Welcome to our build thread! As with about everything in life, my lovely wife @LeeLoo Lola and I will be sharing this build thread as this is our tank and our shared hobby. We've been reefing together for more than 20 years and this thread will chronicle our latest project.

Dimensionally, this is my absolute favorite tank - ever. It's an Innovative Marine EXT170 - 59x30x22. I would have loved the EXT200 (+1ft longer), unfortunately the designated wall will only support the 5ft tank. We have a ~2 year old Innovative Marine EXT75 - it's too small. Great tank, nice quality. It's given us a run for our money too. It was our first and LAST dry rock / dry sand start.

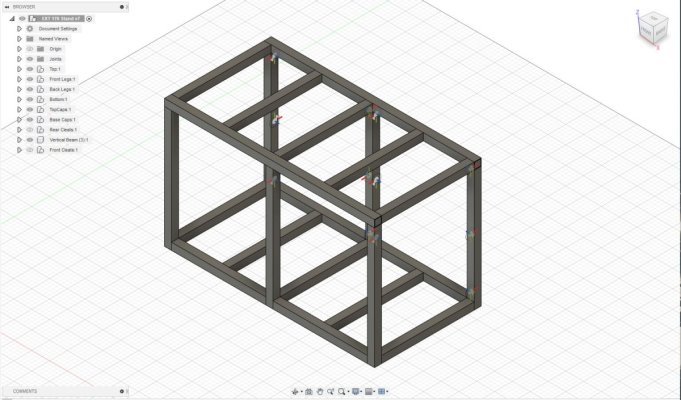

Although I really like the quality of the Innovative tank - I am NOT a fan of the APS stand - at all. It really surprises me that this seems to be such an unpopular opinion too. So with that said, my first project in preparation for the tank was to have a custom steel stand built.

Plans for the new 170:

(Strike-through items are deviations from the original plan. Bold are actuals)

LPS/Softie dominant - fish heavy (we love fish)

(3) XR15 G6 Pros

(2) 48" Blade Glows

40B Sump

60B Sump

Red Sea Reefmat 1200 or 500 (up for discussion)

25w AquaUV sterilizer (existing from my old 150 and already has a new bulb)

(2) Cor20's for Return (Currently have 1 on existing tank)

(1) Cor15 Fuge Pump (Currently feeding the external fuge)

Ecotech Vectra L2 Return Pump

(2) MP40mQD (From existing tank)

(2) Tunze 6095 (bought new with 15% off)

(1) Tunze 6208 Comline Wavebox

(1) Tunze 6105 Eco

Tunze 3155 ATO (From existing tank)

20G External fuge with Kessil H160 Tuna Flora

In-sump fuge with Kessil H160 Tuna Flora

SRO XP2000 Skimmer - From my old 150G. Will replace the AC Pump with a new VarioS-4s

SRO XP2000 Skimmer with a VarioS-4s pump

100lbs Tampa Bay Saltwater Rock + Mature Rock from the 75g

170lbs Tampa Bay Saltwater Sand

Lots of decisions to make and can't wait to get some others opinions. I'm the gear guy. Chrissy is the coral / fish picker / feeder / money spender.

Current Fish list:

(1) Biota Yellow Tang

(1) White tail Bristletooth Tang

(1) Tomini Tang

(1) Magnificent Foxface

(1) Coral Beauty

(1) Flame Angel

(2) Watanabei Angels

(2) Semi-Storm Clowns

(1) Firefish

(1) Royal Gramma

(1) Starry Blenny

(1) Diamond Goby

(4) Lyretail Anthias

(2) Pajama Cardinals

(1) Bangaii Cardnial

More updates to follow!

The thread title wasn't my pick but I'm guessing I'm the clown in this scenario.

Timeline:

5/26 - APS Stand Review and Steel Stand Plans

7/1 - Tank moved to office

7/2 - Removed restrictions from the returns

7/3 - Some wood panels made for the stand

7/9 - Leak test and Plumbing

7/25 - Mounting APEX Modules on DIN Rail

8/11 - I've got crabs

Jeff & Chrissy

Dimensionally, this is my absolute favorite tank - ever. It's an Innovative Marine EXT170 - 59x30x22. I would have loved the EXT200 (+1ft longer), unfortunately the designated wall will only support the 5ft tank. We have a ~2 year old Innovative Marine EXT75 - it's too small. Great tank, nice quality. It's given us a run for our money too. It was our first and LAST dry rock / dry sand start.

Although I really like the quality of the Innovative tank - I am NOT a fan of the APS stand - at all. It really surprises me that this seems to be such an unpopular opinion too. So with that said, my first project in preparation for the tank was to have a custom steel stand built.

Plans for the new 170:

(Strike-through items are deviations from the original plan. Bold are actuals)

LPS/Softie dominant - fish heavy (we love fish)

(3) XR15 G6 Pros

(2) 48" Blade Glows

60B Sump

Red Sea Reefmat 1200

25w AquaUV sterilizer (existing from my old 150 and already has a new bulb)

(1) Cor15 Fuge Pump (Currently feeding the external fuge)

Ecotech Vectra L2 Return Pump

(2) Tunze 6095 (bought new with 15% off)

(1) Tunze 6208 Comline Wavebox

(1) Tunze 6105 Eco

Tunze 3155 ATO (From existing tank)

In-sump fuge with Kessil H160 Tuna Flora

SRO XP2000 Skimmer with a VarioS-4s pump

100lbs Tampa Bay Saltwater Rock + Mature Rock from the 75g

170lbs Tampa Bay Saltwater Sand

Lots of decisions to make and can't wait to get some others opinions. I'm the gear guy. Chrissy is the coral / fish picker / feeder / money spender.

Current Fish list:

(1) Biota Yellow Tang

(1) White tail Bristletooth Tang

(1) Tomini Tang

(1) Magnificent Foxface

(1) Coral Beauty

(1) Flame Angel

(2) Watanabei Angels

(2) Semi-Storm Clowns

(1) Firefish

(1) Royal Gramma

(1) Starry Blenny

(1) Diamond Goby

(4) Lyretail Anthias

(2) Pajama Cardinals

(1) Bangaii Cardnial

More updates to follow!

The thread title wasn't my pick but I'm guessing I'm the clown in this scenario.

Timeline:

5/26 - APS Stand Review and Steel Stand Plans

7/1 - Tank moved to office

7/2 - Removed restrictions from the returns

7/3 - Some wood panels made for the stand

7/9 - Leak test and Plumbing

7/25 - Mounting APEX Modules on DIN Rail

8/11 - I've got crabs

Jeff & Chrissy

Last edited: