- Joined

- Mar 27, 2017

- Messages

- 3

- Reaction score

- 3

Dave:

I own a Radion RMS track and slide system which holds my 3 each XR30W Pro LED lights over my 72” wide display tank. I wanted to use the RMS system to hold my new T5HO light fixtures as well. My goal was to avoid using wire supports for the T5HO fixtures.

I will explain the attached photos as I go along. First is a photo of just the LEDs RMS support bracket before adding the T5s. See photo:

Radions Before T5

The T5HO design uses rectangular brackets which rest on top of the T5 fixtures, held in place by small screws intended to hold the brackets in position. Those screws would not be strong enough to hold the weight of the T5 fixtures and needed a fix. I used a “L” bracket where one side was screwed to the rectangular bracket and the second side to the T5 fixture itself, to add enough strength to support the T5 fixtures.

1. I used my dining room table to assemble the combined fixture, Using one XR30W light as a template I placed and secured the six rectangular LED brackets needed. See photo:

Locate Rectangular Brackets

2. I used a band saw to cut “L” brackets from the Kessel light fixtures tabs included with the T5HO box. That metal was powder coated black and matched the T5 fixture color. I set up a template for my drill press to drill consistently located holes in both ends of these 12 “L: brackets (tabs). See photo: After the photos I touched up the tabs with black paint.

Make L bracket from Kessel holders

3. I used 3mm x 8mm black oxide screws and nuts (Amazon screw kit: ASIN B076BHQMVZ) to fasten the short end of tabs to the rectangular LED brackets. See photo:

Ready to drill T5 hole

4. I removed the reflectors from the T5 to give access to the inside of the T5 fixtures. Using the predrilled holes in the long end of the tab I drilled holes in the T5. There are four screws for each LED fixture. I used 3mm x 8mm screws and nut to attach the 12 tabs to the T5. Now the rectangular brackets are strong enough to hold the weight of the T5 fixtures. I replaced the reflectors on the T5.

5. I loosened the track / slides from the RMS support arms and moved them to my table to complete the assembly.

6. The width between fixtures of the assembled T5HO was so close to the actual width of the XP30W lights, there was no way to snug the lights past the 12 screw heads I added to the side of the T5. The tolerances were just too tight. So I settled on snugging the LED lights, vertically, at the bottom of the added screws.

7. Radion used short 5mm x 3mm screws to attach their RMS slide to the XR30W lights. We had added the thickness of the rectangular bracket, plus the distance to the bottom of the T5 screw heads. In my case, I needed 25mm long screws to ‘reach’ the LEDs from the slides. (If I had drilled the holes in the long end of the tabs higher, or closer to the corner, the replacement screws could have been shorter.)

8. I assembled the lights to the slides using the 5mm x 25mm screws and ½ inch nylon spacers, both purchased at Home Depot. I wanted all my LED and T5 lights wires to exit the assembly to the left. I spliced in additional electrical wire to the T5 plugs to make that work. See photo:

Assembled

9. I returned the completed assembly back the Display Tank, tightening the RMS track to each RMS arms clamped to end of aquarium glass. My guess is the combined assembly weighs over 30 pounds. The clamps might not be designed to hold all the new weight, especially a movement from front to back. I purchased a 1/8 inch brass rod (Lowes). I bent a circle into one end the brass rod, then bent a 90 degree angle next to the circle. I used a wood screw through the circle to secure the rod to a wall stud. Extending the rod to the top of the T5 showed me where I needed to bend a second circle so the rod reached the middle of the T5 fixture. I used a self-tapping screw to secure the rod to the T5. Now the combined assembly cannot move, fore and aft, over the tank.

