In the process of building another tank setup, I picked up three used 1.1 ml BRS dosing pumps. One of the pumps did not come with the mounting bracket. Now I know I can purchase the bracket alone from BRS for $7.99, but why buy it when making it will be a fun little DIY project.

Here’s the BRS bracket I’m talking about:

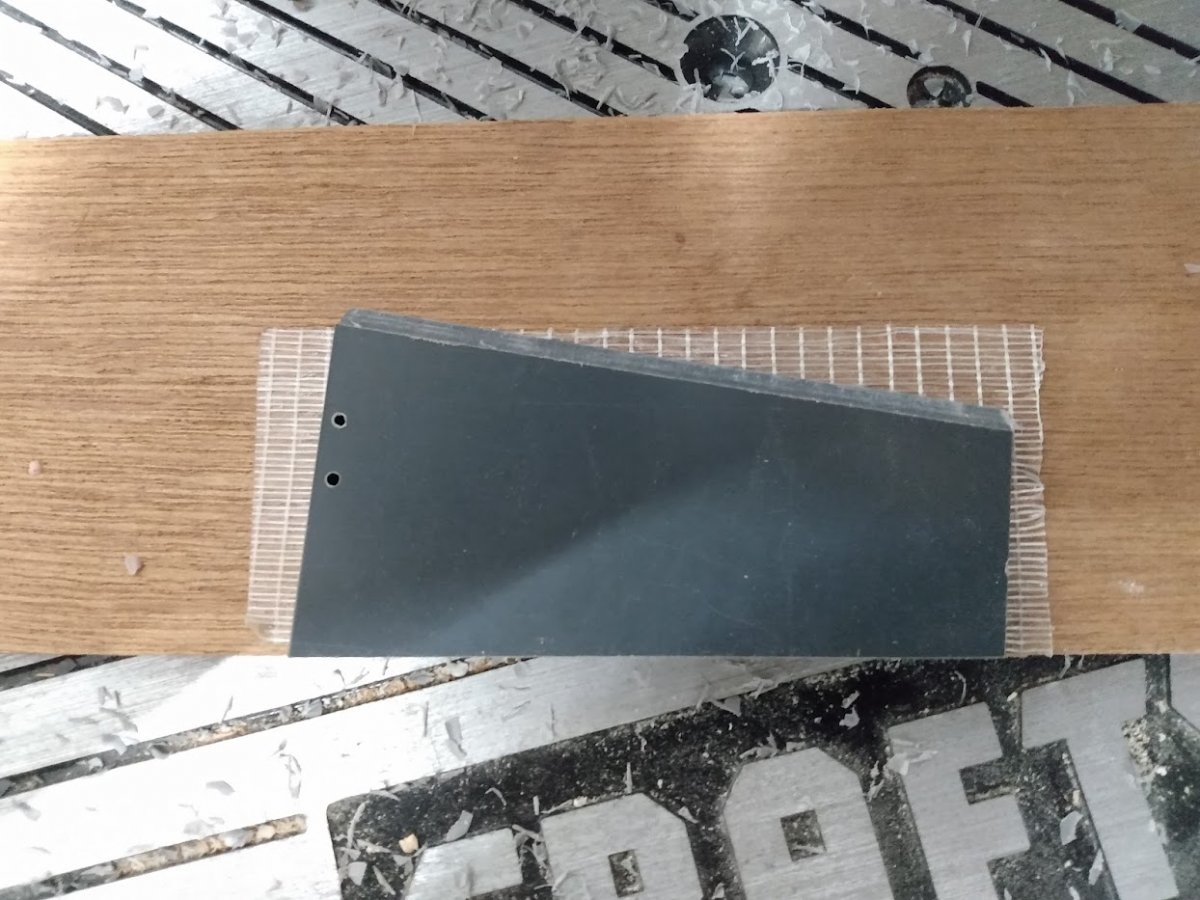

First thing I did was determine the angle of the bracket was 5 degrees, and I found a piece of scrap plastic and cut it at that angle. Originally I thought this was acrylic, but it cut too easily, so I’m guessing it’s vinyl…..but this shouldn’t be a problem.

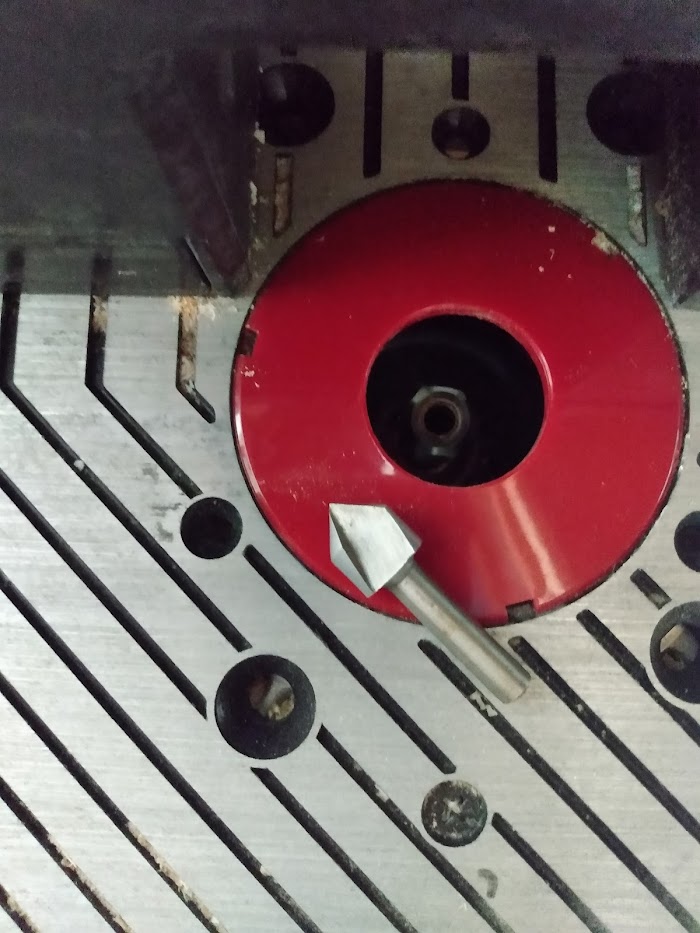

This angled piece has angled sides to lock into the back of the pump. This was found to be a 45, so I’d try using a router bit to cut this chamfered.

To stabilize this small piece of plastic, and make routing safer, it was attached to a piece of scrap wood using two sided carpet tape.

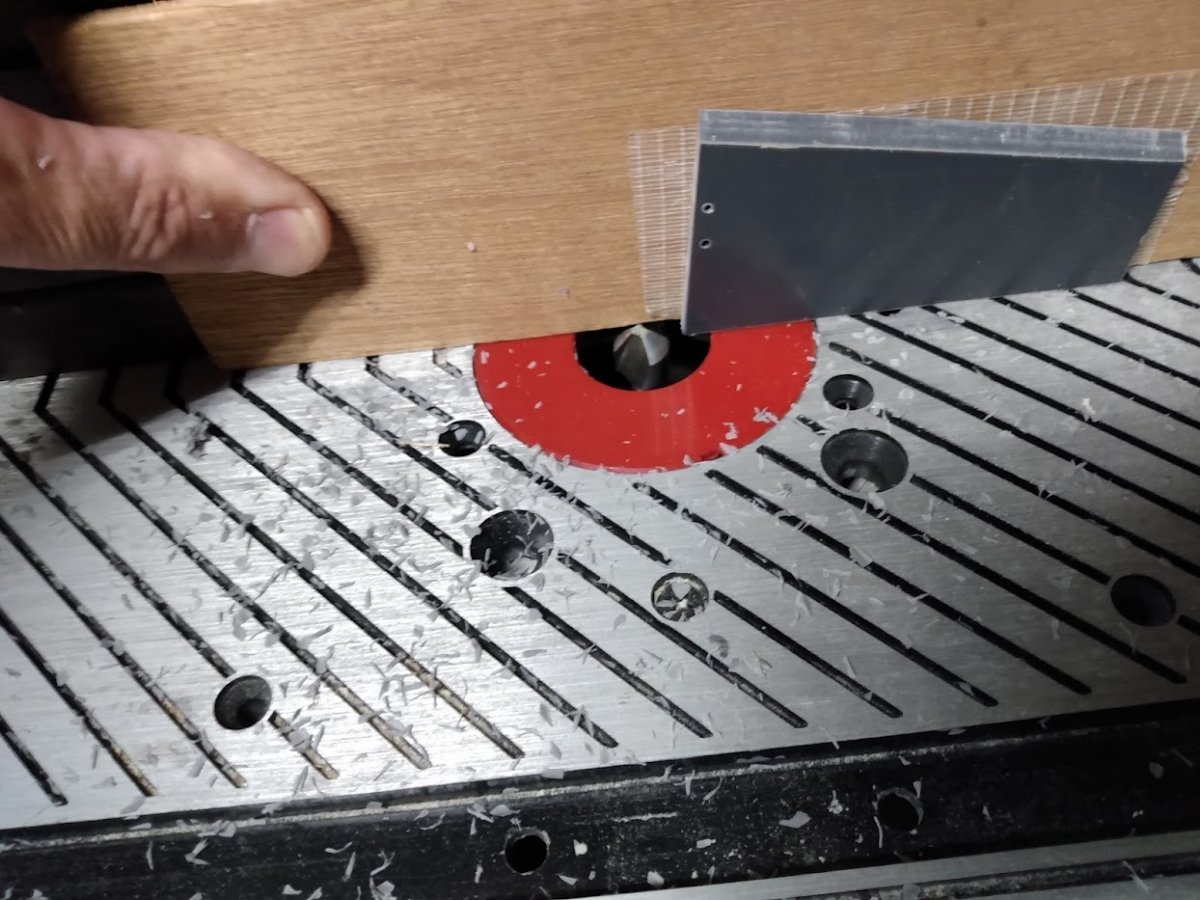

This was slowly adjusted to the bit until just the right amount of material was removed.

Holes were drilled and tapered to accept flathead screws….and here it is side-by-side to the BRS bracket. Now this DIY one does not lock into the pump like the original, but that shouldn’t be a problem mounting the pump vertically.

Here’s the BRS bracket I’m talking about:

First thing I did was determine the angle of the bracket was 5 degrees, and I found a piece of scrap plastic and cut it at that angle. Originally I thought this was acrylic, but it cut too easily, so I’m guessing it’s vinyl…..but this shouldn’t be a problem.

This angled piece has angled sides to lock into the back of the pump. This was found to be a 45, so I’d try using a router bit to cut this chamfered.

To stabilize this small piece of plastic, and make routing safer, it was attached to a piece of scrap wood using two sided carpet tape.

This was slowly adjusted to the bit until just the right amount of material was removed.

Holes were drilled and tapered to accept flathead screws….and here it is side-by-side to the BRS bracket. Now this DIY one does not lock into the pump like the original, but that shouldn’t be a problem mounting the pump vertically.