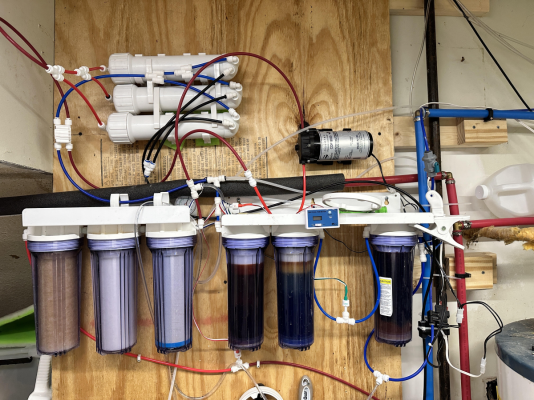

What are the pros and cons of running membranes in series versus parallel. My BRS 150 gpd pro “water saver” version looks to be in series allowing the same water to go through 2 rejections. Would I get better overall rejection running in parallel? I am more interested in “DI saver” over “water saver”.

If in parallel, then I assume I would need to change out the restrictor to one that is 2x current?

If in parallel, then I assume I would need to change out the restrictor to one that is 2x current?