50 ppm TDS in our tap water, which is untreated except for filtration. So only 1 sediment filter and 1 carbon filter. Pressure is 60 at best, sometimes a bit less. TDS after the FilmTec membrane is sometimes 0, sometimes 1. TDS after 2 DI filters is always 0. And after adding a valve after the membrane to deal with TDS creep, the last two samples I sent to ATI for ICPOES have come back with no contamination whatsoever, not even silicon (traces of which are often found in '0 TDS' water.)

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So what's everyone's Tap TDS and how do you handle it?

- Thread starter JoshH

- Start date

-

- Tags

- rodi rodi system tds

- Tagged users None

My spectrapure came with a pressure gauge preinstalled, what we were talking about was adding a second one after my first membrane but before my second membrane(BRS Water saver upgrade so no preinstalled gauge). Mostly to just see the pressure loss after the first to see what my second one is gettingcuriosity you know

Yeah that would be interesting. I'm not sure what normal pressure loss across a membrane is.

AirWaterIce Hurricane dual home/reef... slightly upgraded.

The base unit comes with an inline carbon filter, I added a standard canister for normal carbon cartridges. It also came with a single stage DI cart, I added a 2nd stage.

Well water comes in ~300 on my TDS meter. Through sediment, 5m carbon (just one, I don't have to worry about chlorine or chloramine), and RO membrane. Normally, RO water runs 7-9 on the TDS meter after the RO membrane. Waste water goes to the swimming pool during the summer, down the drain in winter. RO water stored in a 5g pressure tank, feeds a faucet at the kitchen sink, and feeds the ice and water in the fridge. Premeate pump keep the pressure in the storage tank equal to well pressure. From there, it goes back through the 2 stage DI, and to my sump room. Splits there to the timed solenoid/float valve arrangement on my ATO reservoir, and to a manual valve for filling my water change barrel.

In true fashion your setup is... unique, LOVE it! You definitely get the most out of your system.

50 ppm TDS in our tap water, which is untreated except for filtration. So only 1 sediment filter and 1 carbon filter. Pressure is 60 at best, sometimes a bit less. TDS after the FilmTec membrane is sometimes 0, sometimes 1. TDS after 2 DI filters is always 0. And after adding a valve after the membrane to deal with TDS creep, the last two samples I sent to ATI for ICPOES have come back with no contamination whatsoever, not even silicon (traces of which are often found in '0 TDS' water.)

Flushing the first bit is definitely effective and your case is a perfect example. Do you run both DI with mixed bed?

Yeah that would be interesting. I'm not sure what normal pressure loss across a membrane is.

That's what has me curious, now I'm not overly concerned as I have ~85 PSI coming in but it might be significant for someone with much lower PSI running 2 membranes.

+1Exactly, glad to see you say that. People go crazy with expectations of PSI and RO/DI systems.

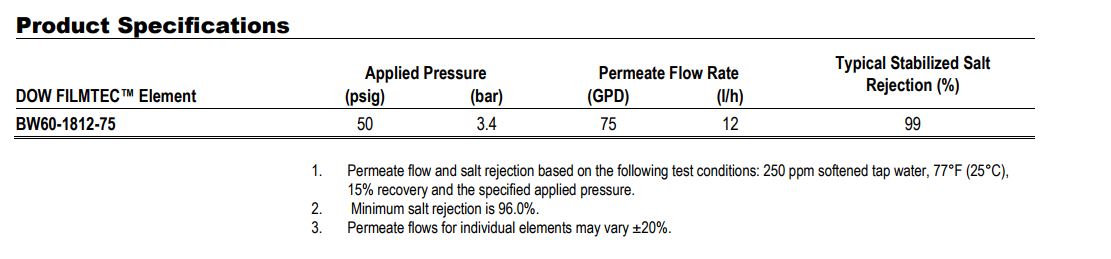

I can't speak for dual membrane setups like the unit from BRS, but I can say that while more pressure is better, it's certainly not necessary. Dow rates their 75GPD membrane at 50PSI. This means that at 50PSI of pressure, you should get the exact product water and rejection rates that Dow quotes in their manual.

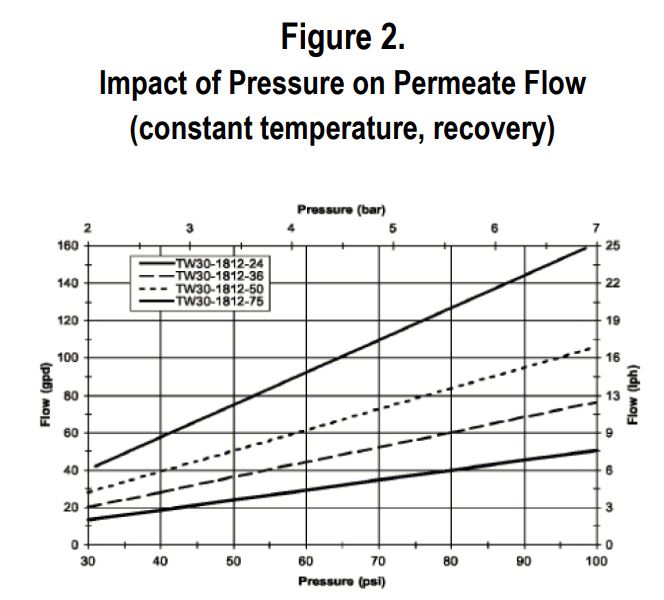

Dow's manual also shows a graph of what type of product water flow you can expect at various pressures. Dow's 75GPD membrane is the top line in the graph below. Note that the product water is 75 GPD at 50PSI:

I don't mean to say that there's no reason to ever run a membrane at higher than 50PSI. But, if your pressure is "only" 50 PSI, relax. For Dow 75GPD membranes, that's plenty. Again, this is only for single membrane setups. But my point stands.

City water in SW MN 850 TDS out of tap, 4 stage RO gets it between 25 and 60. DI to zero. big 60$ bag of brs resign gets me 400 gallons zero tds water on average. 15 cents a gallon

Flushing the first bit is definitely effective and your case is a perfect example. Do you run both DI with mixed bed?

Yes, they're identical. I've thought about trying some other resins, but this is working so well, I don't really have any reason to.

Jeez, that's harsh. I grew up in SE Minnesota. I remember our water was pretty hard, but not sure if it was that hard; my folks did install a water softener tho.City water in SW MN 850 TDS out of tap, 4 stage RO gets it between 25 and 60. DI to zero. big 60$ bag of brs resign gets me 400 gallons zero tds water on average. 15 cents a gallon

City water in SW MN 850 TDS out of tap, 4 stage RO gets it between 25 and 60. DI to zero. big 60$ bag of brs resign gets me 400 gallons zero tds water on average. 15 cents a gallon

850!!!

Yes, they're identical. I've thought about trying some other resins, but this is working so well, I don't really have any reason to.

If it ain't broke... I've thought about running dual even triple DI as well but I have limited space

Yeah that would be interesting. I'm not sure what normal pressure loss across a membrane is.

The incoming side of an ro membrane does not in itself restrict flow, so the pressure seen by two membranes in series will be (approximately) the same, as long as they're both installed proximal to the flow restrictor.

Yes mine is softened before the rodi, I don't remember the science behind how it works but the short of it is softening doesn't lower the tds but makes it easier to lower.Jeez, that's harsh. I grew up in SE Minnesota. I remember our water was pretty hard, but not sure if it was that hard; my folks did install a water softener tho.

Yes mine is softened before the rodi, I don't remember the science behind how it works but the short of it is softening doesn't lower the tds but makes it easier to lower.

I'd be interested on the science behind that, never understood how that works myself.

chipmunkofdoom2

Always Making Something

View BadgesExcellence Award

Article Contributor

Reef Squad Emeritus

I guess so. I mean it works yes of course but at 75 psi you are now making 118 gpd while saving a bit in resin consumption and water expense. If you live in a cold area where your cold water may only be like 40° at 50 psi it's going to take a really long time if you need to make 30 gallons of water.

You're right on the cold water slowing down your production, but if you're making 118GPD, you ideally should still have a product to waste ratio of 1:4. If you're making 118 GPD of product water, you should be sending close to 480 gallons down the drain per day to keep your membrane from developing mineral deposits. You don't get free water at higher PSI. If you do by restricting your waste water, you're shortening the life of your membrane.

Additionally, you would only be saving resin if the product water was significantly lower in TDS at higher pressures. This can be the case, but it's not guaranteed.

I'm not saying that it's not better to have higher pressure. But people go to some pretty crazy lengths to boost their pressure when they're already running 50-60 PSI. I don't think this is a good way to spend time and money.

Let's keep the convo going, who else hasn't chimed in on there setups? For those running dual / triple DI setups have you seen a longer life out of your resin? And anyone running triple RO membranes?

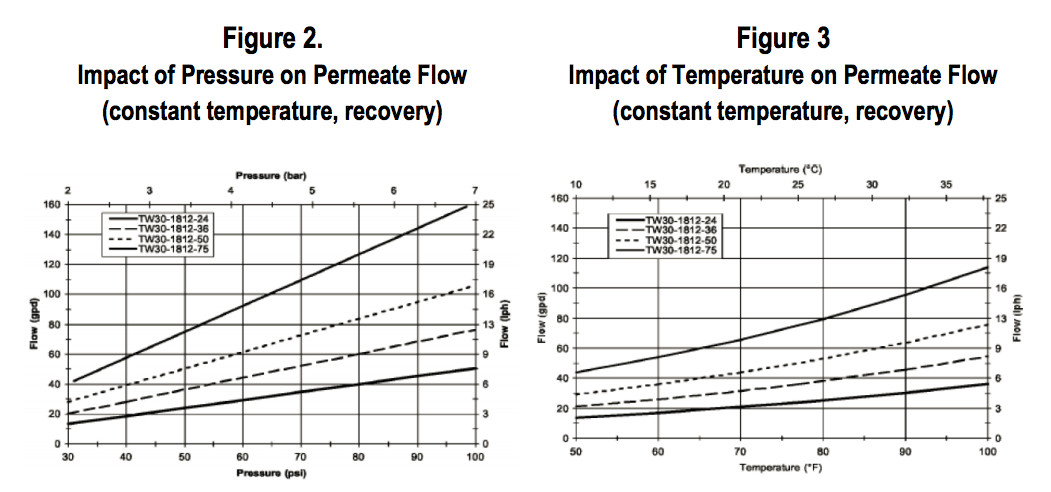

That statement assumes you also have 77F water coming from your tap - which most people don't (average tap temp is around 55F). As the water temp drops, the pressure must (to stay in the "sweet spot") increase in order to compensate. This is why most people need a booster pump - not because of a lack of pressure, but because of a lack of temperature. Another option would be to heat the water to 77F before it enters the membrane, but doing that is almost certainly going to be more difficult (and likely costly) to do than increasing the pressure. Part of that is because increasing pressure has a greater impact on the flow rate than temperature does, so a dollar spent increasing pressure is worth more than a dollar spent increasing temp.But, if your pressure is "only" 50 PSI, relax. For Dow 75GPD membranes, that's plenty.

Data:

Source

My system is currently a BRS dual-membrane 5-stage with booster pump. The numbers right now are:

Temp: 57.2F

Pressure: 75psi

In TDS: 347

Rejected TDS: 462

Post-membrane TDS: 9

Out: 0

The "Rejected TDS" number is likely high because I just turned the system on a bit ago. It's finished it's auto-flush cycle, but there's likely to still be stuff that needs cleaning out from the week+ that it sat unused...

I also capture my waste water (and have an auto-shut-off when either of the 55gal tanks are full). I get about 30gal of RODI water for every 55gal of waste water; basically a 1::2 ratio.

I'll be moving and setting up a new tank later this year. Either then, or when I run out of my current bag of DI resin, I'll be switching over to a 7-stage system (3 different DI canisters). Looking forward to that adventure...

Last edited:

chipmunkofdoom2

Always Making Something

View BadgesExcellence Award

Article Contributor

Reef Squad Emeritus

That statement assumes you also have 77F water coming from your tap - which most people don't (average tap temp is around 55F). As the water temp drops, the pressure must (to stay in the "sweet spot") increase in order to compensate. This is why most people need a booster pump - not because of a lack of pressure, but because of a lack of temperature. Another option would be to heat the water to 77F before it enters the membrane, but doing that is almost certainly going to be more difficult (and likely costly) to do than increasing the pressure. Part of that is because increasing pressure has a greater impact on the flow rate than temperature does, so a dollar spent increasing pressure is worth more than a dollar spent increasing temp.

Data:

Source

My system is currently a BRS dual-membrane 5-stage with booster pump. The numbers right now are:

Temp: 57.2F

Pressure: 75psi

In TDS: 347

Rejected TDS: 462

Post-membrane TDS: 9

Out: 0

The "Rejected TDS" number is likely high because I just turned the system on a bit ago. It's finished it's auto-flush cycle, but there's likely to still be stuff that needs cleaning out from the week+ that it sat unused...

I also capture my waste water (and have an auto-shut-off when either of the 55gal tanks are full). I get about 30gal of RODI water for every 55gal of waste water; basically a 1::2 ratio.

I'll be moving and setting up a new tank later this year. Either then, or when I run out of my current bag of DI resin, I'll be switching over to a 7-stage system (3 different DI canisters). Looking forward to that adventure...

To start with, a 1:2 product/waste ratio will lead to premature membrane failure. Our goal as a hobby seems to be reduce RO waste water, but our membranes need waste water to stay clean. As they reject larger particles, the waste water rinses those larger particles off the membrane's surface and down the drain. Without maintaining a 1:4 ratio, those particles remain on your membrane and will eventually plug the pores, leading to premature failure.

