Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

REEFING DIY: Biggest Wins & Biggest Failures

- QUESTION OF THE DAY

- Thread starter revhtree

- Start date

- Tagged users None

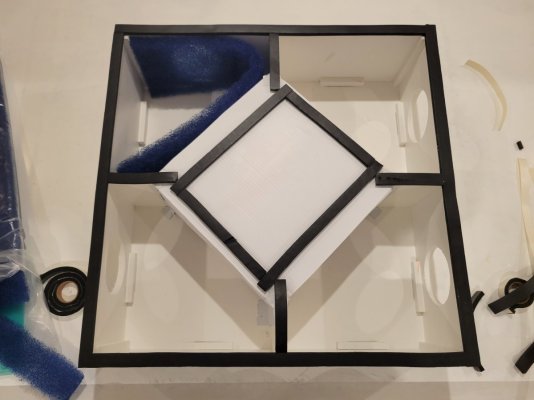

I'm all about DIY! This is my most recent project. It's a plywood AIO frag/growout tank. I've made a few iterations of this over the years as well as multiple stands, canopies, etc. I enjoy woodworking and reef tanks. So I try to combine the two as much as possible.

Attachments

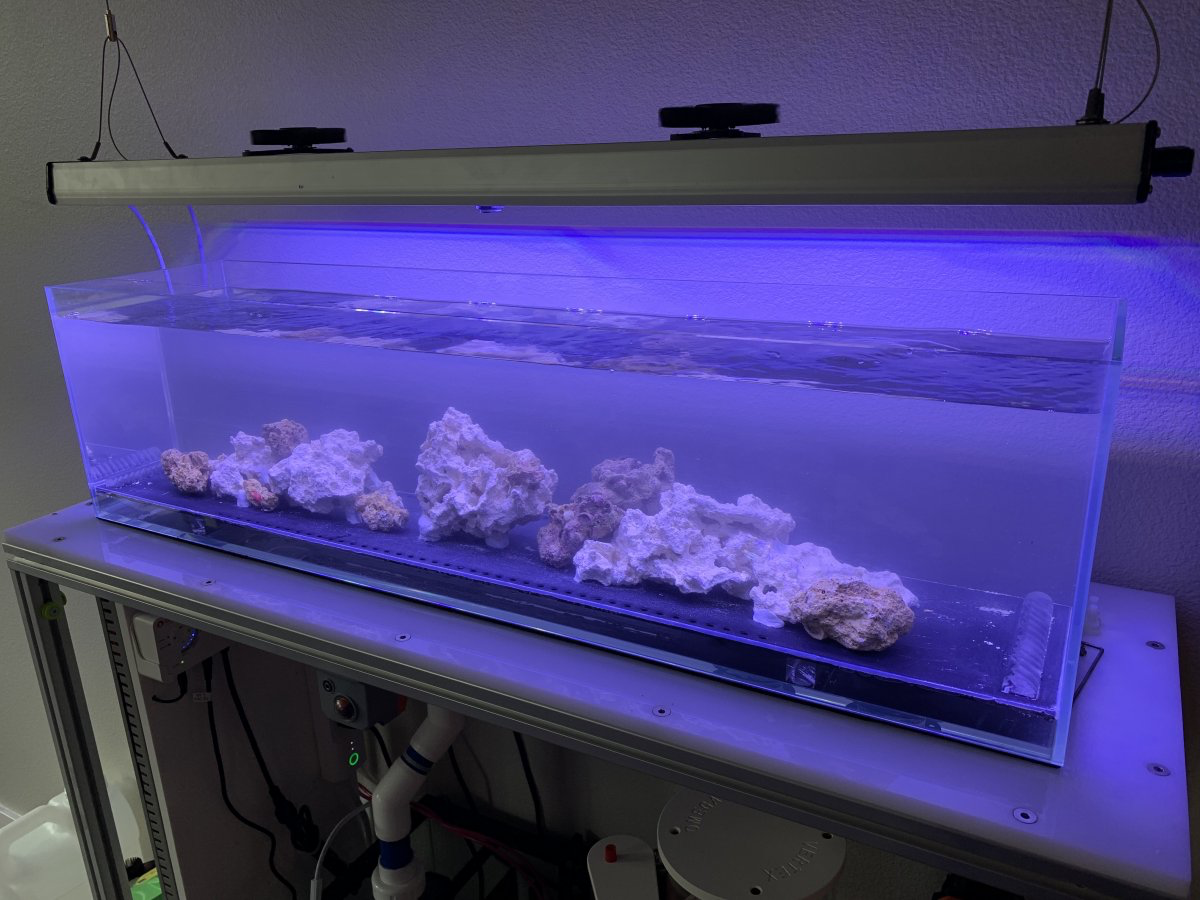

Always DIY my own stands, can’t handle the typical short pre-fab stands height of 25”. I prefer closer to 32-36” depending on tank depth for viewing. I’ve done the 2x4 style, but the last few have been 1x4 and 1x3 framed with ply skinning to keep weight at a minimum. Those 2x4 stands can be a nightmare to move depending on what size they are.

Also have done light pendant setups on the cheap using aluminum channel and recently a couple 2020 aluminum mounts for RedSea LED units.

Also have done light pendant setups on the cheap using aluminum channel and recently a couple 2020 aluminum mounts for RedSea LED units.

Attachments

Pretty cool device! Looks sturdy. Only thing similar I can think of are SQWD device, but these I’ve heard get jammed up. Did you get it to work with 1/4”nylon bearings? Not shown, but what moves the piston up and down?Biggest fail, same device. I used softshot BBs for the bearings. After about two years they started to disintegrate. Had to re-machine it for 1/4" nylon bearings.

- Joined

- May 20, 2020

- Messages

- 8,352

- Reaction score

- 45,562

Over many years I have DIY'd so many things, made a MH light fixture, wet dry filter, several tank stands, gate valve mod for my current skimmer, made a venturi skimmer, filter socks, frozen fish food, acclimation box acrylic and egg crate, brineshrimp hatchery and phyto soda bottle cultures.

So many, I know I'm forgetting a lot, but my journey has been long lol

So many, I know I'm forgetting a lot, but my journey has been long lol

I just realized when I copy and pasted it from the DIY thread the video didn't make it.Pretty cool device! Looks sturdy. Only thing similar I can think of are SQWD device, but these I’ve heard get jammed up. Did you get it to work with 1/4”nylon bearings? Not shown, but what moves the piston up and down?

The piston (PVC tube) spins via an electrical motor (.5 RPM).

Easier to see in the planning stage,

Water comes in from right side, enters piston opening (bottom in this picture), goes up and out the top opening. As piston rotates, flow is reversed.

The ring of bearings (which are not shown in the real life picture) were needed to combat the side loading forces of the water pressure which tended to lock up the piston.

Everything is working good now.

What is the best DIY project you've ever built in this hobby?

That not an easy question to answer. Most proud of my entire DIY aquarium systems but that's a bundle of DIY projects. My DIY skimmer that is gravity fed from display tank drain lines is up there in terms of best. and the aquariums I have built over the years are always on the best list.

Do you consider yourself a good DIY'er?

Personally I do feel I am good at DIY. Nothing better than looking at a successful DIY project and the pride it brings. I can say to myself: I built that, it works(most of the time), I learned new skills (or lessons), and I saved money.

DIY Projects I have completed:

That not an easy question to answer. Most proud of my entire DIY aquarium systems but that's a bundle of DIY projects. My DIY skimmer that is gravity fed from display tank drain lines is up there in terms of best. and the aquariums I have built over the years are always on the best list.

Do you consider yourself a good DIY'er?

Personally I do feel I am good at DIY. Nothing better than looking at a successful DIY project and the pride it brings. I can say to myself: I built that, it works(most of the time), I learned new skills (or lessons), and I saved money.

DIY Projects I have completed:

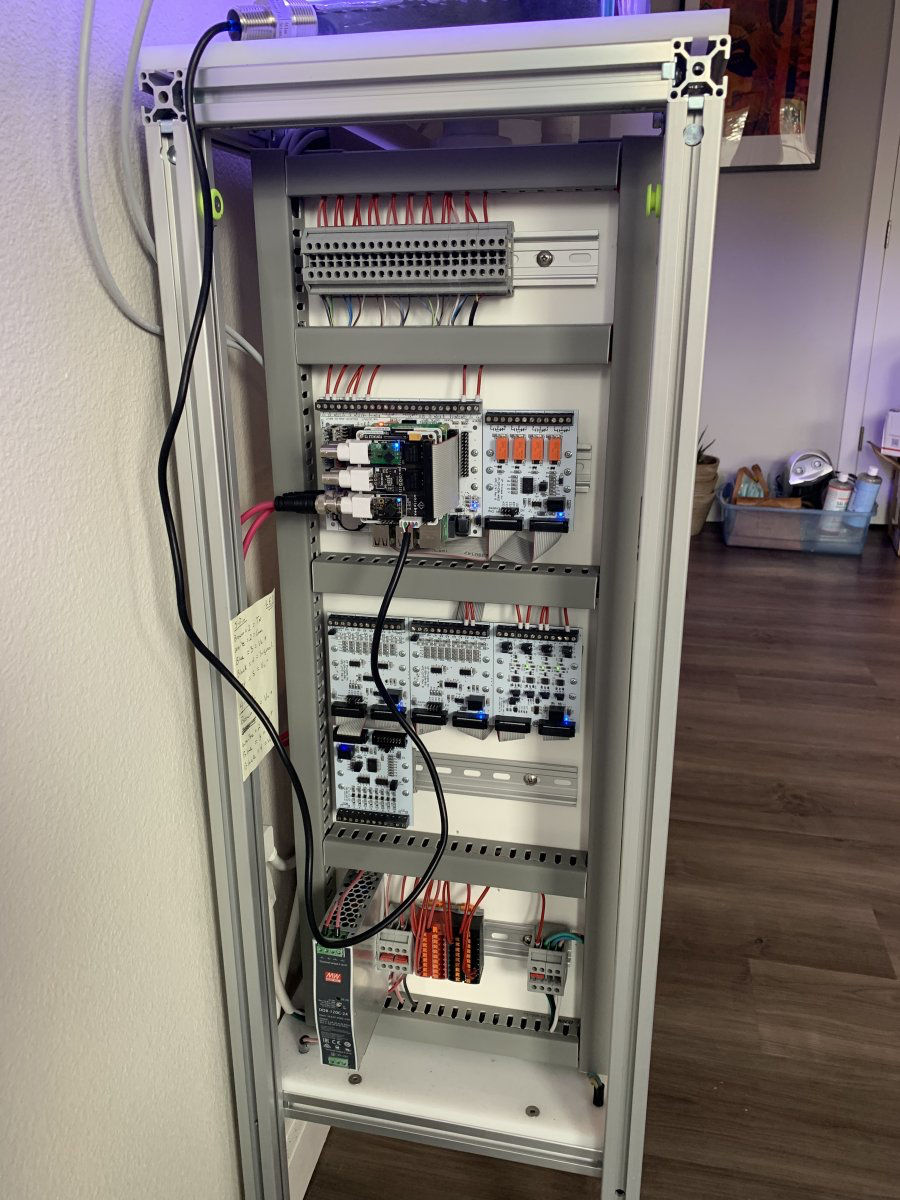

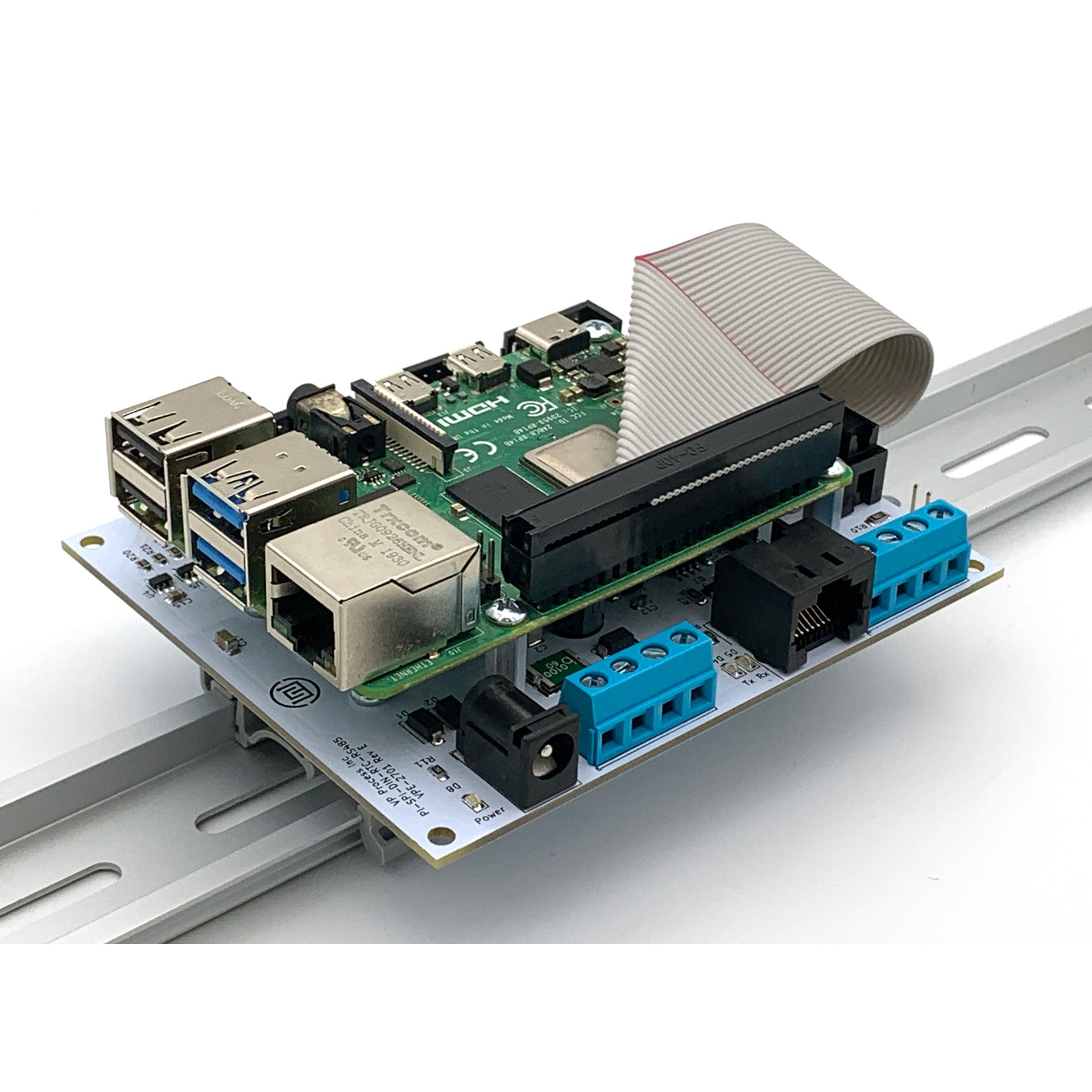

DIY Raspberry Pi controller running a PID loop to keep the display tank at correct wanter level. Exceedingly complex but achieved the goal of eliminating visible plumbing in the display. Overall a very fun proof-of-concept project. I plan to expand this concept to a larger tank once we purchase a home.

False bottom directs flow for drain / return.

Water levels are monitored in display and sump with ultrasonic sensors. Actuated ball valves control return modulating left, right, both with a second operating as a failsafe for the drain to sump. On power outage the failsafe closes to keep the water from draining out of the display.

Lighting is DIY also utilizing Nanobox Reef V3.1 pucks, MakersLED slim housing and 5UP LED drivers. Notice the ultrasonic sensor mounted directly in the middle of the light housing...

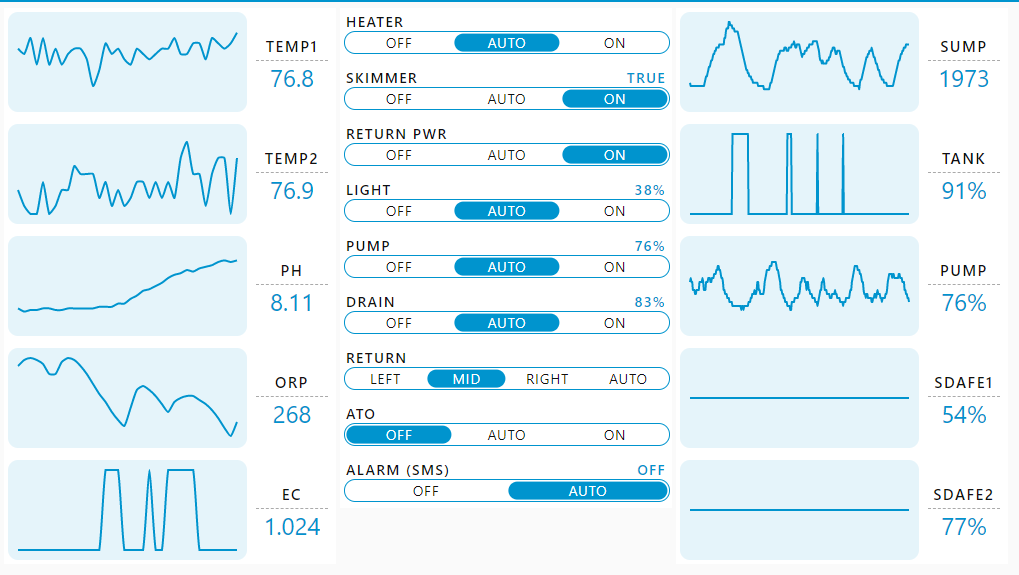

Dashboard utilizing a few custom Node-Red nodes I developed for this project:

