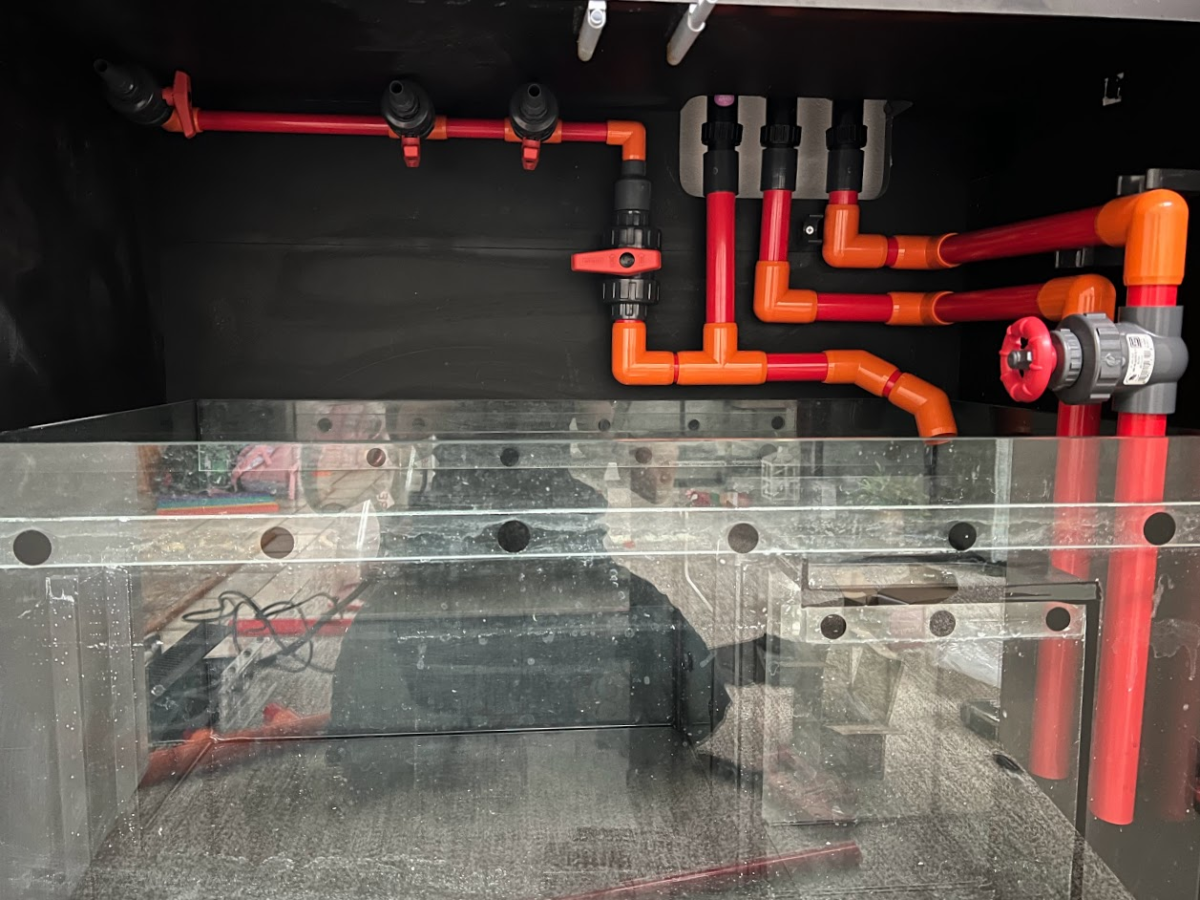

Hey all, this is my first time building out a manifold and really doing any hard plumbing whatsoever. I'm converting my Red Sea Reefer 525XL with a v3 sump to 1" and adding a manifold. I want to glue this together tomorrow which scares me to death, but it just needs to be done. Please let me know if you see any big mistakes or things that I need to adjust. Other than the slightly crooked pipes, of course... this is just a quick dry-fit

I've converted the Red Sea standard 32mm to 1" once it reaches the sump area (basically where the red pipe starts). Two on the right are the down pipe and overflows, 1" gate valve for controlling flow. These are set up almost identical to how the stock pipes are, so not too concerned about that.

The two 45 degree joints are where my return is. I'm connecting a 1" braided vinyl tube for to my return pump just for some additional flexibility here (not connected in the photo).

The 1" return T's out to the main return line back to the DT and also to a 90 degree joint to the manifold. Standard ball valve to entirely shut down the manifold if needed, but plan on leaving it fully open. Immediately after the manifold valve I'm reducing from 1" down to 1/2". Along the top I've added 3 x 1/2" ball valves for additional plumbing down the road if I decide that I need it. The end of each ball valve has a barb to hook in a 1/2" vinyl tube but that can be swapped out since those are just threaded with tape. The very last ball valve to the left of the area is going to feed my fuge which will be a converted ATO tank pushed all the way to the left. It'll just be a 1/2" vinyl tube that feeds the fuge, so it'll just hang off of the barb up there and go down. I'll control the flow of that via the valve (obviously). I will *probably* just let my fuge overflow back into the chamber where the skimmer is. I know I'll get some re-processing of the same water, but I can't imagine it's a huge issue.

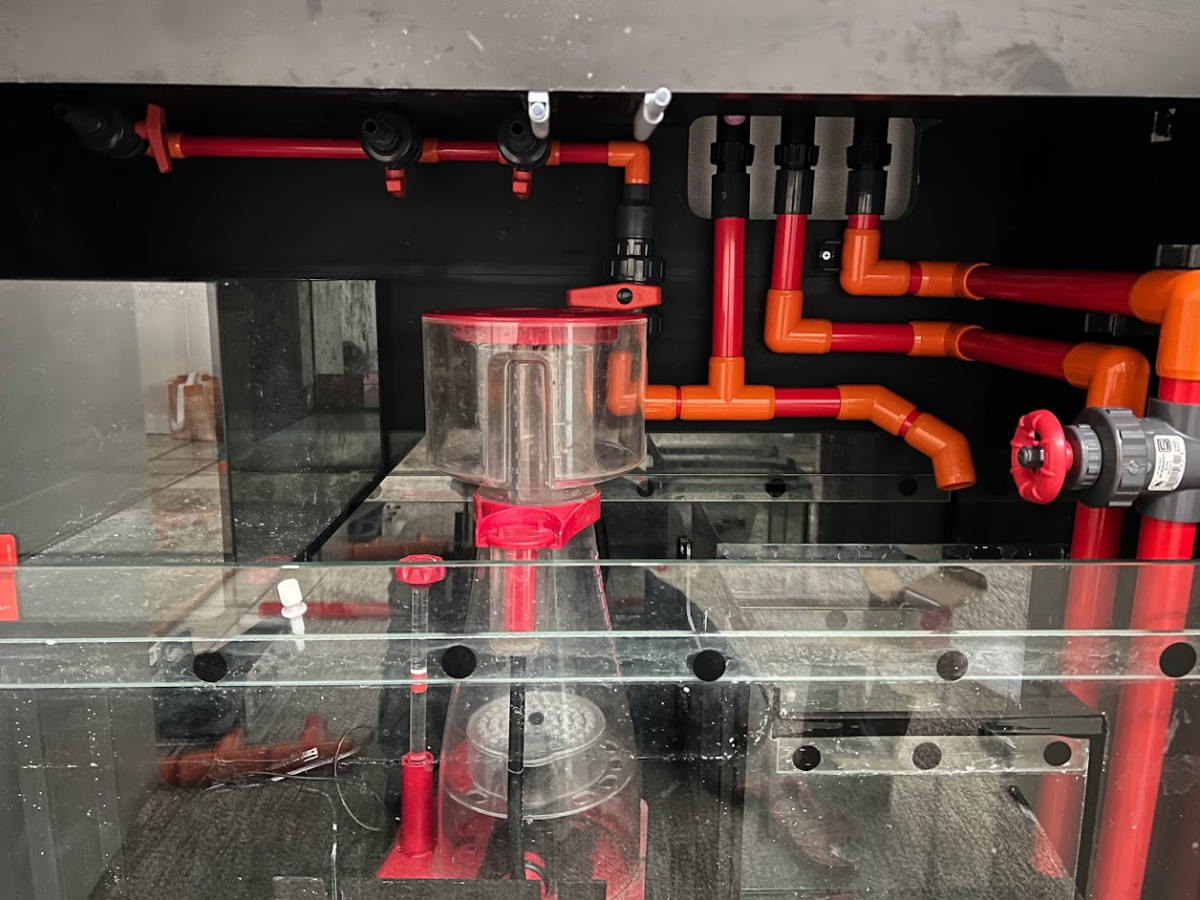

Here's what it will look like with the fuge and skimmer

Please let me know if you see any major issues!

I've converted the Red Sea standard 32mm to 1" once it reaches the sump area (basically where the red pipe starts). Two on the right are the down pipe and overflows, 1" gate valve for controlling flow. These are set up almost identical to how the stock pipes are, so not too concerned about that.

The two 45 degree joints are where my return is. I'm connecting a 1" braided vinyl tube for to my return pump just for some additional flexibility here (not connected in the photo).

The 1" return T's out to the main return line back to the DT and also to a 90 degree joint to the manifold. Standard ball valve to entirely shut down the manifold if needed, but plan on leaving it fully open. Immediately after the manifold valve I'm reducing from 1" down to 1/2". Along the top I've added 3 x 1/2" ball valves for additional plumbing down the road if I decide that I need it. The end of each ball valve has a barb to hook in a 1/2" vinyl tube but that can be swapped out since those are just threaded with tape. The very last ball valve to the left of the area is going to feed my fuge which will be a converted ATO tank pushed all the way to the left. It'll just be a 1/2" vinyl tube that feeds the fuge, so it'll just hang off of the barb up there and go down. I'll control the flow of that via the valve (obviously). I will *probably* just let my fuge overflow back into the chamber where the skimmer is. I know I'll get some re-processing of the same water, but I can't imagine it's a huge issue.

Here's what it will look like with the fuge and skimmer

Please let me know if you see any major issues!