Weird. The Varios 6, for example, seems to ideally have 1.25 inch inner diameter plumbing for the least flow restriction to maximize the flow capacity. Surely other pumps do likewise. However, once you run the plumbing up to the tank, you want something nice to end the plumbing, like a return jet or something. However, I can’t find anything at the end, except the sea swirl, that caters to 1.25 plumbing. Reducing seems like a dumb solution. I don’t want to reduce at the end and defeat somewhat the purpose of the larger pipes. Does no one make 1.25 inch returns?!?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1.25 inch return?!?

- Thread starter KenRexford

- Start date

- Tagged users None

Well, I have a 1.25" adapter on my Sicce - and this connects to a 1.25" y-split that reduces down to two 3/4" diameters for the dual returns. I believe many pumps have the 1.25" adapter for this reason.

- Joined

- Jun 24, 2019

- Messages

- 4,895

- Reaction score

- 4,855

I go from 1.5 to a y that returns two 3/4”

If you take a 1.25 inner diameter pipe, the area of that circle is .390625 times Pi. If you take, instead, a 3/4 inch inner diameter pipe, the area of each circle is 0.140625 times Pi. Or, in simpler numbers, the 1.25 inch pipe is .4 times Pi; the two 3/4 inch pipes are .14 times Pi each. .14 plus .14 = .28. .28 plus .14 is .42. So, it seems that using two 3/4 inch outlets still massively reduces flow -- you would need three of them to be equivalent. Much worse with 1.5 inch pipes, BTW.

If the 1.25 split into two 1-inch outlets, you end up with .25 Pi plus .25 Pi, which is more, but more seems better than less. Is there a splitter from 1.25b to two 1-inch flares? Or, do you still end up with no real options there? I mean, I suppose a simple T into two 1-inch CPR returns might work.

It just seems tons easier of someone made a danged 1.25-inch return jet.

If the 1.25 split into two 1-inch outlets, you end up with .25 Pi plus .25 Pi, which is more, but more seems better than less. Is there a splitter from 1.25b to two 1-inch flares? Or, do you still end up with no real options there? I mean, I suppose a simple T into two 1-inch CPR returns might work.

It just seems tons easier of someone made a danged 1.25-inch return jet.

I go from 1.25 to a 1.25 T and then 1.25 reduced down to a 1” bulkhead on dual returns. Then for each return, I go to a 3/4 Y where each line then connects to 3/4 loc line which then splits into a Y in the tank. So I have 8 returns going into the tank. Plenty of flow and I have a basement sump.

Is anyone else seeing this as bizarre?

I mean, 1.25 seems fairly common. So, you could have a manufacturer (like friggin' Reef Octopus who makes the danged 1.25-inch return pumps) have a simple 1.25-inch return jet.

OR, you could have, "I run a 1.25-inch silicon tubing into a 1.25-inch pipe, up to the top of my tank, where I then have more plumbing parts than for the rest of my tank. I have the 1.25-inch split with a 1-inch T, then from each end of the 1-inch T it then splits into two 3/4-inch T's (4 total), which each have a 3/4-inch outlet into my tank. Unfortunately, that means that my screen top project required 328 right angles for all of the various openings, and unfortunately my tank is shaded by all of the pipes running into the backside of my tank, but the FLOW!"

I really don't want the Flying Spaghetti Monster of pipes to allow me to effectively use a simple 1.25-inch pipe from my return.

I mean, 1.25 seems fairly common. So, you could have a manufacturer (like friggin' Reef Octopus who makes the danged 1.25-inch return pumps) have a simple 1.25-inch return jet.

OR, you could have, "I run a 1.25-inch silicon tubing into a 1.25-inch pipe, up to the top of my tank, where I then have more plumbing parts than for the rest of my tank. I have the 1.25-inch split with a 1-inch T, then from each end of the 1-inch T it then splits into two 3/4-inch T's (4 total), which each have a 3/4-inch outlet into my tank. Unfortunately, that means that my screen top project required 328 right angles for all of the various openings, and unfortunately my tank is shaded by all of the pipes running into the backside of my tank, but the FLOW!"

I really don't want the Flying Spaghetti Monster of pipes to allow me to effectively use a simple 1.25-inch pipe from my return.

No. Having a large adapter on the pump ensures the maximum throughput for the pump as opposed to restricting it at the source.

From what I recall the maximum flow through a 3/4” pipe is something like 1400 Gph, so a pair of 3/4” outlets would still be in excess of 2800 Gph - which would quite frankly be a frightening amount of turnover.

Many reefers also have a manifold tied into their return, so there’s that to consider as well.

From what I recall the maximum flow through a 3/4” pipe is something like 1400 Gph, so a pair of 3/4” outlets would still be in excess of 2800 Gph - which would quite frankly be a frightening amount of turnover.

Many reefers also have a manifold tied into their return, so there’s that to consider as well.

- Joined

- Jun 24, 2019

- Messages

- 4,895

- Reaction score

- 4,855

If you take a 1.25 inner diameter pipe, the area of that circle is .390625 times Pi. If you take, instead, a 3/4 inch inner diameter pipe, the area of each circle is 0.140625 times Pi. Or, in simpler numbers, the 1.25 inch pipe is .4 times Pi; the two 3/4 inch pipes are .14 times Pi each. .14 plus .14 = .28. .28 plus .14 is .42. So, it seems that using two 3/4 inch outlets still massively reduces flow -- you would need three of them to be equivalent. Much worse with 1.5 inch pipes, BTW.

If the 1.25 split into two 1-inch outlets, you end up with .25 Pi plus .25 Pi, which is more, but more seems better than less. Is there a splitter from 1.25b to two 1-inch flares? Or, do you still end up with no real options there? I mean, I suppose a simple T into two 1-inch CPR returns might work.

It just seems tons easier of someone made a danged 1.25-inch return jet.

Who cares? Do you really need 2800+gph return flow? I only turn my tank over 2,5x per hour

But isn't the issue one of how much flow the pump can produce, not how much the pipe can withstand before bursting? I mean, I have always heard that a return pump with about 1700 GPH capacity (from the start) loses real-life capacity as the outlet rises, as angles are used, and as the pipe size diminishes. Sure, two 3/4-inch pipes might be able to "handle" 2800 gph, but won't the necessary T-split and then smaller pipes cause some resistance to flow and thereby reduce the capacity of the pump?No. Having a large adapter on the pump ensures the maximum throughput for the pump as opposed to restricting it at the source.

From what I recall the maximum flow through a 3/4” pipe is something like 1400 Gph, so a pair of 3/4” outlets would still be in excess of 2800 Gph - which would quite frankly be a frightening amount of turnover.

Many reefers also have a manifold tied into their return, so there’s that to consider as well.

Here's what I have seen. I have a Varios 6 pump running into the tank. I have a CPR cs-202 HOB overflow set up Herbie style. The CPR cs-202 handles 1500GPH total, so with a Herbie style it's 750 plus a smidge. However, my 1720 gph pump doesn't fill the tank fast enough for me. I have it at 100% but still have to dial back the overflow quite a bit to create a good siphon. That seems insane to me. So, I'm thinking that with a 1.25-inch pipe and return jet I should be able to run the Varios at something less than 100% with my controller and only barely have the valve dialed for extreme fine-tuning.Who cares? Do you really need 2800+gph return flow? I only turn my tank over 2,5x per hour

Yes, which is also my point: because vertical and horizontal length as well as 45/90-degree turns will reduce flow, you want to start with as high a number as possible at the outset.But isn't the issue one of how much flow the pump can produce, not how much the pipe can withstand before bursting? I mean, I have always heard that a return pump with about 1700 GPH capacity (from the start) loses real-life capacity as the outlet rises, as angles are used, and as the pipe size diminishes. Sure, two 3/4-inch pipes might be able to "handle" 2800 gph, but won't the necessary T-split and then smaller pipes cause some resistance to flow and thereby reduce the capacity of the pump?

In any event, I agree with @piranhaman00 - I’m not sure why this matters.

See my response above. My 1720 GPH pump with 1-inch tubing is not providing enough flow, even at 100%, for one-half of my 1500 GPH Cs-202 herbie style setup without excessive use of the valve closure. I believe that 1.25-inch plumbing would work better, but then I'm stuck with insane complexity at the top of the tank and likely more reduction events. I want a straight flow into the tank that is at maximum efficiency to enable the majority of the dial-back to be done by my controller, nut by the restrictive valve, because restricting the valve means restricting the turnover.Yes, which is also my point: because vertical and horizontal length as well as 45/90-degree turns will reduce flow, you want to start with as high a number as possible at the outset.

In any event, I agree with @piranhaman00 - I’m not sure why this matters.

It's also somewhat possible that my 1-inch tubing, which is about 18 years old, has some restricted flow internally, but it seems to be relatively clear for 18 years of use. I didn't want to replace it unless there is a massive benefit for fears of tin leaching. Y'all have me paranoid. LOL

What’s the size of your tank?

125 gallon, 6' by 18" typical.What’s the size of your tank?

I also have a 6’ tank (160-gallon). I have a Sicce SDC 9.0 (2500 Gph) that connects to a 1.25” y-adapter that diverges into two 3/4” return outlets. It runs @45% and I get somewhere between 550-675 Gph (which is about 3.5-4x turnover).125 gallon, 6' by 18" typical.

I know another reefer with the same tank who upgraded the returns to 1” with an Abyzz A100 which allowed him to get around 850 Gph @50%.

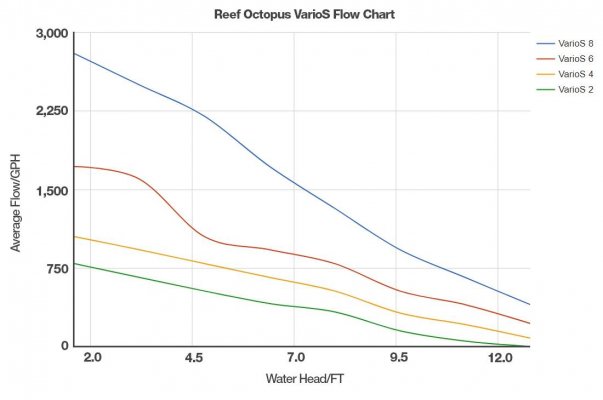

Varios 6 is 1720gph at 0 head. Once you run up to your tank say 5 feet up, that is 5 feet of head. Pump curve shows that max flow at 5 feet of head is roughly 1000-1100 gph.See my response above. My 1720 GPH pump with 1-inch tubing is not providing enough flow, even at 100%, for one-half of my 1500 GPH Cs-202 herbie style setup without excessive use of the valve closure. I believe that 1.25-inch plumbing would work better, but then I'm stuck with insane complexity at the top of the tank and likely more reduction events. I want a straight flow into the tank that is at maximum efficiency to enable the majority of the dial-back to be done by my controller, nut by the restrictive valve, because restricting the valve means restricting the turnover.

Pipe diameter is a minor loss. Changing it will not increase output that much most likely. If you are 1000ish gph to your tank that is the best that pump is going to do.

Who cares? Do you really need 2800+gph return flow? I only turn my tank over 2,5x per hour

You're getting nowhere near advertised values after head & friction losses. That pump will probably do 800-900 GPH to the tank.

Here is a plumbing head loss calculator. If you know your current flow rate you can use that and see what your head loss reduction would be by increasing plumbing size.

pentairaes.com

pentairaes.com

Varios 6 pump curve is fairly flat from 4.5' of head to 7' of head. So unless your return output is less than 4.5' above your pump output, reducing plumbing minor losses will not give more flow.

Pump Calculator | Pentair AES

Pentair is dedicated to excellence in all aspects of our business. Whether you need system design, technical service or unrivaled equipment-you can count on us.

Varios 6 pump curve is fairly flat from 4.5' of head to 7' of head. So unless your return output is less than 4.5' above your pump output, reducing plumbing minor losses will not give more flow.

Attachments

Similar threads

- Replies

- 19

- Views

- 264

- Replies

- 3

- Views

- 123