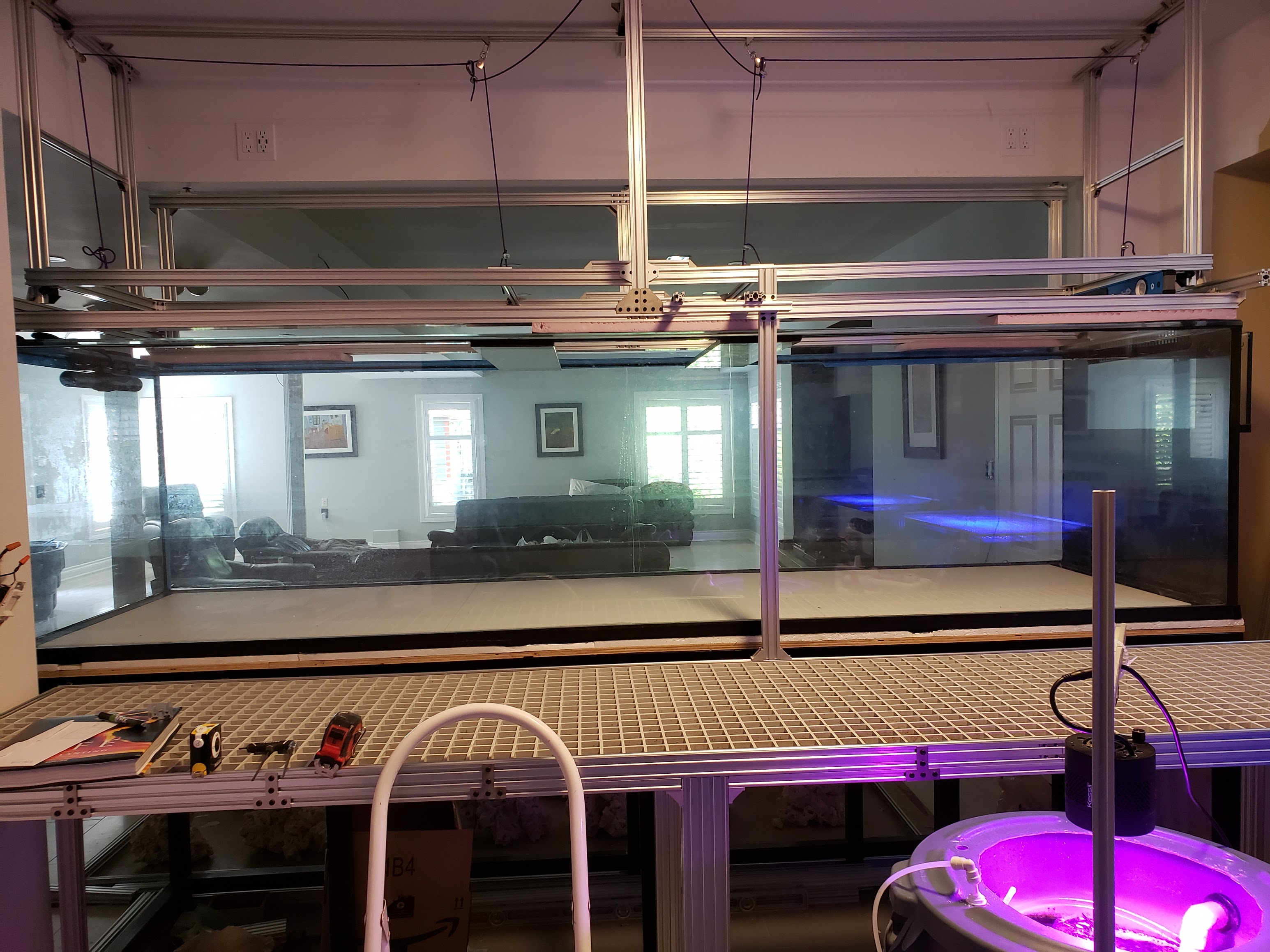

I am using the walk platform to do double duty as both access for me and to support the rails that run along the top of the tank.

