I need help. I have had my tank running with salt water for about a week now, Wednesday night I noticed some bubbles in it and panicked.

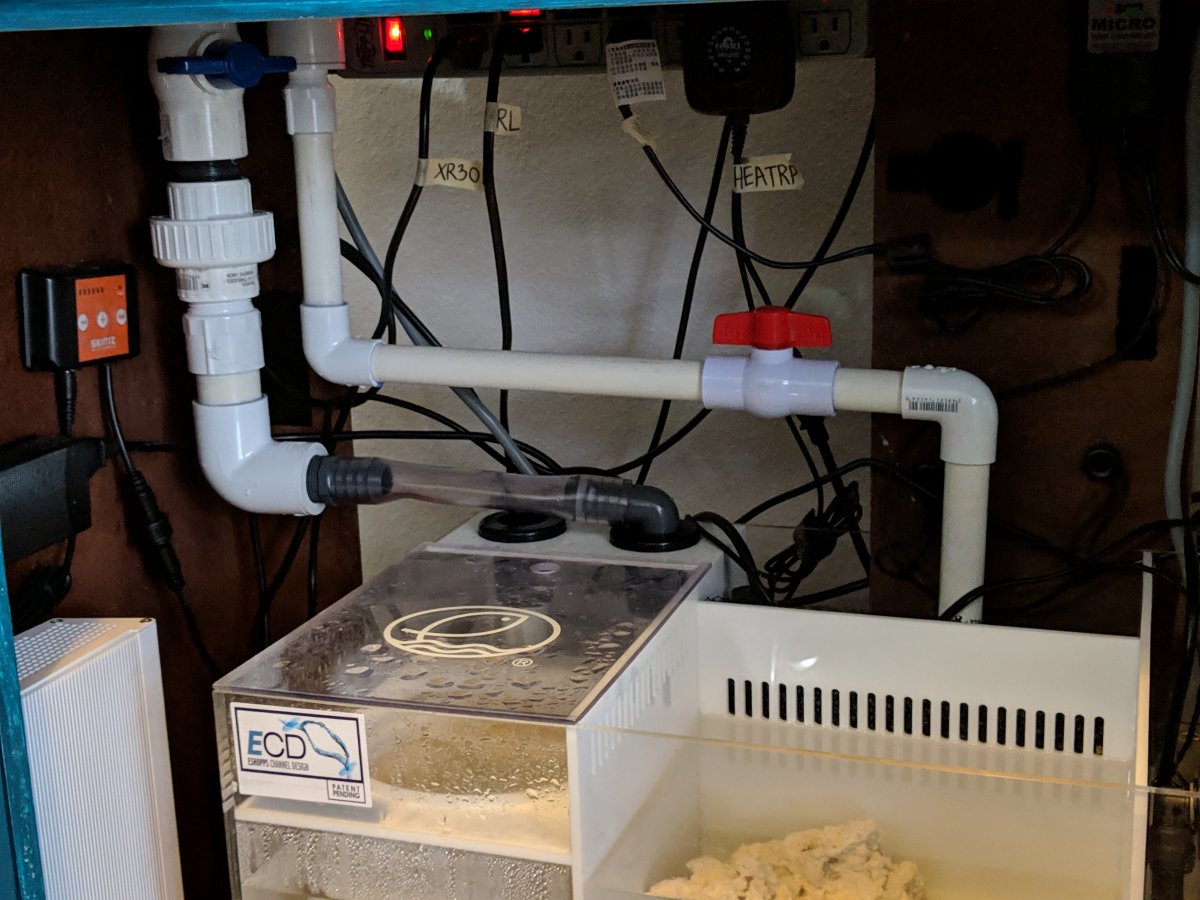

It was leaking from the return tube where it was going from 3/4 to the 1 1/4 union. I panicked. Sealed it (tried) with a butt ton of silicone. Started the flow again yesterday morning and still leaking. So I replaced it with PVC ( which I should have done from the start. I bought the system used and my wife wasn't happy about me spending more money)

But now it's leaking in the slip in the same spot. (Where it's threaded) again, I tried to seal it up and left it over night. This morning it's still leaking. I have heard salt creep might stop it? How long does it take? I'm at the point of just cuttingit all out again and starting over... I should have used unions, it just slipped my mind in planning.

It was leaking from the return tube where it was going from 3/4 to the 1 1/4 union. I panicked. Sealed it (tried) with a butt ton of silicone. Started the flow again yesterday morning and still leaking. So I replaced it with PVC ( which I should have done from the start. I bought the system used and my wife wasn't happy about me spending more money)

But now it's leaking in the slip in the same spot. (Where it's threaded) again, I tried to seal it up and left it over night. This morning it's still leaking. I have heard salt creep might stop it? How long does it take? I'm at the point of just cuttingit all out again and starting over... I should have used unions, it just slipped my mind in planning.

Last edited: