@EdsReefOdyssey - I bought some coral for the new tank

The quarantine tank has them acclimating for the next 4-6 weeks.

The quarantine tank has them acclimating for the next 4-6 weeks.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Loving that, the back flush to stir is great.

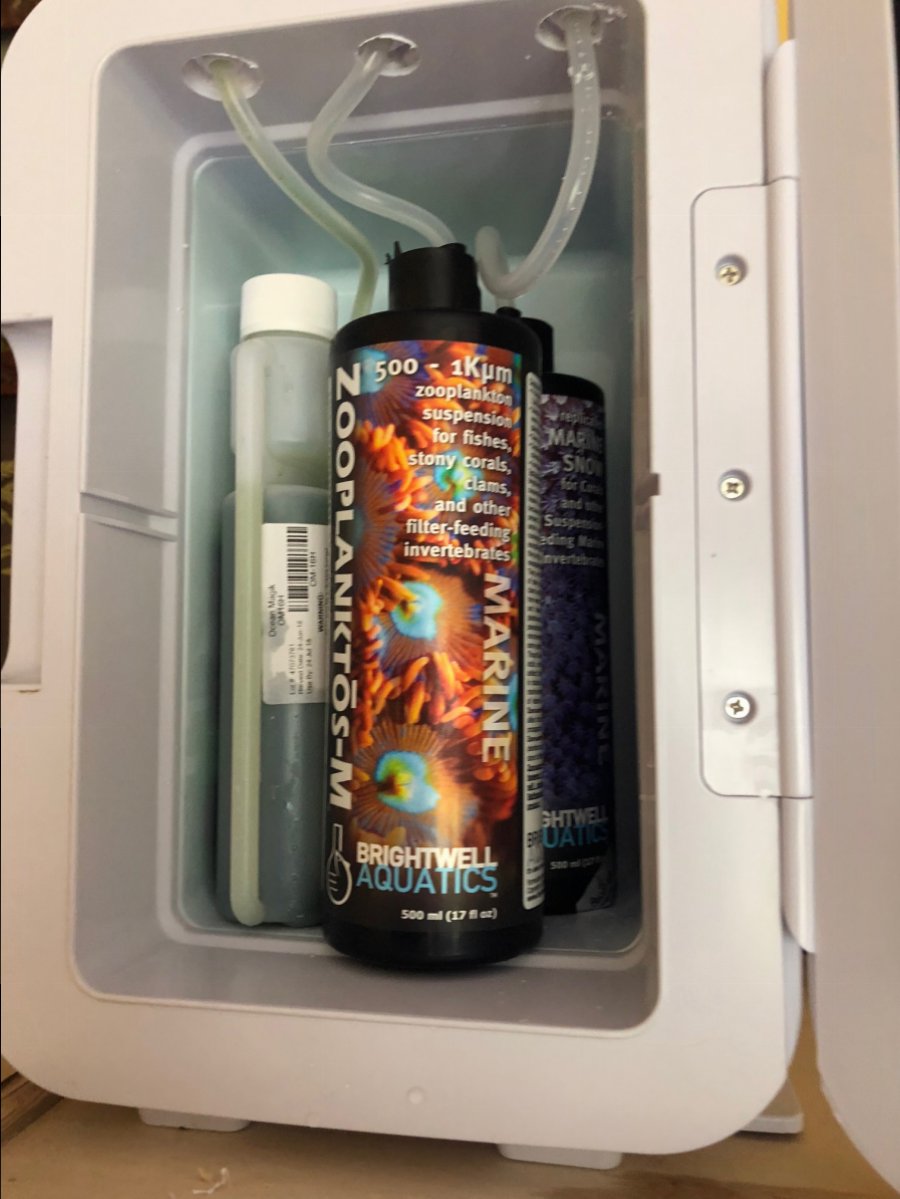

That's great. This is something that I have been planning on (eventually) setting up for a while now, with some Reef Nutrition foods.Yesterday I also set up one of my Auto feeders for the tank. Since I travel I needed to make sure some of my suspended coral food gets done at the same time each and every day. I could not expect friends and family to come over for example at 9:00 at night for broadcast feed the tank

Step 1:

I needed to plumb the dosing lines from where they were going to dose from and to. This is important because the food is going to remain refrigerated I need to dose and then reverse the dose so that the food left in the dosing tube is returned to the refrigerator. To start to determine how much to dose, I used ATO water to determine how much water was in the line.

Below is my cup of ATO water next to me dosing station and refrigerator.

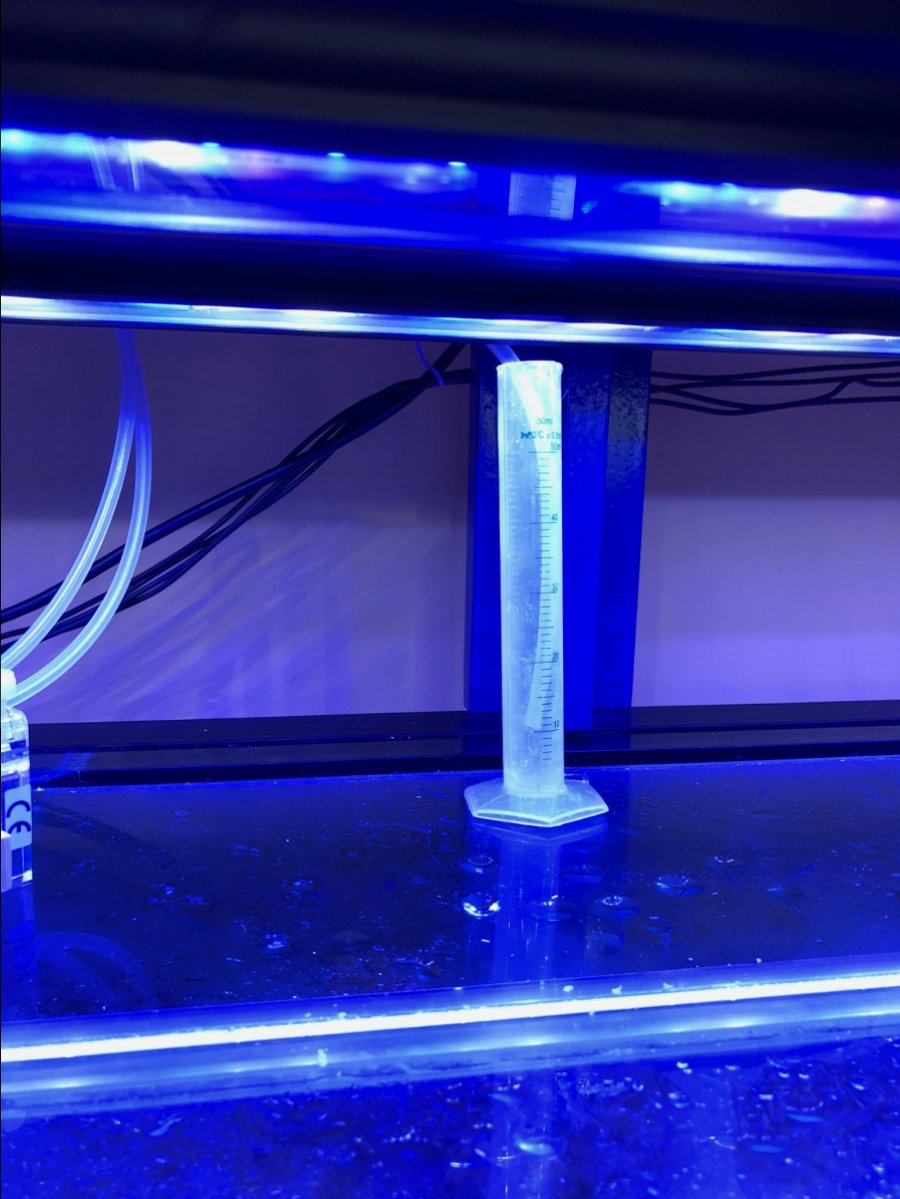

Step 2 - I then placed a measuring container at the end of the dosing line. I then filled the line until it began to drip into the measuring container and then removed the glass of water.

Then I manually ran the pump to see how much water was inside the measuring cup (Emptying the dosing line). For example on pump one it stated 16ml of water was in the line. I did this a few times to make sure it was exact.

Then it rest was easy.

Step 3

I then for example would decide how much I needed to dose, and add it to the measurement I made above. So if I was going to dose 31ML normally I would make the dose 47ML, to make sure 31 ML would enter the tank and 16ML was used to fill the dosing line.

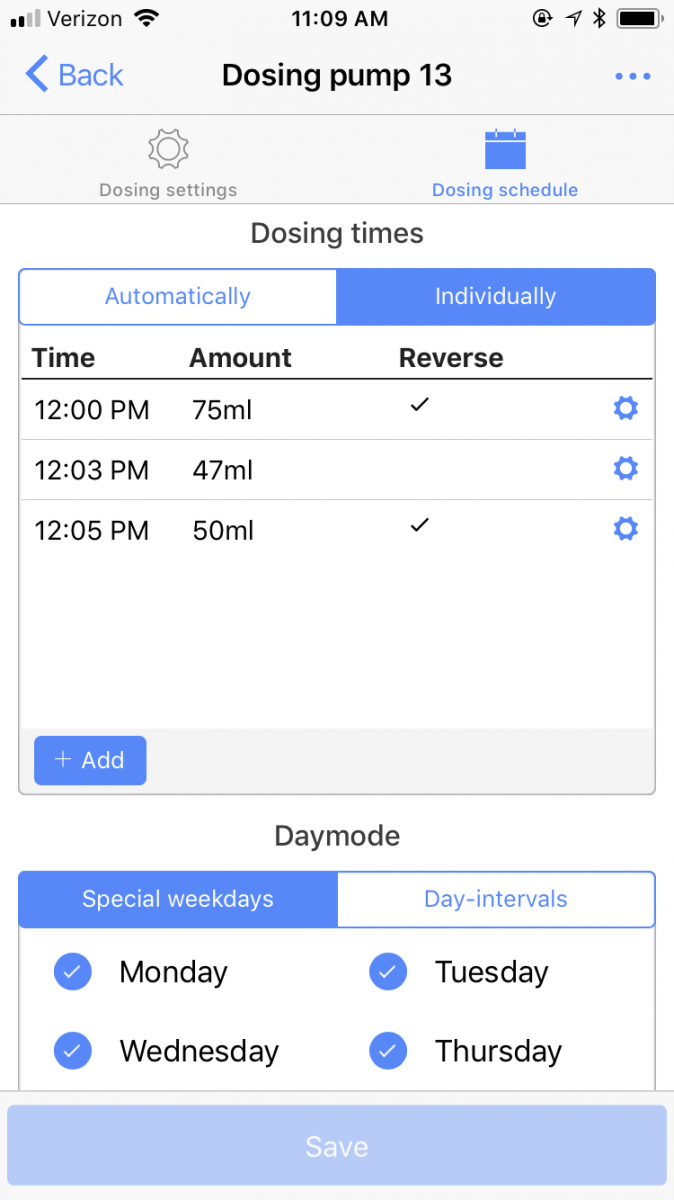

Then using the GHL App all I did was program my dosing pumps to first run in reverse (I did this as a way to mix the solution before dosing) then dose the solution and then reverse again emptying the dosing line. Have to love the GHL dosing pump, reverse action

Below is my Dosing pump 13, where it first runs 75 in reverse, before dosing 31ML into the tank, then it reserves again for 50ml to remove any fluid inside the line.

Can not stress enough you need to do this a few times, it not always straight forward, on one of mine it was 17ml in the line and I needed to dose 10ml and it was not 27Ml but 25ML.

Also you need to test when done with your dosing solution to make sure the numbers remain the same

Once done place your dosing containers in the fridge and your all set

Now my suspended food will dose without any intervention

Ok. So the other end of the tube is in the air above the water? And the only fluid returned to the bottle is the extra amount in the tube itself.Only 16ml of fluid is going back in

The first 75ml is air to help stir content.

Then the 47ml which 16 is used to fill line.

The 75ml (besides this being for stirring) it provides safety if for some reason the 50ml at the end of the dosing the 47ml does not fully clear the line

All in all I am putting 16ml back in each time I do this from the 47ml I originally took out in the dose.

Looking forward to it.Quick Sunday update:

The auto feeder is working great !! I watch the food dispense and then get drawn back into the fridge without any issues.

The tank is slowly clearing up from the algae outbreak the clean up crew is chomping away.

What in store next?

I was going to go with Mp40 and Mp60

In this tank but decided to try something different for additional flow.

Right now I have a red dragon 3 pump which is right now going at 980 gallons and hour, which is at 160 watts and I have 70 watts worth of power I can still put through it.

I want to randomize the flow and decided I will hook up the red dragon 3 pump, and two Tunze pumps to the P4 allow me to control them as stream pumps.

I am going to try for a low and high tide, base, with thunderstorm effects

The pumps are on order along with the specialized cables needed to connect them to the GHL this is gonna to be fun to try

Are you still using these? Would you recommend them?The Vivid Creative Aquatics (https://vividcreativeaquatics.com/)

random flow generators arrived today.

Once the tank is setup I plan to post videos of the patterns they make. Quality of the plastic they used for theses is quite good.

It is a interesting patten when looking through the nozzle.