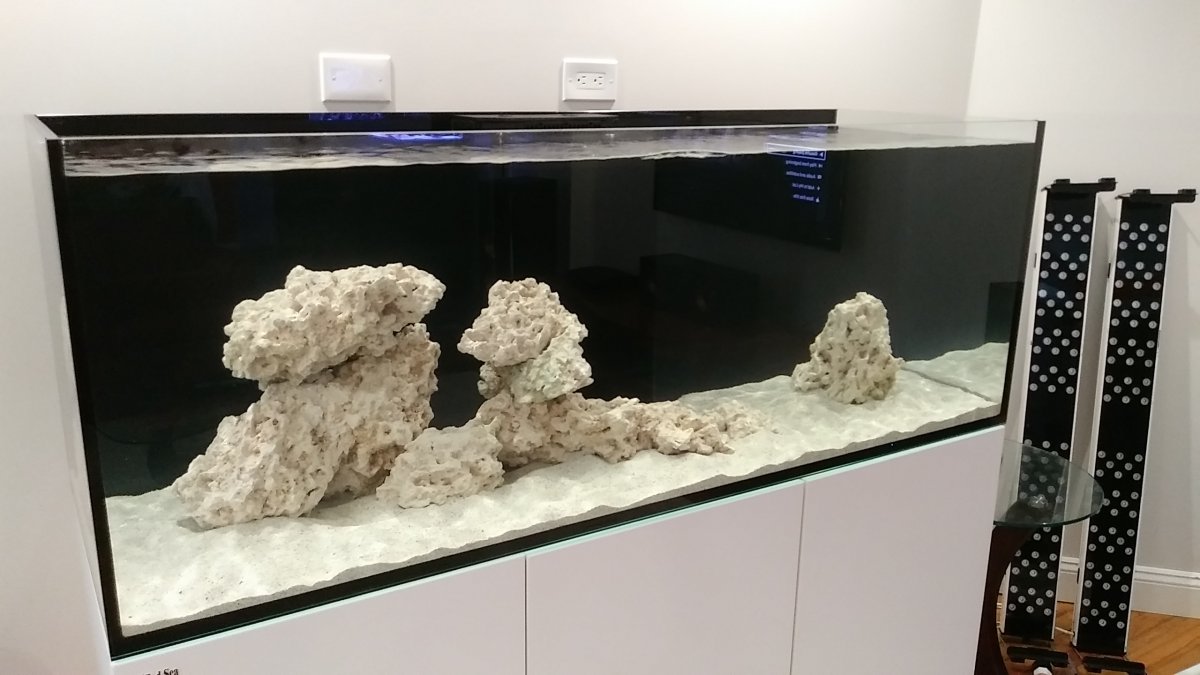

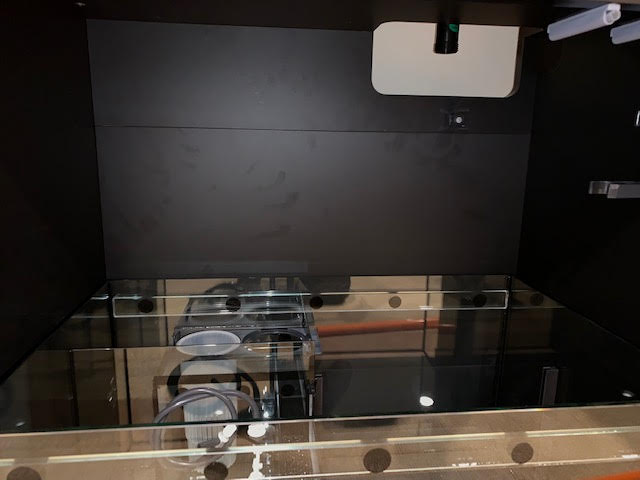

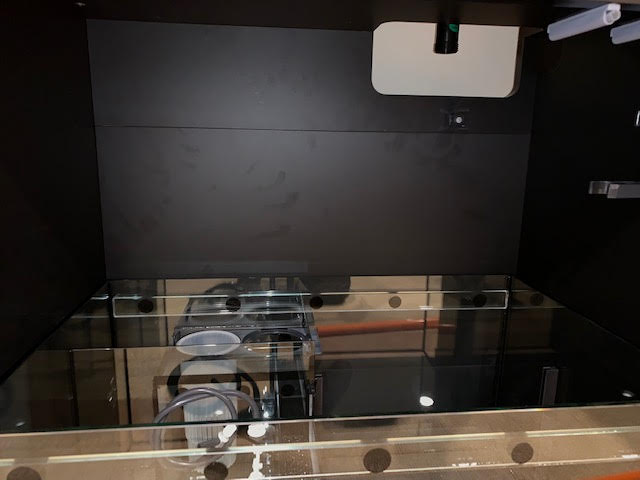

Reefer 525 with two 25s plumbed into it. About 2 months into its cycle with a few LPS and damsels in the side tanks.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Off and Discuss Your Red Sea Reefer Series

- Thread starter Broadfield

- Start date

- Tagged users None

Could this be rigged up to sit on the edge of the glass instead of hanging? Sort of like an open top canopy? I’d like to cut down some of the glare.

I'd imagine once built it could be used (mounted or hung) to your liking. I personally wouldn't want anything resting on the glass and find the whole point in the Reefer is the rimless aesthetics but that's just me.

There are a bunch of options for "floating" the canopy but most of them are fairly labor intensive.Yeah, PVC board is what I'm using. It matches the stand perfect and cuts finishing time to well, none, lol. I'm just working out the brackets and such now. Hoping to build it this weekend. Should cost roughly 200-250 to build. Well worth it. Any tips are more than welcome. I want as close to floating as possible without obvious hangers.

First if the canopy is sturdy enough you MAY be able to simply screw it into the wall and your good - no hanging kit. MDF is fairly heavy and susceptible to humidity so it may not be optimal. I think the idea of using PVC is much better as it weighs much less and is impervious to moisture. One thing to consider is that if your canopy is too heavy it will sag under a load if mounted to a stud covered in sheetrock. Sheetrock will compress under a load. Maybe not on day one but in due time. Perhaps removing the sheet rock, mounting the canopy to the studs and then repairing the sheetrock would be inline with your goals.

Another option would be using a bracket that had a low profile gusset such as this.

These are how I achieved this... no apparent wires or brackets.

There are a few other options but really this is the sturdiest for the amount of work invested.

If this appeals to you let me know. My company sells thousands of them a year and I have dozens of them in bronze (powder coat) in various sizes that were never shipped due to the folks that ordered them going out of business. It will take two and you can have them for free but it will take some work mounting them.

There are several other options that will work as well such as threaded steel dowel rods and "blind" holes drilled into the canopy to slide them into and perhaps some of the new "floating shelves" that HomeDepot sells.

Let me know if you are interested.

I have the RSR 350 V3, thinking about cutting out the filter sock area and installing a Clarisea filter roller.

1. How hard it is to cut out that area and what did you use to do it with?

2. Any pics or tips on doing this modification?

3. Can you do this with the sump in place or do you drain the sump and remove?

Thanks,

1. How hard it is to cut out that area and what did you use to do it with?

2. Any pics or tips on doing this modification?

3. Can you do this with the sump in place or do you drain the sump and remove?

Thanks,

There are a bunch of options for "floating" the canopy but most of them are fairly labor intensive.

First if the canopy is sturdy enough you MAY be able to simply screw it into the wall and your good - no hanging kit. MDF is fairly heavy and susceptible to humidity so it may not be optimal. I think the idea of using PVC is much better as it weighs much less and is impervious to moisture. One thing to consider is that if your canopy is too heavy it will sag under a load if mounted to a stud covered in sheetrock. Sheetrock will compress under a load. Maybe not on day one but in due time. Perhaps removing the sheet rock, mounting the canopy to the studs and then repairing the sheetrock would be inline with your goals.

