- Joined

- Oct 2, 2017

- Messages

- 596

- Reaction score

- 76

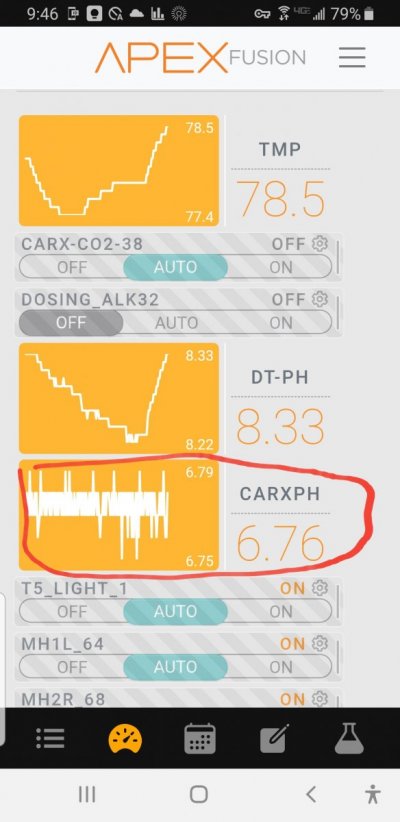

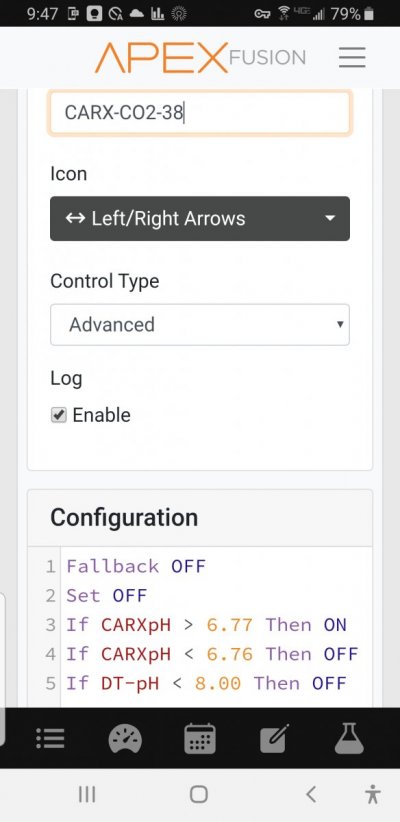

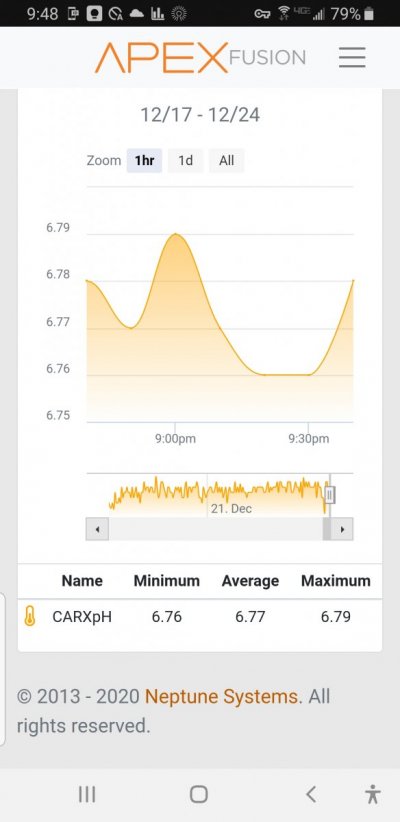

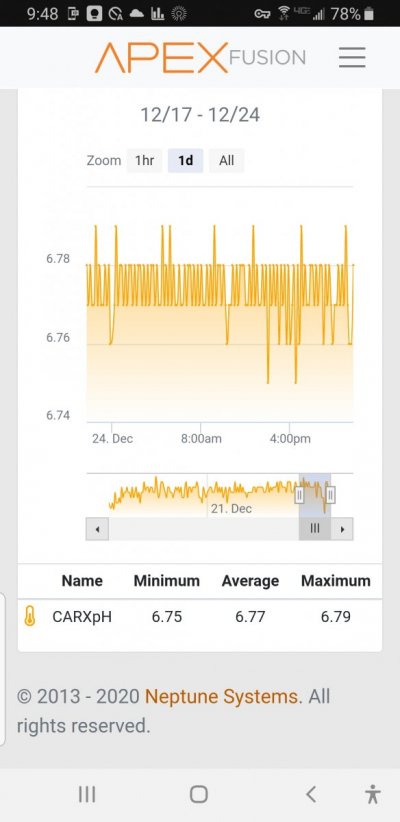

What is the best high pressure rated Check valve to put in between the CO2 tank line feeding into Calcium reactor?

It is an MRC reactor using 1/4 " tubing...Currently using a cheap top fin one that leaks in high bubble rate!

I called BRS and they said use this:

www.bulkreefsupply.com

www.bulkreefsupply.com

tia.........

It is an MRC reactor using 1/4 " tubing...Currently using a cheap top fin one that leaks in high bubble rate!

I called BRS and they said use this:

Ozone Resistant Kynar Check Valve

Ozone Resistant Kynar Check Valves allow one-way water flow and prevent back siphoning. Using ozone resistant materials is absolutely critical when working with ozone. Materials like nylon will melt in a matter of days when it comes in contact with high concentrations of ozone. Inexpensive Ozone...

tia.........

Last edited: