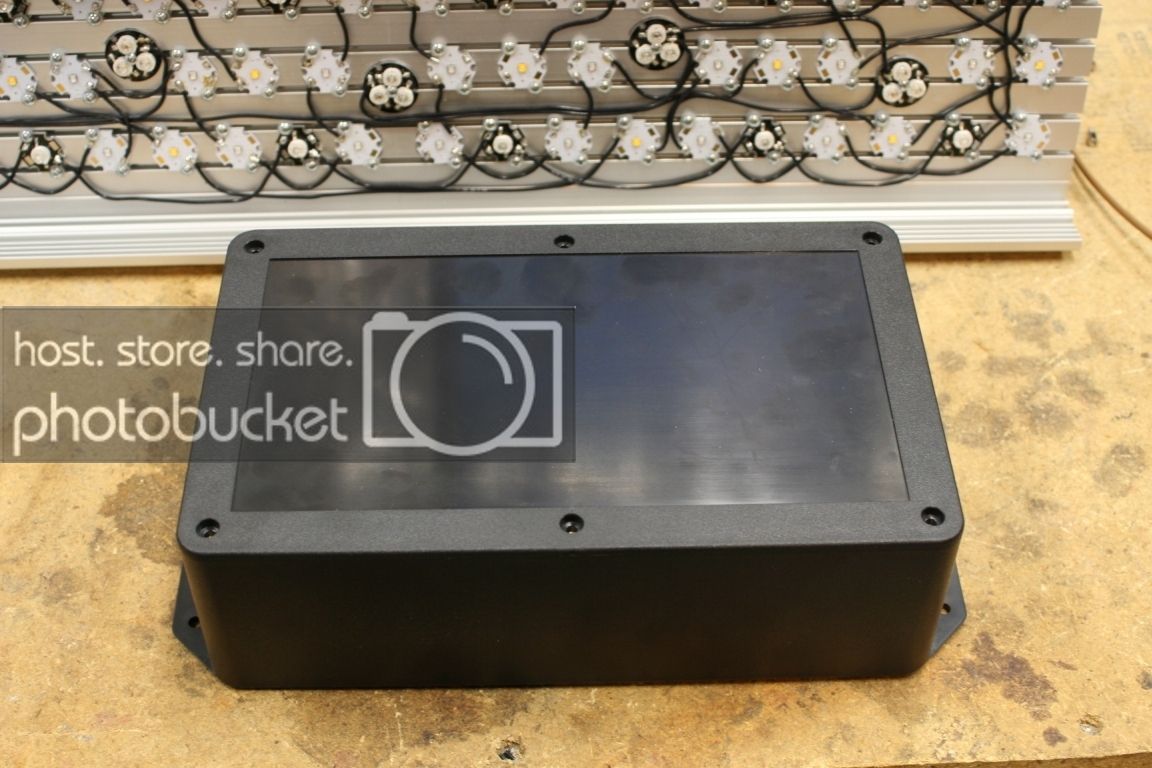

I've been wanting to switch to an LED fixture for some time now and finally decided to go for it. I figured I would start with the 40G frag tank in the basement before I tried to tackle the 120 main display upstairs; I wanted to make sure I would be happy with the color and coverage first. I decided on the MakersLED heat sink because unlike most of the other heatsinks out there, this one actually looks pretty good, as close to a regular light fixture you can get without the awful DIY look. LEDGroupBuy.com is where I got the fixture, drivers and LED's.

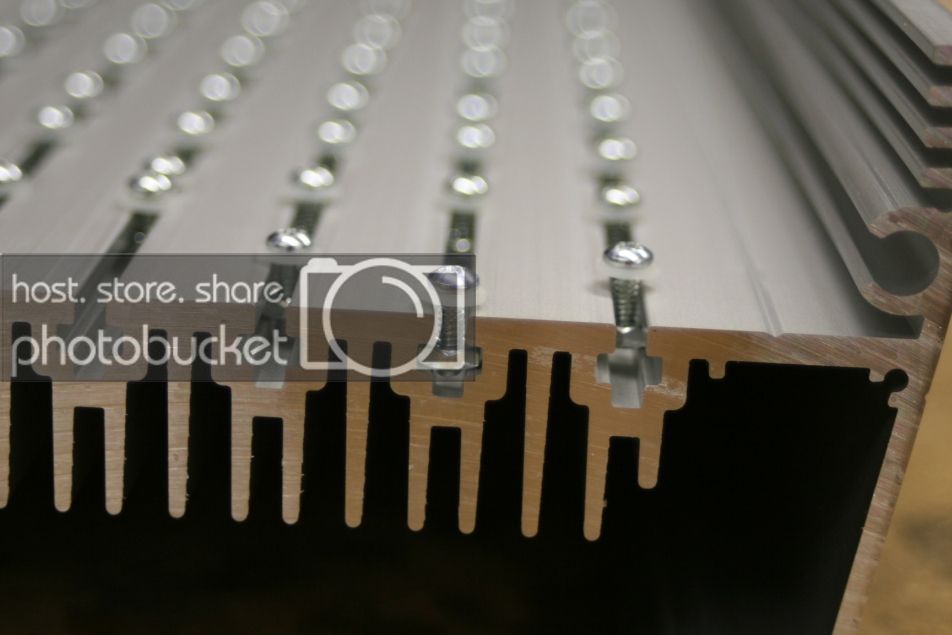

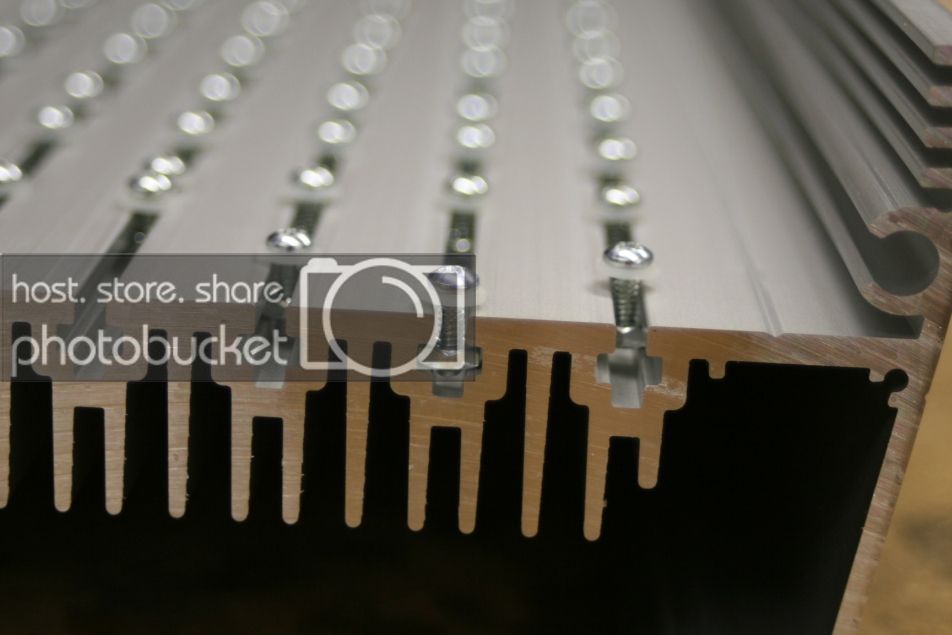

The heatsink comes with 1 cooling fan and enough hardware for 25 LED's for every 12" of heatsink. They also include endcaps to give the fixture a nice clean look and a clear lexan shield that acts as a splash shield.

My LED choices ended up being:

30 Cree XT-E Royal Blue

15 Cree XT-E Neutral White

12 Exotic Hyper Violet

5 Exotic Ocean Coral White OCW combine 3 LED's on one star, Deep Red, Turquoise and cool Blue.

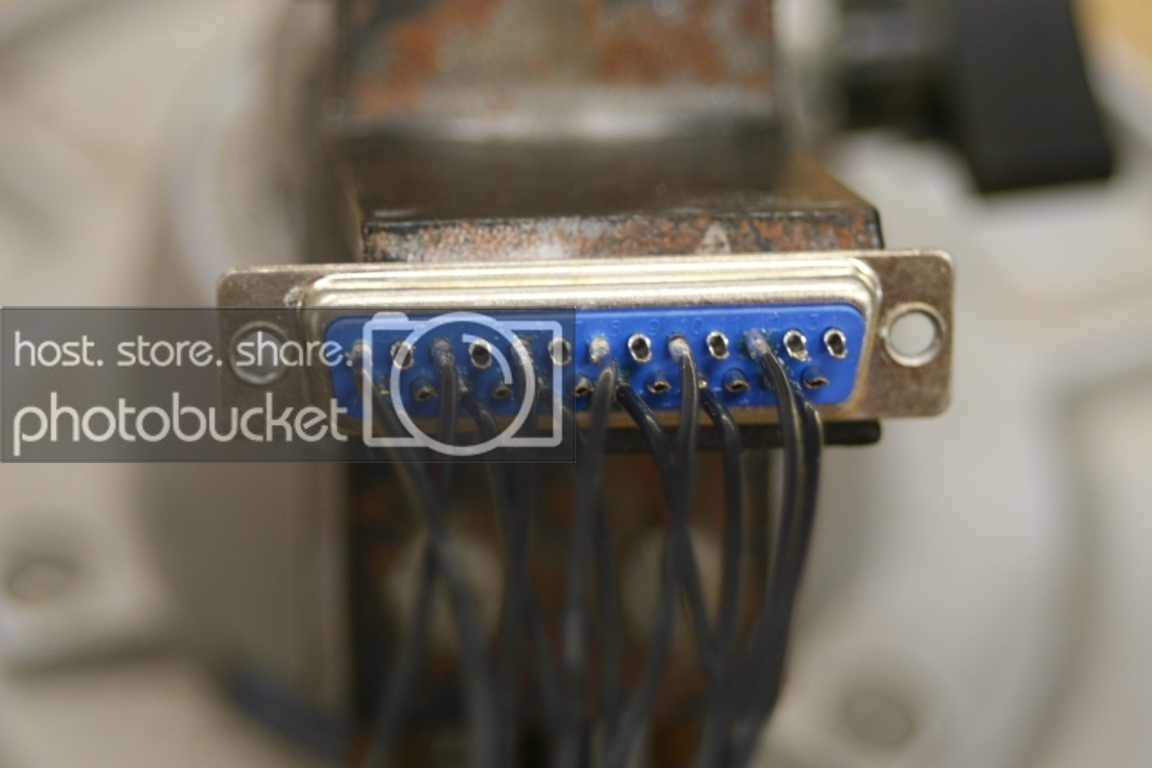

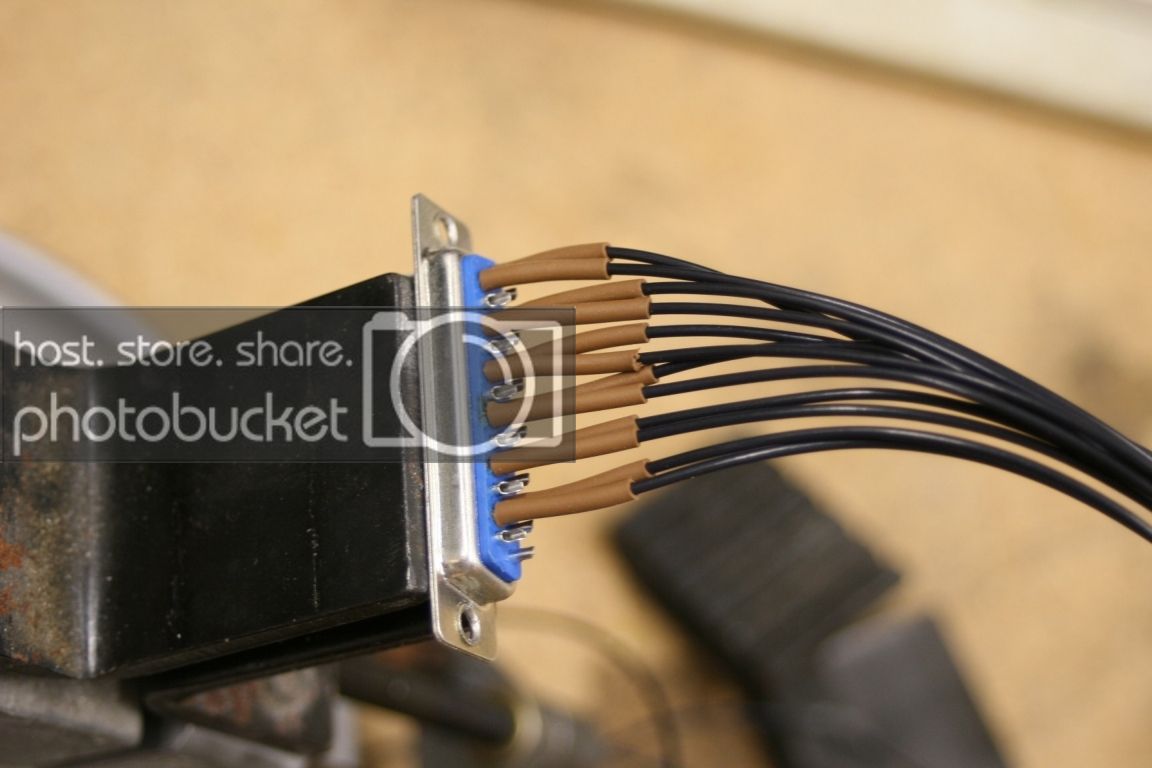

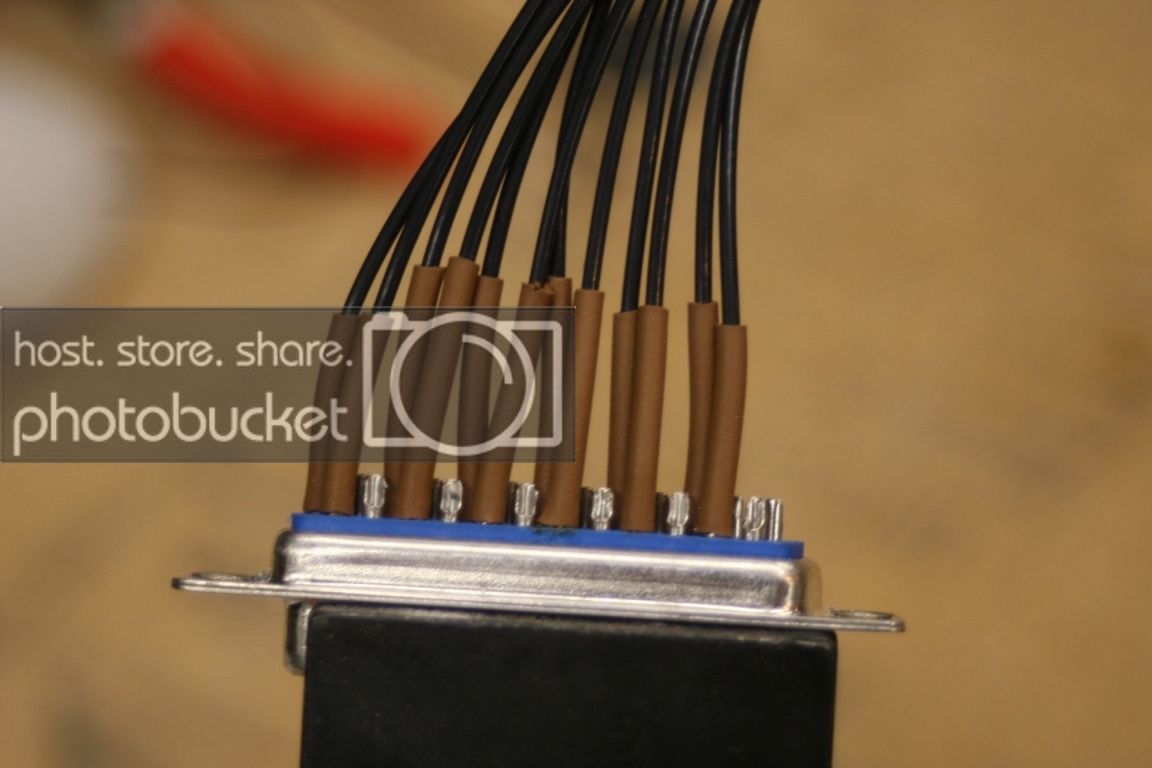

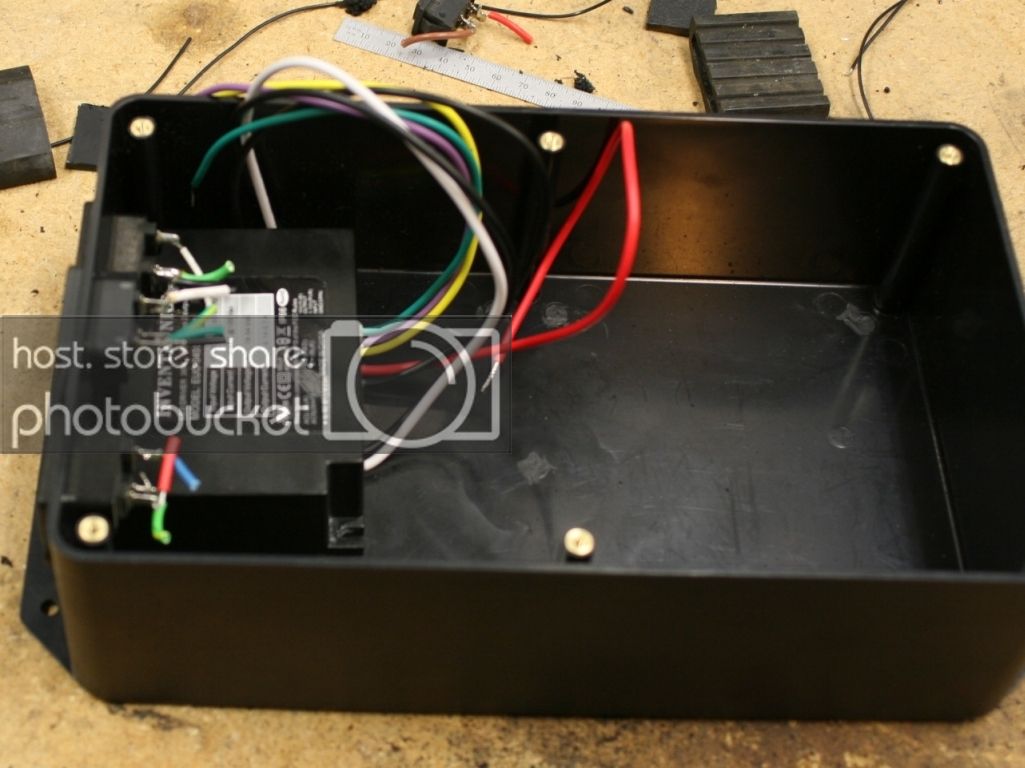

I went with Inventronics dimmable drivers I'll have all channels controlled separately, so RB, NW, OCW and HV all independently dimmable.

The next step was to assemble all the hardware...This part really stinks.

62 LED's x 2 screws per LED = Sore fingers after all plastic washers and nuts are assembled to the screws

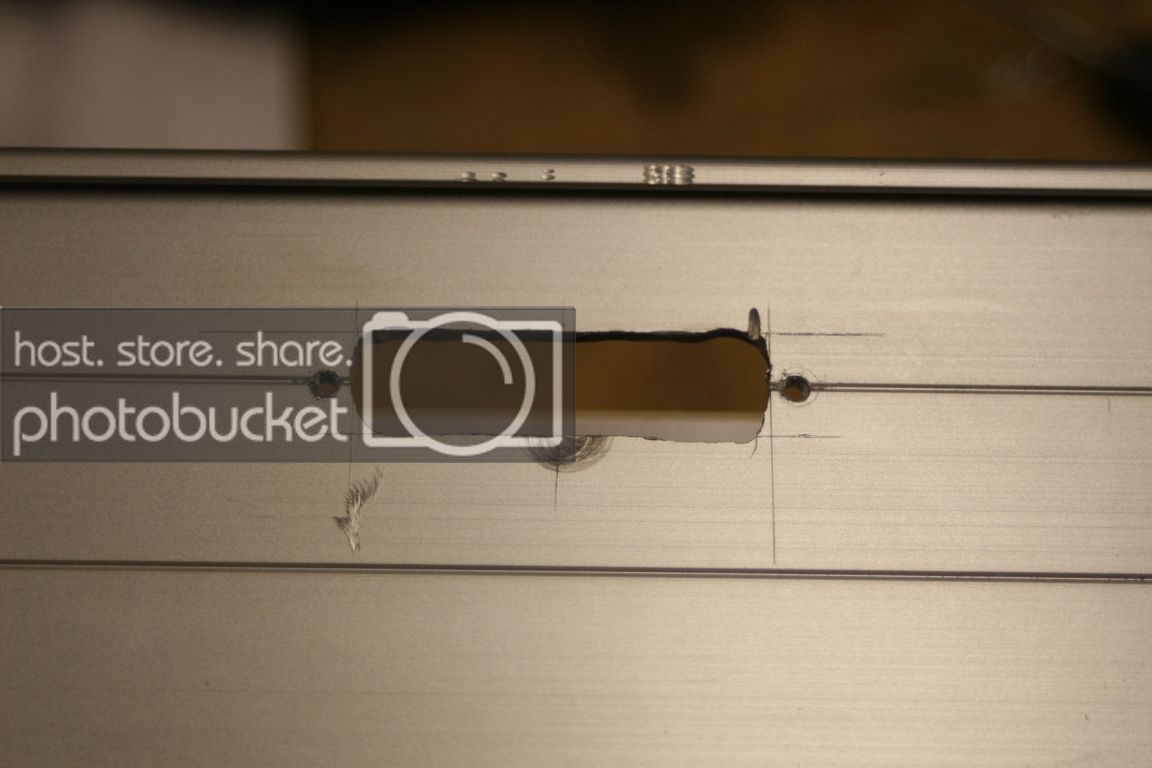

The hardware slides down the slots in the heatsink, making mounting your stars a snap.

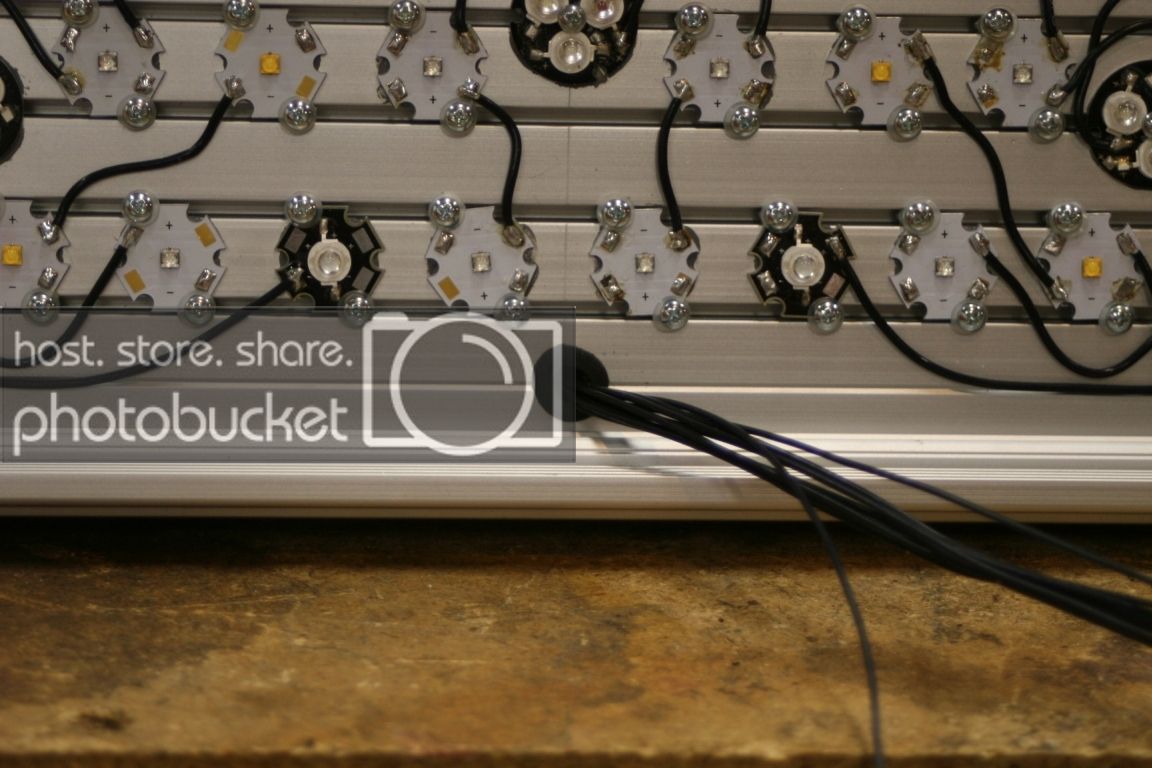

So here's my initial layout. The first three in top row left to right are RB, HV, NW. First three in middle row are NW, RB, OCW.

Next I have to add the thermal compound and hardware to lock the LED's in place. I guess I beter get to it

The heatsink comes with 1 cooling fan and enough hardware for 25 LED's for every 12" of heatsink. They also include endcaps to give the fixture a nice clean look and a clear lexan shield that acts as a splash shield.

My LED choices ended up being:

30 Cree XT-E Royal Blue

15 Cree XT-E Neutral White

12 Exotic Hyper Violet

5 Exotic Ocean Coral White OCW combine 3 LED's on one star, Deep Red, Turquoise and cool Blue.

I went with Inventronics dimmable drivers I'll have all channels controlled separately, so RB, NW, OCW and HV all independently dimmable.

The next step was to assemble all the hardware...This part really stinks.

62 LED's x 2 screws per LED = Sore fingers after all plastic washers and nuts are assembled to the screws

The hardware slides down the slots in the heatsink, making mounting your stars a snap.

So here's my initial layout. The first three in top row left to right are RB, HV, NW. First three in middle row are NW, RB, OCW.

Next I have to add the thermal compound and hardware to lock the LED's in place. I guess I beter get to it