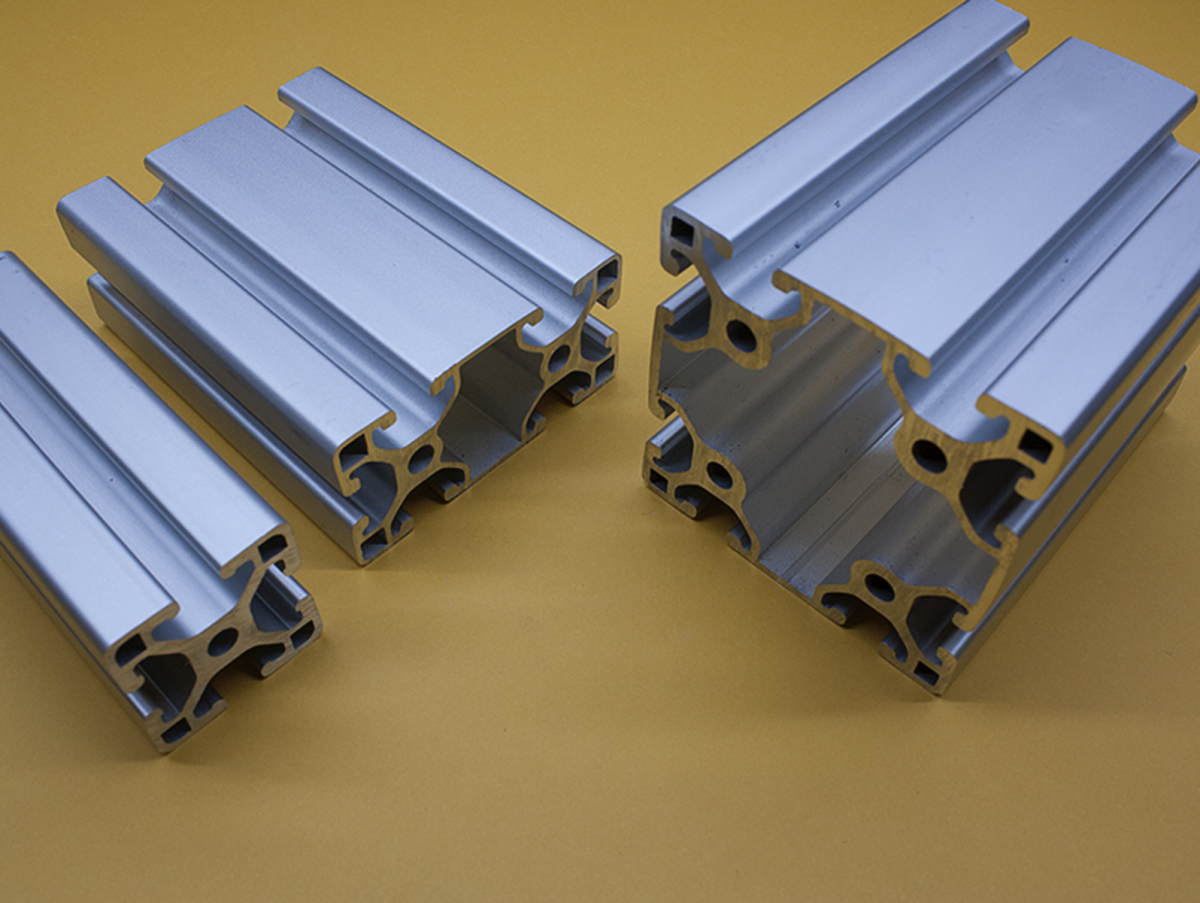

Has anyone skinned a t-slot stand for their aquarium? I really like the PVC composite exterior doors on the Red Sea Reefer and Water Box aquariums but I would feel much more comfortable building my own stand out of aluminum t-slots and making a modern looking skin to wrap around the stand.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Skinning a T-Slot Stand

- Thread starter Rickyrooz

- Start date

- Tagged users None

We use magnet closures on T slot at work. You can use whatever material you want for the skin like that.

Do you have a link where I can buy the magnets you use?We use magnet closures on T slot at work. You can use whatever material you want for the skin like that.

I’m gonna be really honest, I steal them off of machines at work. Then, every 3 months when we have a PM, the safety team comes out and replaces all of the missing or broken ones.

I’m out for a few days because of covid exposure. But when I go back, I’ll get a manufacture name and manufacture part number for you.

I’m out for a few days because of covid exposure. But when I go back, I’ll get a manufacture name and manufacture part number for you.

Amazon search, rare earth magnets. I use them to skin furniture all the time. About to do it on a wood frame this week by countersinking the magnet and putting a thin resin coat over it.Do you have a link where I can buy the magnets you use?

Since we are here and you do a lot of furniture, I have a bunch of 2 part epoxy resin sitting around that I won’t be using. How do you like it as a coating on the section of the stand that the tank sits on? Versus rhino lining?Amazon search, rare earth magnets. I use them to skin furniture all the time. About to do it on a wood frame this week by countersinking the magnet and putting a thin resin coat over it.

Not all two part epoxy has made the same so I would have to know exactly what kind, but I can say for the most part, I don't like using resin as a coating. If things are in super high demand and high traffic I use a product called the water lox. Creates a very hard film finish that will stand up to years of abuse. It also takes a month or more to cure fully. I think right outlining if that's the way you choose it's probably your best bet.Since we are here and you do a lot of furniture, I have a bunch of 2 part epoxy resin sitting around that I won’t be using. How do you like it as a coating on the section of the stand that the tank sits on? Versus rhino lining?

If you're just trying to get rid of some thin epoxy that's about to go bad,, buy some powdered pigments at least one big metallic and make yourself a cool resin flow art piece.

I love this place. There is an expert or artist for everything. Truly appreciate the input!!! I’d have probably realized that I made a big mistake about the time I start the first big pour out on the top.

I opted for something complicated: screw attached wood (ply and hardwood birch)

www.reef2reef.com

www.reef2reef.com

Nano Build - Dinosaur to Phoenix, a new 22G Long mini build

Current design snapshot: Hi! I've been staring at this for far too long Its a poorly neglected planted tank - it overgrows to the point where its just green against the glass, and then I go do a horrific pruning job ripping out a metric ton of java ferns. The above tank state is just...

www.reef2reef.com

www.reef2reef.com

I hit watch, but let ya know...following

I just realized T-Slots are aluminum which is not magnetic

That is why I use magnets with a countersunk hole (I linked to them above) so the magnet can be bolted to a plate that fits into the aluminum slot.

