Very nice overflow

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

75 Gallon Mixed Reef with 40 Breeder sump build

- Thread starter atx100r

- Start date

- Tagged users None

I was able to wipe some off with a papertowel so I suspect once the paint is all dry you can put the tank up the right way and shoot the hose up there and gravity should wash it out. Thats my plan nayway. Glad to hear things went well.I just drilled a 75 and had the same issue as you with the white ground up glass getting under the tank rim. I didn't see it until after painting though. Have to figure out how to get it out.

- Joined

- Jul 12, 2017

- Messages

- 53

- Reaction score

- 34

I'll give the hose a try at some point. Ought to work, but if not, plan B is going to be so shoot water up under the rim with a syringe and 20 gauge needle.

Incidentally, my overflow was also a modular marine. I got the 1600 model (I think). It has 1" bulkheads. Really impressed with the quality. I'm hoping to have everything plumbed for a leak test by the weekend.

Good luck with yours. Keep reporting on it. Looks great.

Incidentally, my overflow was also a modular marine. I got the 1600 model (I think). It has 1" bulkheads. Really impressed with the quality. I'm hoping to have everything plumbed for a leak test by the weekend.

Good luck with yours. Keep reporting on it. Looks great.

- Joined

- Jul 12, 2017

- Messages

- 53

- Reaction score

- 34

If you're taking special requests.... I'd like to see how you affix the front door to the stand so that it is supported but still easy to remove. I want to do the same thing. Thought about running a 2x2 across the bottom opening of the stand to make a lip and then blocking another one higher up on the door itself with a design to let it rest on the lower one and also "catch" it from behind. Then was going to use some kind of cabinet door double roller catches at the top to keep it secure.

I was thinking about doing this for the front of my stand.

(sorry for the huge pic)

(sorry for the huge pic)

Brew I will probably gt the door on this weekend and post some pictures.If you're taking special requests.... I'd like to see how you affix the front door to the stand so that it is supported but still easy to remove. I want to do the same thing. Thought about running a 2x2 across the bottom opening of the stand to make a lip and then blocking another one higher up on the door itself with a design to let it rest on the lower one and also "catch" it from behind. Then was going to use some kind of cabinet door double roller catches at the top to keep it secure.

Not a bad idea. Wonder about noise though?I was thinking about doing this for the front of my stand.

(sorry for the huge pic)

Beautiful stand!

Something I did on the freshwater tank, that I see nobody do. Line up with the bottom of the tank a 1/2" round hole (no paint) with the stand top.

So that inside the stand, you can shine a white LED light into that hole, that lines up with the tank. Thus a night light.

(freshwater tank bottom is not painted, I just make a hole in the stand to shine up.)

Another idea I had, was to use refraction, and placing a bunch of evenly spaced 1/32" holes that line up with the tank bottom/side panels. Fill the holes with in the stand with fiber optic cables, that assemble to a single point, to a RGB Led lamp, like the XMas ones that rotate between colors, or you can choose a specific color.

Thus the colored or white light travels through the fiber optics and splash into the side panels, that light up.

For nighttime / evening viewing of aquarium.

http://www.davidappalachiancrafts.c...ee-pure-glaze-shelves-for-storage-eksotic.jpg

http://www.avso.org/wp-content/uplo...-ideas-for-kitchen-glass-back-wall-16-483.jpg

Something I did on the freshwater tank, that I see nobody do. Line up with the bottom of the tank a 1/2" round hole (no paint) with the stand top.

So that inside the stand, you can shine a white LED light into that hole, that lines up with the tank. Thus a night light.

(freshwater tank bottom is not painted, I just make a hole in the stand to shine up.)

Another idea I had, was to use refraction, and placing a bunch of evenly spaced 1/32" holes that line up with the tank bottom/side panels. Fill the holes with in the stand with fiber optic cables, that assemble to a single point, to a RGB Led lamp, like the XMas ones that rotate between colors, or you can choose a specific color.

Thus the colored or white light travels through the fiber optics and splash into the side panels, that light up.

For nighttime / evening viewing of aquarium.

http://www.davidappalachiancrafts.c...ee-pure-glaze-shelves-for-storage-eksotic.jpg

http://www.avso.org/wp-content/uplo...-ideas-for-kitchen-glass-back-wall-16-483.jpg

Great ideas and links...thanks for sharing...Beautiful stand!

Something I did on the freshwater tank, that I see nobody do. Line up with the bottom of the tank a 1/2" round hole (no paint) with the stand top.

So that inside the stand, you can shine a white LED light into that hole, that lines up with the tank. Thus a night light.

(freshwater tank bottom is not painted, I just make a hole in the stand to shine up.)

Another idea I had, was to use refraction, and placing a bunch of evenly spaced 1/32" holes that line up with the tank bottom/side panels. Fill the holes with in the stand with fiber optic cables, that assemble to a single point, to a RGB Led lamp, like the XMas ones that rotate between colors, or you can choose a specific color.

Thus the colored or white light travels through the fiber optics and splash into the side panels, that light up.

For nighttime / evening viewing of aquarium.

http://www.davidappalachiancrafts.c...ee-pure-glaze-shelves-for-storage-eksotic.jpg

http://www.avso.org/wp-content/uplo...-ideas-for-kitchen-glass-back-wall-16-483.jpg

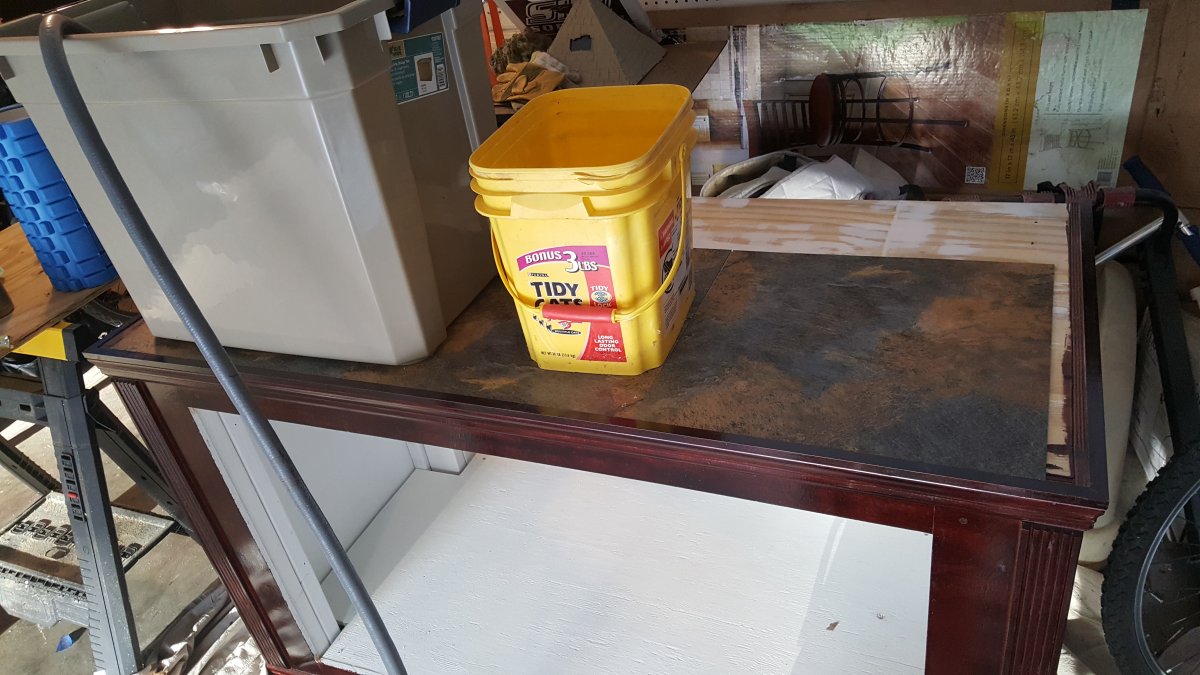

So I finally finished the stand this weekend. The weather hear took a bit of a turn for the worse and I was a bit worried about some of the adhesives curing or not but I took the risk. All in All I think it turned out pretty good. There are some flaws but they may just be things that I notice as I'm so intimate with the build.

I added vinyl tiles to the top surface to closely match my stone fireplace surround. Of course the dimensions of the tile and stand do not match so this required some cutting (I used my circular saw and the Kreg guide). It also required a decision on where to put the cut pieces. I consulted with my wife and she thought center the full tile pieces and then trim pieces for each side.

I then filled some containers with water to add pressure to make sure the adhesive bonded. It was fairly cool here and I was a bit worried about this but all seemed to work out OK.

Once this was done and cured I started working on the attachment for the front panel. As I stated earlier I really wanted to be able to remove the entire thing so I could have unobstructed access to the sump and equipment. I used 1/2" finished plywood for the panel. I cut the panel roughly 1/16" smaller than the hole in the stand. I trimmed the panel making sure to leave and evenly spaced overhang thus creating a lip that the panel can rest on when installed and also stop the panel from being pushed in to far.

I wasnt sure it would work but I decided to try using these double roller catch to secure the top. These are used in my RV for many of the cabinets and they work great there. They are also very inexpensive at my local Loews.

As I wanted a precision fit I did the majority of the catch install with the panel in place held by 2 clam and some shims to make sure it didn't get marked. I must a admit this was a real pain but the resulting fit is spot on.

I was surprised at how well these little things hold the panel in place. I am trying to talk my daughter into doing some kind of mosaic I can add to the front but otherwise she is all done.

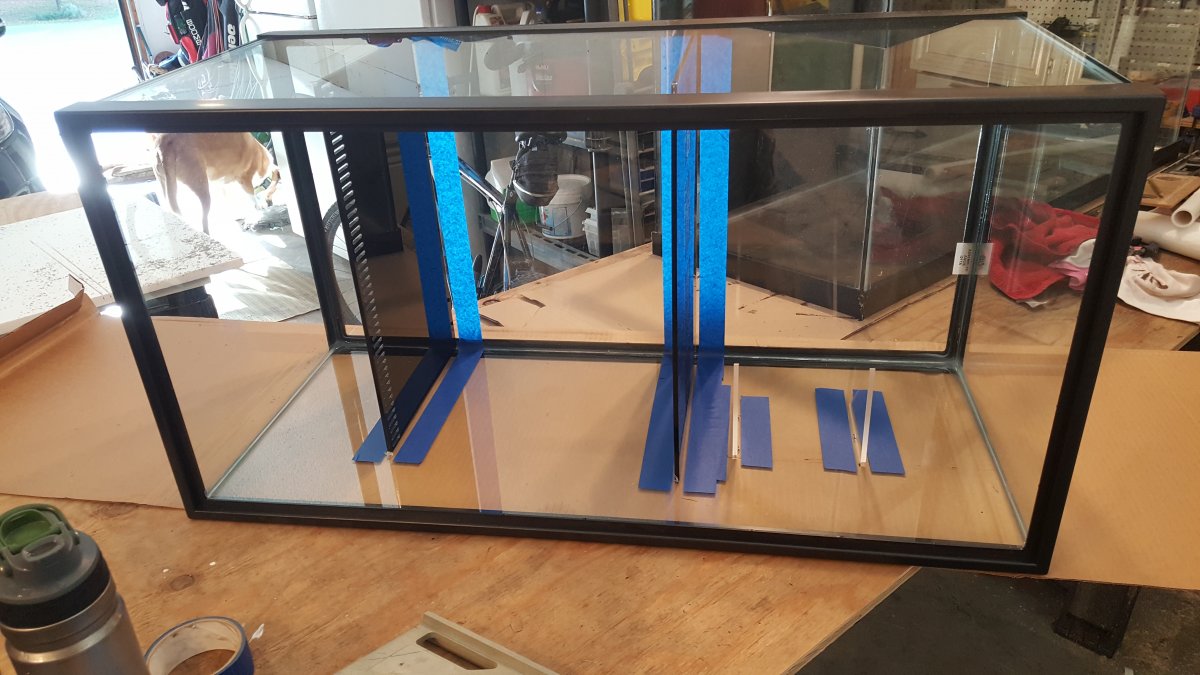

Next thing I started on was the sump. I actually purchased a kit from Innovative Marine (same folks who did the overflow). I built my current sump from scratch using cut glass from Loews. It does it's job but its not the prettiest baby at the show so I deiced to go the kit route. As with the overflow the sump kit is very good quality. They have changed their design from what is shown on the web page and this threw me off for a bit but a few e-mails and I had it all square. I'm still undecided about the new design but will see once it is all put together. The new design really only changes the overflow plate and the sock plate. On the web page they are shown spanning the width of the tank with the overflow plate actually sitting in the lip of the tank touching 3 sides and the bag plate below it touching 3 sides. In an effort to make more room in the sump they now have these 2 items only supported by touching 2 of the tank sides (depending on where you decide to put them). They do include 2 45 deg support triangles for the bag plate as you will see in the pictures.

