Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rsumner's 450gal Home Office Reef

- Monster Build

- Thread starter rsumner

- Start date

- Tagged users None

Thanks. No, it will get pushed back to where it’s only 8” off the back wall.Looks great! Almost there. is the tank in its final spot?

A quick update....I'm still crawling along.

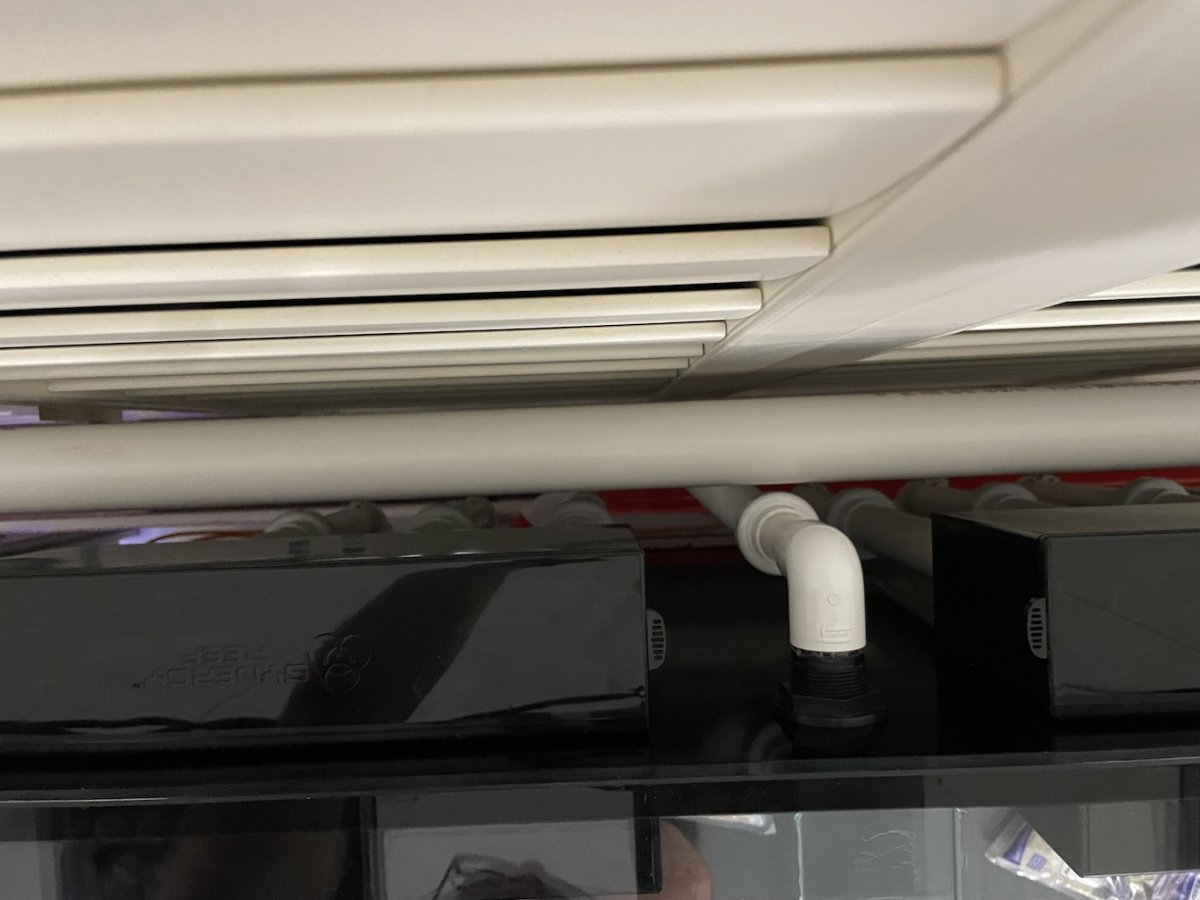

I have the tank moved into its final position, squared and leveled. It's a tight fit behind the tank due to the shutters and those huge 2" return lines, but I made it work. I jumped in the tank and took a picture looking down behind the tank showing you the dual overflows and center return line. The perpendicular pipe you see is the 2" return running from the left side of the tank (where the UVs are) to the two returns on the right side of the tank.

I have two things left before I can do a leak test. First, I need to get the pumps glued to their respective bulkheads inside the return section of the sump (using unions w/barbed fittings and silicon tubing) and plumb the dual check valves to the bulkheads on top of the sump to exit the stand towards the UVs.

After that, I will run the 2" return lines out the left side of the stand to two 2" flow sensors before entering the bottom of the UVs. Water will exit the top of the UV's into 2" Hayward true union ball valves before connecting to the runs that are behind the tank.

You'll notice I have 1/2" side-outs where the plumbing enters the bottom of the UV. I will add 1/2" Hayward ball valves to these side-outs so I can bleed all the water out of the UV body should I need to do any large maintenance on the UV. Since I have 2" ball valves on the exit of each of the UV's, I can shutdown one UV and return pump without affecting the other return path and most importantly no floods.

Getting the UVs perfectly aligned with the return lines isn't an easy task since the UVs aren't attached to the stand and the walls aren't completely square. I hope to have all my measurements confirmed today so I can cut all that pipe for a dry fit.

You should also notice a fresh water supply line in front of the bottom of the UVs that will eventually be plumbed all the way to the right side of the tank for the skimmer auto-clean and RODI system. I'll temporarily plumb some 1/2" PVC that will dump directly into the to the top of the display for the leak test. Once I'm done with the leak test, I'll tear that out and connect it to the 1/2" line that is running behind the stand. Unions are AWESOME!

Lastly, the 1.5" PVC that is running behind the return lines is my drain/waste line that goes outside to the city sewage. I have a full 1.5" pipe going behind the stand to the right side of the tank so I have access to a waste drain for my skimmer auto-clean and RODI waste water. On the left side of the tank, I have two wye's installed on the sewage line. The first wye provides me easy access to dump-out water changes and to connect the Neptune Trident waste line to. The second wye is connected to a clean-out trap just in case I get a clog. Plumbing all of that is a low priority since it isn't a prerequisite for the leak test.

Well, that's it for today.

I have the tank moved into its final position, squared and leveled. It's a tight fit behind the tank due to the shutters and those huge 2" return lines, but I made it work. I jumped in the tank and took a picture looking down behind the tank showing you the dual overflows and center return line. The perpendicular pipe you see is the 2" return running from the left side of the tank (where the UVs are) to the two returns on the right side of the tank.

I have two things left before I can do a leak test. First, I need to get the pumps glued to their respective bulkheads inside the return section of the sump (using unions w/barbed fittings and silicon tubing) and plumb the dual check valves to the bulkheads on top of the sump to exit the stand towards the UVs.

After that, I will run the 2" return lines out the left side of the stand to two 2" flow sensors before entering the bottom of the UVs. Water will exit the top of the UV's into 2" Hayward true union ball valves before connecting to the runs that are behind the tank.

You'll notice I have 1/2" side-outs where the plumbing enters the bottom of the UV. I will add 1/2" Hayward ball valves to these side-outs so I can bleed all the water out of the UV body should I need to do any large maintenance on the UV. Since I have 2" ball valves on the exit of each of the UV's, I can shutdown one UV and return pump without affecting the other return path and most importantly no floods.

Getting the UVs perfectly aligned with the return lines isn't an easy task since the UVs aren't attached to the stand and the walls aren't completely square. I hope to have all my measurements confirmed today so I can cut all that pipe for a dry fit.

You should also notice a fresh water supply line in front of the bottom of the UVs that will eventually be plumbed all the way to the right side of the tank for the skimmer auto-clean and RODI system. I'll temporarily plumb some 1/2" PVC that will dump directly into the to the top of the display for the leak test. Once I'm done with the leak test, I'll tear that out and connect it to the 1/2" line that is running behind the stand. Unions are AWESOME!

Lastly, the 1.5" PVC that is running behind the return lines is my drain/waste line that goes outside to the city sewage. I have a full 1.5" pipe going behind the stand to the right side of the tank so I have access to a waste drain for my skimmer auto-clean and RODI waste water. On the left side of the tank, I have two wye's installed on the sewage line. The first wye provides me easy access to dump-out water changes and to connect the Neptune Trident waste line to. The second wye is connected to a clean-out trap just in case I get a clog. Plumbing all of that is a low priority since it isn't a prerequisite for the leak test.

Well, that's it for today.

A quick update:

I have a few more 2" pipes to measure, cut, and glue to connect the UVs to the rest of the plumbing. These last pipes have been tedious since they aren't connected to the frame and I don't want to screw up the expensive flow sensors and check/ball valves. After that, I can glue the return pumps and I'll be ready for my leak test. I'm going to fill the entire system (about 700 gallons) with plain tap water to do the leak test and run it for about 24 hours. If everything checks out, I'll drain/pump all that water outside into my pool and dry-out the display and sump. I should have time to get all of this knocked out this week.

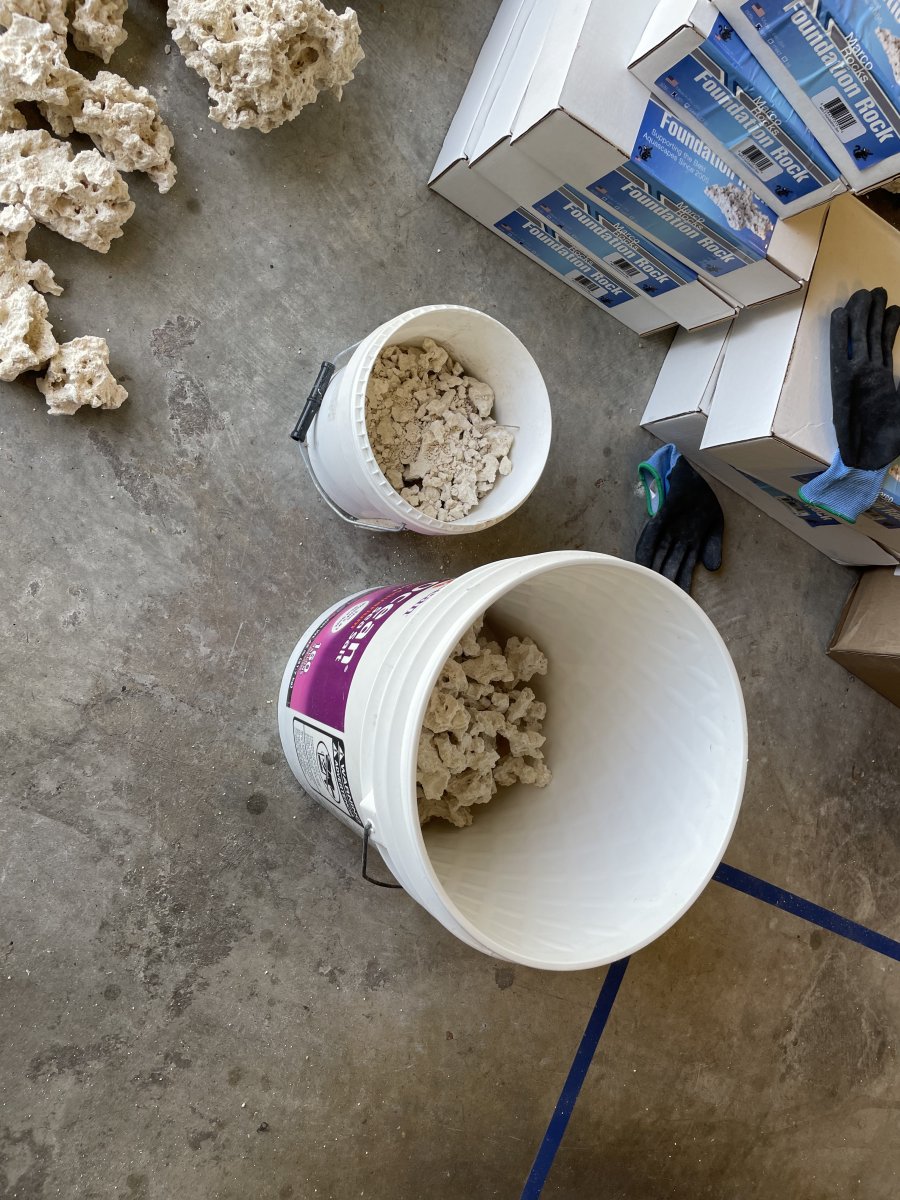

I also found a pretty good deal on Marco rock at aquacave.com (plus they don't charge out of state sales tax), so I ordered 300lbs of their standard rock and 100lbs of shelf rock. Aqua Cave doesn't sell the Marco foundation rocks, so I ordered the large and medium foundation rocks from BRS. The poor Fedex delivery guy hauled all those boxes up my driveway yesterday. I also have 180lbs of CarribSea ARAG-ALIVE Special Grade sand sitting in bags in my laundry room ready to go. I'm not looking forward to aquascaping, but that's the next major hurdle before filling with RODI and salt.

I have a few more 2" pipes to measure, cut, and glue to connect the UVs to the rest of the plumbing. These last pipes have been tedious since they aren't connected to the frame and I don't want to screw up the expensive flow sensors and check/ball valves. After that, I can glue the return pumps and I'll be ready for my leak test. I'm going to fill the entire system (about 700 gallons) with plain tap water to do the leak test and run it for about 24 hours. If everything checks out, I'll drain/pump all that water outside into my pool and dry-out the display and sump. I should have time to get all of this knocked out this week.

I also found a pretty good deal on Marco rock at aquacave.com (plus they don't charge out of state sales tax), so I ordered 300lbs of their standard rock and 100lbs of shelf rock. Aqua Cave doesn't sell the Marco foundation rocks, so I ordered the large and medium foundation rocks from BRS. The poor Fedex delivery guy hauled all those boxes up my driveway yesterday. I also have 180lbs of CarribSea ARAG-ALIVE Special Grade sand sitting in bags in my laundry room ready to go. I'm not looking forward to aquascaping, but that's the next major hurdle before filling with RODI and salt.

Last edited:

Well, all the return lines are glued and I've completed a leak test. I had some pretty bad leaks around my Synergy overflows only to find out I put one pair of the gaskets on the wrong side of the overflow box  . After I fixed those gaskets, those leaks were gone. I had some small trickles coming from my unions, but after tightening those more, those leaks disappeared too. The only leaks I still have are around the 2" Apex flow sensors. I'll have to reapply the thread sealant on those after I drain the system.

. After I fixed those gaskets, those leaks were gone. I had some small trickles coming from my unions, but after tightening those more, those leaks disappeared too. The only leaks I still have are around the 2" Apex flow sensors. I'll have to reapply the thread sealant on those after I drain the system.

I took a little time to play with the Abyzz A200's and tuned the overflows to quiet them a bit. They aren't anywhere near silent yet, but I'll screw around with that once I have RODI and salt water in the tank. I'm going to let things run for the rest of the day and then drain the tank and sump.

I'm going to finish the sewage plumbing and fresh water supply line plumbing next. After that, I'll only have to do a small amount of plumbing to connect the skimmer, but I should be able to put away a ton of crap that's in my office which will be a big relief.

After that, I'm going to crack open all the boxes of Marco rock I got and start scaping.

I took a little time to play with the Abyzz A200's and tuned the overflows to quiet them a bit. They aren't anywhere near silent yet, but I'll screw around with that once I have RODI and salt water in the tank. I'm going to let things run for the rest of the day and then drain the tank and sump.

I'm going to finish the sewage plumbing and fresh water supply line plumbing next. After that, I'll only have to do a small amount of plumbing to connect the skimmer, but I should be able to put away a ton of crap that's in my office which will be a big relief.

After that, I'm going to crack open all the boxes of Marco rock I got and start scaping.

Here's a current full tank shot. Sorry, I already drained it. The water line was completely hidden and at a perfect level when I had it completely filled. Glass Cages did an awesome job. With the water drained again, I took the opportunity to put a level on the internal and external boxes of the overflows. I noticed everything was a little out of level, so I straightened that out. Hopefully that will help silencing things when I fill it again.

The monster skimmer, RODI, and Calcium Reactor will be on the right side. The left side will house the ATO reservoir, 1/3HP chiller, and Kalk reactor. Electrical will be split between both sides with most of the Neptune stuff being on display on the left side. Everything on the left and right will be enclosed in additional extruded aluminum-based cabinets (that I need to build at some point). After that, the tank stand and both cabinets will be wrapped in white cabinet grade plywood. I'll also put a little wrap around the light frame also so everything is hidden.

I got the fresh water and sewage plumbing done:

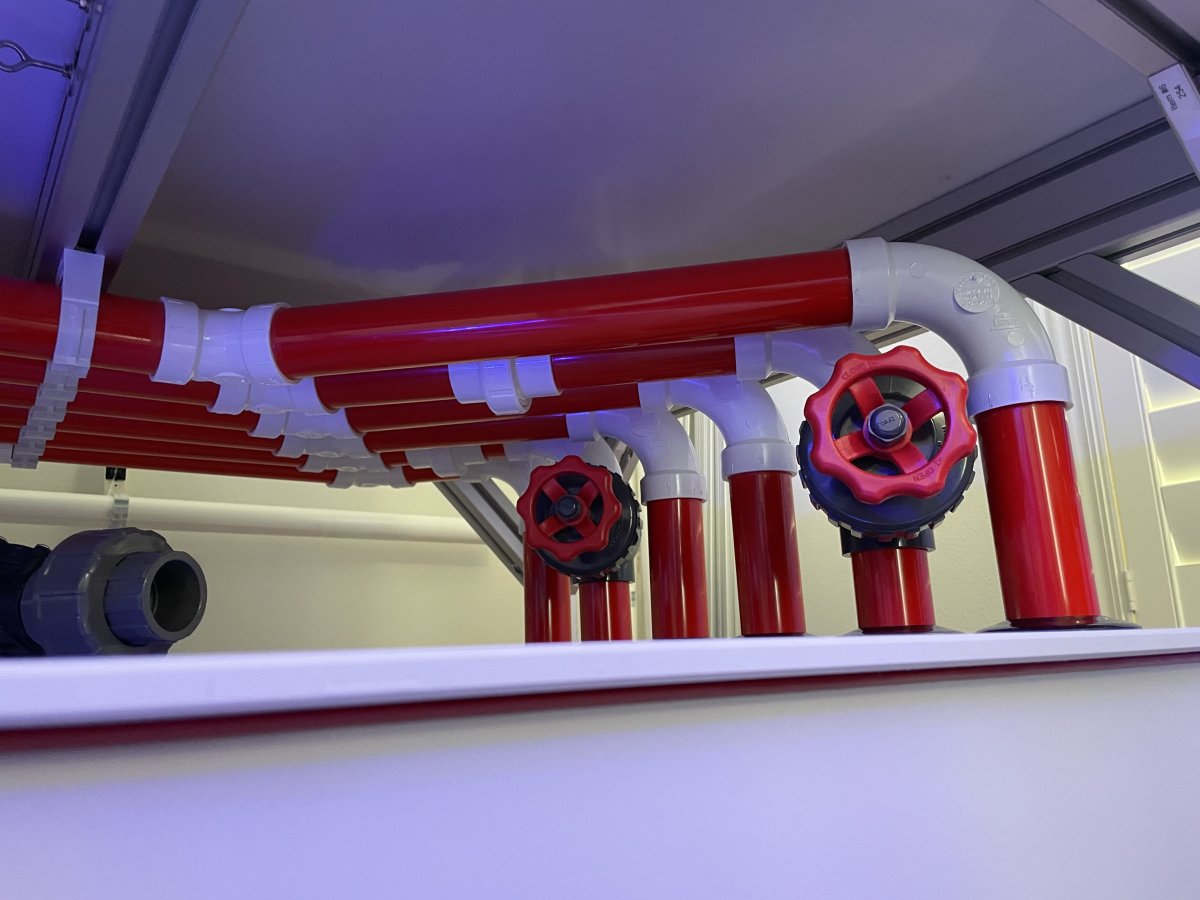

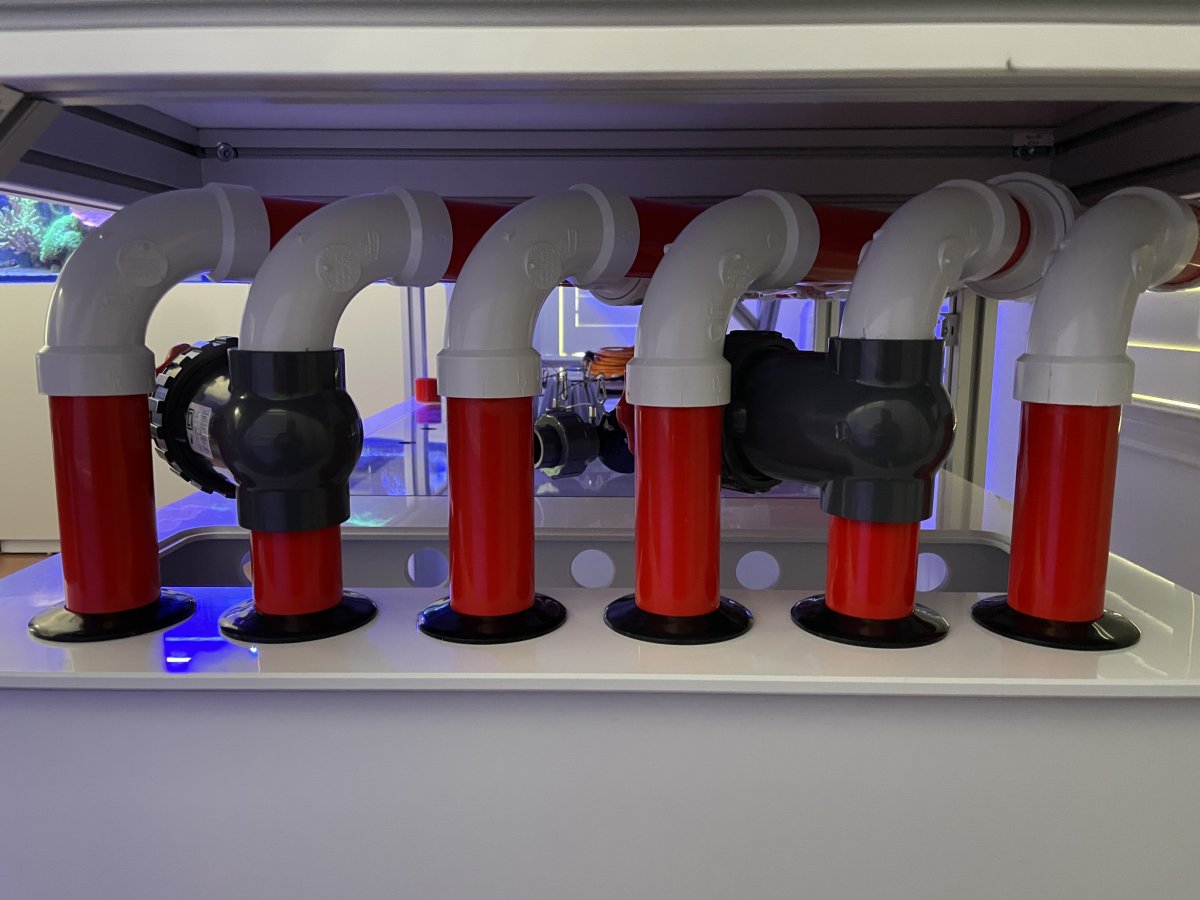

And the huge 2" ball valves are lined-up perfectly.

I drained all 650+ gallons of tap water I used to do my leak test through my new sewage lines today. Oh, how I love not having to run hoses or drag buckets around for major water dumps. Having a drain directly to the city sewage 2ft away is an absolute blessing.

I've got enough space cleared out in the office to start playing with rock next. The wife is out of town for the weekend, so I'll get plenty of time to do some aquascaping.

The monster skimmer, RODI, and Calcium Reactor will be on the right side. The left side will house the ATO reservoir, 1/3HP chiller, and Kalk reactor. Electrical will be split between both sides with most of the Neptune stuff being on display on the left side. Everything on the left and right will be enclosed in additional extruded aluminum-based cabinets (that I need to build at some point). After that, the tank stand and both cabinets will be wrapped in white cabinet grade plywood. I'll also put a little wrap around the light frame also so everything is hidden.

I got the fresh water and sewage plumbing done:

And the huge 2" ball valves are lined-up perfectly.

I drained all 650+ gallons of tap water I used to do my leak test through my new sewage lines today. Oh, how I love not having to run hoses or drag buckets around for major water dumps. Having a drain directly to the city sewage 2ft away is an absolute blessing.

I've got enough space cleared out in the office to start playing with rock next. The wife is out of town for the weekend, so I'll get plenty of time to do some aquascaping.

Looking great!

Awesome. Can’t wait to see the skimmer in action. Curious on the noise With all pumps running. .

I couldn't tell the A200's were even running when I had them on. I know a lot of people use that exact term when they describe their return pump noise, but I intend on doing a dBm noise test and sharing my findings.

I think about watching that skimmer in action every day too. It's sitting on the floor behind the desk in my office right now. It's visible when I'm on web conference calls for work and I get asked every day one of these variations: "What is that thing behind you? Is that a water boiler? Is that a whisky still?"

I had a moment of common sense last night and realized I should probably do my mock aquascaping in the garage. I'm going to tape-off a 8x3ft rectangle on the garage floor. My plan is to build an HNSA-style aquascape as described in this BRS video . I'm planning on creating 4 structures of some kind, but I have no idea yet what they'll look like.

I'm not sure how much progress I'll make today, but wish me luck.

Looking amazing!! Really nice attention to detail!

I’m planning a very similar build myself and actually have the same skimmer - I’m nervous about hooking that drain up to a main drain instead of a collection bucket, just in case it were to start wet skimming like crazy for some reason. Curious how consistent the skimmer is once it’s set so I’ll be seeing how it goes for you.

I’m planning a very similar build myself and actually have the same skimmer - I’m nervous about hooking that drain up to a main drain instead of a collection bucket, just in case it were to start wet skimming like crazy for some reason. Curious how consistent the skimmer is once it’s set so I’ll be seeing how it goes for you.

Aqua Cave did a pretty good job packing the Marco. Only one piece of the shelf rock broke and there was very little rubble from all the standard rock.

I got it all all unpacked and ready to go. Man, I must say, I’m pretty overwhelmed.

I got it all all unpacked and ready to go. Man, I must say, I’m pretty overwhelmed.

What are your stand feet sitting on? NM, I saw it on the next page, lol.Sump has arrived!! Lift gate service was a problem due to the crate being 8ft long, but the driver and I muscled it into the garage and then the teenager next door helped me move it into the house using shoulder dolly straps.

I love your build! I’m working on a 600 gallon and you are giving me inspiration!

Last edited:

the apex flow sensors are a huge pain to seal. use like 3x as much sealant as you think you need.

Thanks for the pointer, @David_CO. This is the first time I've used thread sealant. I usually just use teflon tape on them despite Neptune saying not to. I tried to get the apart and couldn't, so I'll have to get a wrench to help with that so I can reapply the sealant again before filling the tank again.

Ya i'm not sure what it is about the threads on the apex flow sensors but they seem to be cut in a non-standard way or with poor tolerances. When I dry fit them the looseness in the connection was very noticeable. I'm using a handful of the 1 inch ones along with some of the small guys and they are all a problem.

If I did it again I would probably permanently seal the threads with PVC glue or something similar since I have unions on both sides of the sensor anyway.

If I did it again I would probably permanently seal the threads with PVC glue or something similar since I have unions on both sides of the sensor anyway.

Very impressive. Your attention to detail is commendable.New red drain lines are cut and glued. I still need to cut the final pieces to connect these to the dual overflows, but this took a day and a half, so I need a break.

Having the pipe lengths already calculated allowed me to cut them in one trip to the saw and giving me labeled inventory to reference my drawing and spreadsheet when it was time for assembly.

And the final product :

I had to use a strap wrench, but I was finally able to disassemble the 2" flow sensors. I removed as much of the old thread sealant as I could and reapplied thread sealant on the male and female threads this time. Last time, I was pretty conservative with how much I used, but I gave it plenty this time. I left the sensor uninstalled for 48 hours to let the sealant cure before reattaching the unions. Hopefully this resolved the small leak.

I've been working on my aquascape off-and-on for the past few weeks. This past weekend, I finally got the hang of creating the types of designs I want. I hope to have it finished by the end of next weekend so I can start filling the tank again.

I also purchased a jig from Framing Tech that will help me drill the required holes for the internal "quick connectors" that I'm going to use on my 30x30mm extruded aluminum side-cabinets. The jig was pretty expensive, but considering the number of holes I need to drill (and how precise they need to be), I decided to invest in the jig.

I've been working on my aquascape off-and-on for the past few weeks. This past weekend, I finally got the hang of creating the types of designs I want. I hope to have it finished by the end of next weekend so I can start filling the tank again.

I also purchased a jig from Framing Tech that will help me drill the required holes for the internal "quick connectors" that I'm going to use on my 30x30mm extruded aluminum side-cabinets. The jig was pretty expensive, but considering the number of holes I need to drill (and how precise they need to be), I decided to invest in the jig.

Similar threads

- Replies

- 1

- Views

- 88

- Replies

- 1

- Views

- 57

- Replies

- 14

- Views

- 230

New Posts

-

Maco aquascape bonding, I have my planned method, what's your

- Latest: ShakeyGizzard

-

-

-