- Joined

- Apr 12, 2018

- Messages

- 52

- Reaction score

- 133

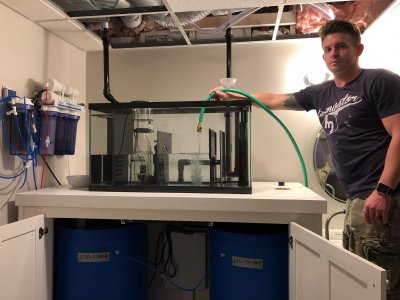

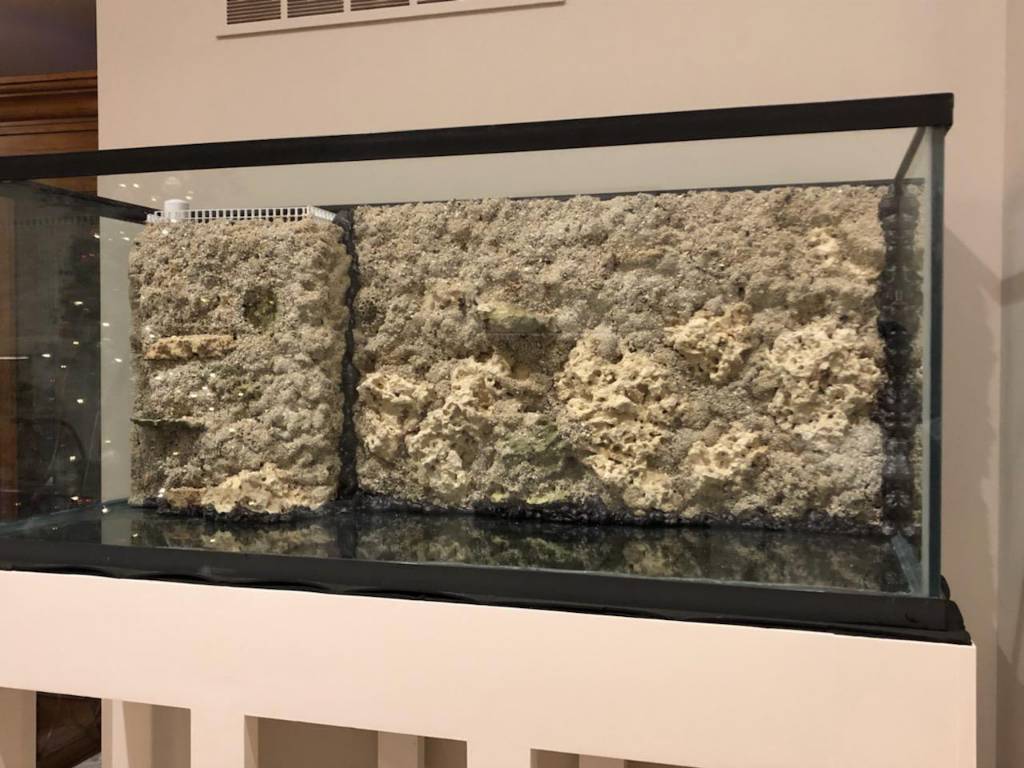

I've been meaning to start this build thread for awhile, but I wanted to get at least halfway done before I created the thread so I could make it somewhat interesting. The title implies a much larger tank than we have, but it is 150 gallon replacing our current 29 gallon biocube. We bought the new tank used and actually got a bigger one than the 120 gallon we originally planned on getting. We wanted to make the tank maintenance as streamlined as possible so I went outside the norm a bit on some of the things for this tank and I will try to explain them as I go along. I am an engineer, so I get kind of giddy doing stuff like this and being able to think outside the box. All comments/critiques are welcome, just make it constructive (i.e. if you aren't a fan of something, you can say that, but also provide what changes you would make to the particular design so others and possibly I can benefit). Enjoy!

I will follow up this first post with pictures and progress, but I wanted to make this first post a living post that I will update as needed.

Tank:

150gal custom tank with starphire glass on all sides

Single corner overflow

60" x 24" x 24"

Sump:

Repurposed 40 gallon tank

Jax.Racks sump baffle kit

Reef Octopus 110INT skimmer

DIY King overflow

RODI:

BRS 5 stage (we have Chloramiine treated water)

Return Pump:

Reeflo Yellowtail

Heaters:

800w Finnex Titanium

JBJ Heater controller

Lights:

3 x Ecotech Radion XR30w Gen4

Powerheads:

TBD

Aquarium monitoring:

Neptune Apex..?

I will follow up this first post with pictures and progress, but I wanted to make this first post a living post that I will update as needed.

Tank:

150gal custom tank with starphire glass on all sides

Single corner overflow

60" x 24" x 24"

Sump:

Repurposed 40 gallon tank

Jax.Racks sump baffle kit

Reef Octopus 110INT skimmer

DIY King overflow

RODI:

BRS 5 stage (we have Chloramiine treated water)

Return Pump:

Reeflo Yellowtail

Heaters:

800w Finnex Titanium

JBJ Heater controller

Lights:

3 x Ecotech Radion XR30w Gen4

Powerheads:

TBD

Aquarium monitoring:

Neptune Apex..?