Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing thread

- Thread starter PurpleMonster

- Start date

- Tagged users None

This is definitely the best approach. You can post process a ton, but usually that will only get the out let surface and be a mm or so thick. Water will only need 1 leak path to start rusting the magnet.IMHO you’d be better off just encasing the magnet in epoxy inside the printed part, since you have no printing experience

I would do it this way:

1. make your print in to halves. Take the first half and put in an epoxy layer, put the magnet on it, fill in with epoxy to cover it, then attach the second half somehow.

2. Fancier way: print it as one part but add a pause when the magnet section is done. Do the epoxy know recess above, resume the print and let it cover. You just have to be careful not to get epoxy on where the resumed print is going to be.

It's something a $125 printer can do.I know NOTHING about 3D printing. Is this something a $300-$400 3D printer can do?

I use mainly modified ender 3 printers and get great results. Tons of stuff for the aquarium, cars, etc.

I print in nylon, petg, pla, wood, carbon fiber modified, etc. No issues.

If you’re printing those filaments that easily on a 125$ printer it’s because your experience pays for the difference over a prusa (or any other good printer). I have 3 printers of different caliber but I always go to the prusa because the mfing thing just works, every time, and I don’t have to mess with it. It’s worth every penny IMO

If you’re printing those filaments that easily on a 125$ printer it’s because your experience pays for the difference over a prusa (or any other good printer). I have 3 printers of different caliber but I always go to the prusa because the mfing thing just works, every time, and I don’t have to mess with it. It’s worth every penny IMO

It didn't happen overnight for sure. I almost gave up several times. I honestly wish I wouldn't have gone cheap at first and I would love to have a prusa and will at some point. But, for now, 4 printers for less than what one costs is fantastic for me.

Yeah no doubt the cost benefit is worth it once you have the experience to make up for it. I started with a crap printer and it was so unreliable it made me hate 3D printing. A print would work fine one day and the next it’d be a chop suey disaster with no changes other than the date. But for new folks, the prusa is worth the dough, if you can swing it. I can’t wait to get my XL

- Joined

- Sep 20, 2018

- Messages

- 1,117

- Reaction score

- 1,090

Yeah no doubt the cost benefit is worth it once you have the experience to make up for it. I started with a crap printer and it was so unreliable it made me hate 3D printing. A print would work fine one day and the next it’d be a chop suey disaster with no changes other than the date. But for new folks, the prusa is worth the dough, if you can swing it. I can’t wait to get my XL

Oh, I pre-ordered the XL also. Five-head version because why not? Actually, I was thinking of getting the Mosaic Palette 3 but changed my mind once the XL was announced.

Oh, I pre-ordered the XL also. Five-head version because why not? Actually, I was thinking of getting the Mosaic Palette 3 but changed my mind once the XL was announced.

got a buddy getting the same. I considered the palette as well

What have you guys made for that tank using 3d printing?

I’ve thought about making something like this

There's huge thread on here about designs folks have come up with. I can't seem to find it now.

I personally have done everything from algae clips to overflows to lighting mounts.

The possibilities are endless.

- Joined

- Sep 20, 2018

- Messages

- 1,117

- Reaction score

- 1,090

got a buddy getting the same. I considered the palette as well

Yep. 5 head for me for the exact same reason. I can’t wait to see what other heads they come up with

I've wanted a coreXY printer for sometime now and also multiple filament printing so even though the price is steep it does kind of make sense to get an XL.

I also suspect the XL won't have to waste a lot of filament purging in between each filament change.

I've wanted a coreXY printer for sometime now and also multiple filament printing so even though the price is steep it does kind of make sense to get an XL.

I also suspect the XL won't have to waste a lot of filament purging in between each filament change.

That was my thought was it didn't appear to purge hardly at all in the video I watched.

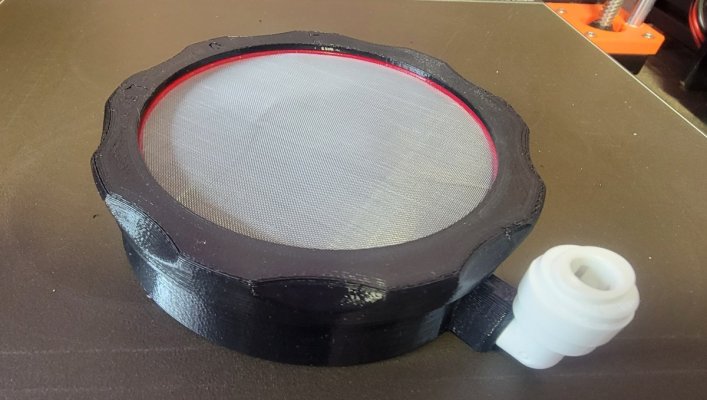

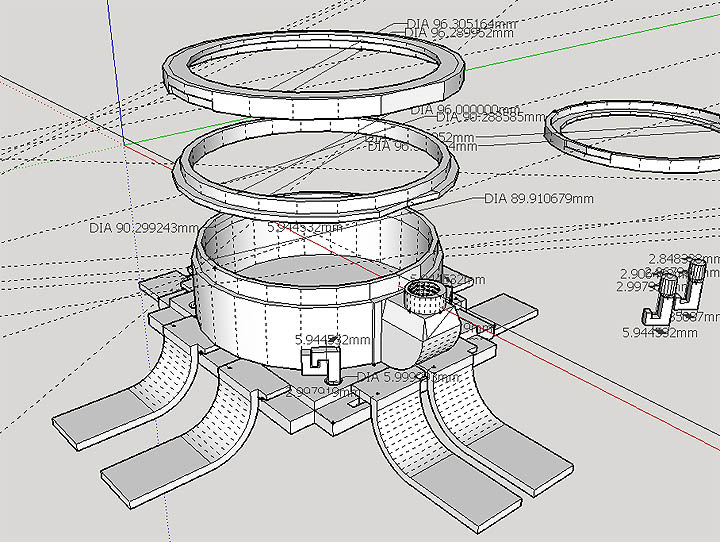

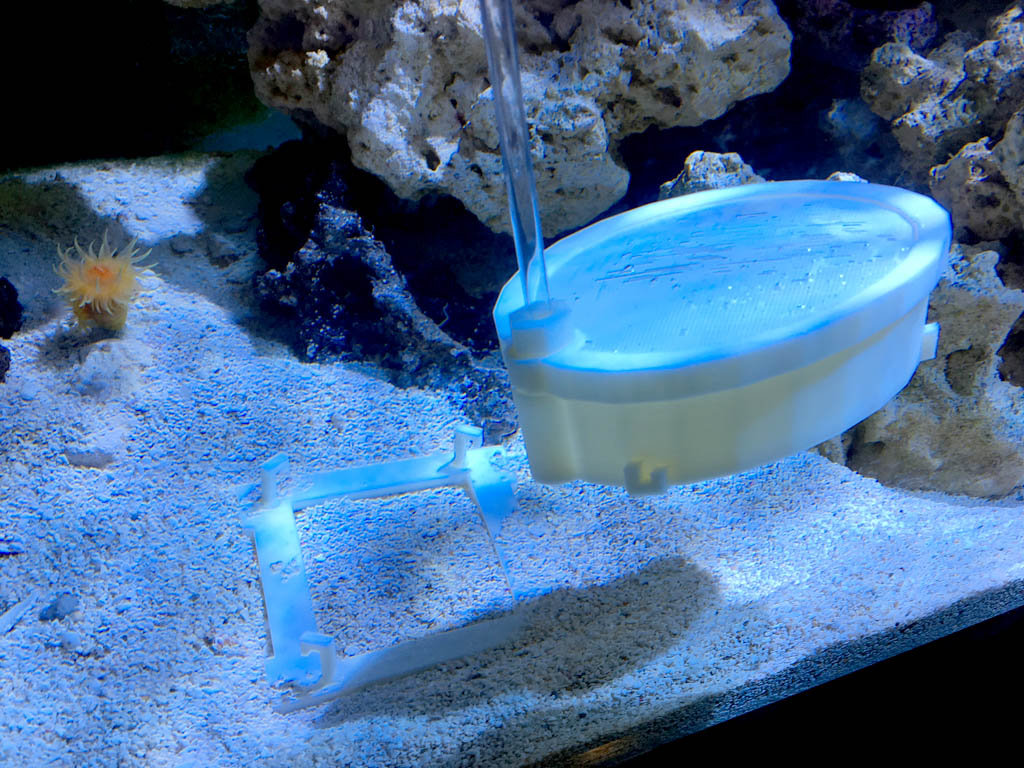

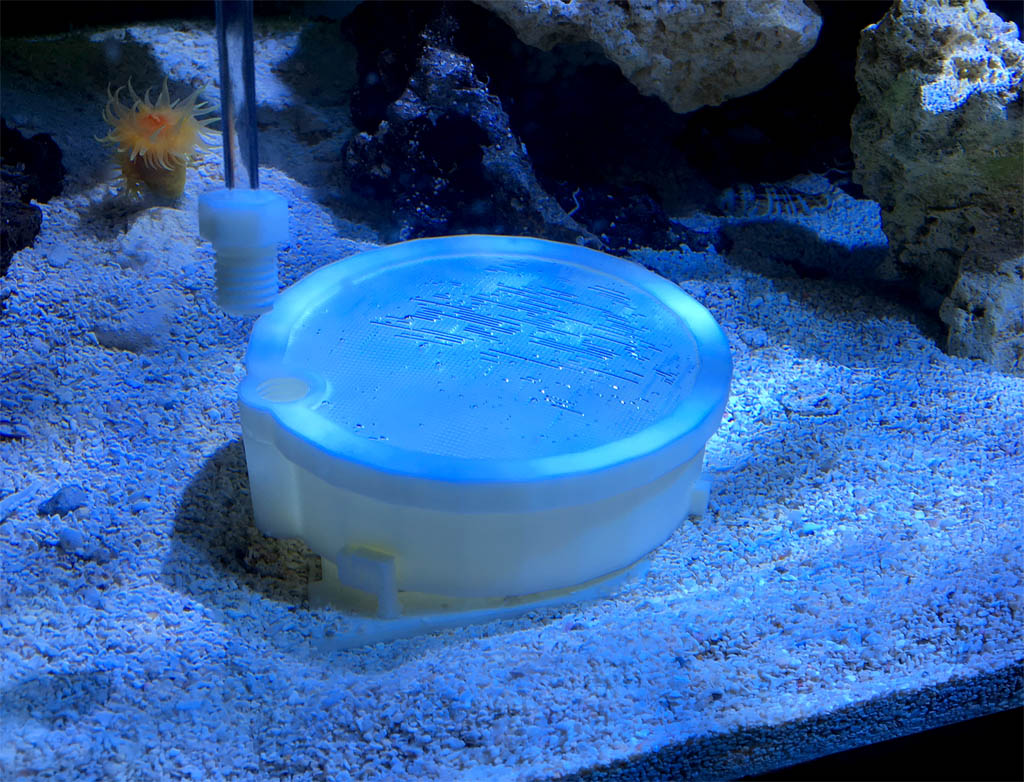

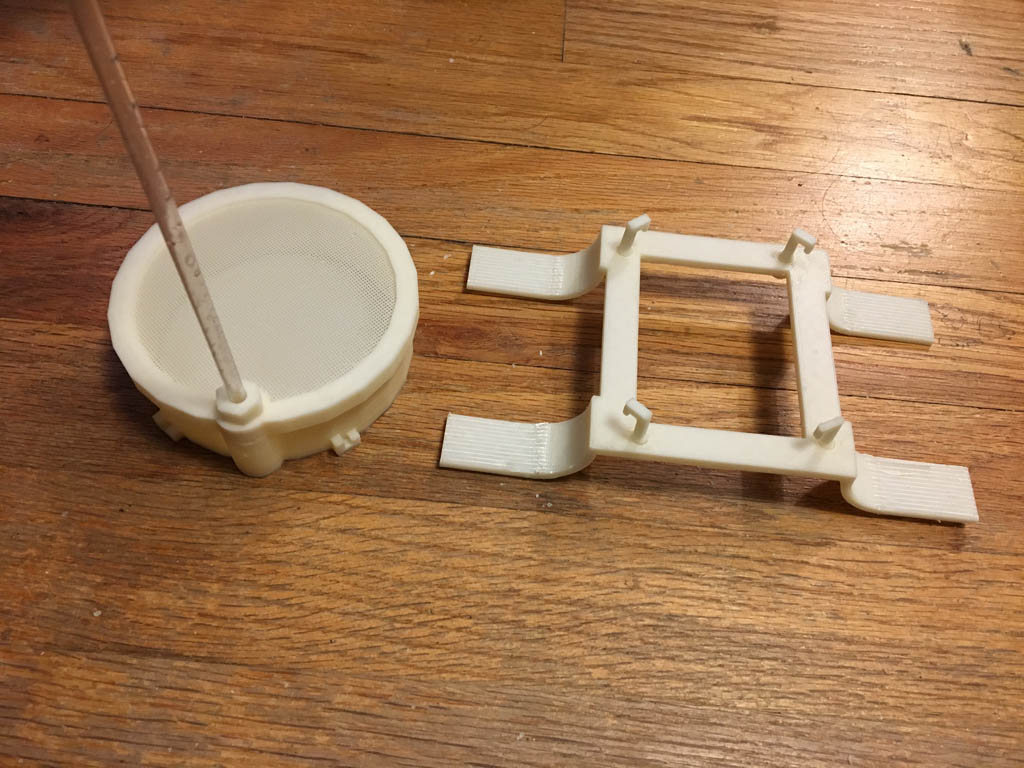

I know this is old but are there any files floating around?Here is the current version:

The top cover now is two pieces. You can use the 3D printed mesh filter, or sandwich it with any filtering material.

The feeder container now connects to the feeding tube without interfering the top cover.

The hooks that hook onto the feeder and the under-sand-base is a plug that you print separately. That is the part that I'm not too happy about.

The legs are all separate as well. They are fiction fitted.

I am indeed I have a printer of my own do you sell the model?

- Joined

- Dec 27, 2018

- Messages

- 3,806

- Reaction score

- 3,734

Mandarin feeding ring? Do you feed food thru the john guest fitting via a pipe?

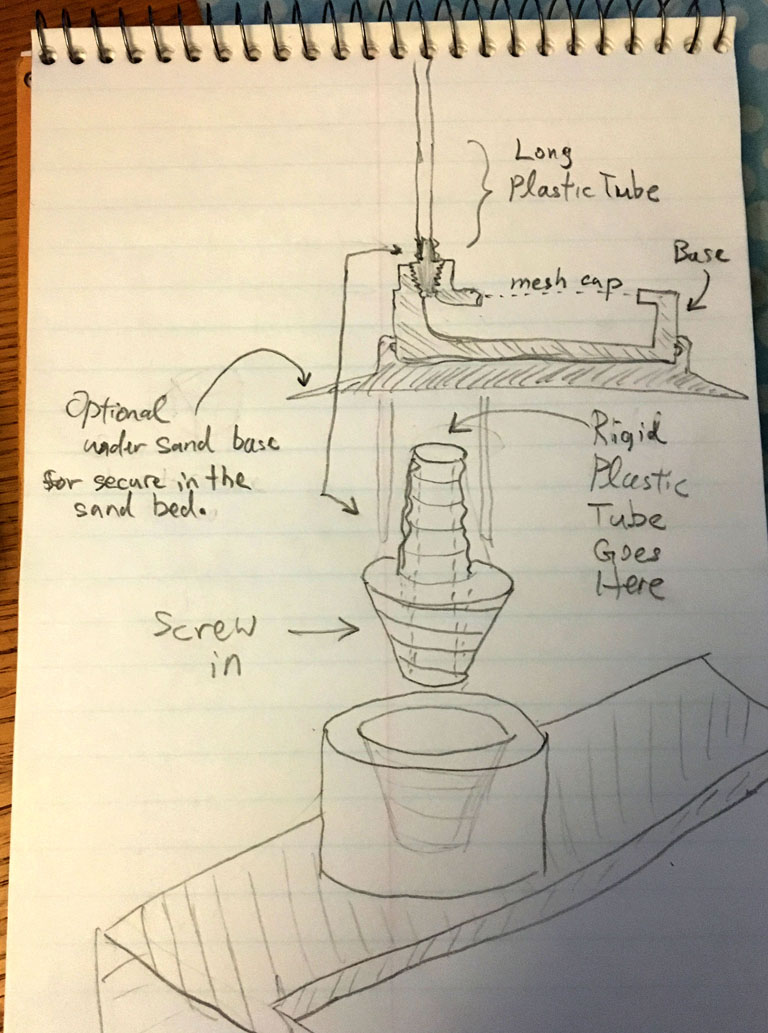

Inspired by PaulB's Mandarin Feeder design, I just made a 3D print version of it. It started almost 2 weeks ago from the drawing board, literally:

Sep 18th: I like to have the tube removable and leave the feeder on the sand bed and let the fish keep picking on it.

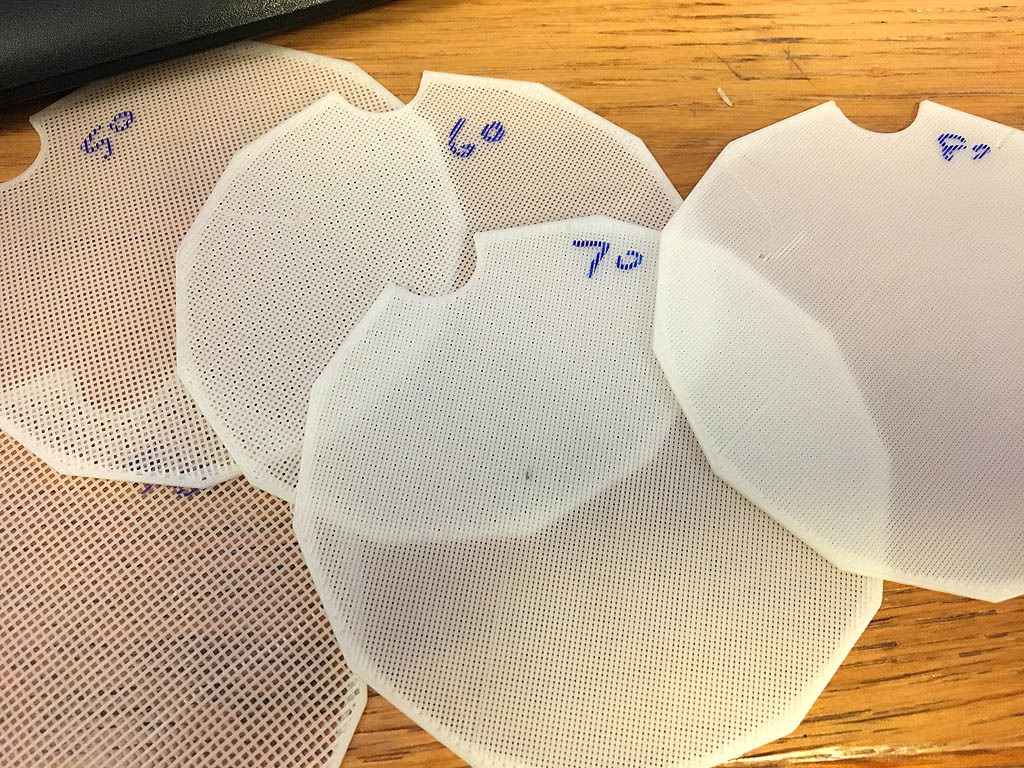

A small connector that always connected to the long plastic tube for pouring the shrimps in. It can then twist onto the base feeder that is sitting on the sand bed. The feeder could have an optional even bigger sand bed base that go under the sand so the feeder won't get blown around by the water current. There will be a cap for the feeder. Either just direct 3D print with tiny holes, or an open cap to allow using a normal mesh.

