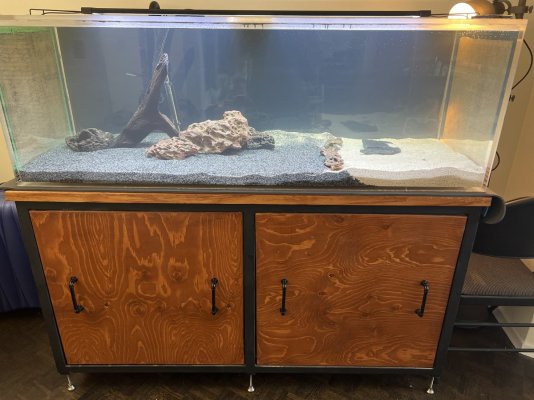

This thread and people here have been very helpful for my build and I was busy with work and personal stuff but yesterday filled my tank with substrate and water.

Can’t understate my appreciation to people such as @Cabinetman and @ReefEco for their support and advise and especially Cabinetman for swooping in saving my project on the penultimate step.

Can’t understate my appreciation to people such as @Cabinetman and @ReefEco for their support and advise and especially Cabinetman for swooping in saving my project on the penultimate step.