- Joined

- Jun 4, 2016

- Messages

- 1,001

- Reaction score

- 455

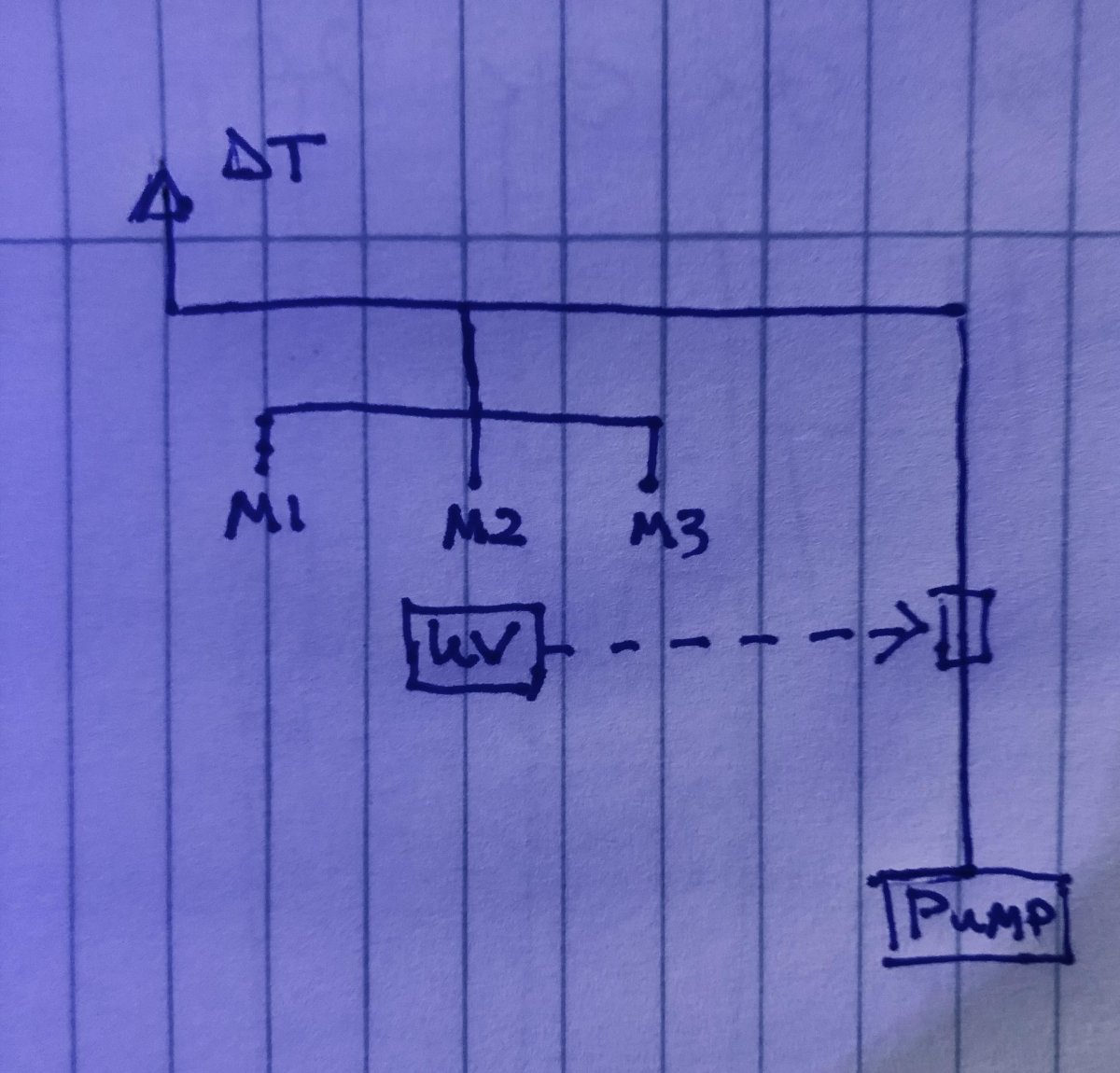

Not sure if this is called closed loop or what, but I'm struggling with UV plumbing. Trying to avoid pumping sump water through UV and back to the sump, but properly go to DT. Need some feedback on the diagram below.

Basically single pump to display. I have a 3 head manifold that I've plumbed in (M1,M2,M3 each with gate value). Will be hooking UV to M2 and it'll return via the dotted line into a Tee off the main return pump line. Question is to water flow and direction. I'm hoping by restricting the flow to M2 to slower, the pressure will be enough to push water to the return tee and ultimately to DT. Is this effective, or will there be some recirculating loop somewhere and I'll never effectively process all tank water.

I'm going in circles maybe over thinking, but looking for help. Thanks@

Basically single pump to display. I have a 3 head manifold that I've plumbed in (M1,M2,M3 each with gate value). Will be hooking UV to M2 and it'll return via the dotted line into a Tee off the main return pump line. Question is to water flow and direction. I'm hoping by restricting the flow to M2 to slower, the pressure will be enough to push water to the return tee and ultimately to DT. Is this effective, or will there be some recirculating loop somewhere and I'll never effectively process all tank water.

I'm going in circles maybe over thinking, but looking for help. Thanks@