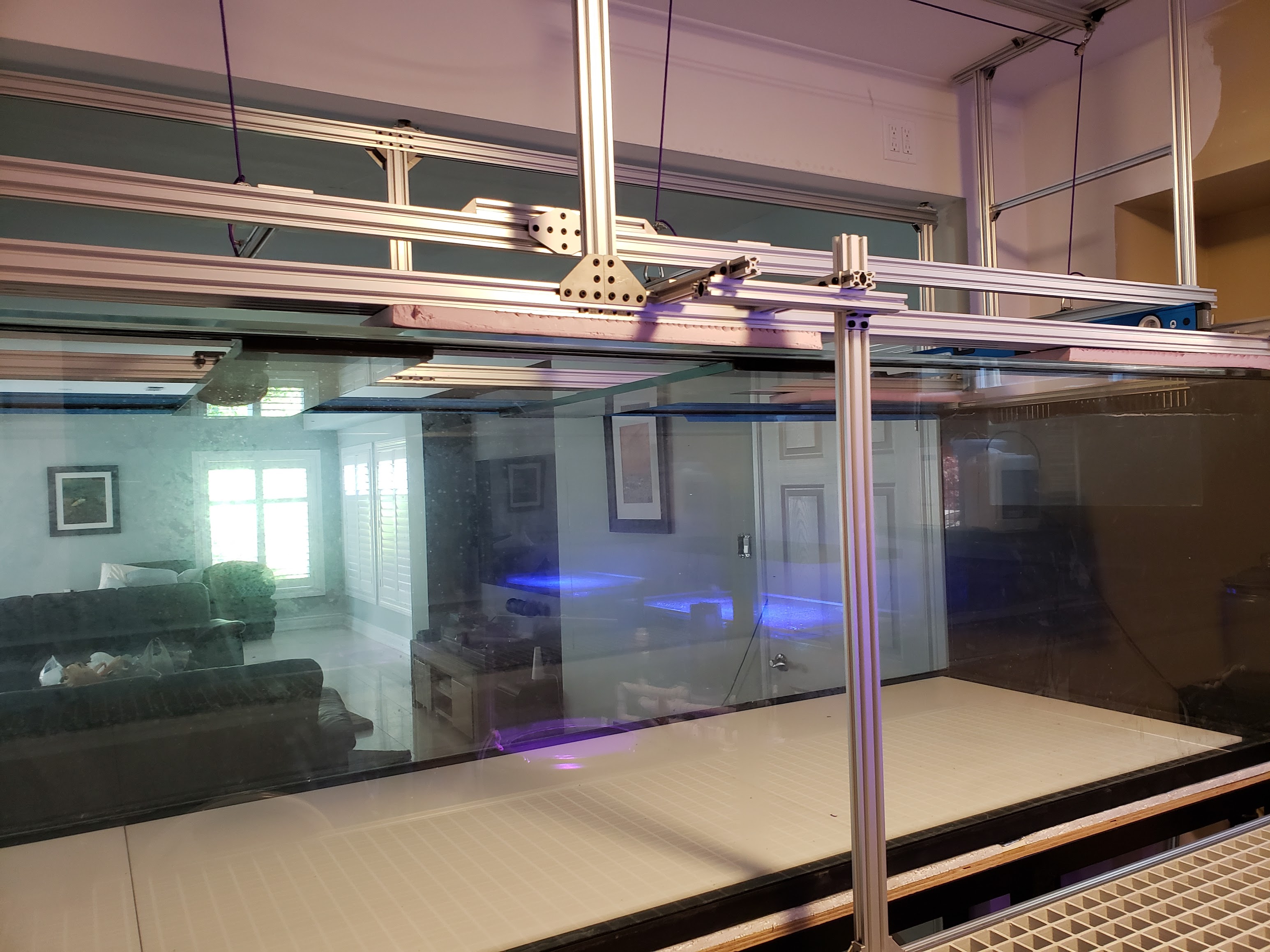

I built a jig to help measure the lengths of extrusion needed. They all ended up different sizes as it turns out, the tank is level, but the floor where the platform is installed rises a fair bit over its length which I had to account for to get the supports to match up.

Here is a close up of the measuring jig in use.