Rod

Rod Attached

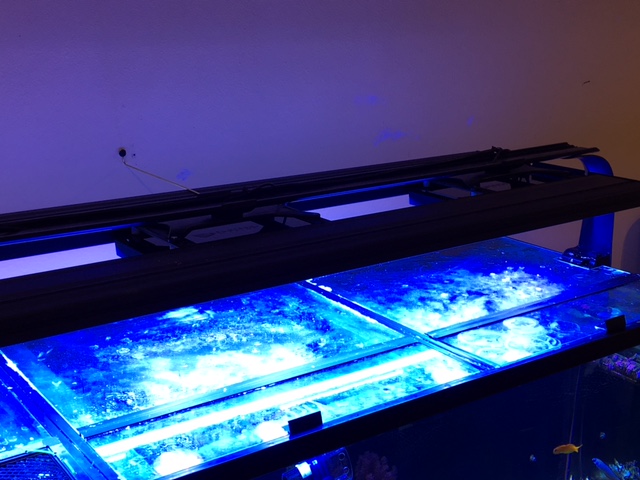

10. The finished project over my 72” 200 gallon tank.

Final

Best wishes, David Morris

I own a Radion RMS track and slide system which holds my 3 each XR30W Pro LED lights over my 72” wide display tank. I wanted to use the RMS system to hold my new T5HO light fixtures as well. My goal was to avoid using wire supports for the T5HO fixtures.

I will explain the attached photos as I go along. First is a photo of just the LEDs RMS support bracket before adding the T5s. See photo:

Radions Before T5

The T5HO design uses rectangular brackets which rest on top of the T5 fixtures, held in place by small screws intended to hold the brackets in position. Those screws would not be strong enough to hold the weight of the T5 fixtures and needed a fix. I used a “L” bracket where one side was screwed to the rectangular bracket and the second side to the T5 fixture itself, to add enough strength to support the T5 fixtures.

1. I used my dining room table to assemble the combined fixture, Using one XR30W light as a template I placed and secured the six rectangular LED brackets needed. See photo:

Locate Rectangular Brackets

2. I used a band saw to cut “L” brackets from the Kessel light fixtures tabs included with the T5HO box. That metal was powder coated black and matched the T5 fixture color. I set up a template for my drill press to drill consistently located holes in both ends of these 12 “L: brackets (tabs). See photo: After the photos I touched up the tabs with black paint.

Make L bracket from Kessel holders

3. I used 3mm x 8mm black oxide screws and nuts (Amazon screw kit: ASIN B076BHQMVZ) to fasten the short end of tabs to the rectangular LED brackets. See photo:

Ready to drill T5 hole

4. I removed the reflectors from the T5 to give access to the inside of the T5 fixtures. Using the predrilled holes in the long end of the tab I drilled holes in the T5. There are four screws for each LED fixture. I used 3mm x 8mm screws and nut to attach the 12 tabs to the T5. Now the rectangular brackets are strong enough to hold the weight of the T5 fixtures. I replaced the reflectors on the T5.

5. I loosened the track / slides from the RMS support arms and moved them to my table to complete the assembly.

6. The width between fixtures of the assembled T5HO was so close to the actual width of the XP30W lights, there was no way to snug the lights past the 12 screw heads I added to the side of the T5. The tolerances were just too tight. So I settled on snugging the LED lights, vertically, at the bottom of the added screws.

7. Radion used short 5mm x 3mm screws to attach their RMS slide to the XR30W lights. We had added the thickness of the rectangular bracket, plus the distance to the bottom of the T5 screw heads. In my case, I needed 25mm long screws to ‘reach’ the LEDs from the slides. (If I had drilled the holes in the long end of the tabs higher, or closer to the corner, the replacement screws could have been shorter.)

8. I assembled the lights to the slides using the 5mm x 25mm screws and ½ inch nylon spacers, both purchased at Home Depot. I wanted all my LED and T5 lights wires to exit the assembly to the left. I spliced in additional electrical wire to the T5 plugs to make that work. See photo:

Assembled

9. I returned the completed assembly back the Display Tank, tightening the RMS track to each RMS arms clamped to end of aquarium glass. My guess is the combined assembly weighs over 30 pounds. The clamps might not be designed to hold all the new weight, especially a movement from front to back. I purchased a 1/8 inch brass rod (Lowes). I bent a circle into one end the brass rod, then bent a 90 degree angle next to the circle. I used a wood screw through the circle to secure the rod to a wall stud. Extending the rod to the top of the T5 showed me where I needed to bend a second circle so the rod reached the middle of the T5 fixture. I used a self-tapping screw to secure the rod to the T5. Now the combined assembly cannot move, fore and aft, over the tank.

Rod

Rod Attached

10. The finished project over my 72” 200 gallon tank.

Final

Best wishes, David Morris