Another option would be using a bracket that had a low profile gusset such as this.

These are how I achieved this... no apparent wires or brackets.

There are a few other options but really this is the sturdiest for the amount of work invested.

If this appeals to you let me know. My company sells thousands of them a year and I have dozens of them in bronze (powder coat) in various sizes that were never shipped due to the folks that ordered them going out of business. It will take two and you can have them for free but it will take some work mounting them.

There are several other options that will work as well such as threaded steel dowel rods and "blind" holes drilled into the canopy to slide them into and perhaps some of the new "floating shelves" that HomeDepot sells.

Let me know if you are interested.

Nice approach, looks great. How long is the upper portion of your brackets (hangers)? I'm about 6 inches off my wall and then roughly 20 inches of tank. A friend of mine also suggested steel rods and swears they'd be sturdy enough. I'm skeptical but may be thinking of rebar and not the right rods (dowels). I'm open to all possibilities and appreciate the offer. How would I go about making the hangers white to match and blend. Not sure the process over powder coat.

Also, any experience with pvc foam board? Ran into it looking up ideas.

Last edited:

Nice approach, looks great. How long is the upper portion of your brackets (hangers)? I'm about 6 inches off my wall and then roughly 20 inches of tank. A friend of mine also suggested steel rods and swears they'd be sturdy enough. I'm skeptical but may be thinking of rebar and not the right rods (dowels). I'm open to all possibilities and appreciate the offer. How would I go about making the hangers white to match and blend. Not sure the process over powder coat.

Also, any experience with pvc foam board? Ran into it looking up ideas.

It weighs very little, not as stiff as lumber, UV resistant and can be laminated with epoxy. What's not to like?

With respect to the bracket size, you will probably need to cover at least half your canopy - so 6 (wall to tank)+12(half the depth of the canopy) = 18" give or take. I have plenty in that size range and regardless of the weight of the canopy and light as long as its under 250 lbs there will be no deflection.

It weighs very little, not as stiff as lumber, UV resistant and can be laminated with epoxy. What's not to like?You may have a little bit of engineering to do finding the right combination for the strength to weight ratio but that's the fun of DIY stuff. Another option might be using luan plywood. The stuff is very lite and soaks up epoxy like mad making it fairly simple to create a water proof canopy and it is also fairly stiff. To finish it roll on a coat of epoxy (tinted is you want) with a "Whizz" cabinet roller, let it dry, sand it, roll another coat on and you are good to go.

With respect to the bracket size, you will probably need to cover at least half your canopy - so 6 (wall to tank)+12(half the depth of the canopy) = 18" give or take. I have plenty in that size range and regardless of the weight of the canopy and light as long as its under 250 lbs there will be no deflection.

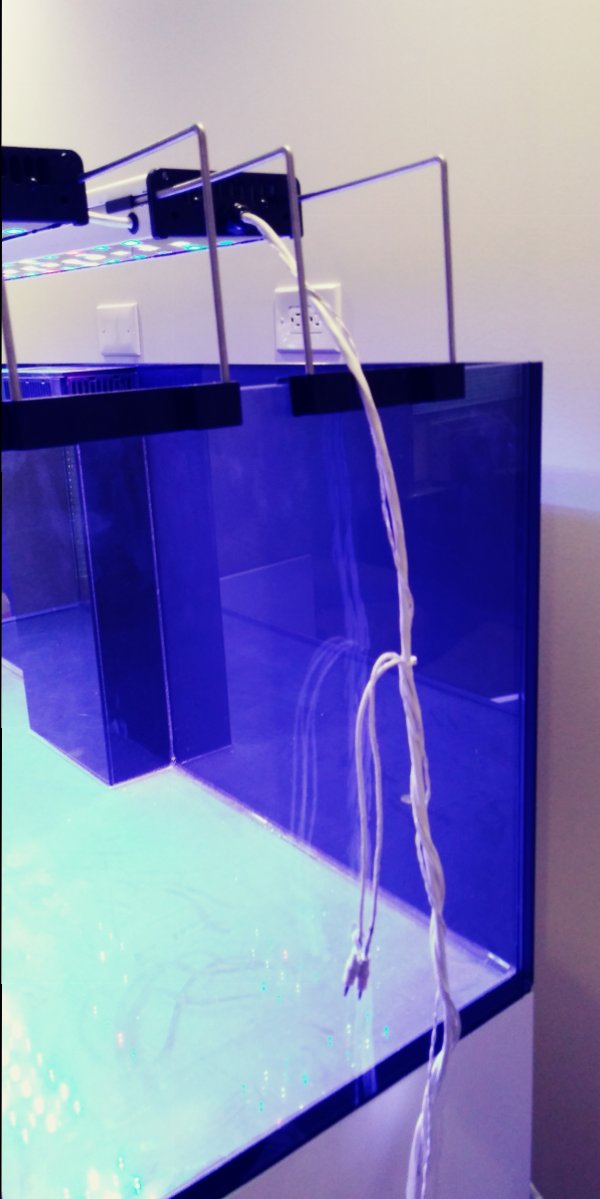

Great advise, I'm looking forward to building soon. I'll probably go with PVC board for the exterior frame as it matches great without any need to finish. PVC Foam Board for the top portion with an inset. I have to come off the wall 7.5 inches and then the canopy will be 19.75 inches. So the total is 27.25 inches and the brackets would have to be within the 25-26 inch range for optimal design. I don't imagine the canopy with lights would even exceed a 60-75 lb. overall weight. I'm basically looking to simply house two strip LED's that as of now have arms that support them. I hate the look and don't like them resting on the tank itself. I'll post a couple images to show what i'm working with but the lights aren't mounted now so they will be when I got the tank for reference. We'll have to discuss details and arrangements if the brackets are to be shipped, I'm in Massachusetts.

By the way the lights came with my tank and I believe were custom built but not sure. If you or anyone for that matter know anything about them it would really help. They are driven by Meanwell drivers (4) and are controlled with a Bluefish LED Controller which I got from Rapid LED.

Great advise, I'm looking forward to building soon. I'll probably go with PVC board for the exterior frame as it matches great without any need to finish. PVC Foam Board for the top portion with an inset. I have to come off the wall 7.5 inches and then the canopy will be 19.75 inches. So the total is 27.25 inches and the brackets would have to be within the 25-26 inch range for optimal design. I don't imagine the canopy with lights would even exceed a 60-75 lb. overall weight. I'm basically looking to simply house two strip LED's that as of now have arms that support them. I hate the look and don't like them resting on the tank itself. I'll post a couple images to show what i'm working with but the lights aren't mounted now so they will be when I got the tank for reference. We'll have to discuss details and arrangements if the brackets are to be shipped, I'm in Massachusetts.

By the way the lights came with my tank and I believe were custom built but not sure. If you or anyone for that matter know anything about them it would really help. They are driven by Meanwell drivers (4) and are controlled with a Bluefish LED Controller which I got from Rapid LED.

So that's a very nice looking setup you have there! Reefers in white always look so nice to me though mine are all black lol. Im considering replacing my Nuvo 20 with a Reefer 250. May need to consider a white one!

PCV board should be strong enough to support those fixtures and you always have the option of laminating more of it inside the canopy if you feel you need to stiffen it up.

So that's a very nice looking setup you have there! Reefers in white always look so nice to me though mine are all black lol. Im considering replacing my Nuvo 20 with a Reefer 250. May need to consider a white one!

PCV board should be strong enough to support those fixtures and you always have the option of laminating more of it inside the canopy if you feel you need to stiffen it up.

Thanks, I really like the white and once the canopy is floating over it I'm sure it will be awesome. Taking it slow and doing it right. I've got it cycled now and once the lights are up I'll transfer my clowns and tangs.

What sort of tangs? I'm considering putting several in my 525. My experience is limited to yellow, powder blue and hippos. I would love an Achilles and Powder Brown but apparently both are considered "expert" level fish. I can grow coral but fish have always been an after thought.Thanks, I really like the white and once the canopy is floating over it I'm sure it will be awesome. Taking it slow and doing it right. I've got it cycled now and once the lights are up I'll transfer my clowns and tangs.

What sort of tangs? I'm considering putting several in my 525. My experience is limited to yellow, powder blue and hippos. I would love an Achilles and Powder Brown but apparently both are considered "expert" level fish. I can grow coral but fish have always been an after thought.

I have a yellow and purple that are very hardy and healthy. I'll probably stick to them, my 2 extreme davinci clowns and a few anthias down the road. I have horrible luck with Coral despite all my efforts. They always seem to lose color and I've researched and own virtually every type of equipment in this hobby. I've never lost a fish in close to 10 years reefing. I'm hoping the Reefer will be a success and Coral do well.

- Joined

- Apr 4, 2016

- Messages

- 170

- Reaction score

- 52

I’d like to replace the 5/8” barb for my return pictured below with a 3/4” barb. Does anyone know what thread pitch I need for the male side of the barb? I think it’s metric, but hear people use standard pipe thread barbs with extra Teflon tape?

You got it. There's a ton of tips and suggestions on this thread. But what you heard is right. Be sure to put the gasket on the new fitting is all and don't over tighten.

- Joined

- Oct 19, 2018

- Messages

- 34

- Reaction score

- 64

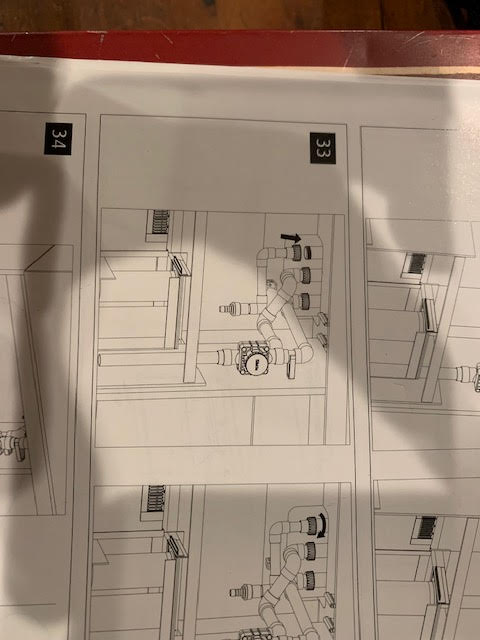

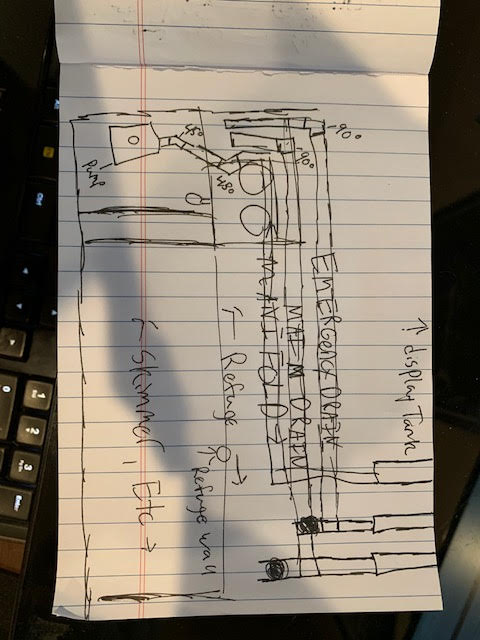

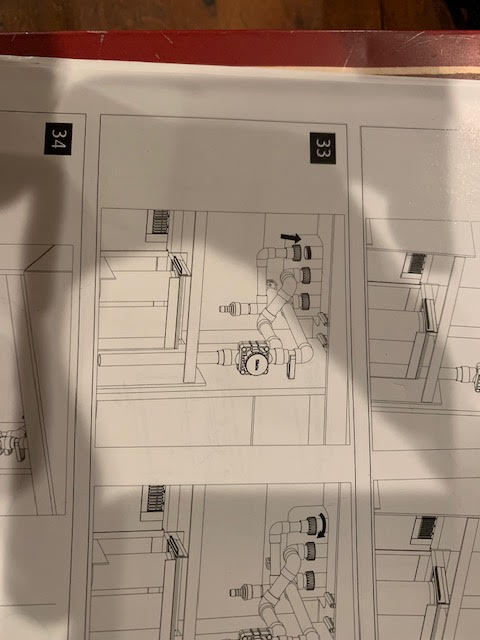

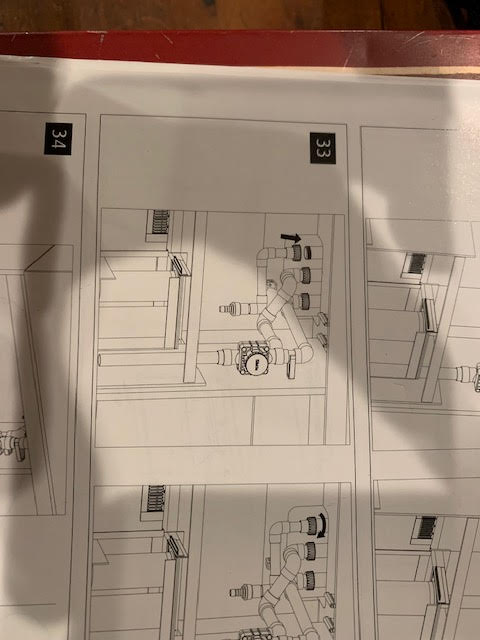

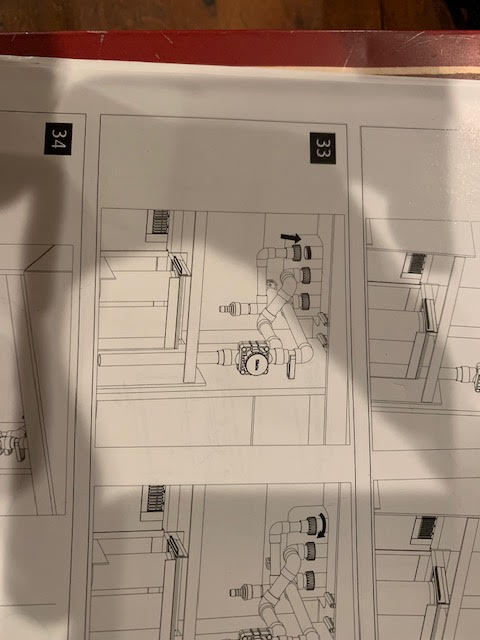

Hi - I just purchased the RSR 350 V3 Sump. I am going to convert all the hard plumbing to standard and wanted to do a manifold to run my AquaMaxx Carbon/GFO reactor and pellet reactor. With the new v3 sumps it has thrown off my entire game plan since the return pump is now on the right hand side and straight piped to the DT as seen in the diagram below. I know a lot of other new reefers are running into this same predicament and there not really any forums or videos out with solutions. Most of the experience reefers are running off the V2 sump. This is my attempt to help kick-start the convo and get feedback from those of you that have way more knowledge and experience with hard plumbing (to be clear I virtually have none besides 8+ months of researching).

The two options I have heard so far: 1.) is running the manifold to the left from a T with a closed valve at the end (could attach another return pump here) - I worry about flow issues here - dont like the idea of diverting the main stream twice. 2.) build a separate manifold with another return pipe - good idea, but want to avoid running two pumps.

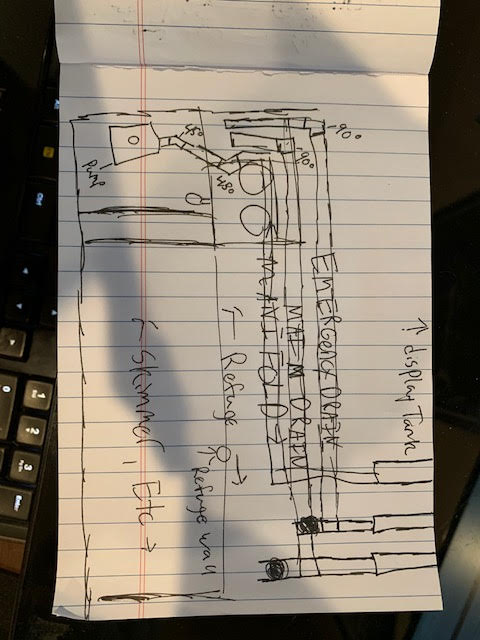

I had another idea I wanted to try. I am thinking of flipping the sump around so the return pump is on the left hand side in the front (similar to V2 sump). I would then hard plumb the Overflow and Main drain pipes to the left as well. I could run the manifold to the right and the two reactors would hang over the filter sock. The pipes would be up against the back of the cabinet so shouldn't interfere with the other equipment (skimmer and refuge lighting). This would put the refuge in the back which isn't ideal, but I could run one return pump (Neptune cor 20) from the manifold up to the DT. I drew a little picture below and also attached a ss of what the sump looks like backwards. (please dont make fun of my terrible drawing and it may be to difficult to depict what I was trying to show but just wanted to give an idea of what I was thinking for feedback)

I would love to hear your comments/suggestions and any potential issues I may run into, pictures are the easiest way for me to digest/understand plumbing.

I'm thinking of starting the dry fit soon to see how it looks, I can always buy more PVC pipe - i'll send pictures after I do. I should preface this by saying I bought all the equipment and plumbing 5-6 months ago assuming I was going to be setting up the v2 sump, so I'm trying to find a compromise without having to return my equipment and being able to run a manifold. Thanks so much.

- i'll send pictures after I do. I should preface this by saying I bought all the equipment and plumbing 5-6 months ago assuming I was going to be setting up the v2 sump, so I'm trying to find a compromise without having to return my equipment and being able to run a manifold. Thanks so much.

The two options I have heard so far: 1.) is running the manifold to the left from a T with a closed valve at the end (could attach another return pump here) - I worry about flow issues here - dont like the idea of diverting the main stream twice. 2.) build a separate manifold with another return pipe - good idea, but want to avoid running two pumps.

I had another idea I wanted to try. I am thinking of flipping the sump around so the return pump is on the left hand side in the front (similar to V2 sump). I would then hard plumb the Overflow and Main drain pipes to the left as well. I could run the manifold to the right and the two reactors would hang over the filter sock. The pipes would be up against the back of the cabinet so shouldn't interfere with the other equipment (skimmer and refuge lighting). This would put the refuge in the back which isn't ideal, but I could run one return pump (Neptune cor 20) from the manifold up to the DT. I drew a little picture below and also attached a ss of what the sump looks like backwards. (please dont make fun of my terrible drawing and it may be to difficult to depict what I was trying to show but just wanted to give an idea of what I was thinking for feedback)

I would love to hear your comments/suggestions and any potential issues I may run into, pictures are the easiest way for me to digest/understand plumbing.

I'm thinking of starting the dry fit soon to see how it looks, I can always buy more PVC pipe

Hi - I just purchased the RSR 350 V3 Sump. I am going to convert all the hard plumbing to standard and wanted to do a manifold to run my AquaMaxx Carbon/GFO reactor and pellet reactor. With the new v3 sumps it has thrown off my entire game plan since the return pump is now on the right hand side and straight piped to the DT as seen in the diagram below. I know a lot of other new reefers are running into this same predicament and there not really any forums or videos out with solutions. Most of the experience reefers are running off the V2 sump. This is my attempt to help kick-start the convo and get feedback from those of you that have way more knowledge and experience with hard plumbing (to be clear I virtually have none besides 8+ months of researching).

The two options I have heard so far: 1.) is running the manifold to the left from a T with a closed valve at the end (could attach another return pump here) - I worry about flow issues here - dont like the idea of diverting the main stream twice. 2.) build a separate manifold with another return pipe - good idea, but want to avoid running two pumps.

I had another idea I wanted to try. I am thinking of flipping the sump around so the return pump is on the left hand side in the front (similar to V2 sump). I would then hard plumb the Overflow and Main drain pipes to the left as well. I could run the manifold to the right and the two reactors would hang over the filter sock. The pipes would be up against the back of the cabinet so shouldn't interfere with the other equipment (skimmer and refuge lighting). This would put the refuge in the back which isn't ideal, but I could run one return pump (Neptune cor 20) from the manifold up to the DT. I drew a little picture below and also attached a ss of what the sump looks like backwards. (please dont make fun of my terrible drawing and it may be to difficult to depict what I was trying to show but just wanted to give an idea of what I was thinking for feedback)

I would love to hear your comments/suggestions and any potential issues I may run into, pictures are the easiest way for me to digest/understand plumbing.

I'm thinking of starting the dry fit soon to see how it looks, I can always buy more PVC pipe- i'll send pictures after I do. I should preface this by saying I bought all the equipment and plumbing 5-6 months ago assuming I was going to be setting up the v2 sump, so I'm trying to find a compromise without having to return my equipment and being able to run a manifold. Thanks so much.

I have the same and the V3 threw me off too. I did hook up a BRS carbon reactor with the MJ1200 pump but ultimately my plan is to get a couple of small Avast Marine reactors which are designed to sit in the sump and have their own sicce pump, looks like two of them could fit in the refugium section and I use the skimmer section as my refugium. So in other words, I hard plumbed the return with no manifold.

I'm going to over haul my sump soon and cut out the filter sock area and install a Clarisea SK-5000 in it's place.

I'm about to abort my canopy build due to cost and lack of tools. I really wanted a floating canopy but have been going over it for weeks now and just want it done. I'm wondering if anyone could suggest some brackets or other ways to mount the lights below that will look nice and not require tearing up my walls or ceiling. I feel my lights look terrible resting on the tank with flimsy metal supports. I've seen tons of pictures but not much information on how or where people have purchased their lighting mounts (hangers). Any tips will be appreciated and Thanks!

- Joined

- Nov 23, 2017

- Messages

- 74

- Reaction score

- 51

What we're you trying to build your canopy out of? Also you're going to either hang with wire cable from ceiling or mount directly to the wall. I mounted my flatting canopy directly into the wall and made it light enough that it would not need much. Screwing into a stud would he your best bet as well fixing up small screw holes if you ever take it down are very doable. I have an open top floating canopy and built wood bracket's that my light bar rests on.I'm about to abort my canopy build due to cost and lack of tools. I really wanted a floating canopy but have been going over it for weeks now and just want it done. I'm wondering if anyone could suggest some brackets or other ways to mount the lights below that will look nice and not require tearing up my walls or ceiling. I feel my lights look terrible resting on the tank with flimsy metal supports. I've seen tons of pictures but not much information on how or where people have purchased their lighting mounts (hangers). Any tips will be appreciated and Thanks!

Thanks. Removing the stock ato helpsNice use of the sump are on the 170. A lot of stuff but yet not cluttered.

Similar threads

- Replies

- 79

- Views

- 5,020

- Replies

- 15

- Views

- 1,564

- Replies

- 12

- Views

- 1,425

- Replies

- 41

- Views

- 6,760