kschweer

Moderator

View BadgesStaff member

Super Moderator

Partner Member 2024

Excellence Award

NJRC Member

Hospitality Award

My Tank Thread

My Aquarium Showcase

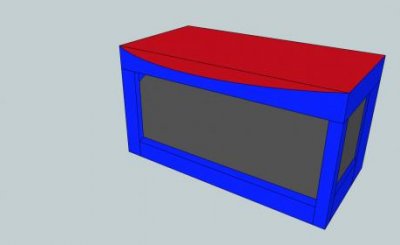

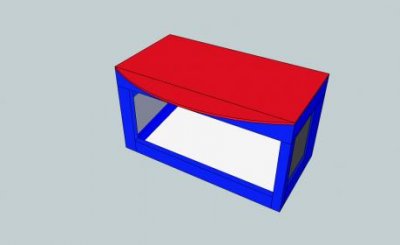

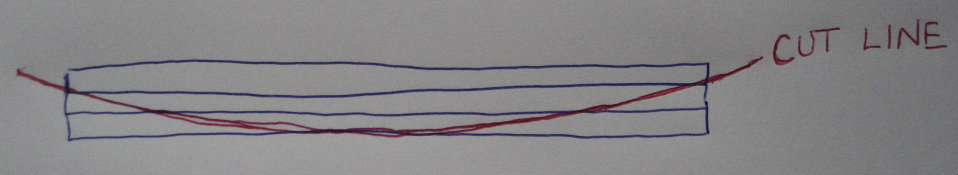

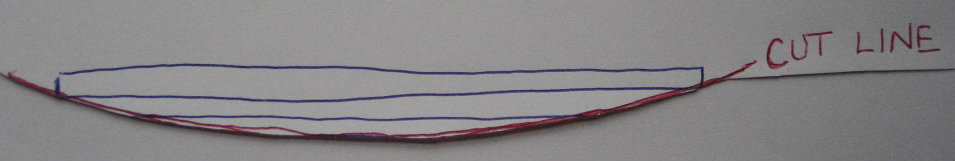

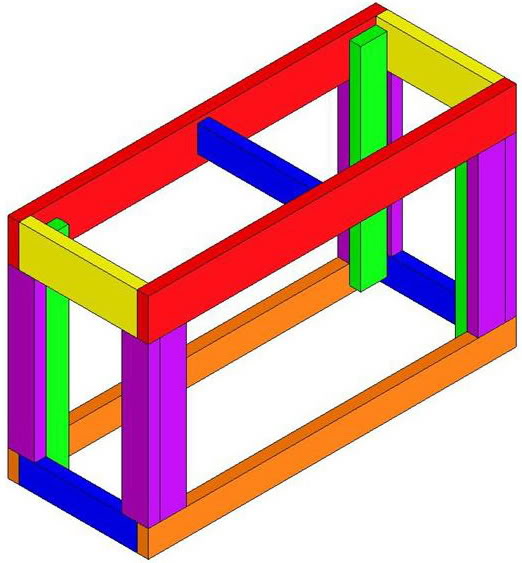

Hey guys, I am interested in building a new stand for my 46 bowfront. Has anyone here ever made a stand for a bowfront? I have seen some people make a rectangle stand for them but I would much rather have it curved. I want to have an open front like I have now (see picture). Any input would be awesome. I'm goin to try and draw up some plans soon but I'm not much of an artist so help there would be great as well. Thanks guys

Last edited: