I adjusted the valve handle, which overtightened of the needle stem allowing it to sink too far into the orifice.What happened to your needle valve?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building an Alanle style dual stage CO2 regulator

- Thread starter Water Dog

- Start date

- Tagged users None

en... it might be easy fix, but I need to check it personally, it is hard to explain but also without the proper equipment is not easy to play around it..Hey folks. I bought a used regulator on eBay but when I hooked it up, the first stage is at 900 psi but the second stage doesnt register any pressure regardless of the knob position. I also noticed some greenish goo in the inlet port. I suspect that the internals are plugged up somehow. Any suggestions on what could be wrong? Should I try to repair it? It’s a really nice stainless Harris.

anyway, let me explain a little.

there are both pressure adjusting screws in the back and front of the regulator. The front is the handle that you can set the output pressure. the back screw, it is for first stage pressure setting-this screw normally covered with a dome cap screw or simply hide away with a tag covering it. All regulator manufacture instruction manual clearly state: first stage pressure setting tempering is not recommended or prohibited ...

The back screw may be all the way loose so the first stage is at "close" position, no gas pass through first stage.

Your regulator is used out of warranty, so tinkering is somewhat ok, but safety and know what you are doing are both necessary. You can turn this back screw with allen key, but you must have a pressure gauge at the interstage(normally at the relief/safety valve port) to monitor the first stage output pressure. Since your regulator is 125 psi max output, the interstage pressure can be set between 150psi-200 psi.

this is the first possible case that no gas pass through the regulator.....

there are some other reasons too, most others require dissembling the regulator, so it is better to have someone that understand how it function to check it, or you can send it to me, just pm.

BTW, the rattling of the second stage is fine, it is the valve at close position, the springs are disengaged and there is room for parts movement, so it rattles.

Last edited:

@bettatail , thanks for the write-up and your offer to help! I actually took it apart already yesterday before I saw your message. I was impatient/curious and I love DIY projects.

Taking off the bonnets was probably the hardest part. I used a vise and a large wrench and quite a lot of elbow grease to get them loose. Then I removed the valve assemblies.

The regulator was full of weird green liquid and goo. The liquid was extremely bitter and acidic tasting ( I got some in my mouth accidentally while trying to blow through the body after I wiped it down). I wonder if it’s some type of condensed gas mixed with corroded brass. The reg is SS, but maybe someone used brass fittings on the inlet (?) Just a theory. Anyway, this green liquid/goo was in every crevice.

I cleaned all the parts with soapy water and then and used some pipe cleaners to clean out all of the ports and connections of the regulator. Then I tested the pathways between the two pressure chambers and between all the high/low ports by blowing through the body at various points and covering others.

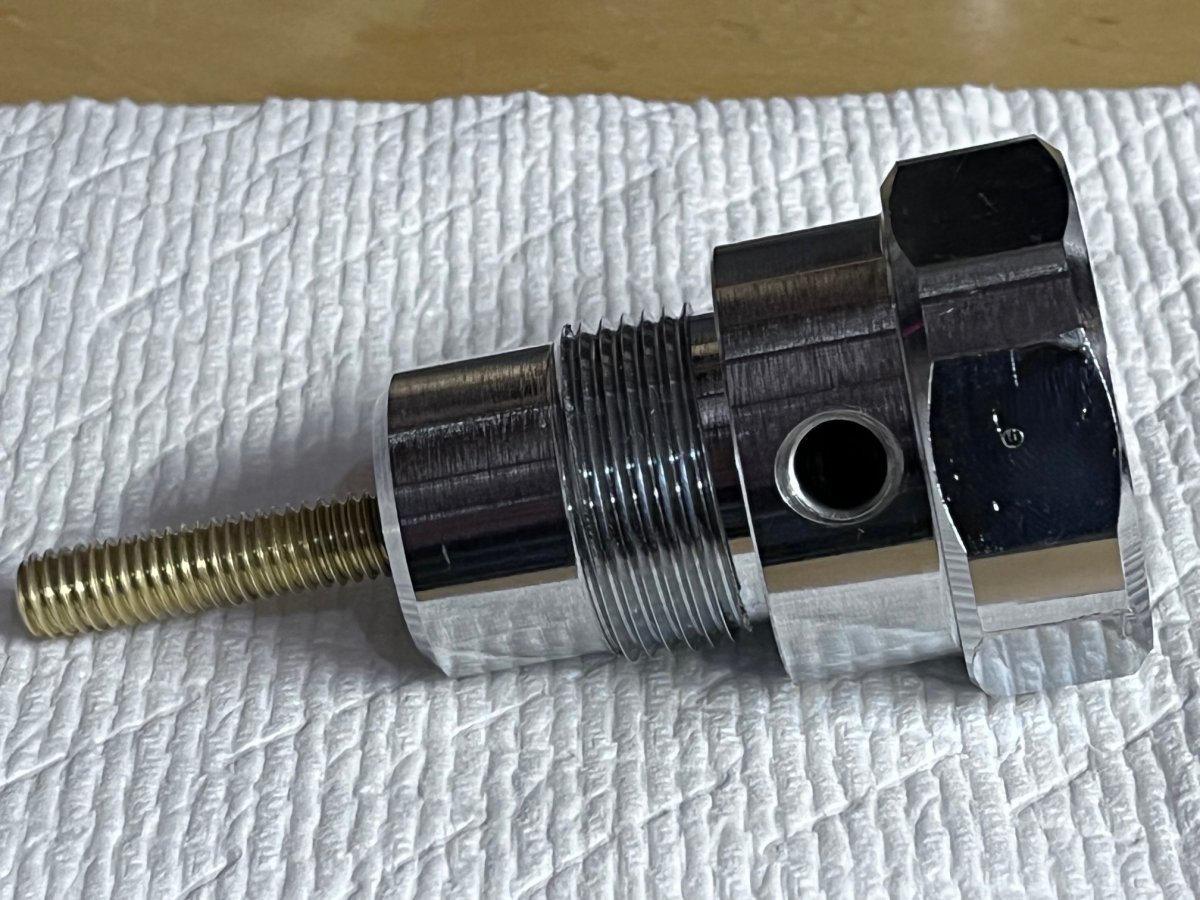

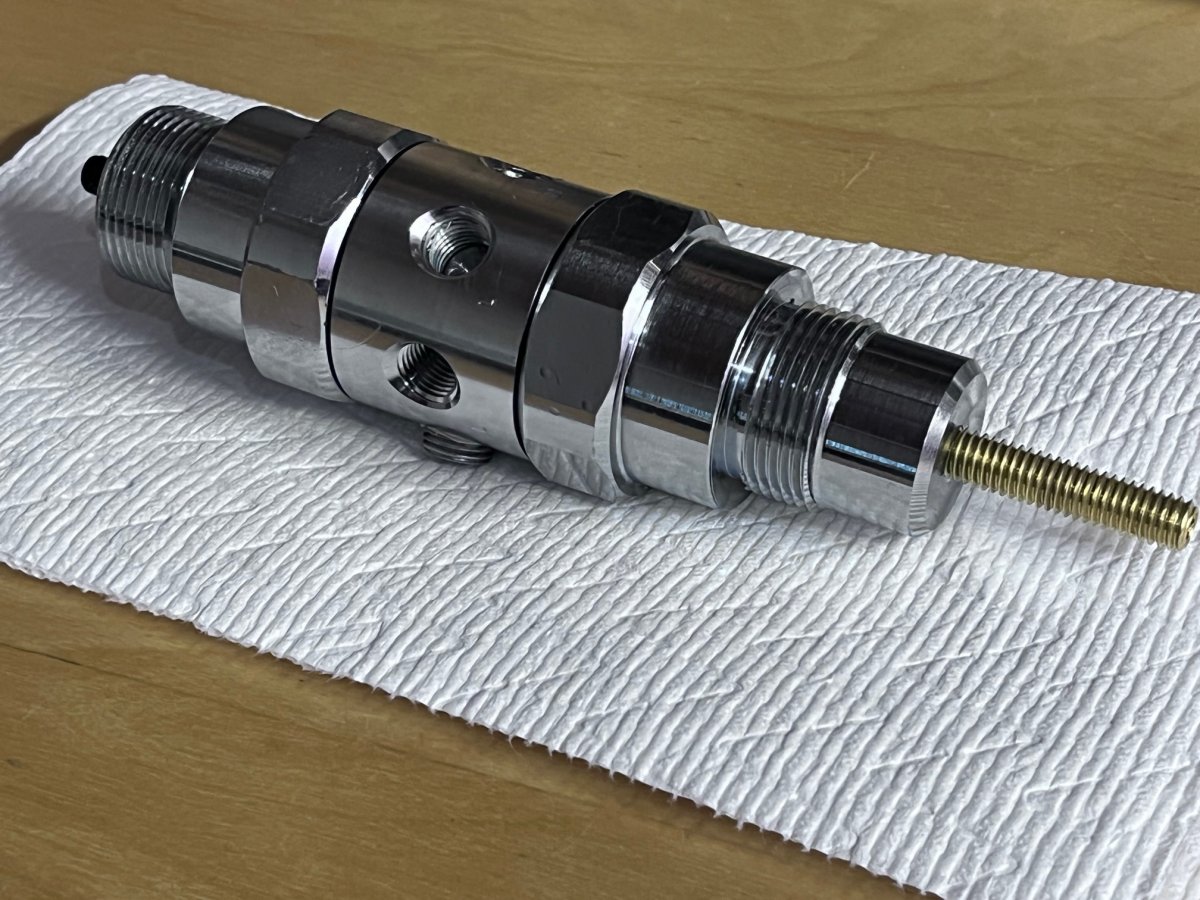

I didn’t take before pictures but here is what it looks like cleaned up.

Body:

Front bonnet (note, you can see some permanent etching on the SS diaphrams left by the green liquid):

Back bonnet:

Valve assemblies:

Taking off the bonnets was probably the hardest part. I used a vise and a large wrench and quite a lot of elbow grease to get them loose. Then I removed the valve assemblies.

The regulator was full of weird green liquid and goo. The liquid was extremely bitter and acidic tasting ( I got some in my mouth accidentally while trying to blow through the body after I wiped it down). I wonder if it’s some type of condensed gas mixed with corroded brass. The reg is SS, but maybe someone used brass fittings on the inlet (?) Just a theory. Anyway, this green liquid/goo was in every crevice.

I cleaned all the parts with soapy water and then and used some pipe cleaners to clean out all of the ports and connections of the regulator. Then I tested the pathways between the two pressure chambers and between all the high/low ports by blowing through the body at various points and covering others.

I didn’t take before pictures but here is what it looks like cleaned up.

Body:

Front bonnet (note, you can see some permanent etching on the SS diaphrams left by the green liquid):

Back bonnet:

Valve assemblies:

Last edited:

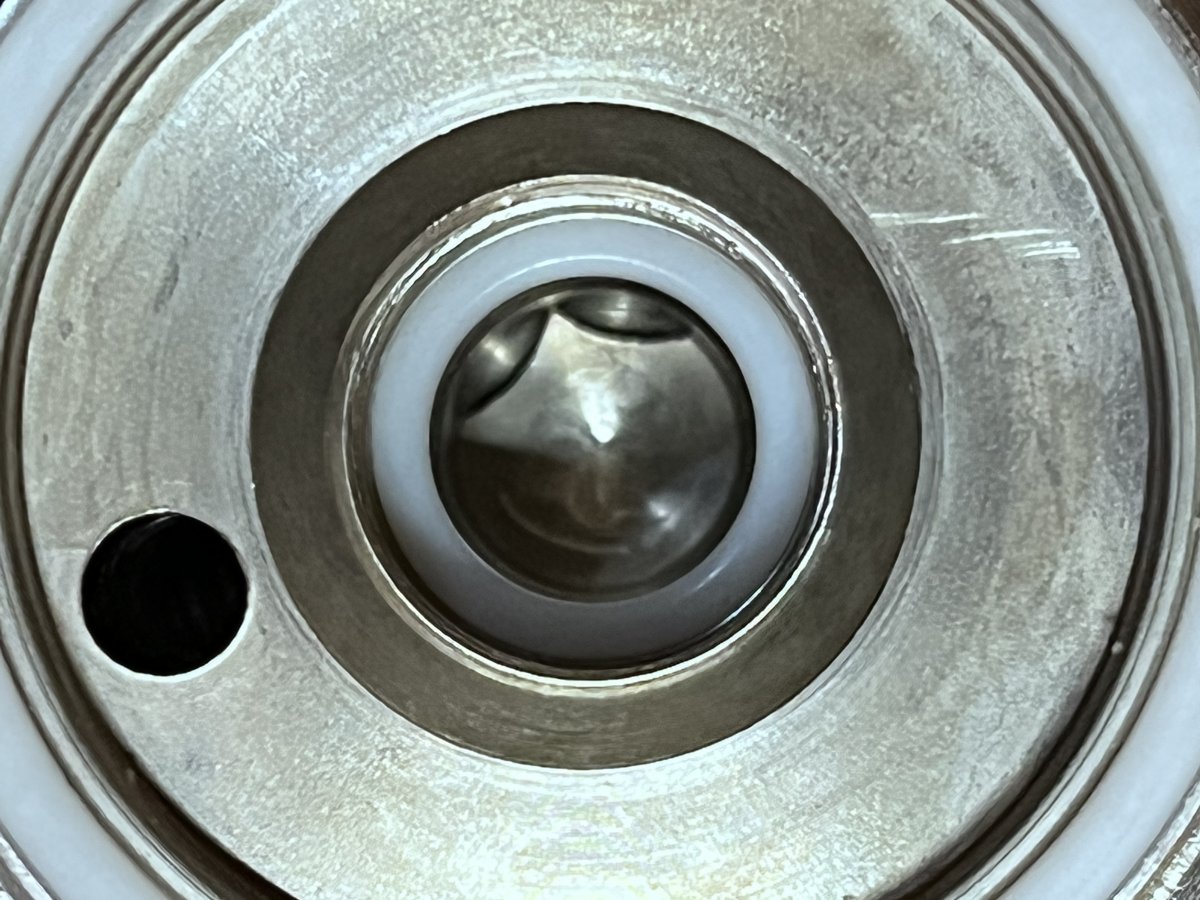

So what I believe was the culprit is that those valves have this fine filter on them that I'm pretty sure was saturated/clogged with the green goo. I soaked them both overnight in some soapy water and rinsed thoroughly this morning and let them both dry.

After that, I reassembled the regulator, and tested it, and voila!

Still waiting for the last elbow from Swagelok to complete the build.

After that, I reassembled the regulator, and tested it, and voila!

Still waiting for the last elbow from Swagelok to complete the build.

congrat!

I think it is fixed at this point, and from the pictures, the problem might be a high pressure damaged first stage diaphragm--it is not actually damaged, but deformed and pushed out of the seat, thus leakage occurred, then whoever tried to stop the leak put the goo--maybe loctite 609 into it, .....

anyway, as long as the diaphragm properly seat on the bonnet/body contact, the slightly out of shape should not be a problem, it is made of stainless steel,

just be careful with the poppet valve assembly, when you put them back to the regulator, if there is no PTFE or stainless steel washer, use sealing compound, because teflon tape not working well on those threads.

I think it is fixed at this point, and from the pictures, the problem might be a high pressure damaged first stage diaphragm--it is not actually damaged, but deformed and pushed out of the seat, thus leakage occurred, then whoever tried to stop the leak put the goo--maybe loctite 609 into it, .....

anyway, as long as the diaphragm properly seat on the bonnet/body contact, the slightly out of shape should not be a problem, it is made of stainless steel,

just be careful with the poppet valve assembly, when you put them back to the regulator, if there is no PTFE or stainless steel washer, use sealing compound, because teflon tape not working well on those threads.

Thanks. Yeah that might be what happened. Whatever it was, it must have been some strong stuff since it permanently etched some steel parts.

The poppet assemblies are seated on hard white washers (probably PTFE). They sit very snug.

After putting the reg back together this morning, I completed a 6+6 hour leak test on the first and second stage using alanle’s instructions and there is absolutely no leak. And most notably, the second stage is responding to the knob input which wasn’t happening before. I’m super stoked about this reg working like new.

The poppet assemblies are seated on hard white washers (probably PTFE). They sit very snug.

After putting the reg back together this morning, I completed a 6+6 hour leak test on the first and second stage using alanle’s instructions and there is absolutely no leak. And most notably, the second stage is responding to the knob input which wasn’t happening before. I’m super stoked about this reg working like new.

wait a minute, I think I made a mistake in the pm with @GarrettT, I thought the leak check instruction that Garrett follow was the one posted back in 2011, but since Yodeling mention there is another leak check from Alan, I need to take a look to see if Alan post the same instruction or made a different procedure.

This is the original leak check instruction.

www.plantedtank.net

www.plantedtank.net

This is the original leak check instruction.

Complete Leak Check, CO2 pressurized system

Exactly. Very informative read.The instructions seem to be the same, just worded differently. But @bettatail also has a third step that tests for leaks between the solenoid and the needle valve.

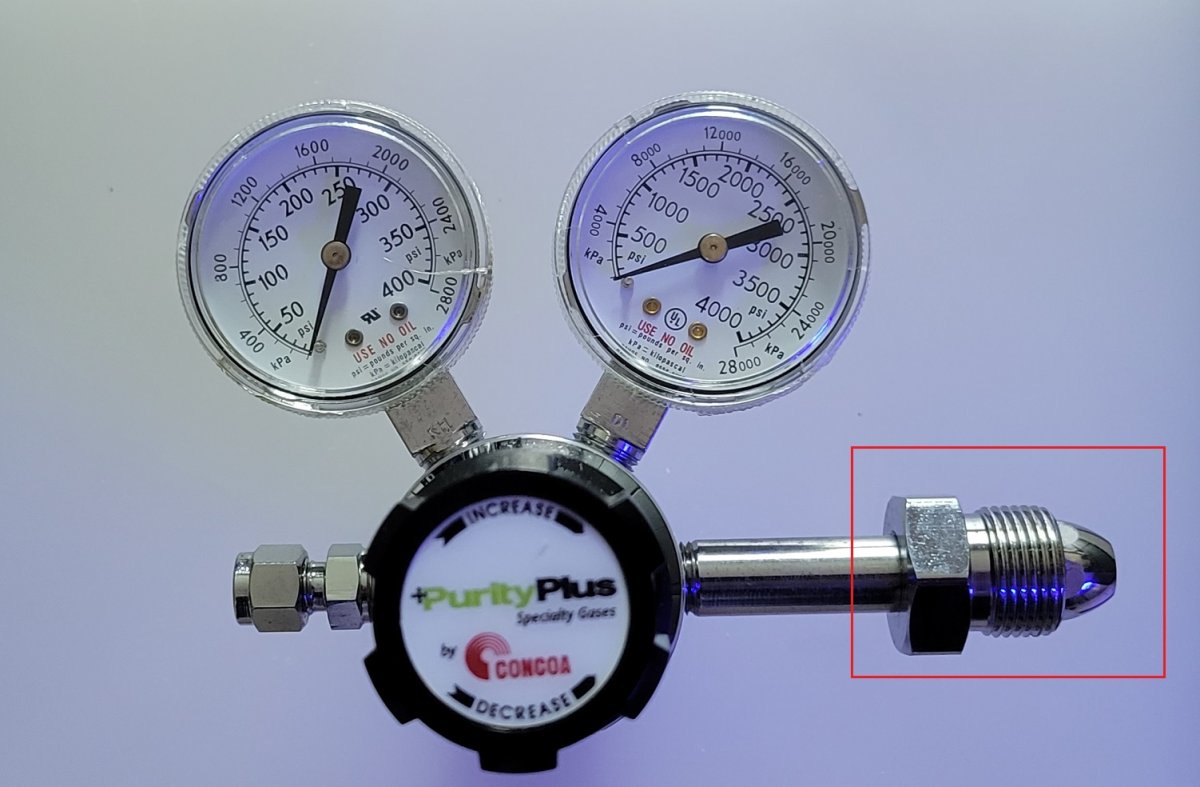

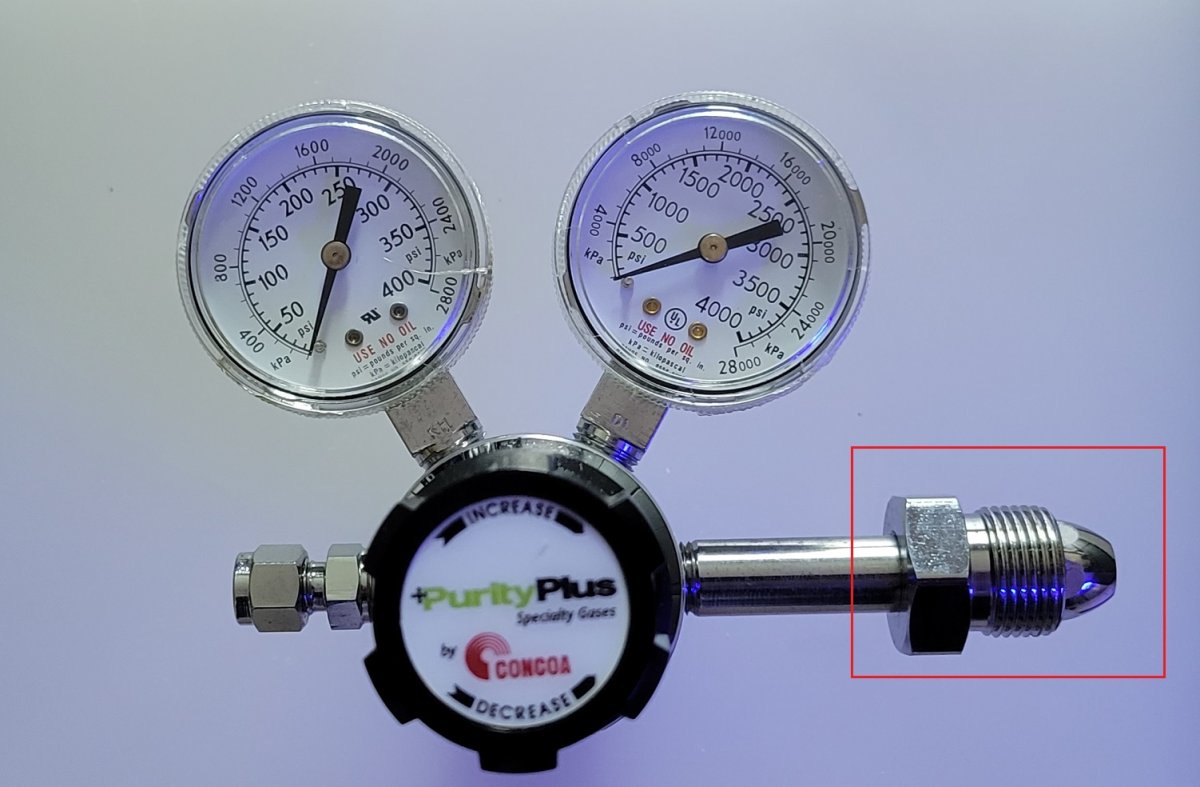

Here's my finished regulator. It's a stainless steel Harris 742, Swagelok SS-SS4-A metering valve with a veriner handle, and a Clippard mouse solenoid. I was waiting for a while for the last elbow.

Ok I figured out that I is for interstage pressure relief.

@Water Dog do I leave the pressure relief port open or do I put a plug in it?

@Water Dog do I leave the pressure relief port open or do I put a plug in it?

- Joined

- Feb 10, 2017

- Messages

- 4,036

- Reaction score

- 2,947

Ok. I'm jumping on board. Can someone let me know what the average price I should be seeing for the parts. When I google for them. They are all over the board.

Hoke 2SLP316 - 2

Burkert 6011a stainless steel solenoid valve.

Swagelok SS-4-HRN-2

Swagelok / Nupro SS-SS4 (1/4”) or SS-SS2 (1/8”).

Hoke 2SLP316 - 2

Burkert 6011a stainless steel solenoid valve.

Swagelok SS-4-HRN-2

Swagelok / Nupro SS-SS4 (1/4”) or SS-SS2 (1/8”).

- Joined

- Aug 13, 2019

- Messages

- 1,786

- Reaction score

- 2,392

In the industry I worked in h = high pressure meaning gas cylinder input and also the high pressure gauge L = low pressure meaning regulated pressure out and low pressure gauge and the I was always plugged. I think, but am not certain, that it used to check for a blown diaphragm on suspected faulty regulator. Again, I don’t claim to know what I’m talking about.Hey guys ... just got a SS 3810 Matheson valve. It has H H I L L ports. What is the I port for, Intermediate? Should I plug this?

Indeed I finally found the reference. That port is for an overpressure valve.In the industry I worked in h = high pressure meaning gas cylinder input and also the high pressure gauge L = low pressure meaning regulated pressure out and low pressure gauge and the I was always plugged. I think, but am not certain, that it used to check for a blown diaphragm on suspected faulty regulator. Again, I don’t claim to know what I’m talking about.

I ended up just plugging it. It has been working well. Thank you for the response.

If it makes you feel any better, I have the exact same regulator and plugged mine as well.Indeed I finally found the reference. That port is for an overpressure valve.

I ended up just plugging it. It has been working well. Thank you for the response.

- Joined

- Feb 10, 2017

- Messages

- 4,036

- Reaction score

- 2,947

Ok. This is what I was instructed to buy back then. I was also told to replace the connector valve to hook up to the tank as its the wrong type. I didn't want to go through all that so I didn't move forward with it. Now it looks like I cracked the guage during storage some how. But its 400 PSI. So I guess I can just get rid of this one as its not suited to what I need. Do you have a reccomendation so I can start all over? Can I get this done with all parts around 350?

- Joined

- Aug 13, 2019

- Messages

- 1,786

- Reaction score

- 2,392

I can’t see but if the low pressure side came with a 400 psi gauge then the internals would need to be changed out to make it work for the much lower pressure used in the hobby. I wouldn’t recommend messing with that unless you are familiar with regulators and since you’re asking I’m guessing you’re not. I would start over myself. You would never be able to get this down to ten psi as it sits.Ok. This is what I was instructed to buy back then. I was also told to replace the connector valve to hook up to the tank as its the wrong type. I didn't want to go through all that so I didn't move forward with it. Now it looks like I cracked the guage during storage some how. But its 400 PSI. So I guess I can just get rid of this one as its not suited to what I need. Do you have a reccomendation so I can start all over? Can I get this done with all parts around 350?

edit. maybe someone can chime in with specific links to appropriate regulators they could use. I’m sure someone sells a built unit on here or eBay.

Absolutely you can. You just have to be patient. I got my SS Matheson 3813 for $120 + $30 shipping on eBay. It looks brand new and was barely used.Do you have a reccomendation so I can start all over? Can I get this done with all parts around 350?

Similar threads

- Price: 250

- Shipping Available

- Replies

- 1

- Views

- 483

- Replies

- 10

- Views

- 950

- Replies

- 0

- Views

- 235