazing but when it comes to putting it apart how hard/easy it is??? im still debating whether I get it or not base on the sump size not much room to maneuver, of course you have the right side of cabinet to add piping but I've not seen a build where ppl use the right side to keep open space on sump area..

all of your comments are highly appreciated!!

The UV is completely able to be separated as well and I recently tested that with the leak post above.

The main return and the manifold that goes to the media reactors are one piece but is all able to be removed.

The Media Reactors can be separated from the manifold for refilling/maintenance.

Overall every piece of equipment under 'the hood' is able to be removed and maintained. I even tested this during my dry fit will all my sump equipment hooked up to ensure I have ample space to maneuver things out as needed. The one aspect from a maintenance that might be a tad difficult is replacing the fleece roller. Right now it appears I'll need to remove the entire roller mat assembly, but I've seen some YouTube videos of folks stapling the new roll to the old one and it seems to just pick it right up...we'll see if that works in the real world.