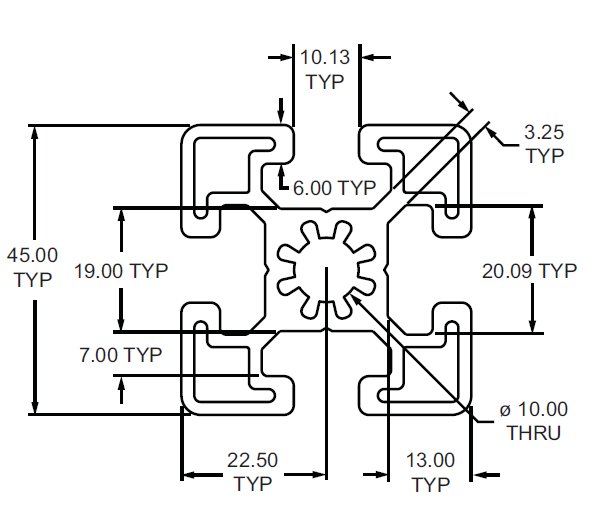

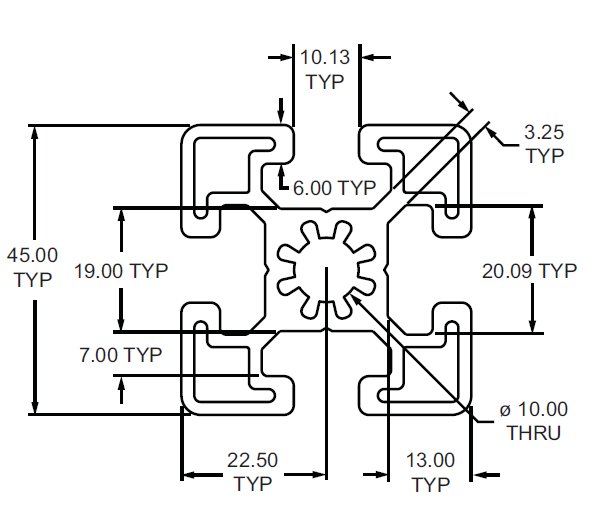

The 45 series t-slot is too large for any magnet I could find. Most ring magnets fit a #8 or #6 screw.

- Joined

- Jan 12, 2020

- Messages

- 1,424

- Reaction score

- 1,429

I'm guessing you've never worked with t-slot before. you don't need the screw to attach to the slot... you put a plate in the slot and screw into that plate. A #8 machine screw has a thread diameter of .165". The slot opening on a typical 45 series t-slot is 10.13mm (.39"). Not sure what the problem is... you just need some 19mm plates (.74") with holes tapped to fit the #8 thread size. Trusty me I've built a lot of things with t-slot, and this can easily be done.

Classy lolI’m gonna be really honest, I steal them off of machines at work. Then, every 3 months when we have a PM, the safety team comes out and replaces all of the missing or broken ones.

I’m out for a few days because of covid exposure. But when I go back, I’ll get a manufacture name and manufacture part number for you.

