- Joined

- Apr 20, 2019

- Messages

- 90

- Reaction score

- 53

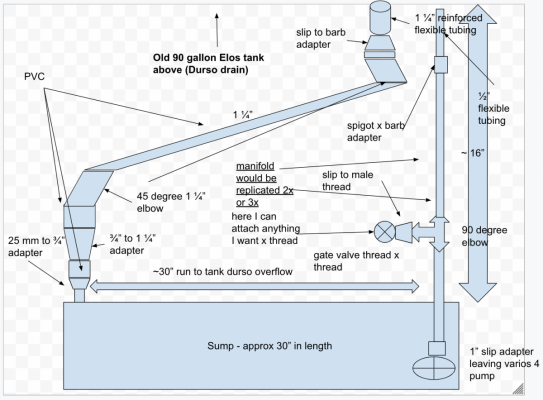

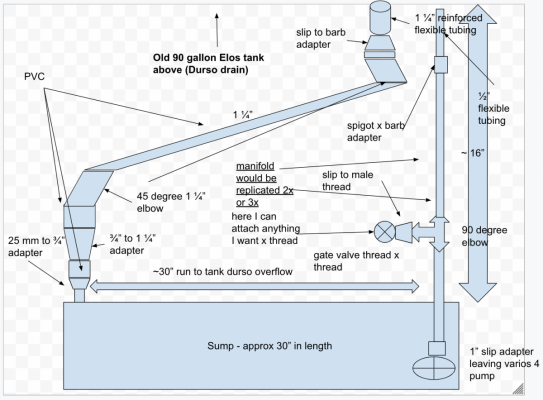

Greetings. I'm looking for some comments on the plumbing design for my 90 gallon build. It's an older 90 gallon Elos tank (circa 2005) with a new Icecap 30 sump in a custom new stand. I checked with Elos America due to the tank age and they said I should be OK (even shared photos).

The diagram is definitely not to scale. I was thinking of going with schedule 80 fittings since they seem to be easier to find. For the PVC I was actually considering going schedule 40 to allow for more flow (but please let me know if this is a silly idea). I have an AWC system all built out schedule 80 (fittings + PVC) so it feels a little weird to go with schedule 40 pipe for the tank, unless I'm deliberately optimizing for flow rate.

A couple of things in a particular I need expert advice on:

* For the return to the sump you can see I chose to go from flexible hose to PVC immediately when entering the stand and then to make a diagonal horizontal run with 1 1/4" PVC. Keeping the return quiet is not super important to me as the tank will be in my basement, but would still like this to be optimized to be quiet.

* For the return to the tank, I'm not sure when to transition from 1" to 1/2" when working with the PVC. If I go with 1" I have a larger diameter pipe to run to the manifold and increase theoretical flow rate, but I'm not sure I need it (one of the benefits is 1/2" gate valves are cheaper). At the same time 1/2" PVC feels very tiny to me and overly restricting. Should I run it with 1" or 3/4" and then do the reduction to 1/2" right at the bottom of the stand where it meets the tubing?

So there it is. Definitely the most complex plumbing design I've had to come up with. Feel free to tear it to shreds.

The diagram is definitely not to scale. I was thinking of going with schedule 80 fittings since they seem to be easier to find. For the PVC I was actually considering going schedule 40 to allow for more flow (but please let me know if this is a silly idea). I have an AWC system all built out schedule 80 (fittings + PVC) so it feels a little weird to go with schedule 40 pipe for the tank, unless I'm deliberately optimizing for flow rate.

A couple of things in a particular I need expert advice on:

* For the return to the sump you can see I chose to go from flexible hose to PVC immediately when entering the stand and then to make a diagonal horizontal run with 1 1/4" PVC. Keeping the return quiet is not super important to me as the tank will be in my basement, but would still like this to be optimized to be quiet.

* For the return to the tank, I'm not sure when to transition from 1" to 1/2" when working with the PVC. If I go with 1" I have a larger diameter pipe to run to the manifold and increase theoretical flow rate, but I'm not sure I need it (one of the benefits is 1/2" gate valves are cheaper). At the same time 1/2" PVC feels very tiny to me and overly restricting. Should I run it with 1" or 3/4" and then do the reduction to 1/2" right at the bottom of the stand where it meets the tubing?

So there it is. Definitely the most complex plumbing design I've had to come up with. Feel free to tear it to shreds.