Ya those barbed BH's that come with tanks are junk. The barbed end is thin and when you clamp down all they do is flex and they don't give a tight fit. I see you went with a better way but if you put some silicone onto the barb and then slide the hose on and clamp it you will be fine but that's just a temp fix in my book.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barbed connection just can't take the pressure!

- Thread starter Gopi

- Start date

- Tagged users None

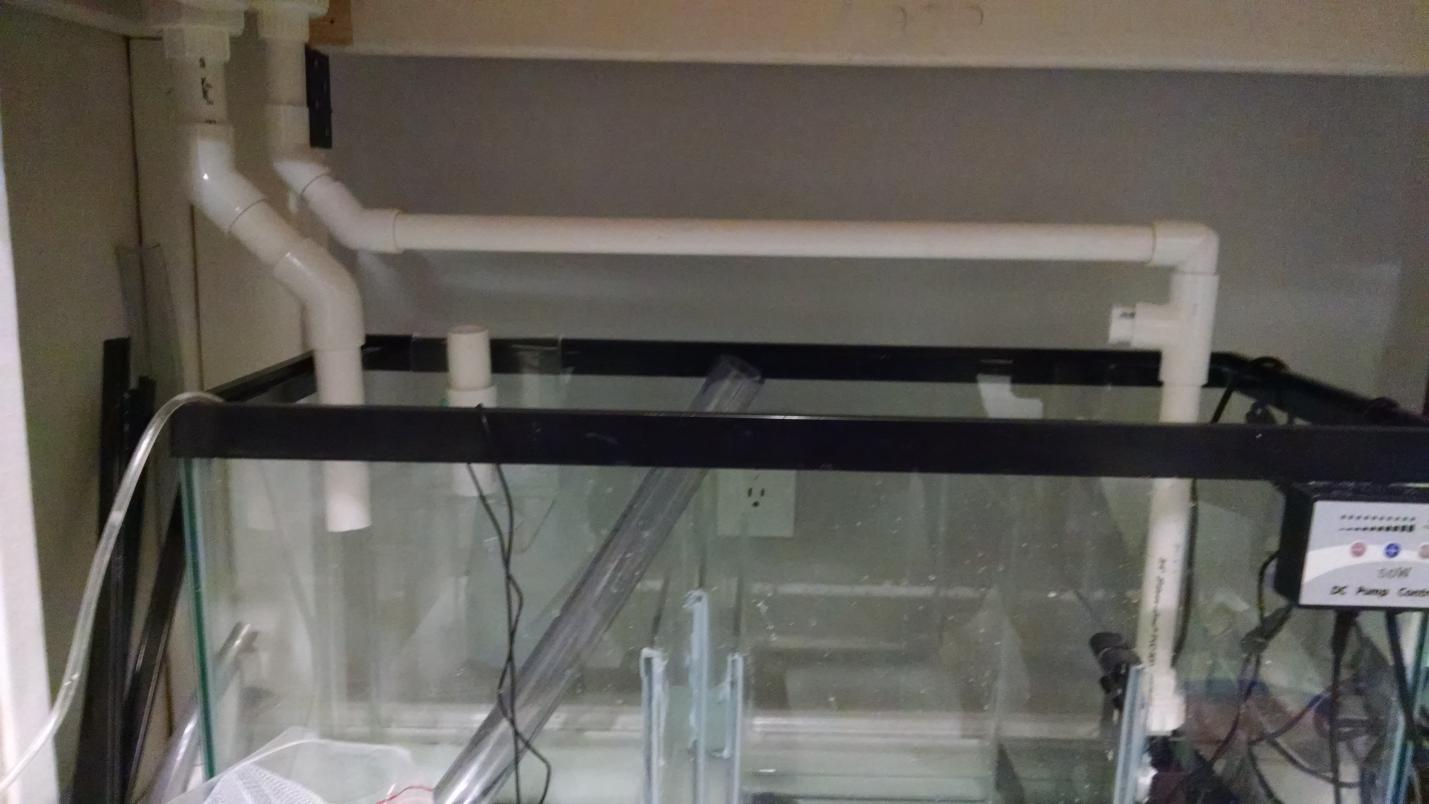

*big sigh* I was finally able to get everything plumbed and... New return bulkhead leaks. Actually, water is seeping between gasket and glass. I just can't seem to get a good seal and I'm worried about over tightening the nut. Also learned I didn't cut my hole in the stand top quite large enough so my knuckles scrape up there. I was able to get a good seal prior to gluing PVC together so not sure what I did there...I just really want to get my sump going!

Picture is actually pre-glue, I added another union to the left of the 90 elbow on the return. The 45° elbows weren't playing nicely on that end...

Picture is actually pre-glue, I added another union to the left of the 90 elbow on the return. The 45° elbows weren't playing nicely on that end...

The reason it is leaking is you are supporting way too much piping with the bulkhead. It is acting like a lever and pulling the bulkhead down causing stress. Use something like plumbers strap or long zip ties and fasten it up to the botom of the stand out close to the return pump end to take that weight off the bulkhead and relieve the stress. At the same time I would find some better barbed nipples and add a short section of vinyl tubing on the pump discharge otherwise you will be fighting vibrations and noise travelling through the PVC pipes from the pump. Ridgid piping is a PITA for sound and vibrations so the vinyl acts as a damper or buffer plus it relieves the stress from any misalignments in the PVC which always happens no matter how hard we try to keep things straight, plumb and level.

Thanks, AZ, I thought the support was a problem. I'll see what I can do to fix that. And, can you clarify about where to put the vinyl tubing? I'm not sure what you mean. I have the pump sitting down in filter sponge that I cut a section out of to fit the body...

One issue is the sponge will start trapping detritus and require cleaning or you will have nitrate issues.

I would screw a barbed nipple into the union you have on the pumps discharge add6" or more of heavy wall or braided reinforced vinyl ubing then into another barbed nipple at the tee you have before the 90. This will relieve stress on the pumps volute and dampen any vibration and sound transmission.

I would screw a barbed nipple into the union you have on the pumps discharge add6" or more of heavy wall or braided reinforced vinyl ubing then into another barbed nipple at the tee you have before the 90. This will relieve stress on the pumps volute and dampen any vibration and sound transmission.

Ah. OK. I should actually be able to replace most of the section up to the T with vinyl tubing...I still have the threaded-barbed fitting for the pump from when it was soft plumbed. I do have the end of the vertical PVC glued into the T though so I'll have to see about that one... I'm assuming I could use a slip-barbed fitting there. I actually think part of the problem is that the vertical pipe ended up being a bit short, so this will help 2 causes. I didn't glue the fitting from pump to union or the bottom of the vertical tube to union because I was feeling lazy and didn't care since it would stay submerged. That piece seemed to work out well for me.

If that piece was short your pump is probably not sitting perfectly flat on all 4 feet and plumb. In the pump industry we call that "soft foot" and it leads to pump wear, vibration and sound transmission through the ridgid piping. The length of vinyl will help this as long as it is the correct length and flexible.

OK. I *finally* got the return line fixed. (Hurt my back, working on the sump was a no-go for awhile.) I got a good seal with the bulkhead, replaced the vertical piece from the pump with tubing, have the horizontal piece supported using 2 zip-tie loops and a J hook (and it's as a level as I can get it.) No leaks there and the pump is sitting flat on the bottom of the sump.

So, naturally, now the drain bulkhead is leaking in a couple spots. :frusty: First, it was at the union, i fixed that. Then it was at the PVC-bulkhead junction, fixed that (guess I hadn't glued well enough?). Then it was the gasket. I can fix one but not all of them at 1 time. I think when I'm less frustrated/hungry I'll go back to my original bulkhead and vinyl tubing there.

The other issue I've discovered, is that even with the DCT4000 on the lowest setting, it's a tad fast for the drain. The water level is actually about a 1/2 cm ABOVE my baffels but not flowing fast enough to keep the pump fully covered. Not sure how to fix that one, but first I need to get the plumbing set...

So, naturally, now the drain bulkhead is leaking in a couple spots. :frusty: First, it was at the union, i fixed that. Then it was at the PVC-bulkhead junction, fixed that (guess I hadn't glued well enough?). Then it was the gasket. I can fix one but not all of them at 1 time. I think when I'm less frustrated/hungry I'll go back to my original bulkhead and vinyl tubing there.

The other issue I've discovered, is that even with the DCT4000 on the lowest setting, it's a tad fast for the drain. The water level is actually about a 1/2 cm ABOVE my baffels but not flowing fast enough to keep the pump fully covered. Not sure how to fix that one, but first I need to get the plumbing set...

Now about that DCT4000

Yay! I've finally gotten all the leaking issues solved! Now, just the pump speed problem. (DCT4000, so quiet, so strong and I love the gradual start!)

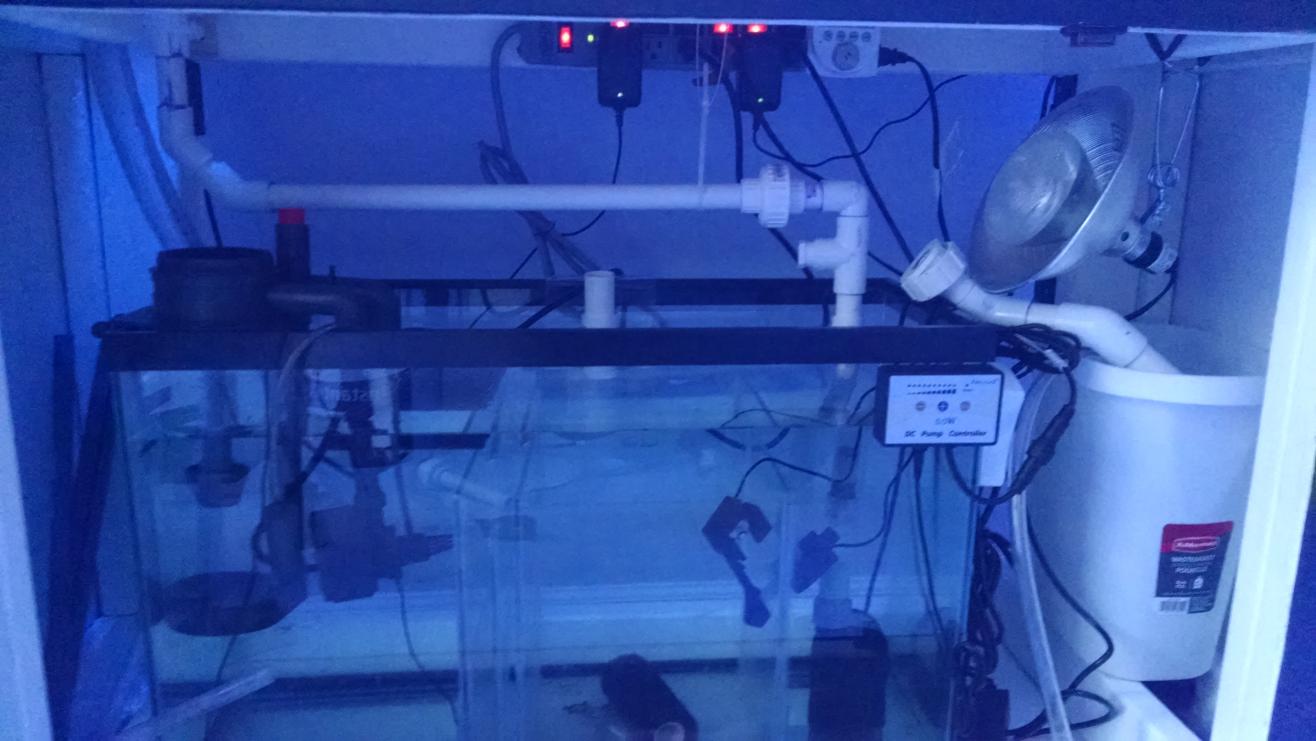

Here is the sump with pump and skimmer off and the overflow chamber empty. I do have some room so if I need to add another gallon or two I could without overflowing the sump. I took the skimmer cup off so more of the plumbing is visible: (um, just ignore the floating float valves, sock holder, and random sponges...)

Here it is with pump and skimmer on. At this point, the water is still higher than the 'over' baffles but the top of the pump is exposed and starting to suck air. The pump is set at it's lowest level. I didn't include a valve in my plumbing because I figured that's what the adjustable speed was for!

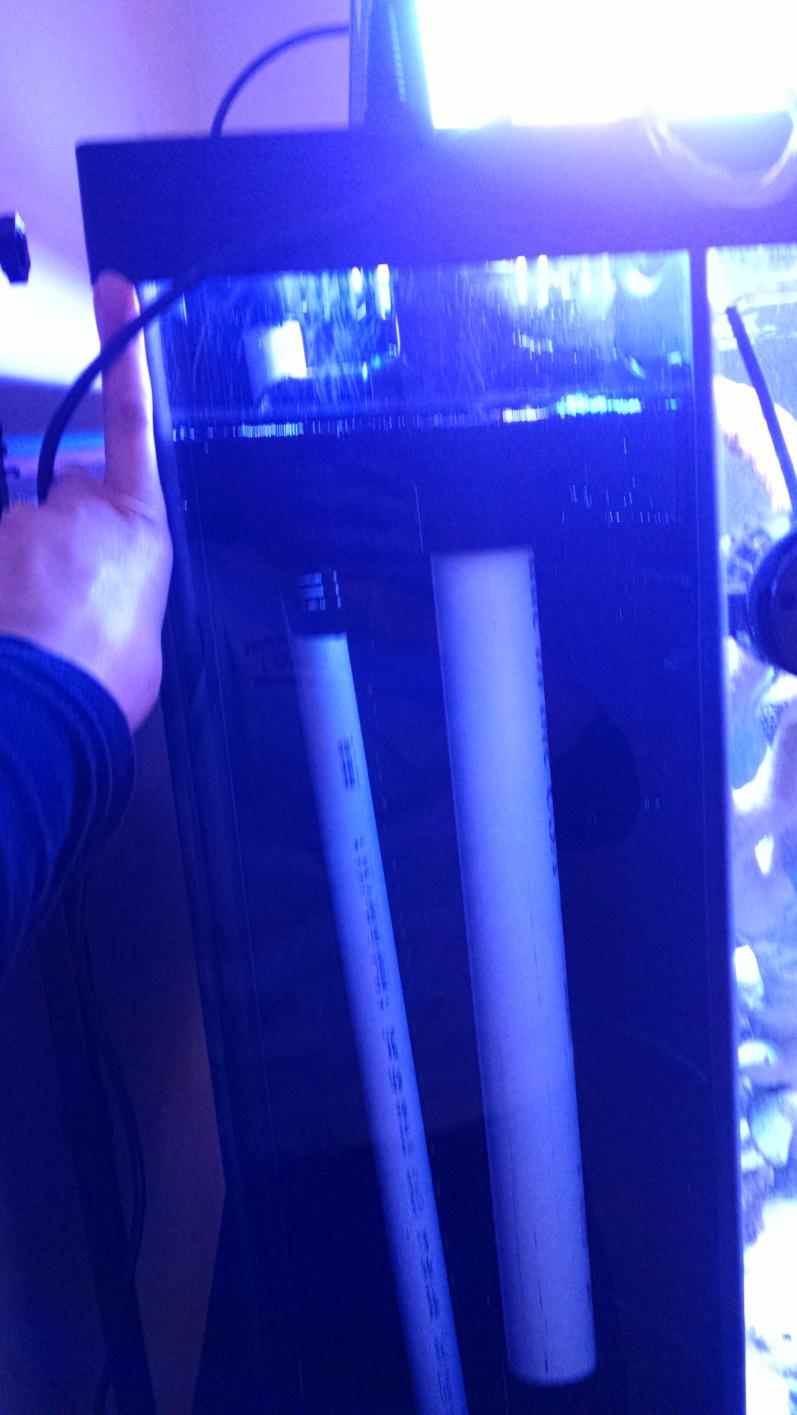

At least the overflow is silent. These are the pipes that came with the tank. Is this a good water height or should I shorten the durso pipe and drop it down? Would dropping it help with balancing flow through the sump at all? (I'm thinking less water volume there, more water volume in sump?)

These are the pipes that came with the tank. Is this a good water height or should I shorten the durso pipe and drop it down? Would dropping it help with balancing flow through the sump at all? (I'm thinking less water volume there, more water volume in sump?)

I'm considering what to do here to have more balanced flow between pump and drain:

1) Do I just need to add more water to the sump? Since the water level is still above the 'over' baffles, I feel like that's a no. I might be wrong.

2) Add a valve? If so, where? Restrict flow or redirect it?

At least I'm learning a lot...

Yay! I've finally gotten all the leaking issues solved! Now, just the pump speed problem. (DCT4000, so quiet, so strong and I love the gradual start!)

Here is the sump with pump and skimmer off and the overflow chamber empty. I do have some room so if I need to add another gallon or two I could without overflowing the sump. I took the skimmer cup off so more of the plumbing is visible: (um, just ignore the floating float valves, sock holder, and random sponges...)

Here it is with pump and skimmer on. At this point, the water is still higher than the 'over' baffles but the top of the pump is exposed and starting to suck air. The pump is set at it's lowest level. I didn't include a valve in my plumbing because I figured that's what the adjustable speed was for!

At least the overflow is silent.

I'm considering what to do here to have more balanced flow between pump and drain:

1) Do I just need to add more water to the sump? Since the water level is still above the 'over' baffles, I feel like that's a no. I might be wrong.

2) Add a valve? If so, where? Restrict flow or redirect it?

A)I could cut the horizontal pipe and add after the union and just restrict flow without redirecting it. (And maybe include more unions on either side of the valve for possible cleaning? Would that pipe then need more support?)

B)I could add it and an elbow where the T is capped and redirect flow into the sump. (I feel like that would definitely need more support then.)

C) I don't really have space below the T and between the pump because I have a 1inch threaded x barb adapter to 1 inch tubing, then a 1in-3/4in reducer to 3/4 tubing to 3/4 adapter to the PVC pipe...eventually making it's way to the 3/4 bulkhead.

B)I could add it and an elbow where the T is capped and redirect flow into the sump. (I feel like that would definitely need more support then.)

C) I don't really have space below the T and between the pump because I have a 1inch threaded x barb adapter to 1 inch tubing, then a 1in-3/4in reducer to 3/4 tubing to 3/4 adapter to the PVC pipe...eventually making it's way to the 3/4 bulkhead.

At least I'm learning a lot...

Similar threads

- Replies

- 5

- Views

- 106

- Replies

- 31

- Views

- 1,017

- Replies

- 25

- Views

- 699