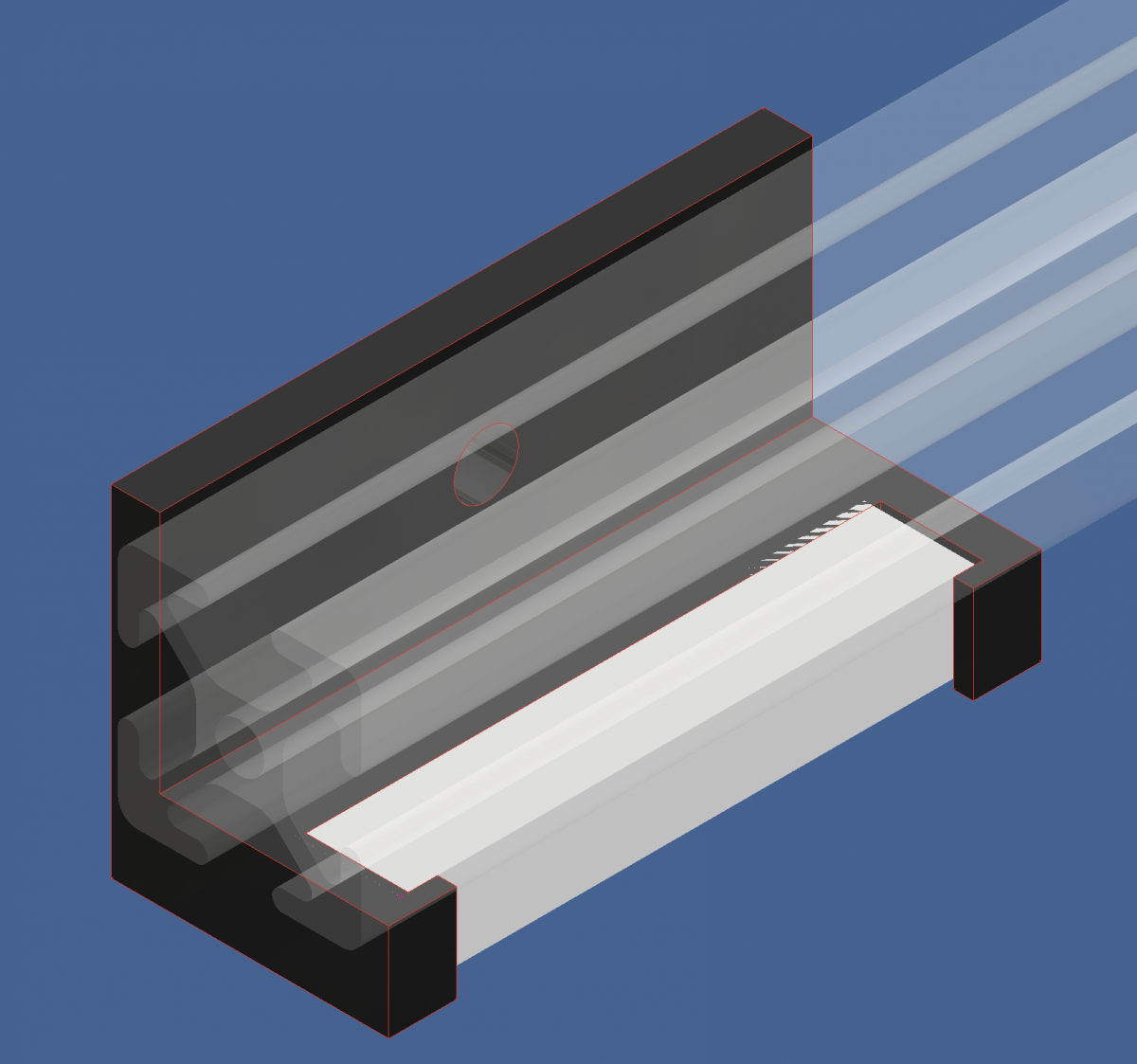

I got brackets with my stand from Chris Benner. They will let you easily attach wood to skin the stand. My wife is currently designing the skin for the stand. The brackets are like $5 each. The picture attached shows 2 brackets.

I'm guessing you've never worked with t-slot before. you don't need the screw to attach to the slot... you put a plate in the slot and screw into that plate. A #8 machine screw has a thread diameter of .165". The slot opening on a typical 45 series t-slot is 10.13mm (.39"). Not sure what the problem is... you just need some 19mm plates (.74") with holes tapped to fit the #8 thread size. Trusty me I've built a lot of things with t-slot, and this can easily be done.

You can also use the "roll-in" T-slot nuts. which don't require pre-seating into the channel. They're a bit finicky if not held square to the slot though.

I would recommend the L bracket approach. I've even 3d-printed some magnet brackets to help hold doors closed. Its attached to the rear using a standard nut / roll in nut (M6 screw in my case, used metric)

- Joined

- Jan 12, 2020

- Messages

- 1,424

- Reaction score

- 1,429

I don't do doors on a t-slot stand. I prefer to be able to easily remove the entire skin for greater access to do maintenance.You can also use the "roll-in" T-slot nuts. which don't require pre-seating into the channel. They're a bit finicky if not held square to the slot though.

I would recommend the L bracket approach. I've even 3d-printed some magnet brackets to help hold doors closed. Its attached to the rear using a standard nut / roll in nut (M6 screw in my case, used metric)

I don't do doors on a t-slot stand. I prefer to be able to easily remove the entire skin for greater access to do maintenance.

Same techniques can hold on panels. I can easily remove my side panels, and my front doors are full width.

Similar threads

- Replies

- 17

- Views

- 614

- Replies

- 26

- Views

- 614

- Replies

- 82

- Views

- 2,141

New Posts

-

AFTER SALE IS LIVE!!! 20th Anniversary Sale | Take an EXTRA 30% off Already-Discounted Corals!!

- Latest: Reefing_addiction

-

-

-

*** TUNZE PREMIUM GLASS CARE GIVEAWAY!!! *** Two Prizes for Two Winners!!!

- Latest: Reefing_addiction