This actually came about because my Avast kalk stirrer is maxed out, meaning my evaporation is now my limiting factor. If I ran my system with kalk only it would drop from an alk of 8.5 to 6.5 in about three days. I was sitting around thinking about what am I going to do for my next step. Long story short I kinda just thought F-it and turned off my calcium reactor and dosed kalk slurry for a whole day. I hit 8.3 ph for the first time in a long time. Also my nightly low was over 8!!!!Ok, software is where I can speak. Be VERY VERY careful with feedback loops. Maybe a second PH probe is in order. If one piece of what you doing screws up ... and it will. You want to have some sort of precautions built in to deal with it. Redundancy is key here.

PH is a good pinch point to ensure levels don't get out of hand. I think that what you are going to find is that you will not be using as much of slurry as you think you will. It doesn't take very much to make things happen.

Also just as an aside. I am not sure what got on you on this contraption, but there are cleaner ways to deal with this. Please don't think that this is me saying don't do what you are doing. I ABSOLUTELY think you should, because the learning is worth way more than just buying something and using it without really understanding it. The way that I deal with Kalk is with a Kalk stirrer and a doser. I use my other method as filler for what the Kalk can't keep up with. Just a thought.

I think you are on to it. Keep posting it will be a fun ride for sure.

As for the pH probe I hear you. I have double control on this as I have an alkatronic so if my alk were to go above my set point I would be notified and I could turn off my kalk slurry system. I am actually looking into using my alkatronic to dose the kalk slurry. It has a feedback loop that is very conservative but people are holding their alk very constant with it.

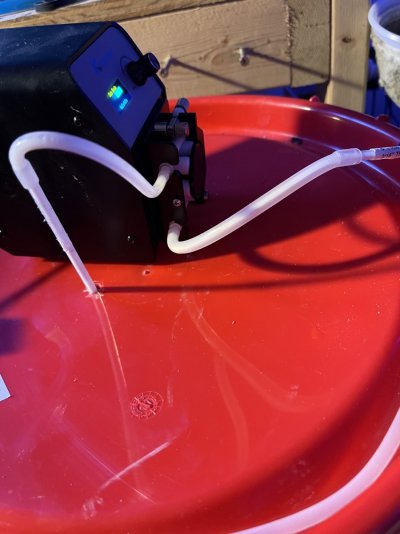

as you can see I am going to have fun with this one!!!