flows.nodered.org

flows.nodered.org

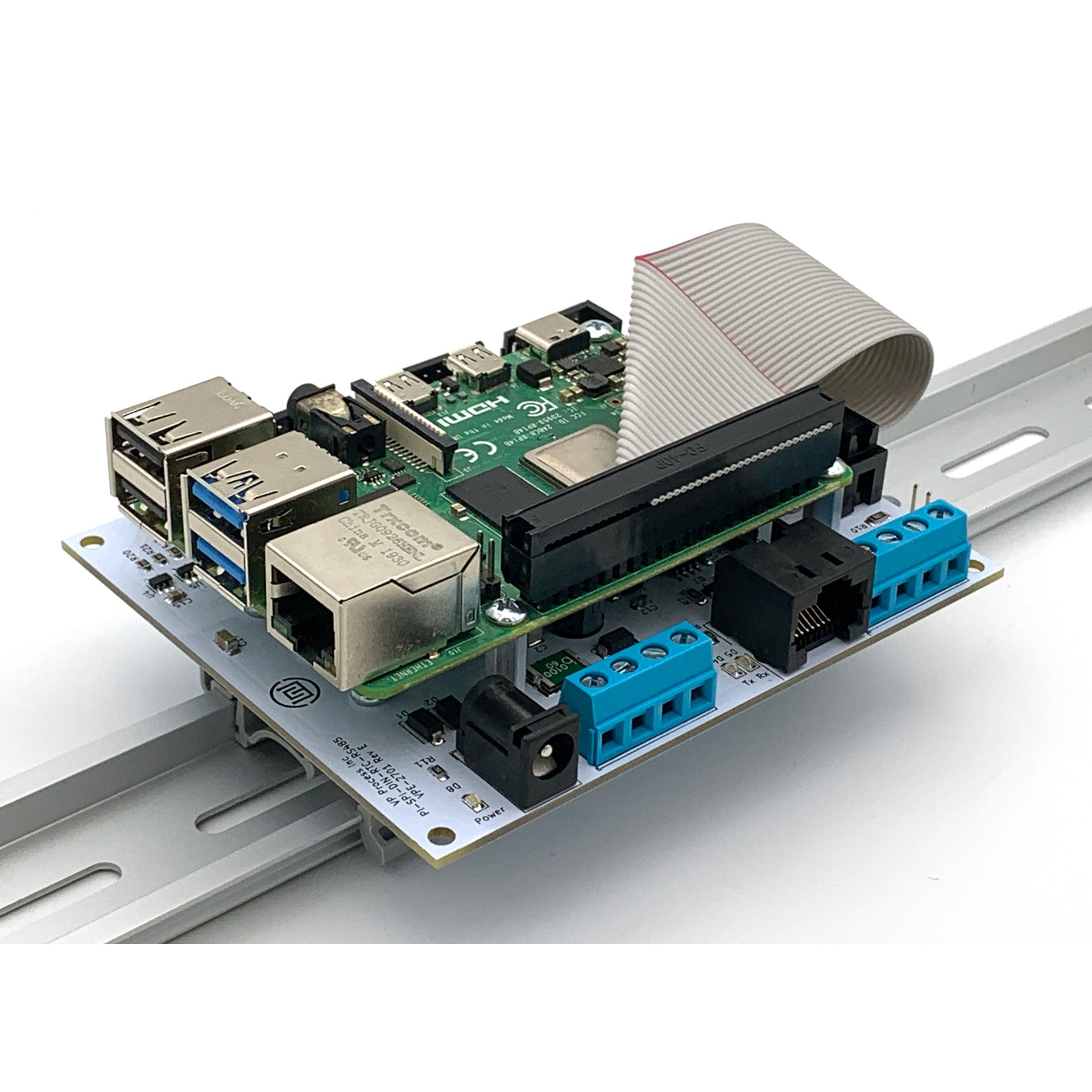

Raspberry Pi 4 running Node-Red with hardware by Atlas Scientific and Widgelords:

widgetlords.com

widgetlords.com

atlas-scientific.com

atlas-scientific.com

False bottom directs flow for drain / return.

Water levels are monitored in display and sump with ultrasonic sensors. Actuated ball valves control return modulating left, right, both with a second operating as a failsafe for the drain to sump. On power outage the failsafe closes to keep the water from draining out of the display.

Lighting is DIY also utilizing Nanobox Reef V3.1 pucks, MakersLED slim housing and 5UP LED drivers. Notice the ultrasonic sensor mounted directly in the middle of the light housing...

Dashboard utilizing a few custom Node-Red nodes I developed for this project:

node-red-contrib-ezo

Node to communicate with Atlas Scientific Ezo modules over I2C.

Raspberry Pi 4 running Node-Red with hardware by Atlas Scientific and Widgelords:

PI-SPI-DIN Product Group

Raspberry Pi Input/Output I/O ModulesDIN Rail MountableAnalog Input, Analog OutputDigital Input, Frequency and Pulse InputRelay Output, RS485

widgetlords.com

widgetlords.com

Atlas Scientific | Environmental Robotics

Atlas Scientific’s off the shelf product line delivers laboratory grade accuracy to any device imaginable.

I made an 80-gallon 1/2" plexiglass tank myself. It worked well with no leaks, but eventually got tired of too many scratches and switched to glass. Now I run an overly complex 8 tank system that uses one sump. I still use a 35-gallon self-made plexiglass tank from 15 years ago as a frag tank/refugium.

Similar threads

-

- Poll

- Replies

- 70

- Views

- 3,520

- Replies

- 1

- Views

- 217

- Replies

- 25

- Views

- 1,201

-

- AMS: Article

- Replies

- 28

- Views

- 5,581