I started by using a dry erase marker to outline where my baffles and 45 degree supports will go.

I then placed the baffles using a small drop of hot glue to hold them in place while I siliconed. It doesn't take much and this worked really well. Last time I tried using tape and clamps and it was like trying to herd cats. Please note that at this point there is still a 3rd baffle the needs to be installed after these items are in and cured.

I also used my speed square to make sure everything was perpendicular.

I then flipped the tank on its side and hot glued my 45 degree supports for my sock plate.

Once this was done I added some painters tape to catch any stray silicone. This isn't required but the little extra time really makes for a clean looking system

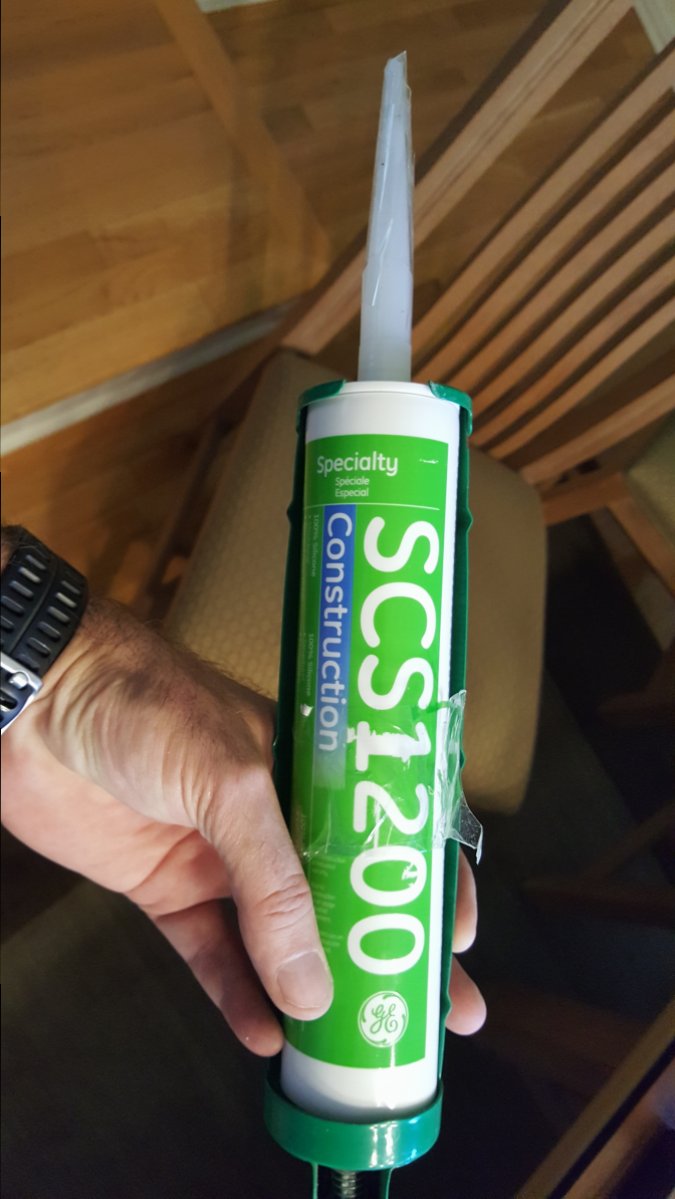

I purchased and used GE SCS1200 from Modular Marine when I order the kit. Last time I built a sump I used store bought 100% silicone. This silicone came with a screw on tip that allows for very precise application of silicone. For that reason alone I would recommend this product. One other note the application instructions are on the SDS sheet you need to download at the GE web page. I'm not sure why they are not on the tube. After reading those I found out this product should not be applied at or below 40 f. As a result and to my wife's dismay the operation has now been shifted to our dining room/...

I finished application for these items and will let it cure a few days before I do the final baffle at the return pump that needs to be elevated off the bottom and the also the overflow plate that will house 2x 3/4" bulkheads and 1 x 1' bulkheads.

I added vinyl tiles to the top surface to closely match my stone fireplace surround. Of course the dimensions of the tile and stand do not match so this required some cutting (I used my circular saw and the Kreg guide). It also required a decision on where to put the cut pieces. I consulted with my wife and she thought center the full tile pieces and then trim pieces for each side.

I then filled some containers with water to add pressure to make sure the adhesive bonded. It was fairly cool here and I was a bit worried about this but all seemed to work out OK.

Once this was done and cured I started working on the attachment for the front panel. As I stated earlier I really wanted to be able to remove the entire thing so I could have unobstructed access to the sump and equipment. I used 1/2" finished plywood for the panel. I cut the panel roughly 1/16" smaller than the hole in the stand. I trimmed the panel making sure to leave and evenly spaced overhang thus creating a lip that the panel can rest on when installed and also stop the panel from being pushed in to far.

I wasnt sure it would work but I decided to try using these double roller catch to secure the top. These are used in my RV for many of the cabinets and they work great there. They are also very inexpensive at my local Loews.

As I wanted a precision fit I did the majority of the catch install with the panel in place held by 2 clam and some shims to make sure it didn't get marked. I must a admit this was a real pain but the resulting fit is spot on.

I was surprised at how well these little things hold the panel in place. I am trying to talk my daughter into doing some kind of mosaic I can add to the front but otherwise she is all done.

Next thing I started on was the sump. I actually purchased a kit from Innovative Marine (same folks who did the overflow). I built my current sump from scratch using cut glass from Loews. It does it's job but its not the prettiest baby at the show so I deiced to go the kit route. As with the overflow the sump kit is very good quality. They have changed their design from what is shown on the web page and this threw me off for a bit but a few e-mails and I had it all square. I'm still undecided about the new design but will see once it is all put together. The new design really only changes the overflow plate and the sock plate. On the web page they are shown spanning the width of the tank with the overflow plate actually sitting in the lip of the tank touching 3 sides and the bag plate below it touching 3 sides. In an effort to make more room in the sump they now have these 2 items only supported by touching 2 of the tank sides (depending on where you decide to put them). They do include 2 45 deg support triangles for the bag plate as you will see in the pictures.

I started by using a dry erase marker to outline where my baffles and 45 degree supports will go.

I then placed the baffles using a small drop of hot glue to hold them in place while I siliconed. It doesn't take much and this worked really well. Last time I tried using tape and clamps and it was like trying to herd cats. Please note that at this point there is still a 3rd baffle the needs to be installed after these items are in and cured.

I also used my speed square to make sure everything was perpendicular.

I then flipped the tank on its side and hot glued my 45 degree supports for my sock plate.

Once this was done I added some painters tape to catch any stray silicone. This isn't required but the little extra time really makes for a clean looking system

I purchased and used GE SCS1200 from Modular Marine when I order the kit. Last time I built a sump I used store bought 100% silicone. This silicone came with a screw on tip that allows for very precise application of silicone. For that reason alone I would recommend this product. One other note the application instructions are on the SDS sheet you need to download at the GE web page. I'm not sure why they are not on the tube. After reading those I found out this product should not be applied at or below 40 f. As a result and to my wife's dismay the operation has now been shifted to our dining room/...

I finished application for these items and will let it cure a few days before I do the final baffle at the return pump that needs to be elevated off the bottom and the also the overflow plate that will house 2x 3/4" bulkheads and 1 x 1' bulkheads.

Very very very nicely don the stand and sump all looks very well and top notch

Do you have a plan yet for plumbing the external overflow box? Mine is too small for the traditional bean animal plumbing with two u-tubes. I'm thinking of using a strainer for the full siphon, u-tube for the open channel, and straight pipe for the back up.

Ya so I did quite a bit of reading on that you might check out this link...I will be doing a strainer on the full and probably nothing on the open and emergency to start...if I have noise problems which based on the article I shouldn't I will add the U tube to the open...my over flow has a cover on the internal and external box so the odds of smithing getting in there are very very small...Do you have a plan yet for plumbing the external overflow box? Mine is too small for the traditional bean animal plumbing with two u-tubes. I'm thinking of using a strainer for the full siphon, u-tube for the open channel, and straight pipe for the back up.

http://gmacreef.com/herbie-overflow-reef-tank-plumbing-method-basics/ I got the sump almost finished last night....probably going to get everything in the house this weekend and get the plumbing all figured out...

I didn't get a lot of time to work on the tank this weekend. I live in a rural area and sometimes getting the supplies I need can be difficult. Specifically getting all the right PVC fittings can be a real pain.

I finished siliconeing the sump by adding the drain plate and the final baffle that needs to be elevated of the bottom for a bubble trap.

I then put on 4 coats of flat black paint to the back and sides of the sump. I'm pretty happy with how it turned and it looks much better than my first DIY attempt.

I insulated an LED light on the cabinet and then did a dry fit of the sump in the cabinet. I believe I will position the sump to the right in the cabinet so I will have a very straight drop for my overflow and straight return. As you will see in the pictures there is room to move the sump all the way to the right the only issues is the 2x4 leg will partially block access to the return chamber. IF I pull sump out so it so even with the edge of the 2x4 it gives me about 15 inches of room on the left hand side for my ATO water supply (5-10 gallons) (I've been thinking about putting this on a pullout shelf to make filling that much easier), carbon reactor and to possibly add a doser down the road..

Hopefully I can get the plumbing dry fit this week and possible get this thing installed this coming weekend.

I finished siliconeing the sump by adding the drain plate and the final baffle that needs to be elevated of the bottom for a bubble trap.

I then put on 4 coats of flat black paint to the back and sides of the sump. I'm pretty happy with how it turned and it looks much better than my first DIY attempt.

I insulated an LED light on the cabinet and then did a dry fit of the sump in the cabinet. I believe I will position the sump to the right in the cabinet so I will have a very straight drop for my overflow and straight return. As you will see in the pictures there is room to move the sump all the way to the right the only issues is the 2x4 leg will partially block access to the return chamber. IF I pull sump out so it so even with the edge of the 2x4 it gives me about 15 inches of room on the left hand side for my ATO water supply (5-10 gallons) (I've been thinking about putting this on a pullout shelf to make filling that much easier), carbon reactor and to possibly add a doser down the road..

Hopefully I can get the plumbing dry fit this week and possible get this thing installed this coming weekend.

So I finally started the transition this weekend. So I'm going from a 55 with a 20 long sump so in preparation I started by making, transporting and storing a bunch of water in advance. I used several heavy duty plastic storage bins that I had in the garage. I first cleaned them all out then placed them close to where I would be setting up the new tank. Luckily I had a few spare heaters to bring them up to temp. I then shuttled water in 5 gallon buckets back and forth to fill them up. For water storage I built a stacked system with 2 20 gallon tanks. I keep the top one filled with RODI water and the bottom with mixed Salt water. I made sure I had both of these filled also. Even with this much water I ended up being 4 gallons short (of slat water) and had to make some on the spot.

Friday night after work I got the stand, tank and sump moved into position. My plan was to move everything out of the 55 gallon too temporary storage then get it out of the way and move the new tank into the same location then transfer all the stuff from storage into the new tank. I also need to complete the plumbing but due to the low temps here I decided to complete that in the house where the tubing and such would be easier to work with.

New tank staged but needs plumbing, back panel installed and adjustments for light fixture holder due to difference in tank height.

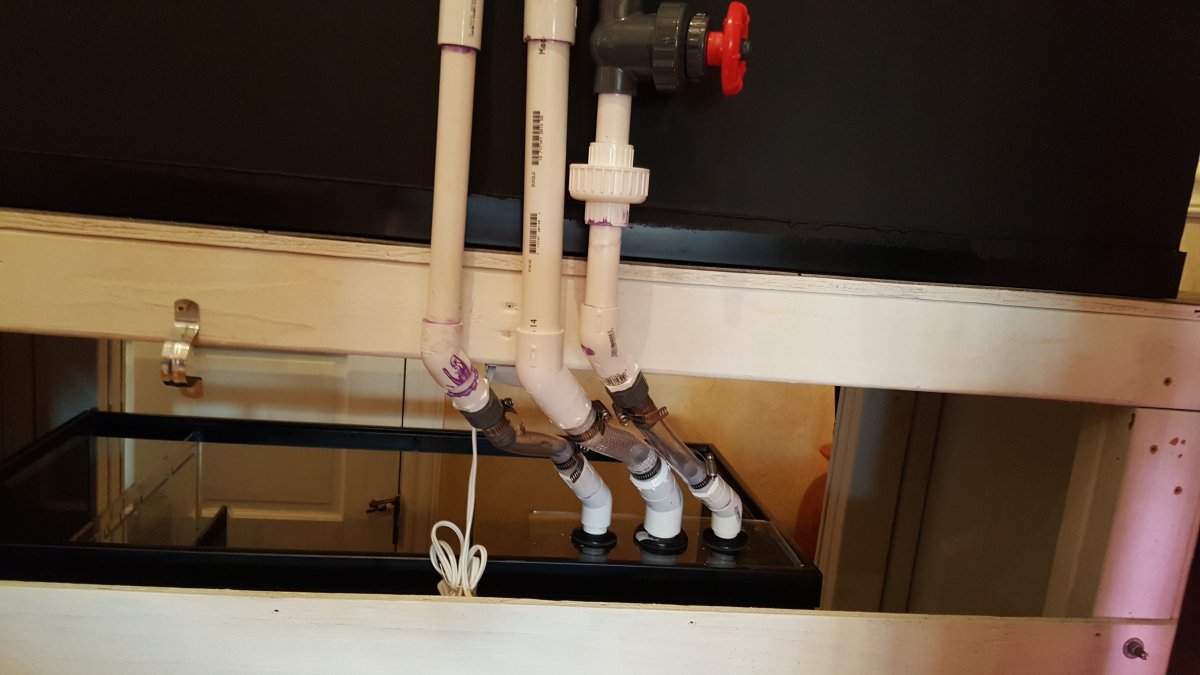

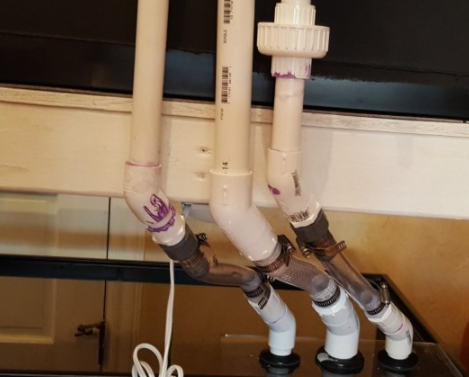

I added the back panel and 2 blocks of wood to raise the light fixture so it would be positioned correctly for the new tank. I am using the Bean Animal drain system (something I have never used before) on the new system so there is a bit of a learning curve there for me. My old 55 had an external overflow that worked OK but has some drawbacks. I have a 3/4" full siphon with a gate valve with unions, 3/4" trickle drain and 1" emergency drain. I started dry fitting everything but ran into issues getting all the right connectors. The problem part believe it or not was the 3/4" slip nozzle piece. I have gotten them before at Lowes but as luck would have it they had none and I need 4 for this job. At my local True value they had 2 with male threads and 2 with female threads. Both of these types require me adding another piece in between to go from slip to thread. I bit the bullet and bought them as my options were

I used flexible pipe to bridge my hard connections from the tank and into the sump. It took me all of Saturday to get this done believe it or not. And the icing on the cake was a mistake I made with the last connection and glued the wrong piece in the wrong location. It was already 5:00PM and I decided to call it quits for the day.

One more trip to Lowes early Sunday morning to get the pieces I need to fix my mistake and I then started the swap over process.

I used a large igloo cooler to hold the rock and most of the tank water. I placed the fish in another container that holds roughly 20 gallons and transferred the remaining tank water and sump water.

I then pulled the old tank out of the way and moved the new tank into position and reversed the process. The entire process took me roughly 8 hours and I was stressed the entire time...Luckily my family and dog were out of the house so I wasnt tripping over anybody. I have all the electrical system plugged in and running but will need to go back this week and mount items and route wires. I think I am getting a protean skimmer for my birthday and I will be adding that also in a few weeks. I added some Fiji Mud (murky water in sump) to the sump and transferred my old pond matrix and plan to get some algae growing in there ASAP. I ran tests on my drain and return to make sure nothing would overflow in the case of a power outage and all checked out. Well I'm glad the transition is done. All my corals were out by the end of the evening. My fish seemed OK but I haven't seen my Royal Gramma since I put him in the new tank. He's pretty shy so hopefully he will be out when I get home from work...Oh one other thing the Bean Animal method works fantastic and I cant believe how quiet it is. I even had a silencer on my external overflow but it doesn't come close to this.

Friday night after work I got the stand, tank and sump moved into position. My plan was to move everything out of the 55 gallon too temporary storage then get it out of the way and move the new tank into the same location then transfer all the stuff from storage into the new tank. I also need to complete the plumbing but due to the low temps here I decided to complete that in the house where the tubing and such would be easier to work with.

New tank staged but needs plumbing, back panel installed and adjustments for light fixture holder due to difference in tank height.

I added the back panel and 2 blocks of wood to raise the light fixture so it would be positioned correctly for the new tank. I am using the Bean Animal drain system (something I have never used before) on the new system so there is a bit of a learning curve there for me. My old 55 had an external overflow that worked OK but has some drawbacks. I have a 3/4" full siphon with a gate valve with unions, 3/4" trickle drain and 1" emergency drain. I started dry fitting everything but ran into issues getting all the right connectors. The problem part believe it or not was the 3/4" slip nozzle piece. I have gotten them before at Lowes but as luck would have it they had none and I need 4 for this job. At my local True value they had 2 with male threads and 2 with female threads. Both of these types require me adding another piece in between to go from slip to thread. I bit the bullet and bought them as my options were

I used flexible pipe to bridge my hard connections from the tank and into the sump. It took me all of Saturday to get this done believe it or not. And the icing on the cake was a mistake I made with the last connection and glued the wrong piece in the wrong location. It was already 5:00PM and I decided to call it quits for the day.

One more trip to Lowes early Sunday morning to get the pieces I need to fix my mistake and I then started the swap over process.

I used a large igloo cooler to hold the rock and most of the tank water. I placed the fish in another container that holds roughly 20 gallons and transferred the remaining tank water and sump water.

I then pulled the old tank out of the way and moved the new tank into position and reversed the process. The entire process took me roughly 8 hours and I was stressed the entire time...Luckily my family and dog were out of the house so I wasnt tripping over anybody. I have all the electrical system plugged in and running but will need to go back this week and mount items and route wires. I think I am getting a protean skimmer for my birthday and I will be adding that also in a few weeks. I added some Fiji Mud (murky water in sump) to the sump and transferred my old pond matrix and plan to get some algae growing in there ASAP. I ran tests on my drain and return to make sure nothing would overflow in the case of a power outage and all checked out. Well I'm glad the transition is done. All my corals were out by the end of the evening. My fish seemed OK but I haven't seen my Royal Gramma since I put him in the new tank. He's pretty shy so hopefully he will be out when I get home from work...Oh one other thing the Bean Animal method works fantastic and I cant believe how quiet it is. I even had a silencer on my external overflow but it doesn't come close to this.

Congrats on the successful move. And extra props for doing it all by yourself! I'm dreading transferring everything. Seems like no matter how much you plan ahead it's gunna take all day and it's gunna be very stressful. Especially when the new tank and stand are going in the same spot as the old one.

Very clean and nice build! Definitely going to be epic!

One thing that at least in the pic looked a bit worrying (potentially anyway) was that one of the tubing from the overflow looked like it was starting to kink. The one on the left in the pic:

I can see why and I understand the hassle. But one way to remedy it could be to make the transition to tubing further up the back of the tank. That way it has more room to flex in a larger radius. And maybe to use reinforced tubing.

Maybe it's not a big deal as it's not the main drain but I just thought that it stood out a little in the pic and that I should bring it up at least.

Hope to see an update soon!

One thing that at least in the pic looked a bit worrying (potentially anyway) was that one of the tubing from the overflow looked like it was starting to kink. The one on the left in the pic:

I can see why and I understand the hassle. But one way to remedy it could be to make the transition to tubing further up the back of the tank. That way it has more room to flex in a larger radius. And maybe to use reinforced tubing.

Maybe it's not a big deal as it's not the main drain but I just thought that it stood out a little in the pic and that I should bring it up at least.

Hope to see an update soon!