Minifoot77

Jack of all trades and a master of none

View BadgesPartner Member 2024

Midwest Reefer

Rock Pool Reef Keepers

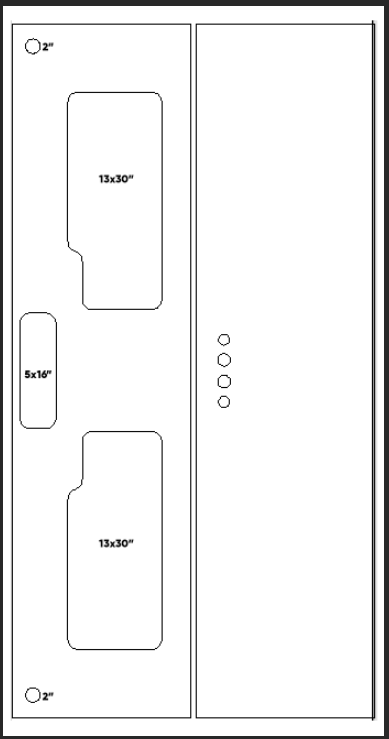

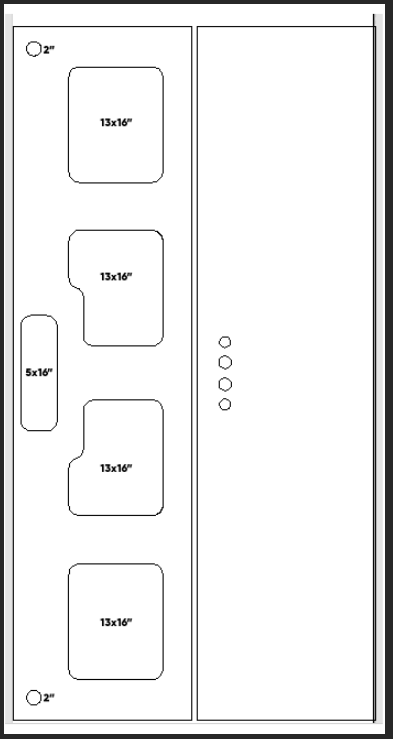

Diy margarita blender now we are talkin...After further FB from the client, we are looking at a two access opening design with a center mount OF. The drains will be dual 1 inch and the returns will be dual 3/4 inch. Each return will be independent with its own Sicce SDC pump. Tank walls are 1/2 inch and the top will be thicker at 3/4 inch. The OF will have weirs on three sides with 1/8 inch by 1-1/2 inch slots. Adjustable black polycarb gates on all sides. Two 2 inch thru holes, one each in the back corners will allow for wave makers, margarita blenders or other in tank accessories. Returns will be on both short walls. The OF will also have a separate black polycarb lid. Black back. The images are split views, the top pattern and the corresponding drill pattern of the bottom panel.