Hello all!

I'm experiencing cavitation on the Sicce SDC 9.0 pump running my closed loop even if I dial it down to minimum "throttle" on the controller. No bubbles in my flow meter downstream, just a popping/whirring/whooshing sound at the pump inlet. It's honestly not a surprise given my intake setup and the extremely-cramped space in the stand under my 52gal tank, so I'm working on a solution and need advice about a specific element of the design...

First, an overview of the current inlet pipe causing the problems... Water comes over the side of the tank through two 3/4" siphon lines and through a large Y to combine into a 1.5" pipe before passing through three 45 elbows and a series of reducers to match the Sicce's 1" inlet. The dual 3/4" pipes were a consequence of the tank layout (preferring a central intake despite the presence of a center brace, plus also wanting smaller pipes in-tank) and the idea to combine into a 1.5" master drain was an attempt to offset the negative flow effects of the elbows and minimize resistance.

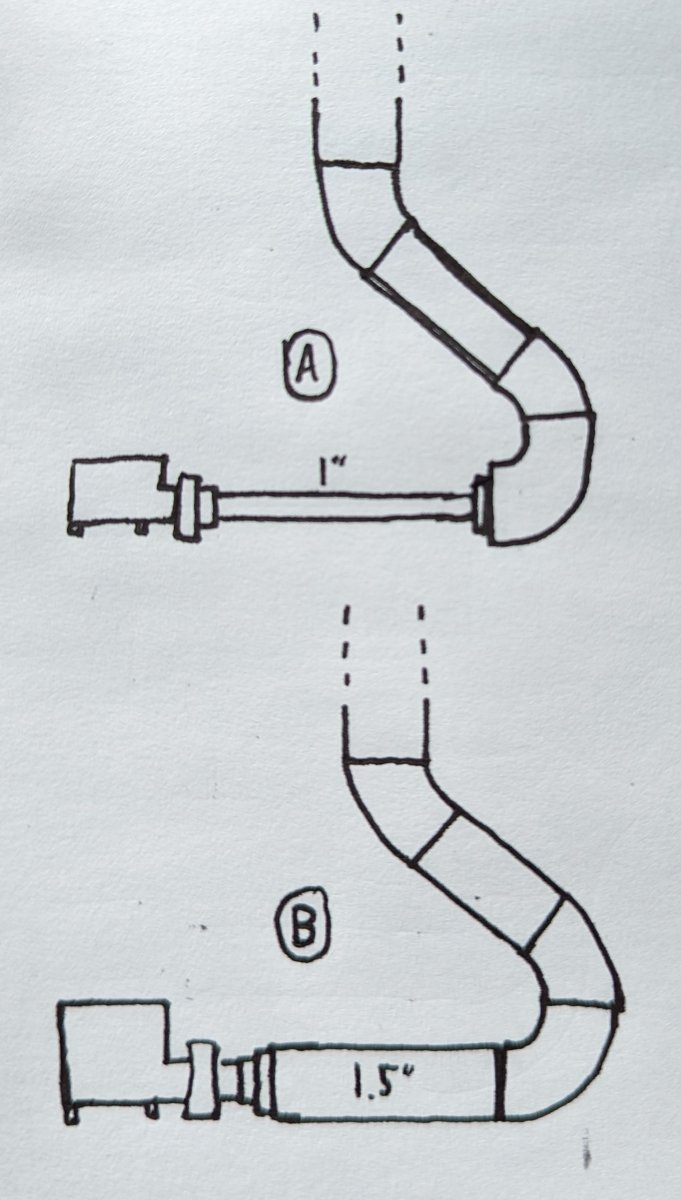

This obviously hasn't worked, so now I'm considering a new strategy that's compatible with the "10D" rule of running a straight section of pipe 10x the pump's input diameter before any elbows. In my case that'd be 10", extending all the way to the house wall behind the tank, and would require more elbows (which is, of course, undesirable and what I was originally trying to avoid) so the pipe could double-back on itself. Here's my question: where do I put the reducer bushings to bring the pipe down to 1"? (please forgive the quality of the sketch)

Option "A" would potentially have the advantage of smoother flow to the pump because the only restriction between the 10" run of 1" pipe and the pump would be a 1" MPT adapter, but would come with more overall flow resistance.

- on the other hand -

Option "B" would have less flow resistance by keeping the much larger 1.5" diameter for the 10" straight section, but would require multiple step-down reducers at the pump's mouth (like in the pictures above) or one big step in the form of a 1.5" slip to 1" MPT fitting (an uncommon part I'd have to order from FlexPVC).

What do you think? If it helps, my goal isn't to run this pump full-out: it's a replacement for a much noisier Iwaki pushing water through two Nu-Clear canisters and other in-line accessories (UV, heater, purigen, etc, all on valved bypass lines) and I'll likely want to run it at about 50% throttle. Thanks!

I'm experiencing cavitation on the Sicce SDC 9.0 pump running my closed loop even if I dial it down to minimum "throttle" on the controller. No bubbles in my flow meter downstream, just a popping/whirring/whooshing sound at the pump inlet. It's honestly not a surprise given my intake setup and the extremely-cramped space in the stand under my 52gal tank, so I'm working on a solution and need advice about a specific element of the design...

First, an overview of the current inlet pipe causing the problems... Water comes over the side of the tank through two 3/4" siphon lines and through a large Y to combine into a 1.5" pipe before passing through three 45 elbows and a series of reducers to match the Sicce's 1" inlet. The dual 3/4" pipes were a consequence of the tank layout (preferring a central intake despite the presence of a center brace, plus also wanting smaller pipes in-tank) and the idea to combine into a 1.5" master drain was an attempt to offset the negative flow effects of the elbows and minimize resistance.

This obviously hasn't worked, so now I'm considering a new strategy that's compatible with the "10D" rule of running a straight section of pipe 10x the pump's input diameter before any elbows. In my case that'd be 10", extending all the way to the house wall behind the tank, and would require more elbows (which is, of course, undesirable and what I was originally trying to avoid) so the pipe could double-back on itself. Here's my question: where do I put the reducer bushings to bring the pipe down to 1"? (please forgive the quality of the sketch)

Option "A" would potentially have the advantage of smoother flow to the pump because the only restriction between the 10" run of 1" pipe and the pump would be a 1" MPT adapter, but would come with more overall flow resistance.

- on the other hand -

Option "B" would have less flow resistance by keeping the much larger 1.5" diameter for the 10" straight section, but would require multiple step-down reducers at the pump's mouth (like in the pictures above) or one big step in the form of a 1.5" slip to 1" MPT fitting (an uncommon part I'd have to order from FlexPVC).

What do you think? If it helps, my goal isn't to run this pump full-out: it's a replacement for a much noisier Iwaki pushing water through two Nu-Clear canisters and other in-line accessories (UV, heater, purigen, etc, all on valved bypass lines) and I'll likely want to run it at about 50% throttle. Thanks!