- Joined

- Dec 18, 2015

- Messages

- 558

- Reaction score

- 191

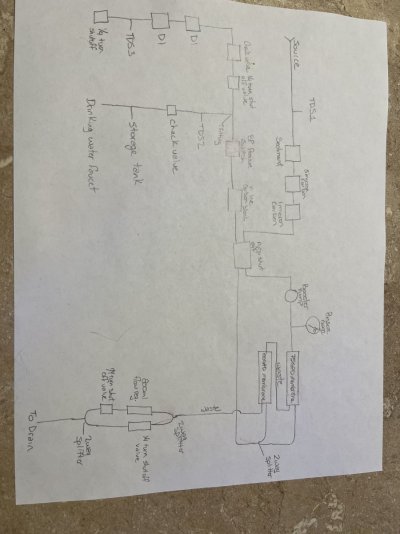

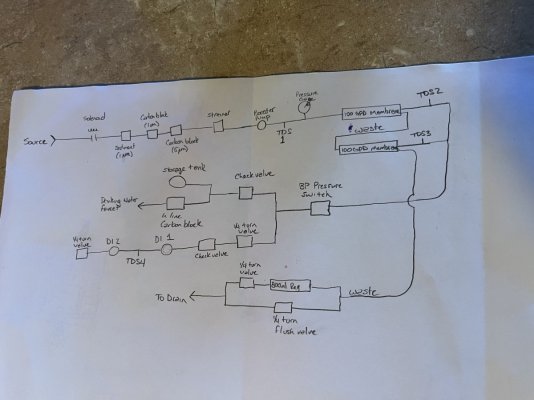

Good day all. We’ve moved to a new house and since moving my setup to the new house, the booster pump only kicks on when I’m making DI water. When the system kicks on to refill the drinking water storage tank, the booster pump remains off. This was not the case at the old house, and I’ve been racking my brain to figure out why. Attached is a photo of the system and a 1 line diagram of the plumbing.

The auto shut off valve and flow regulator were replaced during the intallation in the new house.

It’s not the end of the world because the water pressure here is 60psi without the booster, so I guess technically I don’t even need the pump. I sure do like not understanding though.

The auto shut off valve and flow regulator were replaced during the intallation in the new house.

It’s not the end of the world because the water pressure here is 60psi without the booster, so I guess technically I don’t even need the pump. I sure do like not understanding though.