- Joined

- Jul 20, 2018

- Messages

- 895

- Reaction score

- 1,513

I was able to make a water tight box using solvent and cheap PVC board from home depot - working my way up to making a big sump. An 8 x 4 sheet is about 60 dollars. 1/2 inch thick. Very cheap compared to acrylic, very easy to join with solvent, lighter, and easier to acquire. It's also flexible (not good) and I am not sure how strong the solvent joined joints are compared to acrylic. I think I can overcome the flexibility with lots of joints and a euro-brace type of top.

Ultimately, I am looking to build something about 6 feet long, 18 inches high, and 24 inches wide. There will be baffles and other supports about every 18 inches as well as bracing top and bottom. Making a mid sized prototype this weekend.

Question: What would happen if I made a sump using solvent, and then re-enforced the critical joints using hot gas welding? Would the remnants of the solvent bond somehow interfere with the hot gas welded joint? I can get a hot gas welder and PVC sticks for about 160 dollars from Amazon. It also might be easier to just chamfer the edges and JUST weld it. Most of the opinions I have found suggested doing something more than just solvent joining the edges. I could also cut DADOs - but the precision needed to get it right would lead to swearing and wastage of material - in my hands.

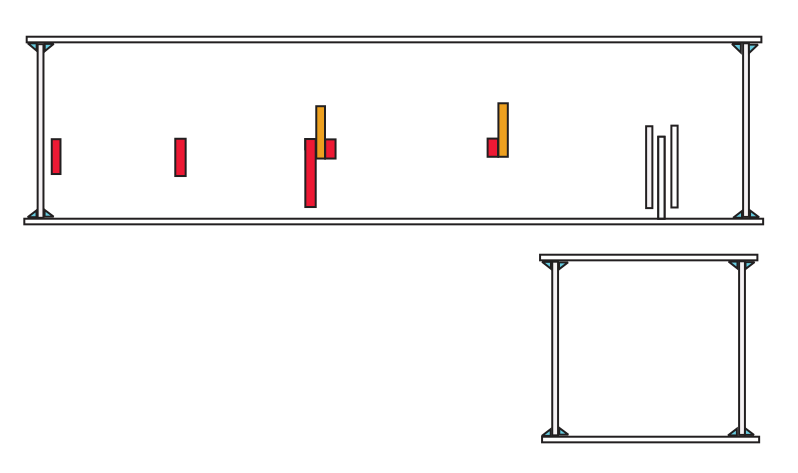

The schematic shows the white 1/2 inch PVC, red and orange are baffles and vertical shelf supports, and the blue triangles would be room for hot weld beads. I could weld the vertical joints in the same way - just not shown here.

Any other tips for joining PVC panels are also welcome?

Ultimately, I am looking to build something about 6 feet long, 18 inches high, and 24 inches wide. There will be baffles and other supports about every 18 inches as well as bracing top and bottom. Making a mid sized prototype this weekend.

Question: What would happen if I made a sump using solvent, and then re-enforced the critical joints using hot gas welding? Would the remnants of the solvent bond somehow interfere with the hot gas welded joint? I can get a hot gas welder and PVC sticks for about 160 dollars from Amazon. It also might be easier to just chamfer the edges and JUST weld it. Most of the opinions I have found suggested doing something more than just solvent joining the edges. I could also cut DADOs - but the precision needed to get it right would lead to swearing and wastage of material - in my hands.

The schematic shows the white 1/2 inch PVC, red and orange are baffles and vertical shelf supports, and the blue triangles would be room for hot weld beads. I could weld the vertical joints in the same way - just not shown here.

Any other tips for joining PVC panels are also welcome?