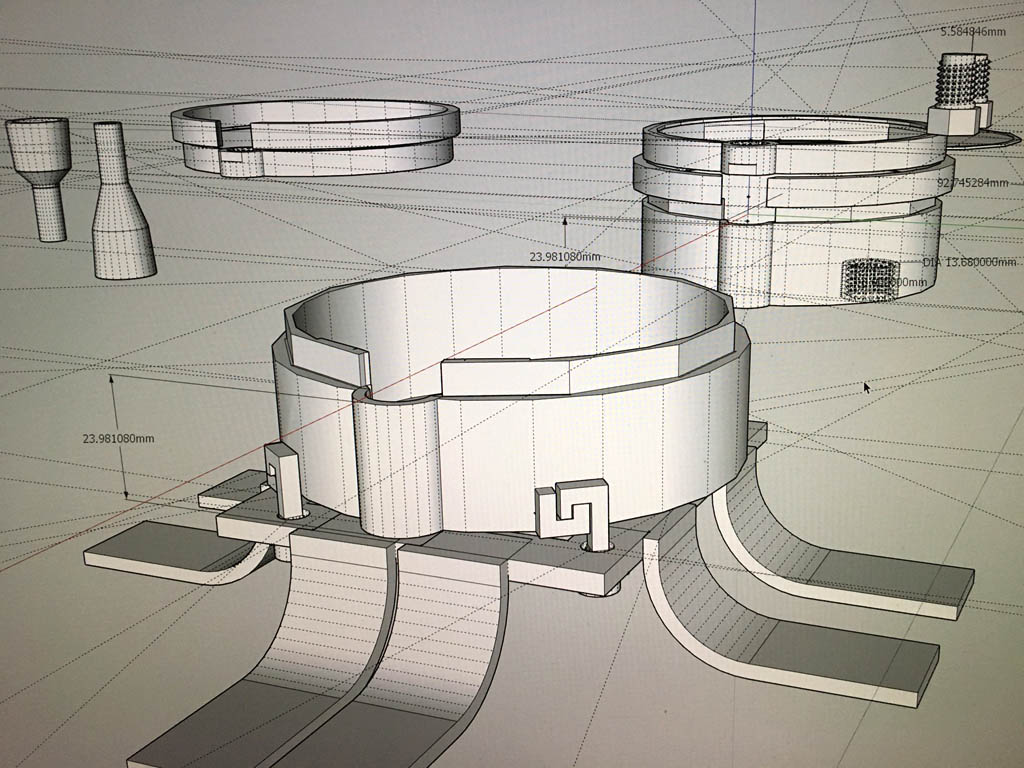

Sep 25th: After many days and many re-design for real world issues, here is the latest design:

The feeder is anchored down by the base to avoid floating away or getting blown around by the reef tank water current. Just a push and a twist on the feeding tube, and the feeder can be removed from the under-sand-anchor:

After pouring in the BBS, you can unscrew the feeding tube from the feeder. The rigid air tube is compression fitted to the screw-like connector. You can put in a blind-plug to close the hole without getting your hand wet.The screw-like connector is loosely fitted until the last turn.

Here is the under-sand-base and the feeder:

Everything is modular design. If you have a thinner/thicker air-tube, just need to re-print the screw-like compression connector. If you have a different size funnel, just re-print the funnel-airtube connector.

The screens are changeable as well.

The next revision is work-in-progress to have interchangable under-sand mounting legs, so that it could be buried in various places and situations.

would you care to share the stl files for this?

Good luck - that user was last seen more than 3 years agowould you care to share the stl files for this?

You may not be interested in this option, but it's sold on www.4daquatics.com

Similar threads

- Replies

- 2

- Views

- 100

- Replies

- 20

- Views

- 1,119