On the topic of cold source water, yes, a booster pump will increase the product flow. I don't believe, however, that you will get cleaner water by using a booster pump with colder source water. You might get lower TDS water, but that's because of the higher pressure, not because cold source water produces higher TDS. My TDS remains steady from winter to summer, when product water is coldest and warmest. If your goal is to buy a booster pump to decrease final TDS, that's a fine goal. With a TDS of 347 ppm out of the tap, it sounds like a booster pump makes sense for you. However, I would not buy one with the goal of producing more product water when the source water is cold. If you have exceptionally high water demands and your RO system simply can't keep up in the winter, then a booster pump might be necessary, but I don't think this is the case for very many reefers. Spending $200+ to produce 75 GPD instead of 50 GPD seems like an awful lot of money, especially when you consider most reefers don't wait for their water: they turn on their system, fill a reservoir, and use it when they need it.

But, to each his own.

Last edited:

- Joined

- May 26, 2016

- Messages

- 676

- Reaction score

- 569

My well water tds is 1600.

I use a booster pump and it drops the effluent to about 20.

I then degass it for 24 hours and then pump it through a dual di setup.

This gets me 0 tds, and doesn't eat my resin like running it straight from the ro membrane.

I use a booster pump and it drops the effluent to about 20.

I then degass it for 24 hours and then pump it through a dual di setup.

This gets me 0 tds, and doesn't eat my resin like running it straight from the ro membrane.

A 1:4 product/waste ratio would be the expected for a single membrane. When you add a second membrane inline with the first, the ratio is cut in half - or better (down to 1:1.5 or so in some scenarios). Unless you have really high TDS starting water, this will not impact the life of the membranes because the first membrane acts as expected (producing 1:4 ratio) while the second is fed the waste water. This waste water also gets a 1:4 ratio, which stacks with the first to give a final ratio of around 1:2 - all without a reduction in membrane performance (again; unless you have high TDS water to start). This is why places like BRS sells the second membrane upgrade kit as a "water saver" upgrade. Here is a video they did on this topic.To start with, a 1:2 product/waste ratio will lead to premature membrane failure.

For myself, I expect the following (in order of importance):Our goal as a hobby seems to be reduce RO waste water

- The system *must* produce clean water (as measured to 0 TDS). Why: Produce usable water.

- The system *should* have the best product/waste ratio possible. Why: Save money on water bills & be drought-friendly

- The system *should* be able to produce high volumes of water when needed. Why: Be able to handle emergency situations

- The materials and supplies in the system *should* be utilized as best as possible. Why: Save money

I don't feel like my priorities are all that unusual in this hobby. The last two may swap for some people, but as the video link above demonstrated, the two goals aren't in contention very often.

Sorry; it looks to me like you contradict yourself here, so I don't think I'm understanding you correctly... Cleaner water and lower TDS are basically the same thing, right? And a booster pump's whole goal is to increase pressure. So if you add a booster pump (increasing your pressure) and get lower TDS water, then you are getting cleaner water because of the booster pump, right?I don't believe, however, that you will get cleaner water by using a booster pump with colder source water. You might get lower TDS water, but that's because of the higher pressure, not because cold source water produces higher TDS.

In terms of temp; lower temperature water has a higher viscosity than higher temp water. Viscosity is relevant to the effectiveness of the membrane because the membrane is semipermeable and designed to handle a specific viscosity of water at a specific pressure to generate the ideal flow rate conditions for filtration. When the water is lower temp/higher viscosity, it takes more pressure to generate the same ideal flow rate. This is reflected in "Figure 3" from my previous post.

- Joined

- Aug 5, 2017

- Messages

- 1,493

- Reaction score

- 1,881

I am very envious of all of you guys with TDS in the 0-100 mark. Mine can easily break 1000 here in SE Wisconsin. Usually I run 600-850. I buy water rather than run a RO/DI unit because I burn through membranes. If I wanted to make water efficiently I need at least 6-7 membranes before the DI stage.

- Joined

- Aug 5, 2017

- Messages

- 1,493

- Reaction score

- 1,881

City water in SW MN 850 TDS out of tap, 4 stage RO gets it between 25 and 60. DI to zero. big 60$ bag of brs resign gets me 400 gallons zero tds water on average. 15 cents a gallon

Forget to add cost of source water

Similar threads

- Replies

- 7

- Views

- 155

- Replies

- 11

- Views

- 159

- Replies

- 7

- Views

- 317

- Replies

- 13

- Views

- 465