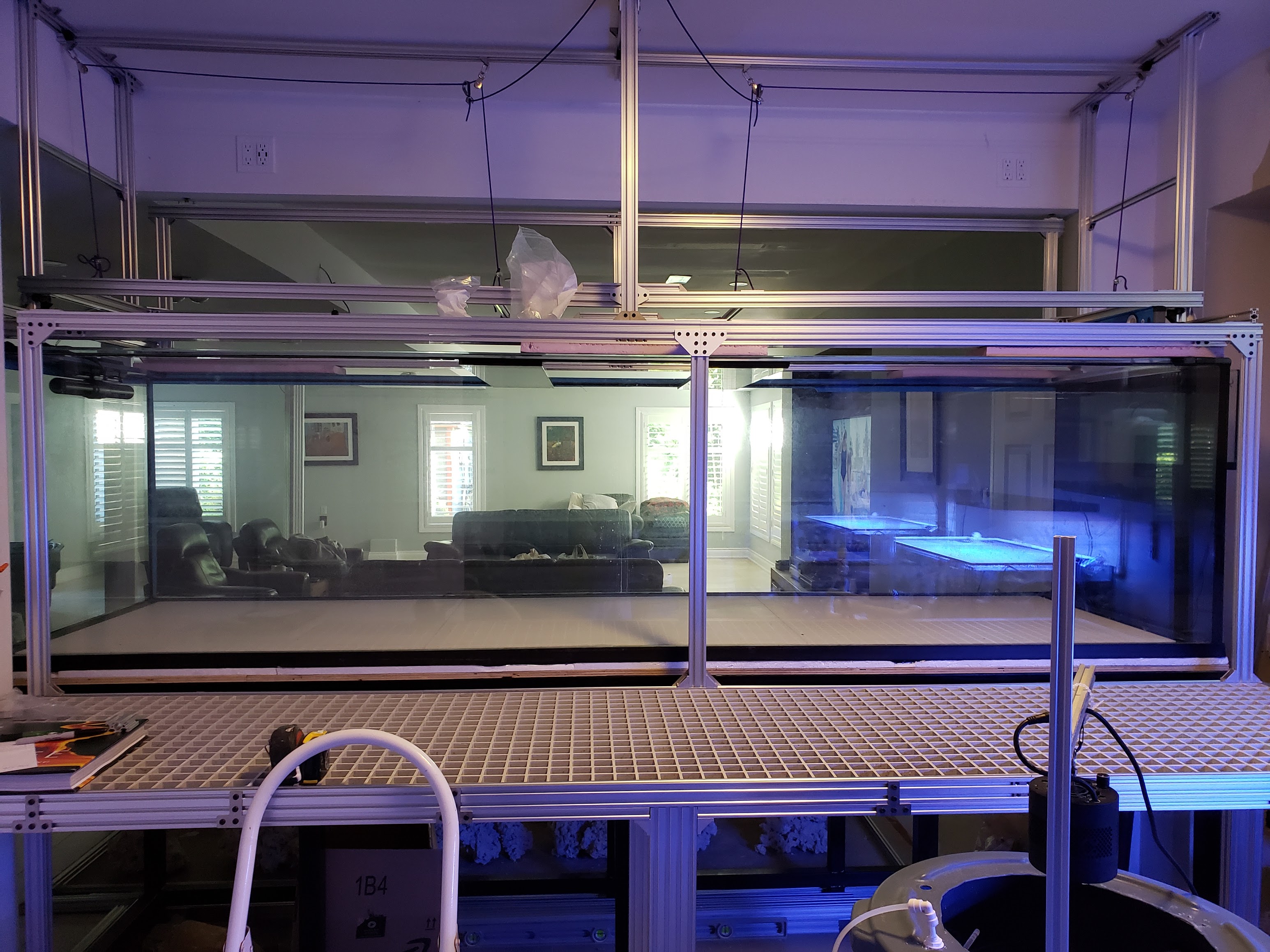

The supports and top frame are in place here.

You can also see the first attempt at a lifting mechanism for the light rail. The carriages on the uprights on each of the four corners work great, but the pulleys were not great. More updates on this front later.

Dennis

I built a jig to help measure the lengths of extrusion needed. They all ended up different sizes as it turns out, the tank is level, but the floor where the platform is installed rises a fair bit over its length which I had to account for to get the supports to match up.

Here is a close up of the measuring jig in use.

The supports and top frame are in place here.

You can also see the first attempt at a lifting mechanism for the light rail. The carriages on the uprights on each of the four corners work great, but the pulleys were not great. More updates on this front later.

Dennis