The second batch of 50 blue LEDs arrived today. I soldered in the 40 new LEDs and applied the Arctic Silver Ceramique 2 thermal compound on the finned aluminum. I did this by first distributing the compound over the plate.

By the way, one $7 tube (25g), of this compound does the two plates in a fixture.

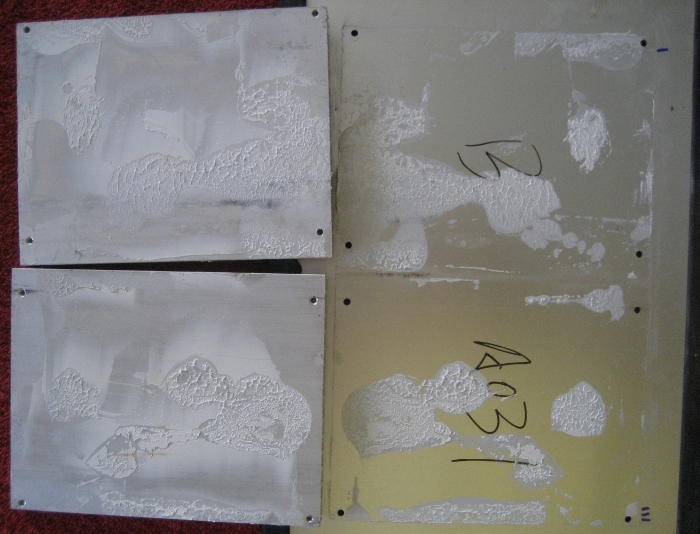

I then spread this compound around like icing a cake. Now this is what the proper amount of compound looks like on one of these plates.

So I'm now back to where I started......two Apollo's working properly over my tank! Wooo Hooo!

I still have another eBay China fixture coming in some time this week and I now want to pull apart the TauTronics that I was using while I fixed the Apollos and see what's wrong with that. The blues on that fixture went out 3-4 days ago and I'm thinking its a driver. It never ends!

By the way, one $7 tube (25g), of this compound does the two plates in a fixture.

I then spread this compound around like icing a cake. Now this is what the proper amount of compound looks like on one of these plates.

So I'm now back to where I started......two Apollo's working properly over my tank! Wooo Hooo!

I still have another eBay China fixture coming in some time this week and I now want to pull apart the TauTronics that I was using while I fixed the Apollos and see what's wrong with that. The blues on that fixture went out 3-4 days ago and I'm thinking its a driver. It never ends!