I still haven't made the cinder block stand for my tank. I've currently got a 20 long I'd like to eventually try to make into a sump again, so I keep looking at it like "but I wouldn't be able to fit it under the blocks. . .

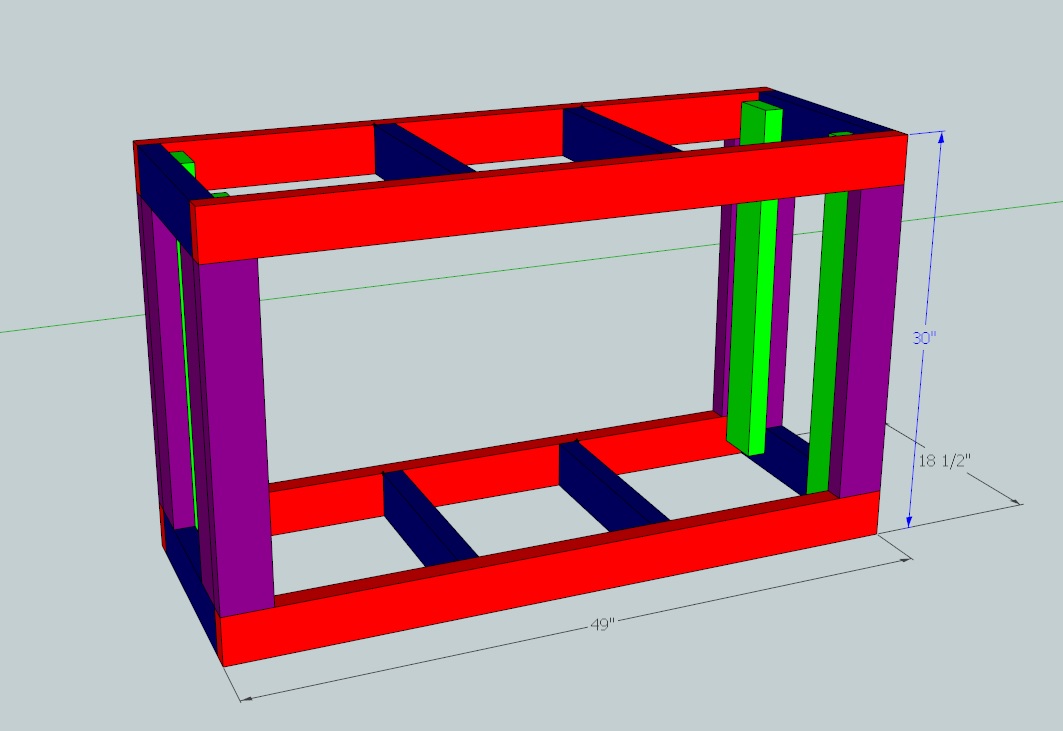

Option A: Rocket Engineer's 2x4 stand. The big issue I've got with that (besides being terrified I wouldn't be able to get it 100% square) is I don't want to skin it, I'd rather have it open if I did it that way, but I've seen tons of things saying you have to skin it or it'll sheer sideways and end up with your tank on the floor in pieces. Is that a huge issue for a 40 breeder, and without skinning with plywood, is there a different way to make sure the side to side is not going to be an issue on a 3 foot tank?

Option B: Get a 60 (breeder?) since they're on sale at petco now, and do a DIY AIO conversion for it. I'd need to find more egg crate for the lid, and need to find a hangar for my lights (I used to have one? Not that I know HOW to hang them) and they might not be long enough (24") for the nearly 4 foot span of the tank. But my fish would be happier, and I could maybe get another one or two for it at some point, and putting a few stacks of blocks under it, I'd still have plenty of room for the jug for my topoff.

I'd honestly prefer to stick with the 3 foot tank, but I would be willing to do either. Which seems like a safer bet?

Sorry I'm so indecisive and have too many questions!

Option A: Rocket Engineer's 2x4 stand. The big issue I've got with that (besides being terrified I wouldn't be able to get it 100% square) is I don't want to skin it, I'd rather have it open if I did it that way, but I've seen tons of things saying you have to skin it or it'll sheer sideways and end up with your tank on the floor in pieces. Is that a huge issue for a 40 breeder, and without skinning with plywood, is there a different way to make sure the side to side is not going to be an issue on a 3 foot tank?

Option B: Get a 60 (breeder?) since they're on sale at petco now, and do a DIY AIO conversion for it. I'd need to find more egg crate for the lid, and need to find a hangar for my lights (I used to have one? Not that I know HOW to hang them) and they might not be long enough (24") for the nearly 4 foot span of the tank. But my fish would be happier, and I could maybe get another one or two for it at some point, and putting a few stacks of blocks under it, I'd still have plenty of room for the jug for my topoff.

I'd honestly prefer to stick with the 3 foot tank, but I would be willing to do either. Which seems like a safer bet?

Sorry I'm so indecisive and have too many questions!