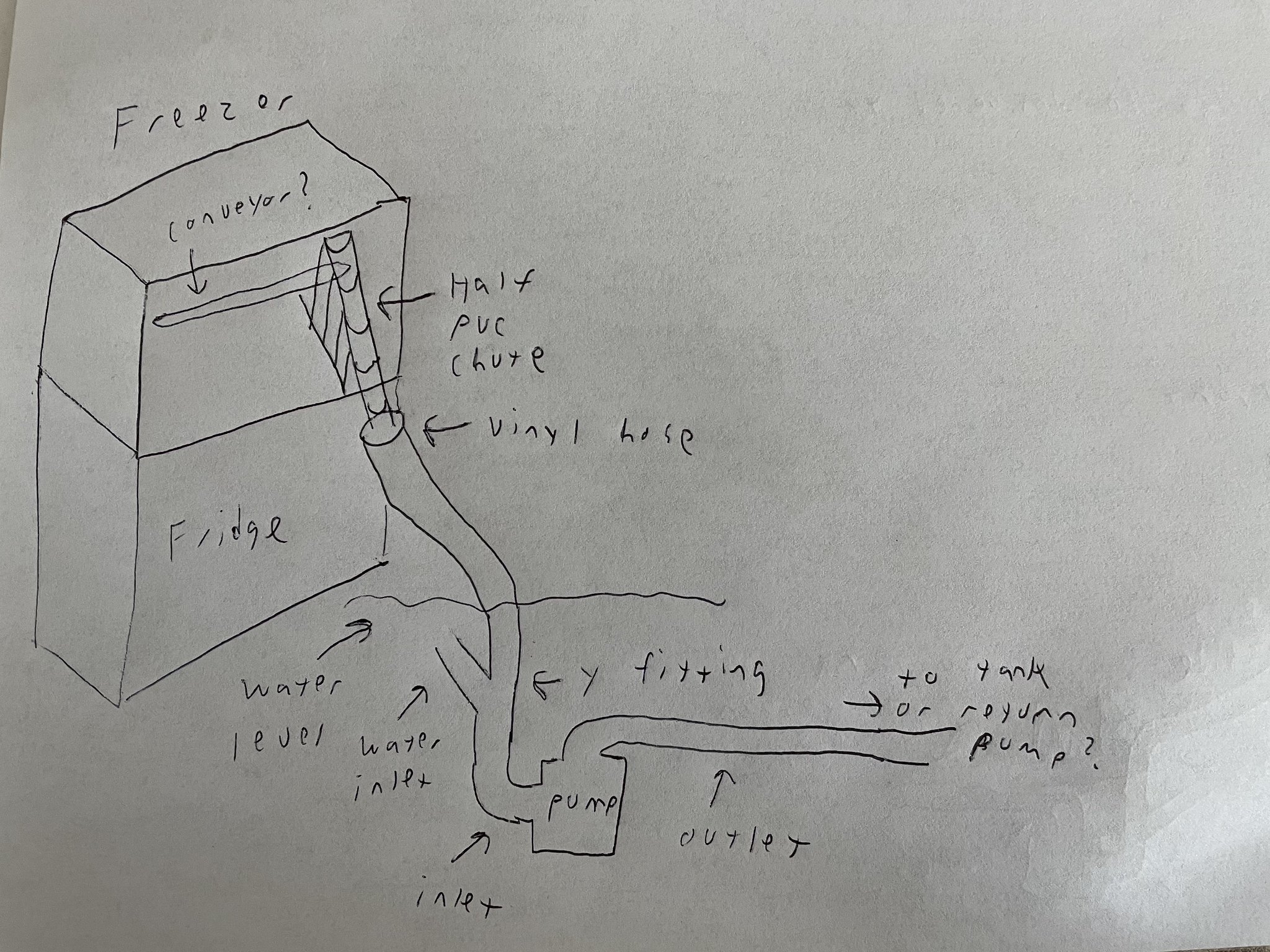

Every DIY frozen feeder I have seen has relied on a refrigerated slurry. The only version that I've seen that would last more than a day requires making your own food with preservatives. I'm looking to build a true frozen feeder that can be used with any frozen food without degrading the food quality. I've broken this idea down into three components (listed below). The diagram at the bottom of this post shows my first thoughts on how to accomplish these three pieces. The first piece is where I need the most input as electronics/robotics is not a strength of mine.

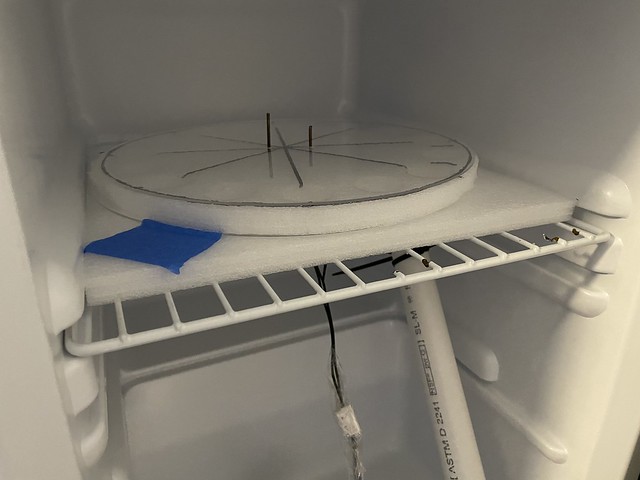

1. Getting the frozen food out of the freezer at a specific time in a specific volume

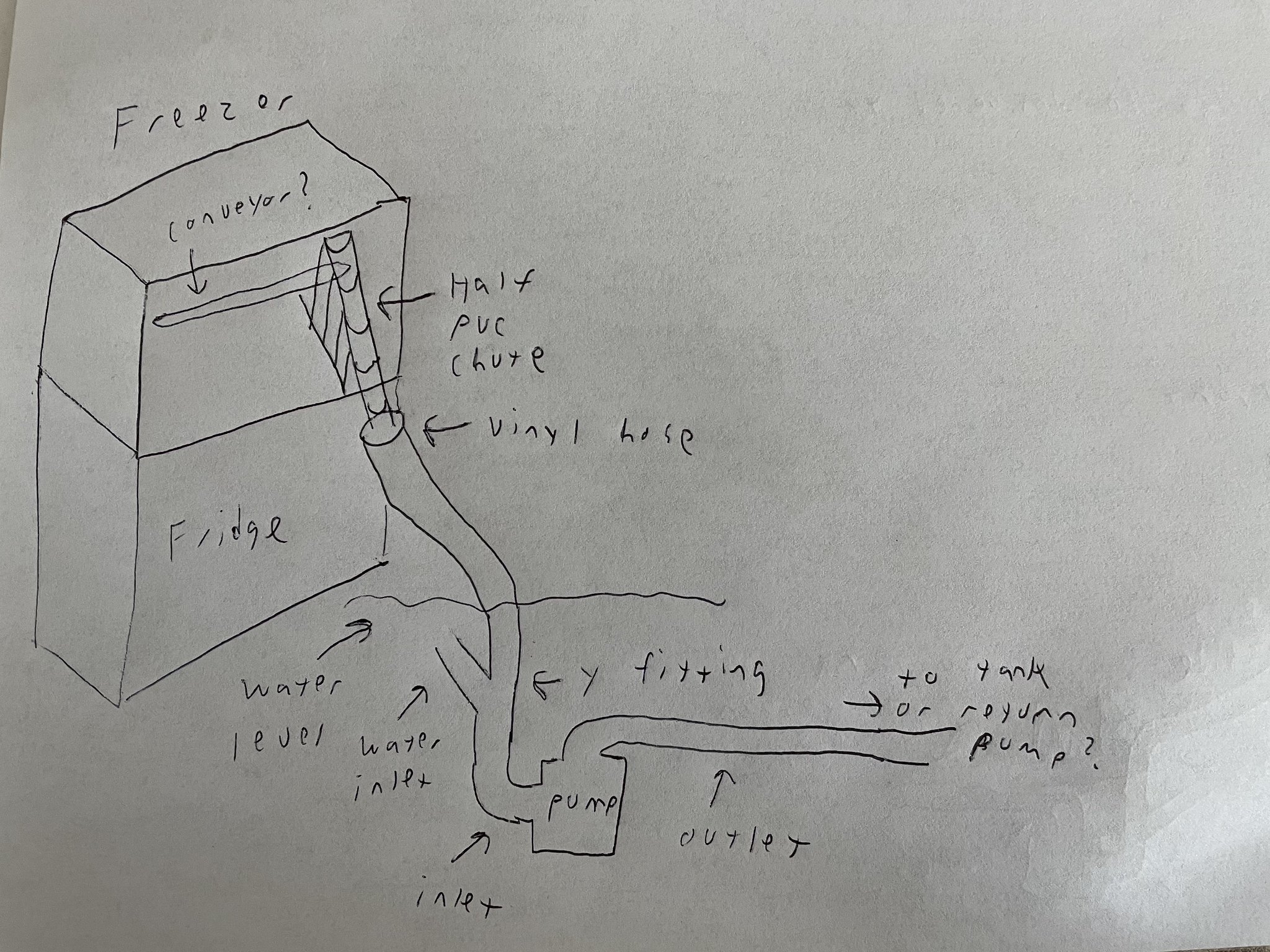

- My sump is ~20" off the ground so I am looking to use a two door mini fridge, with the freezer on top, to use gravity to get the frozen food into the sump

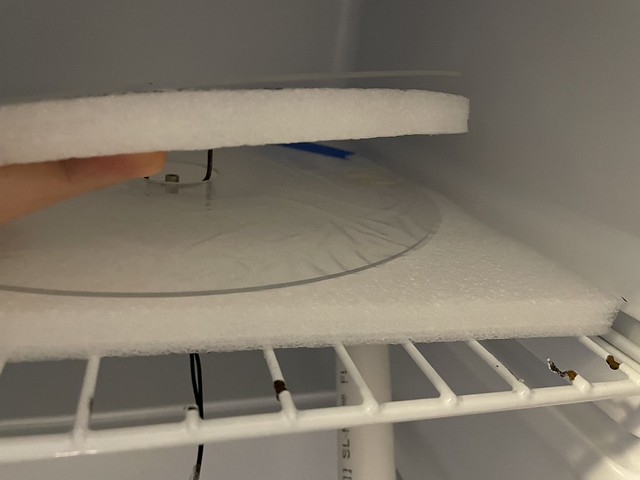

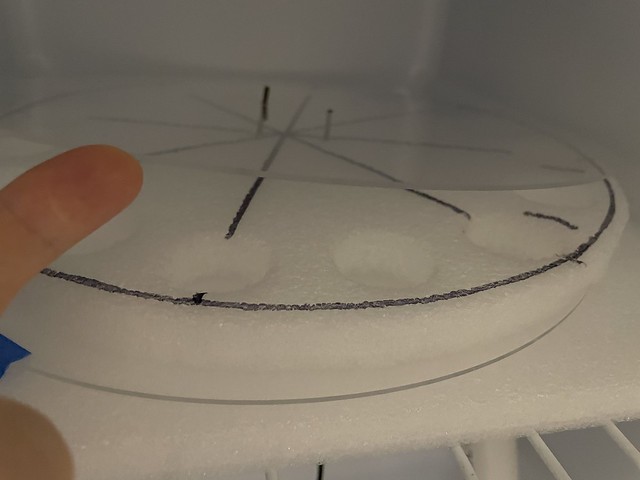

- In the diagram, on the side of the freezer is a slanted piece of PVC, cut in half length wise, that goes through a hole in the door of the fridge. My idea is to have conveyor belts where the frozen food is pre-portioned on the belts and a motor turns on throughout the day to drop one portion into the PVC chute.

- Questions:

- Are there any pre-fabricated conveyor belts that would fit this need? I tried searching for mini ones but didn't find anything at this small of a scale.

- If not, any DIY instructions anyone can point me to for this? The motor would need to turn on for a couple of seconds at set times throughout the day.

- Does anyone have a better idea of how to get the frozen food out of the freezer? I want to maximize the number of feedings that can be done. Ideally 120 to allow a month of 4x a day.

2. Thawing the food/chopping it up into bite size pieces

- In the diagram below the chute drops into the top of a Y-fitting that connects to a pump (likely the maxijet I have lying around). The pump will be off when the food drops in so the food can soften/thaw for a few minutes before being shredded by the pump. The idea being that frozen food would likely break the impeller over time. The other opening on the Y-fitting is to allow tank water into the pump so it doesn't run dry.

- Any concerns about this that I'm not thinking of?

3. Delivering it to the tank

- The pump in step 2 will deliver the food to the tank and be controller by a standard timer. The only thing I am debating is running a dedicated line from this pump to the tank or pumping it into the intake of the return pump.

- Anyone have a preference on these two options, or a third option?

4. Any other comments/suggestions?

1. Getting the frozen food out of the freezer at a specific time in a specific volume

- My sump is ~20" off the ground so I am looking to use a two door mini fridge, with the freezer on top, to use gravity to get the frozen food into the sump

- In the diagram, on the side of the freezer is a slanted piece of PVC, cut in half length wise, that goes through a hole in the door of the fridge. My idea is to have conveyor belts where the frozen food is pre-portioned on the belts and a motor turns on throughout the day to drop one portion into the PVC chute.

- Questions:

- Are there any pre-fabricated conveyor belts that would fit this need? I tried searching for mini ones but didn't find anything at this small of a scale.

- If not, any DIY instructions anyone can point me to for this? The motor would need to turn on for a couple of seconds at set times throughout the day.

- Does anyone have a better idea of how to get the frozen food out of the freezer? I want to maximize the number of feedings that can be done. Ideally 120 to allow a month of 4x a day.

2. Thawing the food/chopping it up into bite size pieces

- In the diagram below the chute drops into the top of a Y-fitting that connects to a pump (likely the maxijet I have lying around). The pump will be off when the food drops in so the food can soften/thaw for a few minutes before being shredded by the pump. The idea being that frozen food would likely break the impeller over time. The other opening on the Y-fitting is to allow tank water into the pump so it doesn't run dry.

- Any concerns about this that I'm not thinking of?

3. Delivering it to the tank

- The pump in step 2 will deliver the food to the tank and be controller by a standard timer. The only thing I am debating is running a dedicated line from this pump to the tank or pumping it into the intake of the return pump.

- Anyone have a preference on these two options, or a third option?

4. Any other comments/suggestions?