Finally replaced the very aging and somewhat tempermental Qidi Tech 1 I was using for one-off things with a Bambu X1C. I realize my comparison point is a pretty old printer (Flash Forge clone), but this thing is able to knock out parts like nothing else with basically no fuss.

Outside of another project I was working on, I'm experimenting with a skimmer neck cleaner. Instead of a neck cleaner which just brushes off the gunk, what if it made an attempt at raising it slowly into the cup?

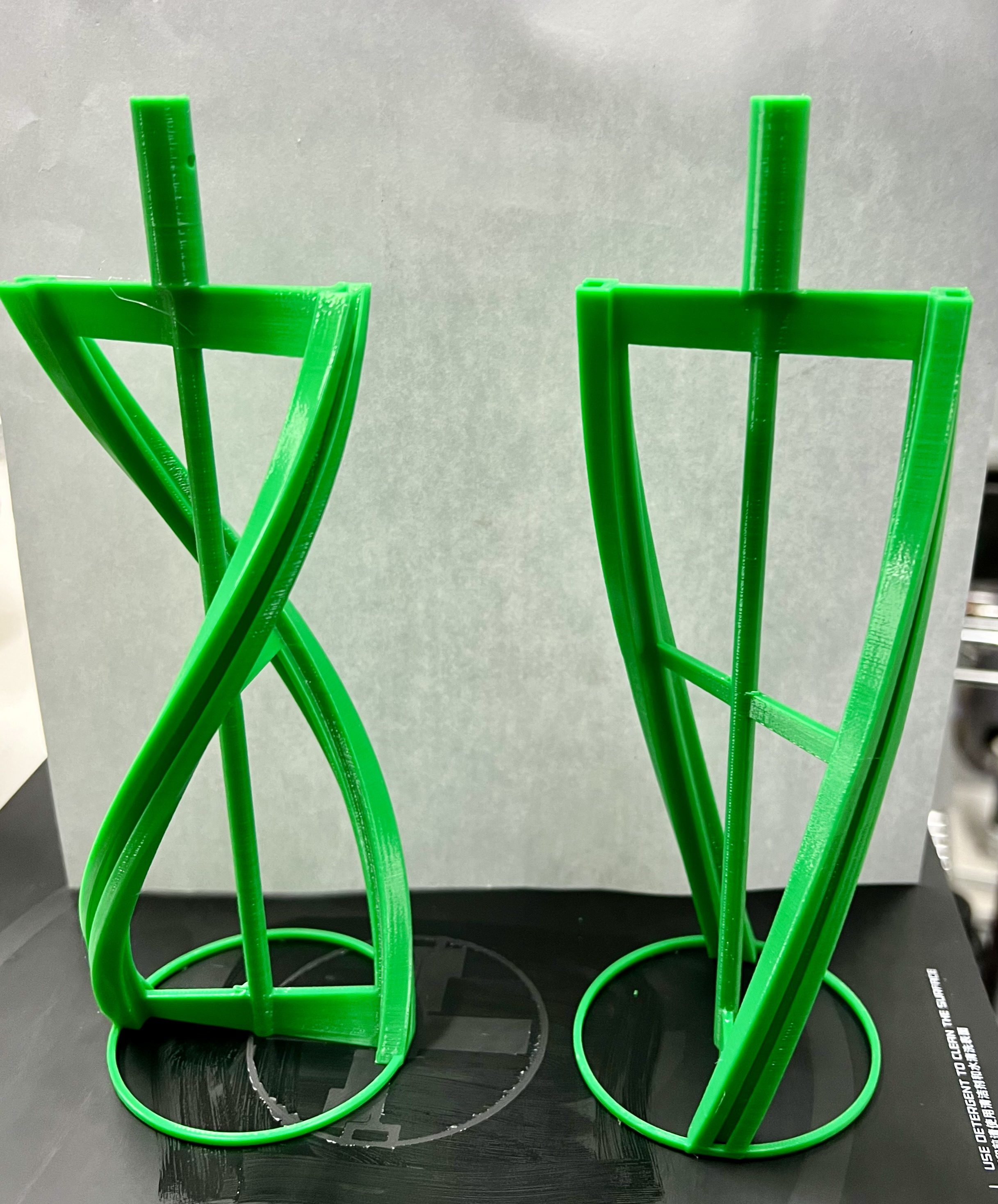

Here is a prototype for the wiper assembly. It uses two silicone wiper blade inserts ($10 on Amazon, come in fun colors!) as the actual wiper mechanism.

Early fit check of a half-height prototype. I didn't cut and insert the full length wiper blades yet, just some small scraps to check clearance.

Wiper blade fit check:

The prototypes are all in PLA so far (not for actual use). I also want to play with the angle of the helix (revolutions over height). The model is fully parameterized for different skimmer dimensions.

Outside of another project I was working on, I'm experimenting with a skimmer neck cleaner. Instead of a neck cleaner which just brushes off the gunk, what if it made an attempt at raising it slowly into the cup?

Here is a prototype for the wiper assembly. It uses two silicone wiper blade inserts ($10 on Amazon, come in fun colors!) as the actual wiper mechanism.

Early fit check of a half-height prototype. I didn't cut and insert the full length wiper blades yet, just some small scraps to check clearance.

Wiper blade fit check:

The prototypes are all in PLA so far (not for actual use). I also want to play with the angle of the helix (revolutions over height). The model is fully parameterized for different skimmer dimensions.

Last edited: