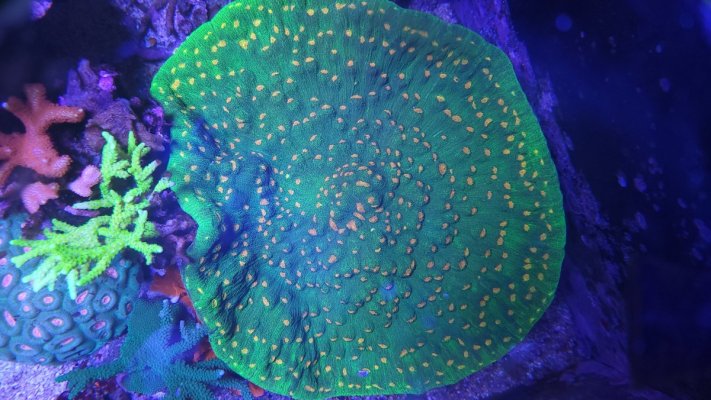

Got the closed loop stand pipes lifted a bit. had to bring the RFG nozzles up a few inches due to coral growth. Coral naturally want to grow into the flow - especially the kind of flow these Random Flow Generators are creating. They seem to love the strong, intermittent broad flow and are simply growing right into it, blocking to the flow further down the tank.

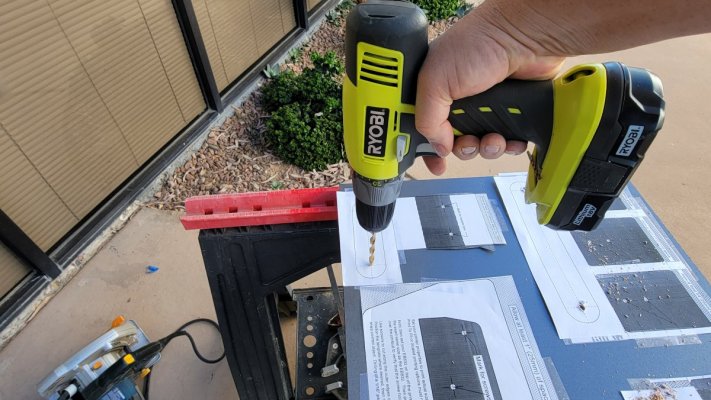

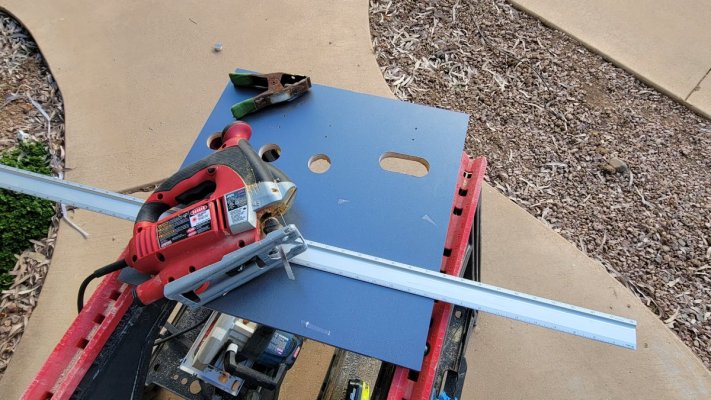

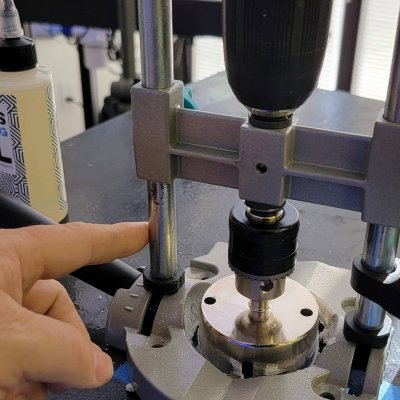

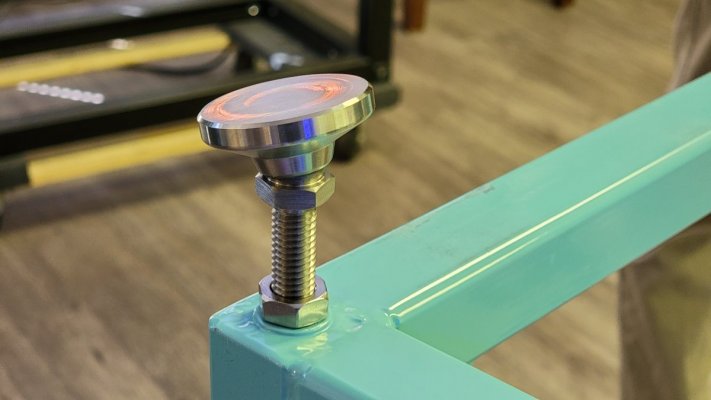

I also took this opportunity to use our new Multidapter in place of the threaded NPT fittings. This allow me to shave off nearly 3/4in off the total length of the RFG nozzle on the end of the elbow fitting.

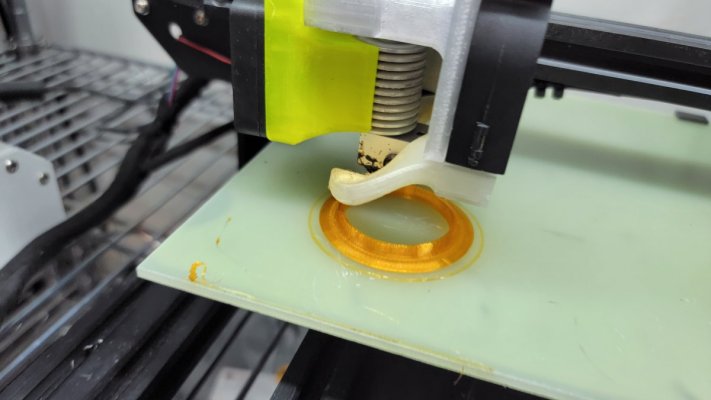

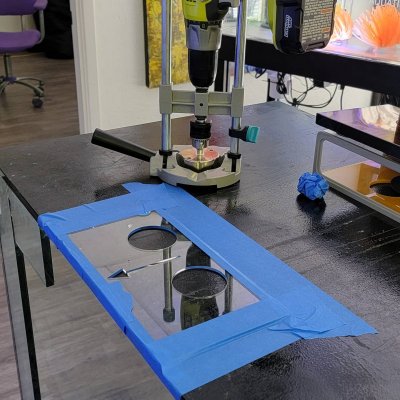

You can see the difference in this pic between the old setup and the new - its a pretty significant amount

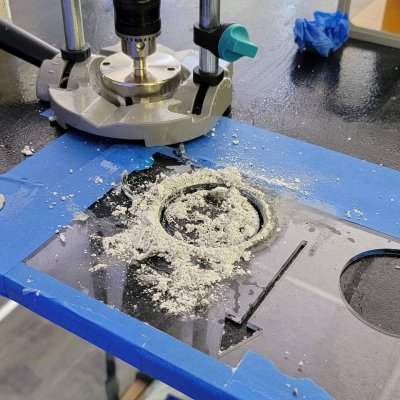

Here are the results - flow looks amazing!

I also took this opportunity to use our new Multidapter in place of the threaded NPT fittings. This allow me to shave off nearly 3/4in off the total length of the RFG nozzle on the end of the elbow fitting.

You can see the difference in this pic between the old setup and the new - its a pretty significant amount

Here are the results - flow looks amazing!