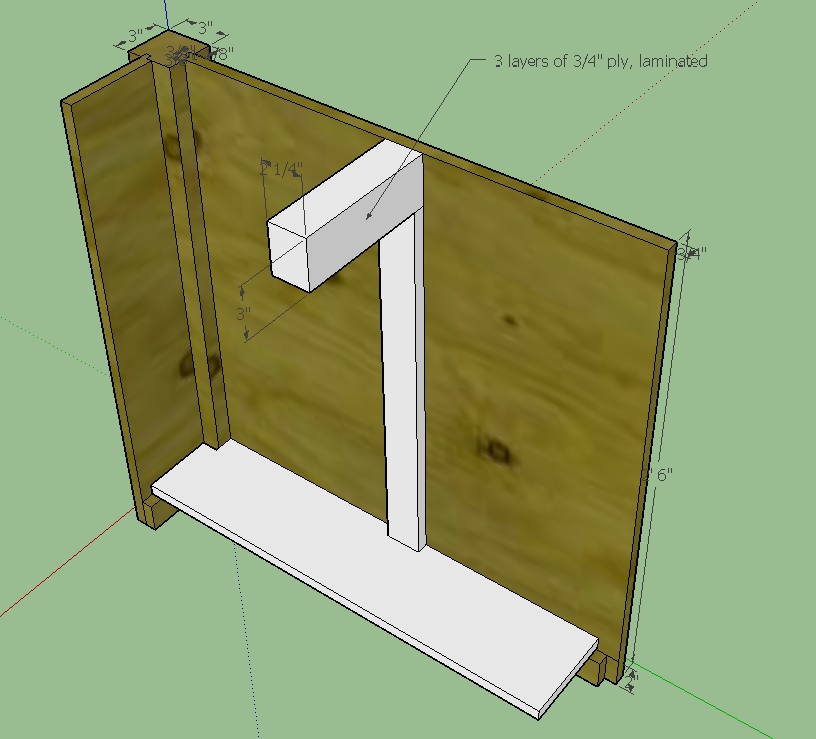

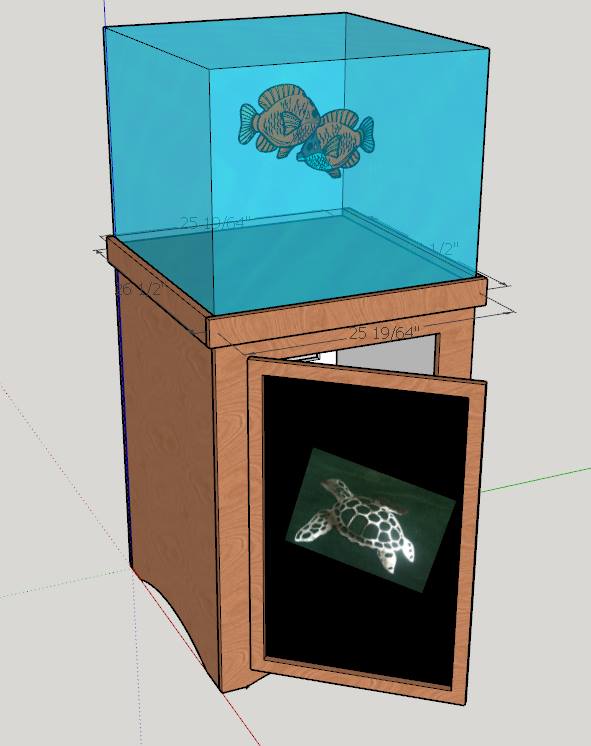

I just finished this last monday actually. I upgraded from a 40 gallon breeder I set up with a 20 gallon refugium to a 120 gallon with a 40 gallon breeder as my refugium. I still need to add some texture (possibly stone texture) and some trim but heres what I got so far....ohh an some doors still....

The top will have covers for the port holes up there and the big refugium hole will have a door a long with the supply area. I built this stand to hid the plumbing of the over flow box and the return lines no hanging wires and I built this stand to erect the aquarium off the wall so i can view my tank from 3 sides allowing me to use all of my reef for viewing and corals and never loose sight of a wondering anemone again lol.

The top will have covers for the port holes up there and the big refugium hole will have a door a long with the supply area. I built this stand to hid the plumbing of the over flow box and the return lines no hanging wires and I built this stand to erect the aquarium off the wall so i can view my tank from 3 sides allowing me to use all of my reef for viewing and corals and never loose sight of a wondering anemone again lol.