Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cinder block tank stand??

- Thread starter JDJP

- Start date

- Tagged users None

- Joined

- Apr 28, 2014

- Messages

- 575

- Reaction score

- 279

The 4x4s through the cement blocks (technically, cinder blocks haven't been made for decades, but everybody knows the type of precast concrete block you are talking about) is a bad idea as there is little strength in that direction. The holes need to be vertical.

Does the plumbing not line up with the gaps? You could notch out sections to clearance for the plumbing. The weight would be transfered primarily through the outer wall of the structure. I probably wouldn't go cutting a channel from top to bottom (though that would probably be fine as long as the rest of the structure is solid), but removing enough material to make space for the drains would be fine.

Plywood or other supports across the middle are unnecessary.

As long as the upper surface is flat and level, and you have it on a sloid foundation, you should be fine.

Are you just stacking the blocks, or are you using mortar?

Does the plumbing not line up with the gaps? You could notch out sections to clearance for the plumbing. The weight would be transfered primarily through the outer wall of the structure. I probably wouldn't go cutting a channel from top to bottom (though that would probably be fine as long as the rest of the structure is solid), but removing enough material to make space for the drains would be fine.

Plywood or other supports across the middle are unnecessary.

As long as the upper surface is flat and level, and you have it on a sloid foundation, you should be fine.

Are you just stacking the blocks, or are you using mortar?

- Joined

- Sep 18, 2015

- Messages

- 386

- Reaction score

- 135

I didnt see this untill now, but yeah I do know the blocks are stronger with the wholes vertical after doing more research.The 4x4s through the cement blocks (technically, cinder blocks haven't been made for decades, but everybody knows the type of precast concrete block you are talking about) is a bad idea as there is little strength in that direction. The holes need to be vertical.

Does the plumbing not line up with the gaps? You could notch out sections to clearance for the plumbing. The weight would be transfered primarily through the outer wall of the structure. I probably wouldn't go cutting a channel from top to bottom (though that would probably be fine as long as the rest of the structure is solid), but removing enough material to make space for the drains would be fine.

Plywood or other supports across the middle are unnecessary.

As long as the upper surface is flat and level, and you have it on a sloid foundation, you should be fine.

Are you just stacking the blocks, or are you using mortar?

I did think about running drain lines down the holes in the block, and they even sell a trench block that makes a gap i could run thr pipe through, but it seems like it may be difficult to plumb with the tank on the block.

Ive actually gone back to the lumber idea, but with a little twist, and i need more advice.

- Joined

- Sep 18, 2015

- Messages

- 386

- Reaction score

- 135

So i have a bunch (50-60 pieces) of 2"x6"x4' pressure treated lumber.

The catch is its pretty well used..

Its from my buddy's dock. So the one side is pretty weathered and the bottom looks pretty good.

So id like to try to utilize it to build a stand, but obviously would need to make it extra beefy due to the wood not being nice and new.

My first thought is to triple them up vertically at the corners and middle front and back, frame around the outside top and bottom and lay some boards flat across the top like a deck.

But that still leaves the problem of plumbing...

Any suggestions?

The catch is its pretty well used..

Its from my buddy's dock. So the one side is pretty weathered and the bottom looks pretty good.

So id like to try to utilize it to build a stand, but obviously would need to make it extra beefy due to the wood not being nice and new.

My first thought is to triple them up vertically at the corners and middle front and back, frame around the outside top and bottom and lay some boards flat across the top like a deck.

But that still leaves the problem of plumbing...

Any suggestions?

- Joined

- Feb 20, 2018

- Messages

- 31

- Reaction score

- 21

You could corner where your overflow is, and have two sets of towering cinder blocks making a right angle, leaving a void where you can run your overflow pipes. I would still use some kind of a frame, don't let the tank sit directly on the cinder blocks, as they are very brittle if stress builds up on one side more than the other. Same reason you shouldn't use cinder blocks for jack stands, distribute the weight evenly.

- Joined

- Sep 18, 2015

- Messages

- 386

- Reaction score

- 135

Thats a good idea, and i could do the same with the make shift 6x6sYou could corner where your overflow is, and have two sets of towering cinder blocks making a right angle, leaving a void where you can run your overflow pipes. I would still use some kind of a frame, don't let the tank sit directly on the cinder blocks, as they are very brittle if stress builds up on one side more than the other. Same reason you shouldn't use cinder blocks for jack stands, distribute the weight evenly.

- Joined

- Feb 20, 2018

- Messages

- 31

- Reaction score

- 21

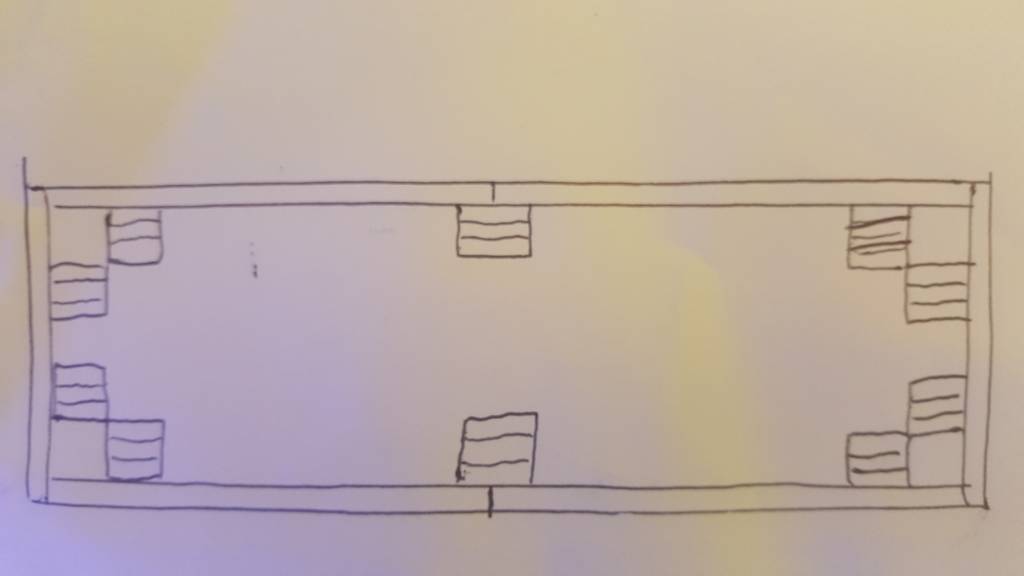

Yea that should be plenty of support and keep your plumbing accessible. Better yet, you wont have to worry about drilling your glass. Getting everything level and plumb should be fairly easy too if you're using 6x6 posts.Maybe something like this looking from top down and lay boards across the top..

Keep in mind your sump width or anything you plan on storing under the tank, with the center posts there. however if you use a 2x6 or even 2x8 for the frame you wont need center supports maybe just some angle supports if anything.

Typically, floor joists are framed in with 2x8 so you can trust, as long as the weight is distributed it will easily hold the weight of the tank. without the need for atleast the front center support.

Last edited:

Similar threads

- Replies

- 7

- Views

- 503

- Replies

- 75

- Views

- 1,769