Converting to standard plumbing...

Cut down the original RSR piping...

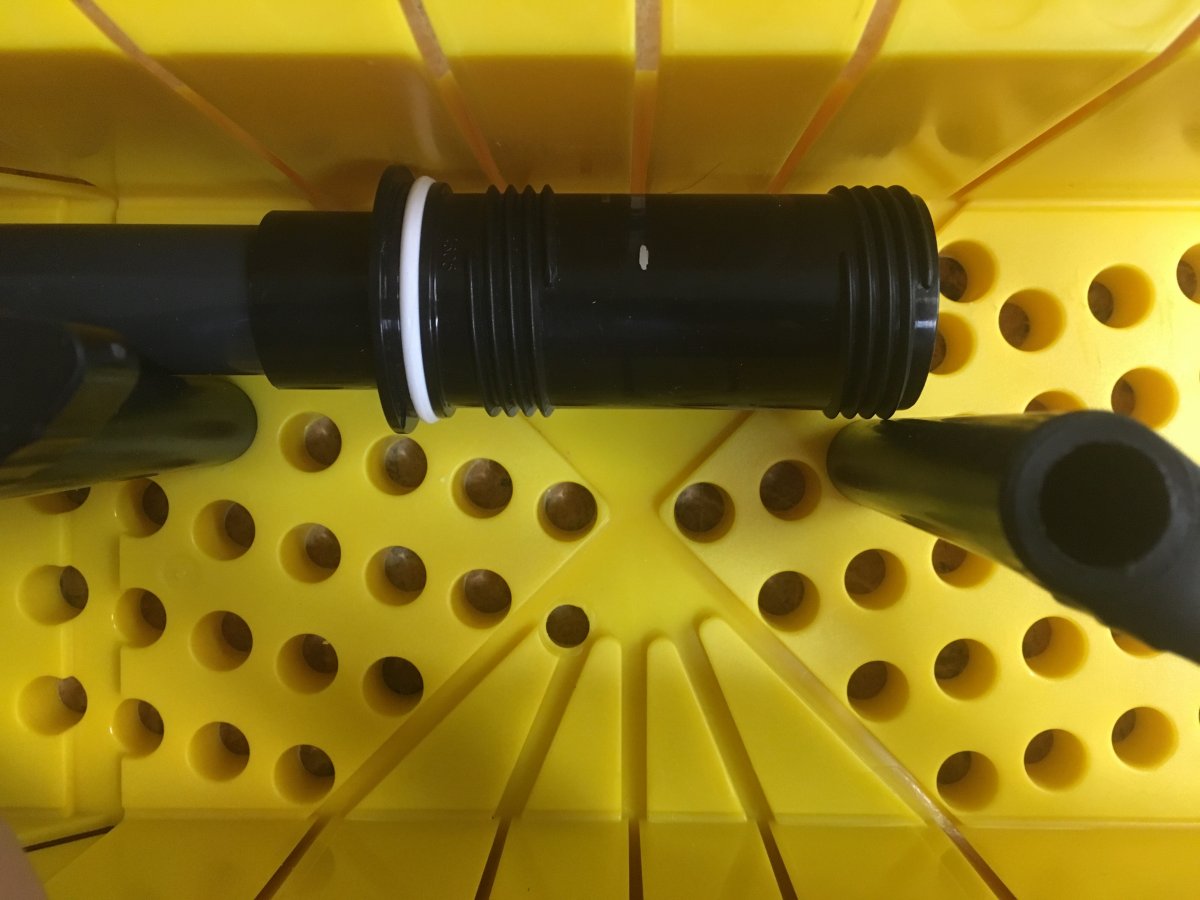

My hole saw arbor fit perfectly into a cutdown 1” threaded nipple...

I chucked it up in my drill and turned it down on my belt sander...

It fits perfectly... RSR plumbing converted to 1” standard.

Do this two more times and it’s a done deal!

Cut down the original RSR piping...

My hole saw arbor fit perfectly into a cutdown 1” threaded nipple...

I chucked it up in my drill and turned it down on my belt sander...

It fits perfectly... RSR plumbing converted to 1” standard.

Do this two more times and it’s a done deal!