redfishbluefish

Stay Positive, Stay Productive

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Article Contributor

NJRC Member

Hospitality Award

My Tank Thread

I've decided to start a new build thread after experiencing a seam failure in my original 90 gallon tank. The build of that tank is here:

RFBF's Five Footer

I also thought it appropriate to include one of my favorite quotes from Yogi Berra in the new title of my build.

So this re-do began with ordering a new custom tank from Glass Cages, that was delivered on February 10. The new tank is the exact dimensions....60" x 18" x 21" high, but now with Euro Bracing and Low E Glass on the front panel. So here's my new baby just inside the front door of the house.

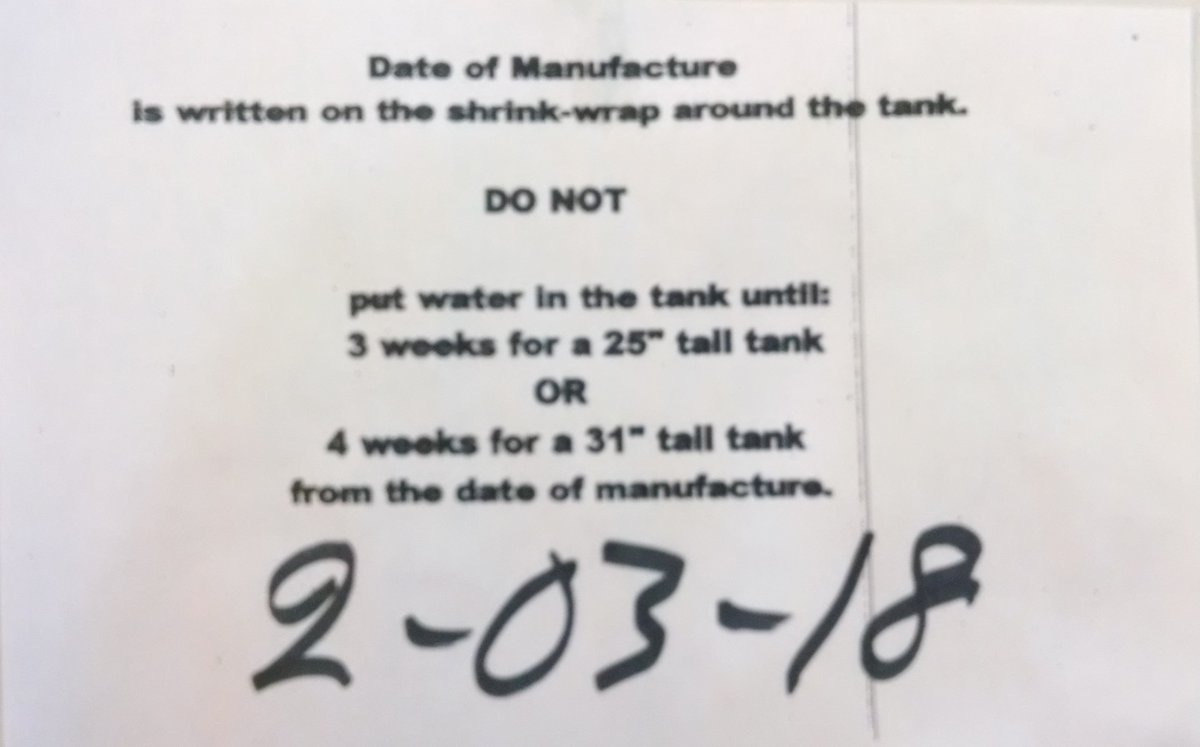

They also included a copy of the Birth Certificate. Born February 3, 2018.

Born February 3, 2018.

Since I'm starting from scratch, I figure I have 1 1/2 to 2 months while the new rock is bleached and cured.

The first thing I started with today was the return lines coming up over the top of the tank. The original has four wye Loc-Lines coming up over the back of the tank.

With the new tank having Euro Bracing, I have to deal with that and the now dual cross bracing. I don't think two Loc-Lines in each section would fit nicely. Here's one holding it as close to the one brace as I can.

So now I'm thinking to go down to just two wye Loc-Lines in each of the two outer sections, centered in that section. To test, I did pull off two Loc-Lines and covered the pipes with my fingers.....no problem going down from four to two.

Off to HD for pipe and fittings.

The new build has begun!

RFBF's Five Footer

I also thought it appropriate to include one of my favorite quotes from Yogi Berra in the new title of my build.

So this re-do began with ordering a new custom tank from Glass Cages, that was delivered on February 10. The new tank is the exact dimensions....60" x 18" x 21" high, but now with Euro Bracing and Low E Glass on the front panel. So here's my new baby just inside the front door of the house.

They also included a copy of the Birth Certificate.

Since I'm starting from scratch, I figure I have 1 1/2 to 2 months while the new rock is bleached and cured.

The first thing I started with today was the return lines coming up over the top of the tank. The original has four wye Loc-Lines coming up over the back of the tank.

With the new tank having Euro Bracing, I have to deal with that and the now dual cross bracing. I don't think two Loc-Lines in each section would fit nicely. Here's one holding it as close to the one brace as I can.

So now I'm thinking to go down to just two wye Loc-Lines in each of the two outer sections, centered in that section. To test, I did pull off two Loc-Lines and covered the pipes with my fingers.....no problem going down from four to two.

Off to HD for pipe and fittings.

The new build has begun!