Just wanted to start my build thread, even though I still have a ways to go before it’s complete. I’ll start with a FTS of my current tank. A recently converted FOWLR 125. This was a Petsmart Black Friday Special that I bought for $349, no tax, at the local Petsmart. This is what I bought:

www.petsmart.com

www.petsmart.com

I then made some modifications, starting with the stand. I raised the tank platform up 3 1/2 inches by inserting sections of 1x4 oak on top of the existing supporting particleboard. I built new doors out of particleboard that I had cut to size at the local Home Depot. On the tank, I drilled the back and added a medium size Eclipse external overflow. Eventually I ended up with this. This is the review that I posted to the Petsmart website.

This is what it looks like now

This is what it looks like now

I also built a matching open-style canopy to hold the light fixture and block the glare. The canopy allows access to the glass canopy doors which allows access to the tank itself for feeding and minor cleaning and aquascaping.

I also built a matching open-style canopy to hold the light fixture and block the glare. The canopy allows access to the glass canopy doors which allows access to the tank itself for feeding and minor cleaning and aquascaping.

Aqueon® LED Aquarium & Stand Ensemble - 125 Gallon | fish Aquariums | PetSmart

Aqueon® LED Aquarium & Stand Ensemble - 125 Gallon at PetSmart. Shop all fish aquariums online

I then made some modifications, starting with the stand. I raised the tank platform up 3 1/2 inches by inserting sections of 1x4 oak on top of the existing supporting particleboard. I built new doors out of particleboard that I had cut to size at the local Home Depot. On the tank, I drilled the back and added a medium size Eclipse external overflow. Eventually I ended up with this. This is the review that I posted to the Petsmart website.

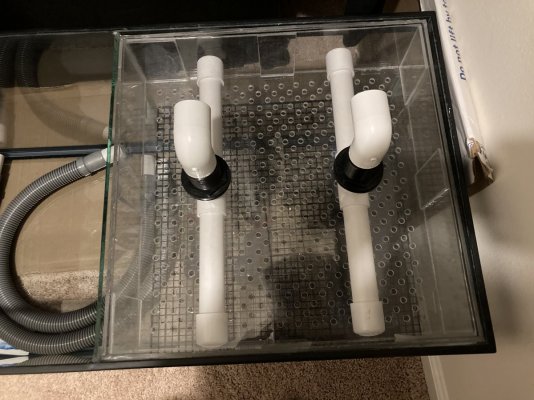

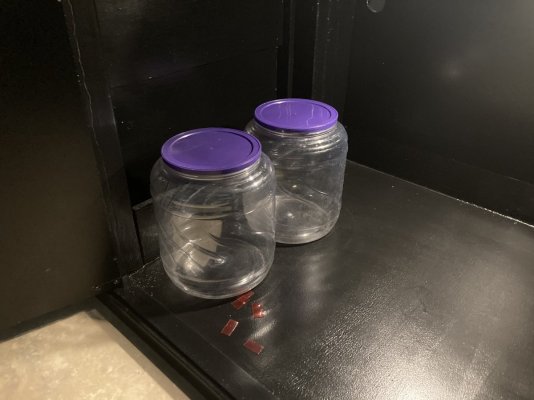

Amazing potential

Bought on Black Friday 2017. Spent a few months modifying the tank. Added a removable dry rock rubble back wall and an Eclipse medium-sized overflow. Also modified the stand to make room for a 10-Gallon quarantine tank, custom-made wet/dry filter and 10-Gallon auto top-off system. Very happy with this product. Excellent quality.

This is what it looks like now

This is what it looks like now

I also built a matching open-style canopy to hold the light fixture and block the glare. The canopy allows access to the glass canopy doors which allows access to the tank itself for feeding and minor cleaning and aquascaping.

I also built a matching open-style canopy to hold the light fixture and block the glare. The canopy allows access to the glass canopy doors which allows access to the tank itself for feeding and minor cleaning and aquascaping.

Last edited: