12/6/2018 - Day 62

I don't even feel like I'm updating the same build thread at this point - it's been so long! I have no specific excuse any different from my last one (busy; work, new house, life,...). Sleep deprivation, I suppose, is as good a reason as any...

Soon after the above post, we got all the drywall in place and opened up the archway where the tank would fit:

The floor in the above picture was still wet from the acid-wash/cleaning process that I did in order to prepare the surface for an epoxy layer. This wasn't hard work, but it did take a few days of cleaning/drying cycles. While that was going on, I was rather impatient with all the delays, so I assembled the stand. It went together mostly as planned. It's upside down here, awaiting the self-leveling feet to be attached:

Adding the feet turned out to be a pain. Not that it was difficult to add them, but the holes where the foot plates mounted needed to be tapped with the appropriate thread. I had the tools to do such, but it snapped on the second hole. Which then required me to get another one from the local hardware store - which also snapped after just two holes. At that point, I decided to get something better than the stuff I was finding locally - ordered a pair of carbon steel ones from Amazon. Took a few days to get to me, so meanwhile I went back to the floor. The epoxy went on rather easily. I added some grit to the mix and then used the included flakes; the result is a floor that has good traction even when wet:

I sealed up the edges with rubber trim and silicone sealant. I'm not going to test it unless I must, but I'm pretty sure that it'll be able to hold some water if it needs to. If not, anything that does leak under would end up in the garage (and then out to the street) and not into the house, so there's that, at least. Yay!

Once the floor dried, I painted the room (above) and then moved on to installing the light rails. These were quickly designed while I was ordering the stand parts, so I was really hoping it would all work out. It did - and it didn't. My plan was (is) to have each light roll out on a track, allowing me to clean the tank without lights in my way. The problem came when I opened the boxes with the rollers in them. I had thought I'd ordered some wheels that had bearings in them, but the ones I have are just screws holding a metal ring pushed into a plastic wheel - no real bearings to speak of. Checking my order, they are what I ordered (serves me right for not taking my time). Beyond that, none of the parts seemed to fit together correctly... To top it off, I did a poor job of cutting the hanging wires to the same length, so had to shift the crossbar to account for that. Not a huge deal, per-se (I planned for having to level them some), but it does look rather... off. Still; everything plugged into the EB8 I purchased for the purpose;

The lights don't really roll out all that well, so I'll have to rebuild them at some point in the future. For now, I'm moving on to other things and will come back to this when I get frustrated with having lights in my way. ;-)

With the lights in place, I moved all the big things into the room - mostly the water mixing station and a storage rack.

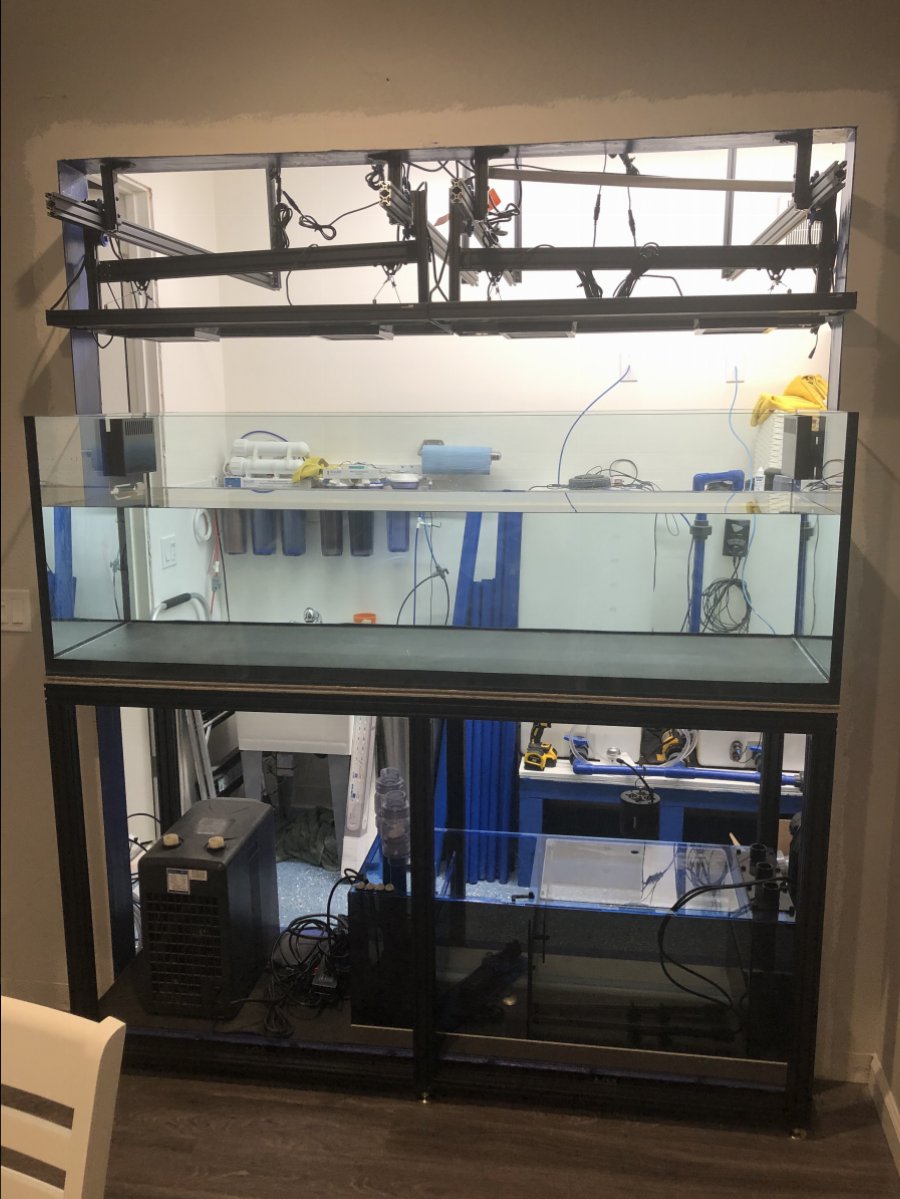

With all the big stuff in place, I moved the stand into it's forever home:

I added the 3/4" flooring plywood to both the tank and sump rails. That was easy enough; even went ahead and painted the sump board to help protect it some. At that point, it was time to call in some help to lift the tank into position! I had planned on using the guys who moved our hot tub. They had offered to charge me $300. Instead, I went around the corner to where new homes are being built and had the foreman (whom I have worked with all throughout the house build) find a couple of guys to help me move it (for the far more reasonable rate of $50 per person). I unpacked the crate and got my first actual look at the tank!

The tank is well built and nearly everything was as I expected. The only thing wrong with it is that the back had been painted. I'm not really sure that I ever asked for it not to be, so no foul or fault on the builder there. In any case - and to make short of a lot of heavy lifting - the four of us lifted the ~450# tank into position. I followed that up by putting the sump and some gear into position and attaching the overflows. Luckily, it all fit according to plan!

At this point, I ran into a snag. The stand is certainly strong enough to hold up the tank, but the deflection was too much to trust. I went online and ordered some 45-angle supports that I could add to fix that. The delivery time was "8-10 days", however, and I was hoping to get things in place before then. I ended up solving it by attaching some l-brackets to the stand and the wall frame. Even relatively small (~2") brackets, it worked better than I expected - even with just one, the tank no longer wobbled! I added the second, of course, but I no longer worried about the deflection. When the angle pieces arrived yesterday, I went ahead and added them to the stand as well. I'm pretty confidant that the stand is now as stable as it needs to be.

Still have plumbing to do before I can fill it. I drew it all out ahead of time and ordered some of what I'd need, but now with everything in place, I'm glad I didn't order too much more. After looking at it all, I've redesigned the plumbing. Again. :-| I drew it all out and ordered a bunch more pieces from BRS - which should mostly be here tomorrow. Meanwhile, I cleaned off the paint using acetone and a razor blade. Then filled it with 100gal of RO/DI water - well below the drains, but enough to empty my water tanks so that I can fill them up again.

I'll try and update again in the next few days - hopefully once I get the plumbing in place...

I don't even feel like I'm updating the same build thread at this point - it's been so long! I have no specific excuse any different from my last one (busy; work, new house, life,...). Sleep deprivation, I suppose, is as good a reason as any...

Soon after the above post, we got all the drywall in place and opened up the archway where the tank would fit:

The floor in the above picture was still wet from the acid-wash/cleaning process that I did in order to prepare the surface for an epoxy layer. This wasn't hard work, but it did take a few days of cleaning/drying cycles. While that was going on, I was rather impatient with all the delays, so I assembled the stand. It went together mostly as planned. It's upside down here, awaiting the self-leveling feet to be attached:

Adding the feet turned out to be a pain. Not that it was difficult to add them, but the holes where the foot plates mounted needed to be tapped with the appropriate thread. I had the tools to do such, but it snapped on the second hole. Which then required me to get another one from the local hardware store - which also snapped after just two holes. At that point, I decided to get something better than the stuff I was finding locally - ordered a pair of carbon steel ones from Amazon. Took a few days to get to me, so meanwhile I went back to the floor. The epoxy went on rather easily. I added some grit to the mix and then used the included flakes; the result is a floor that has good traction even when wet:

I sealed up the edges with rubber trim and silicone sealant. I'm not going to test it unless I must, but I'm pretty sure that it'll be able to hold some water if it needs to. If not, anything that does leak under would end up in the garage (and then out to the street) and not into the house, so there's that, at least. Yay!

Once the floor dried, I painted the room (above) and then moved on to installing the light rails. These were quickly designed while I was ordering the stand parts, so I was really hoping it would all work out. It did - and it didn't. My plan was (is) to have each light roll out on a track, allowing me to clean the tank without lights in my way. The problem came when I opened the boxes with the rollers in them. I had thought I'd ordered some wheels that had bearings in them, but the ones I have are just screws holding a metal ring pushed into a plastic wheel - no real bearings to speak of. Checking my order, they are what I ordered (serves me right for not taking my time). Beyond that, none of the parts seemed to fit together correctly... To top it off, I did a poor job of cutting the hanging wires to the same length, so had to shift the crossbar to account for that. Not a huge deal, per-se (I planned for having to level them some), but it does look rather... off. Still; everything plugged into the EB8 I purchased for the purpose;

The lights don't really roll out all that well, so I'll have to rebuild them at some point in the future. For now, I'm moving on to other things and will come back to this when I get frustrated with having lights in my way. ;-)

With the lights in place, I moved all the big things into the room - mostly the water mixing station and a storage rack.

With all the big stuff in place, I moved the stand into it's forever home:

I added the 3/4" flooring plywood to both the tank and sump rails. That was easy enough; even went ahead and painted the sump board to help protect it some. At that point, it was time to call in some help to lift the tank into position! I had planned on using the guys who moved our hot tub. They had offered to charge me $300. Instead, I went around the corner to where new homes are being built and had the foreman (whom I have worked with all throughout the house build) find a couple of guys to help me move it (for the far more reasonable rate of $50 per person). I unpacked the crate and got my first actual look at the tank!

The tank is well built and nearly everything was as I expected. The only thing wrong with it is that the back had been painted. I'm not really sure that I ever asked for it not to be, so no foul or fault on the builder there. In any case - and to make short of a lot of heavy lifting - the four of us lifted the ~450# tank into position. I followed that up by putting the sump and some gear into position and attaching the overflows. Luckily, it all fit according to plan!

At this point, I ran into a snag. The stand is certainly strong enough to hold up the tank, but the deflection was too much to trust. I went online and ordered some 45-angle supports that I could add to fix that. The delivery time was "8-10 days", however, and I was hoping to get things in place before then. I ended up solving it by attaching some l-brackets to the stand and the wall frame. Even relatively small (~2") brackets, it worked better than I expected - even with just one, the tank no longer wobbled! I added the second, of course, but I no longer worried about the deflection. When the angle pieces arrived yesterday, I went ahead and added them to the stand as well. I'm pretty confidant that the stand is now as stable as it needs to be.

Still have plumbing to do before I can fill it. I drew it all out ahead of time and ordered some of what I'd need, but now with everything in place, I'm glad I didn't order too much more. After looking at it all, I've redesigned the plumbing. Again. :-| I drew it all out and ordered a bunch more pieces from BRS - which should mostly be here tomorrow. Meanwhile, I cleaned off the paint using acetone and a razor blade. Then filled it with 100gal of RO/DI water - well below the drains, but enough to empty my water tanks so that I can fill them up again.

I'll try and update again in the next few days - hopefully once I get the plumbing in place...

Last edited: