Thanks wallyB. looking forward to seeing the new and Improved video.Good to see someone is interested. I'm working on a video and details during my testing. The feeder is working perfectly with the improved design. I can add more pumps-tubes to this setup and feed more tanks since this design allows for easy expansion to multiple tanks (one food source). The Anthias is really happy now since he get's fed small portions 4 times a day.

I will start a new thread and link it on this thread.

Stay tuned.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY (Auto) FROZEN FOOD FEEDER

- Thread starter WallyB

- Start date

- Tagged users None

Sorry for the delay....things got busy.

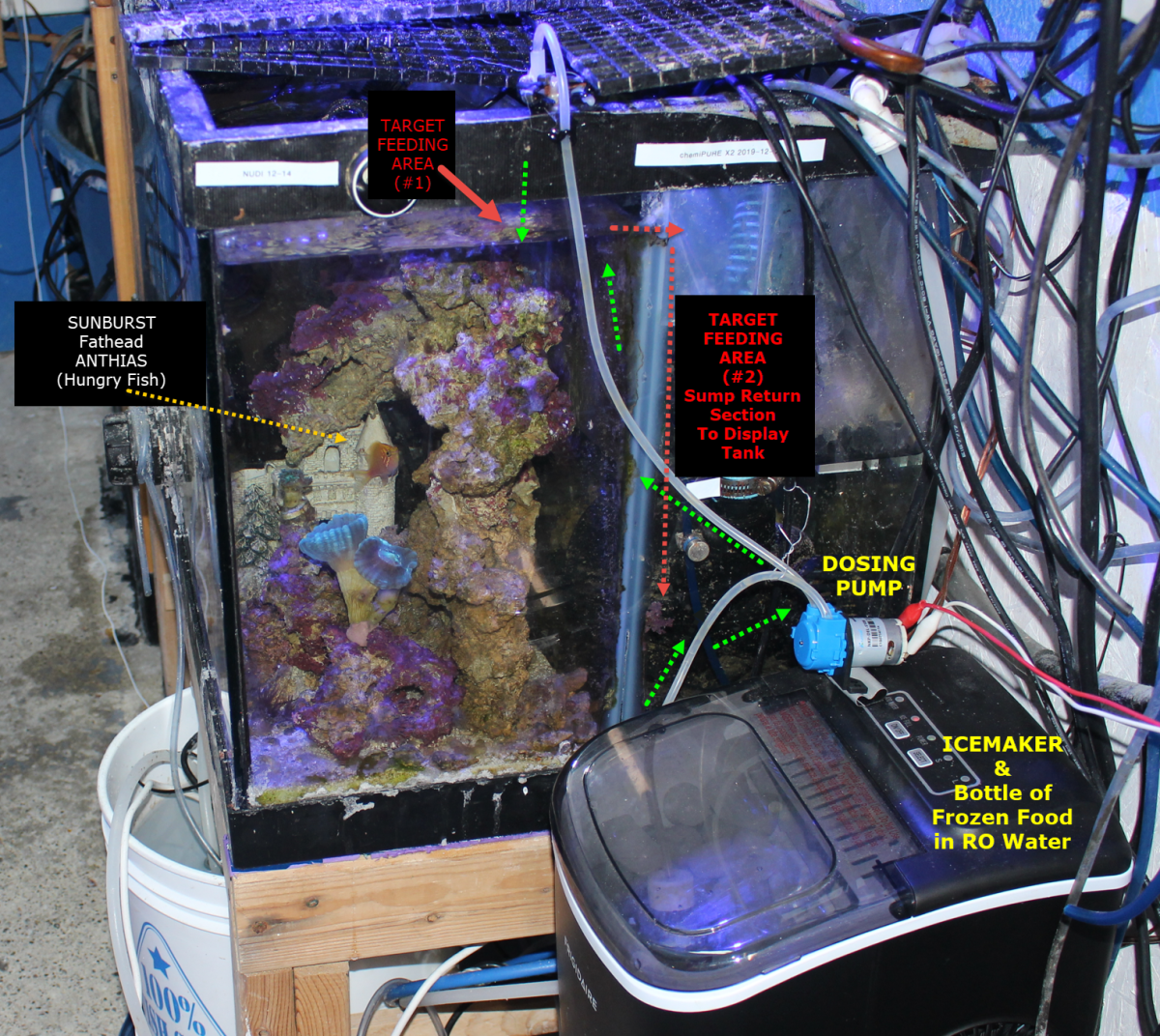

The Feeder is running Perfect. My Sunburst Anthias fish is now getting fatter and is not as shy as in the past. I'm using this feeder (using one pump) and now may add (2nd pump) to feed all 3 of my tanks. The first pump actually feed two tank since The Sunburst Anthias is in a section of my Sump. Some of the food overflow that tank and goes into my sump return section which flows to the 110G office tank.

I've shot the video and need to sitch together the Frozen Feeder Demo ...shouldn't be be long.....It's just shows ice being made, pump pumping and fish eating. These instructions tell how to make one.

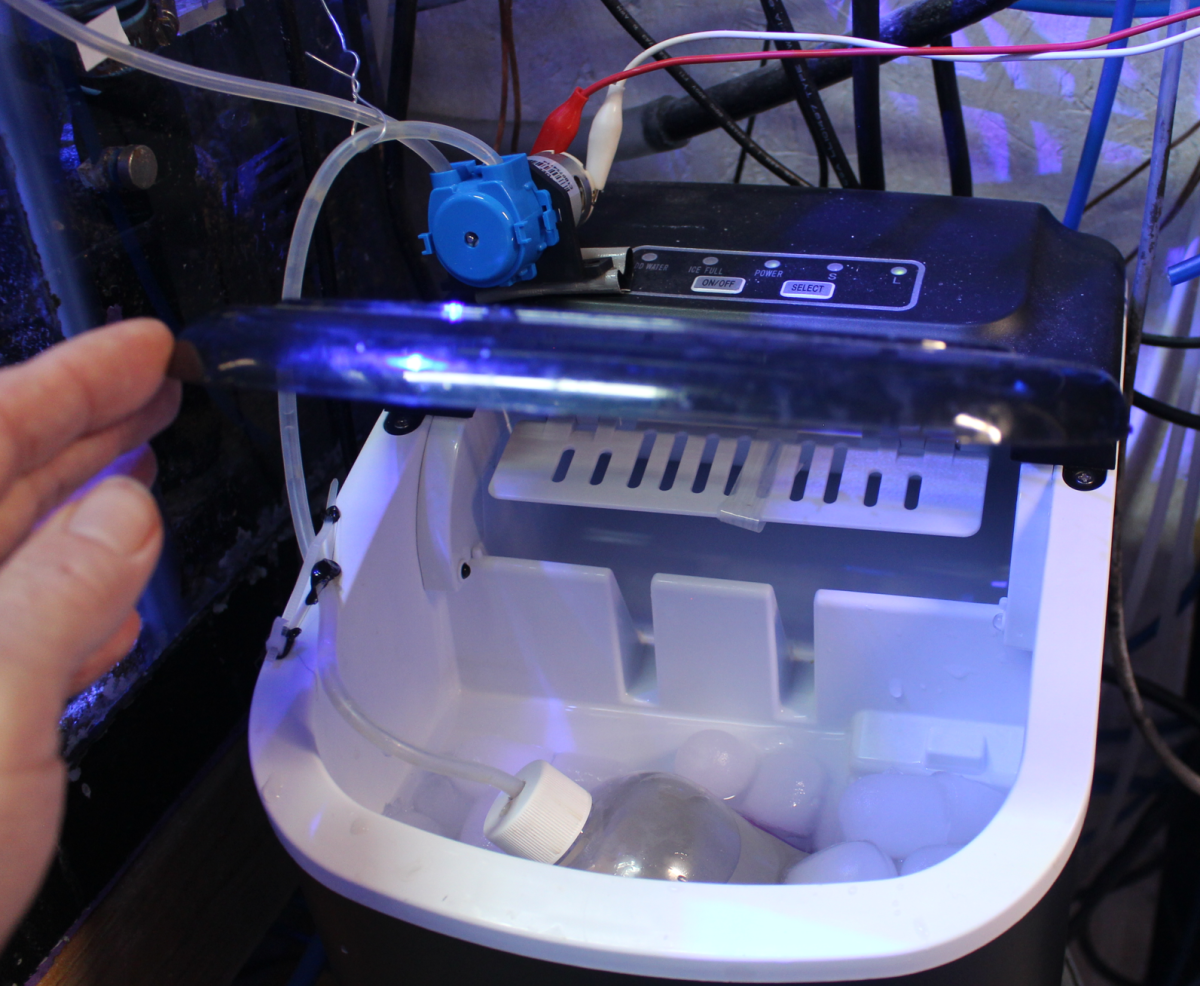

This is the setup.

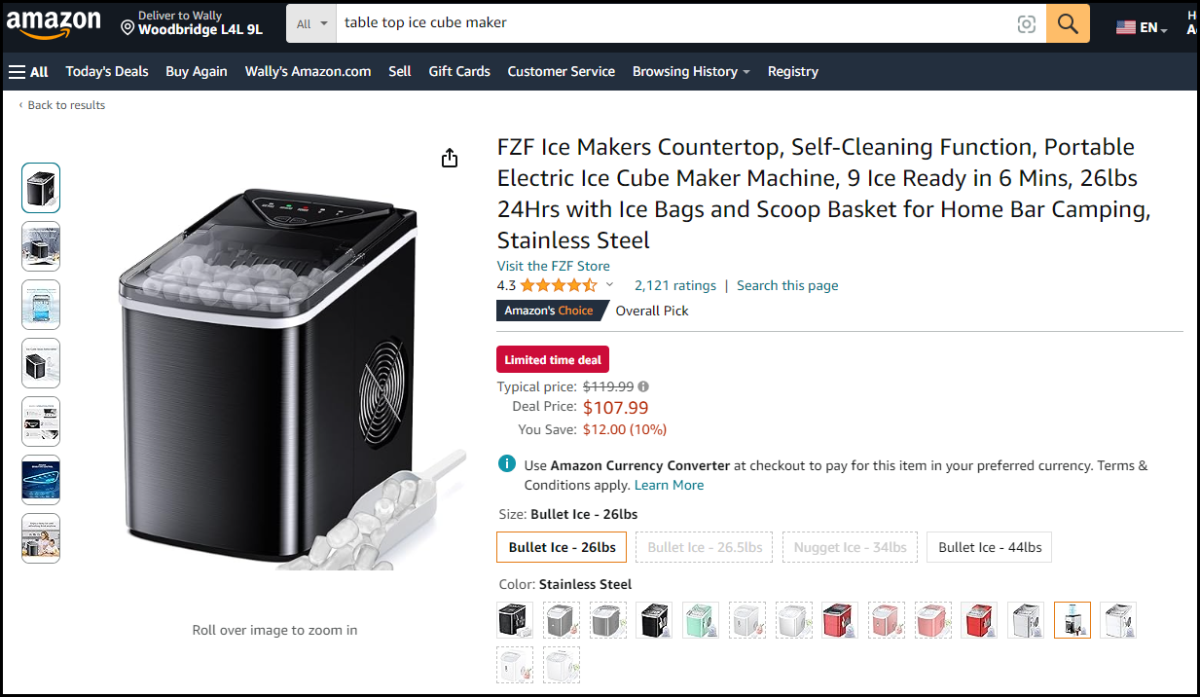

It's pretty simple. You need an Ice Cube Maker like one of these.

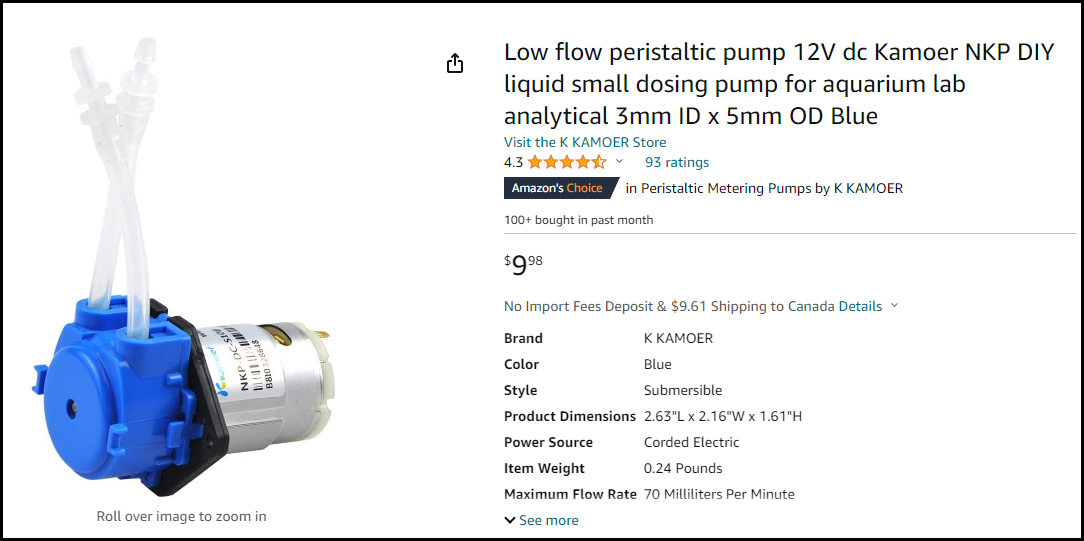

Then a Peristaltic (dosing) Pump....like this one. 12 Volt or 6 Volt...Your choice depending on what kind of power supply you have. I use Kamoer brand for quality.

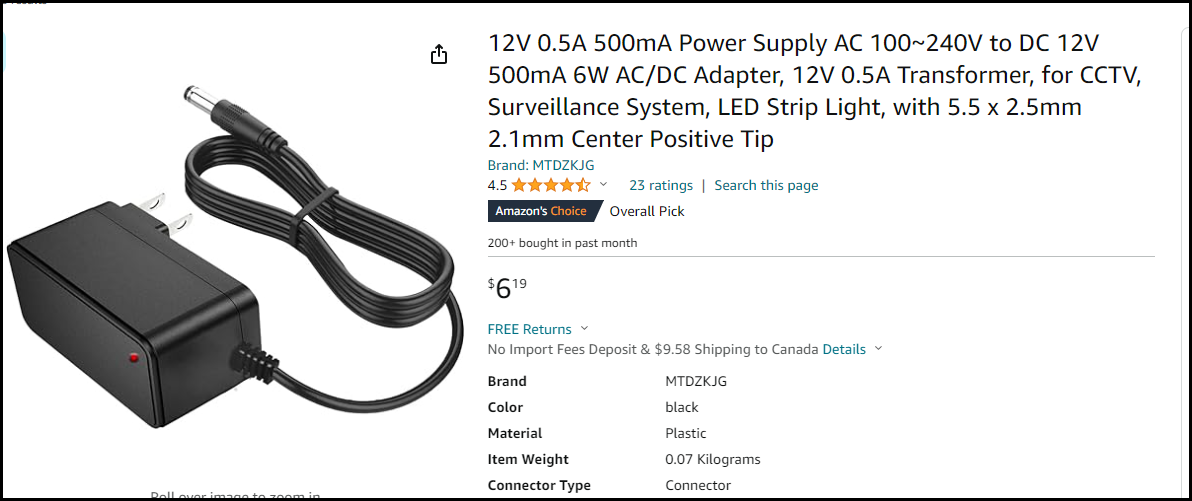

A power supply to run the pump. For the above pump you would need a 12 Volt, 500 miliaAmp AC Adapter. You may have a few kicking around from old electronics. If not you need to purchase on of these.

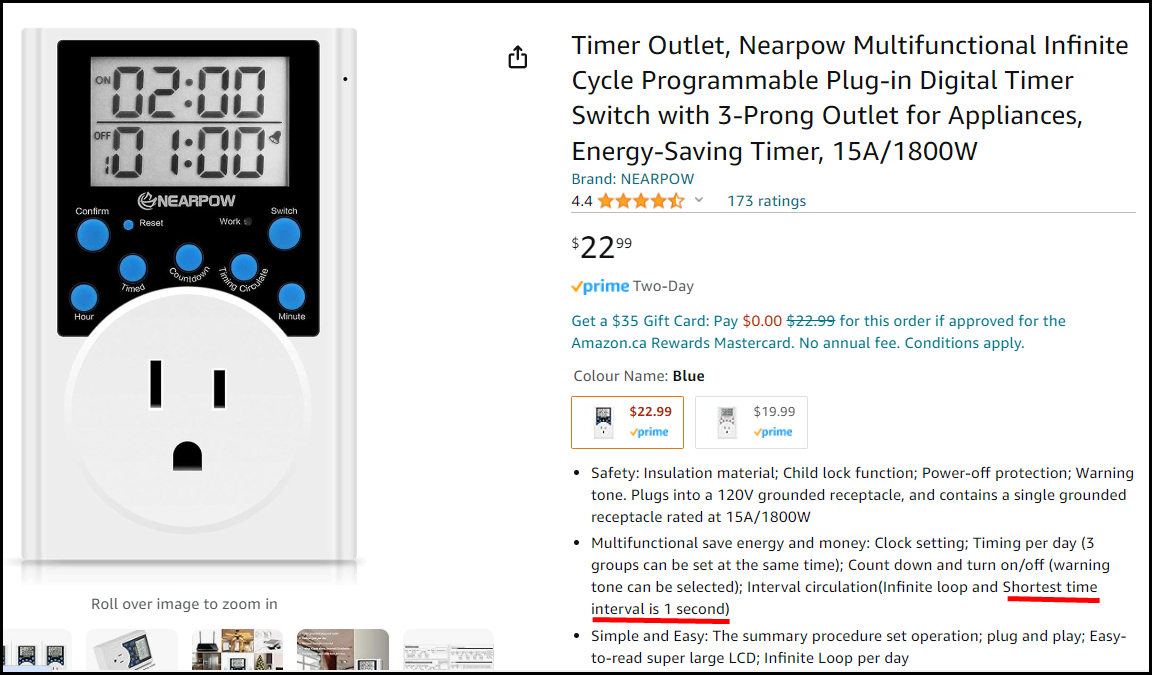

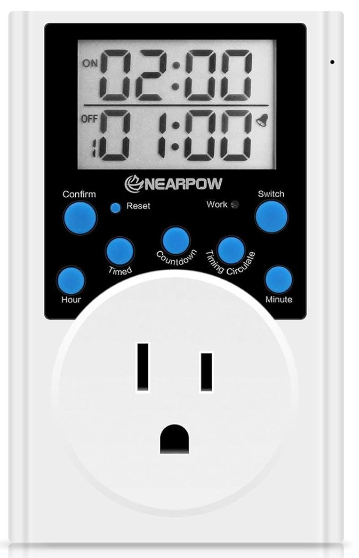

If you have an Neptune Apex or other smart controller you can turn control things that way. If you don't have a controller then you need a Smart Timer. The timer you need something that can have on and off or duration in seconds, NOT minutes.

That's all you need beside tubing, a bottle, and frozen food.

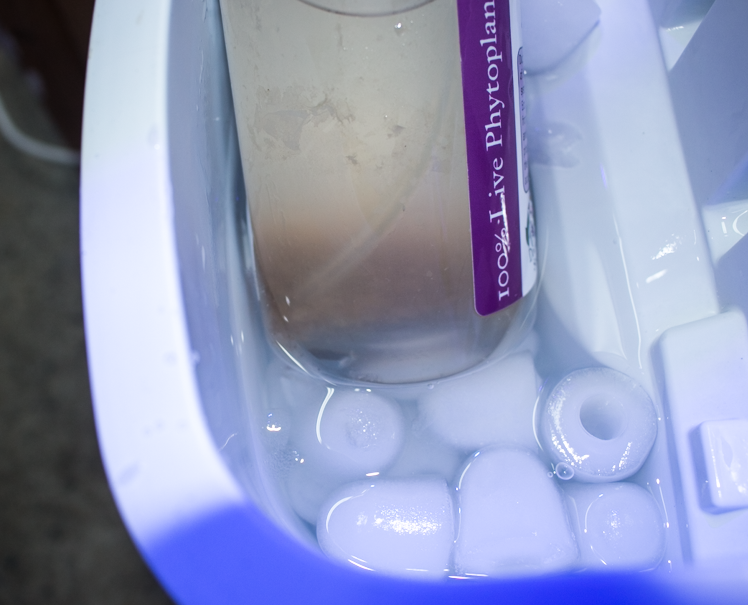

The setup and run is simple. The ice cube maker makes ice continously to keep it full and food cold. The compartment for the ice is also the source of the water to make the ice. As ice melts that water is again used to make more ice so it's a perpetual ice machine on the same water. You need to find a bottle that fits in the comparment and fill it with water and food. I prefer to melt my forzen food and remove the liquid throught a brine shrimp net before adding the food into the container filled with RO water (pre-chilled). I drilled a hole in the cap of the bottle and then I ran silicone dosing pump tubing from bottle to pump and pump to tank feeding location.

This is the Bottle of Food I use. I use mix of Frozen Brine Shrimp and Mysis.

It's important you have the tubing placed properly into the bottle so it's at the bottom and at the edge of bottle so when bottle is slightly tilted laying in ice the food always is at the tube end. Drilling a hole in the cap of the bottle to be snug helps keeping tubing from shifting out of position. The food will always settle to the bottom of the bottle.

Then push bottle down into ice. Slightly tilted.

Bottle and contents will be kept nice a cold to keep food fresh for a whole week of auto feeding.

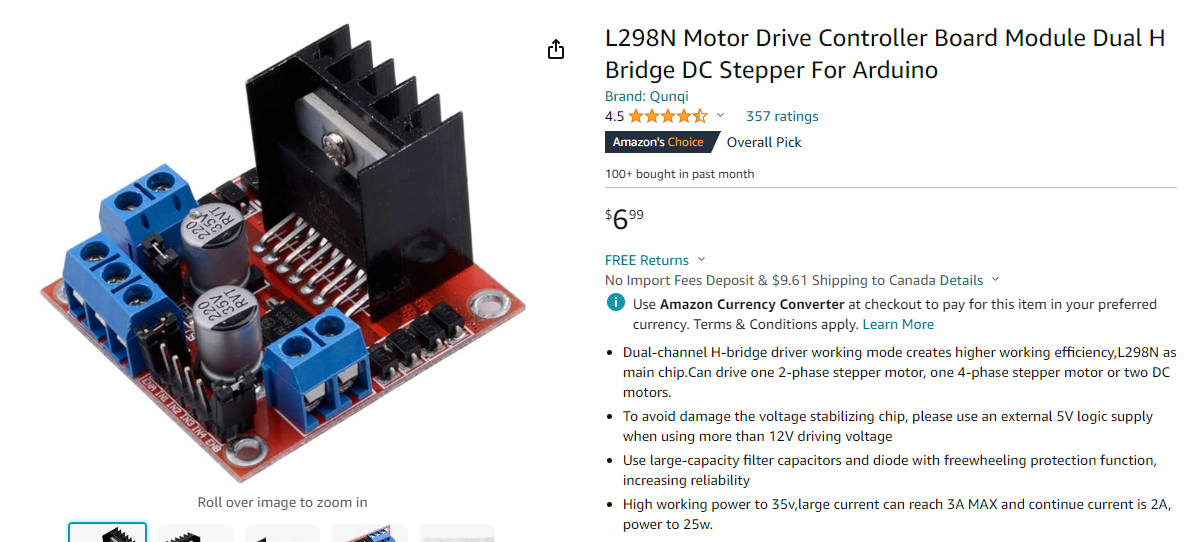

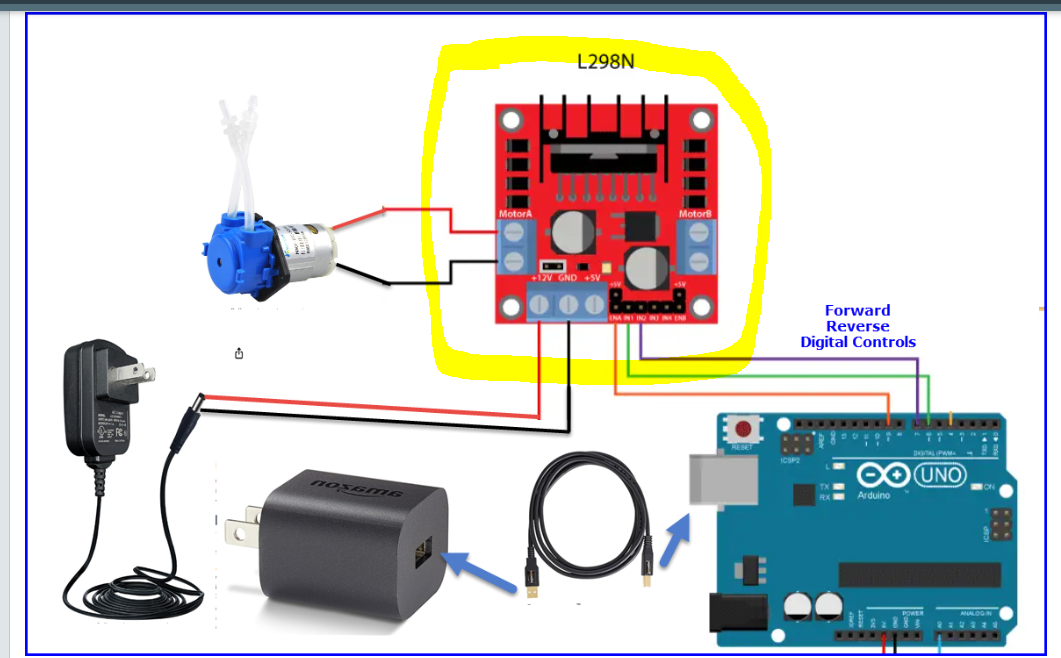

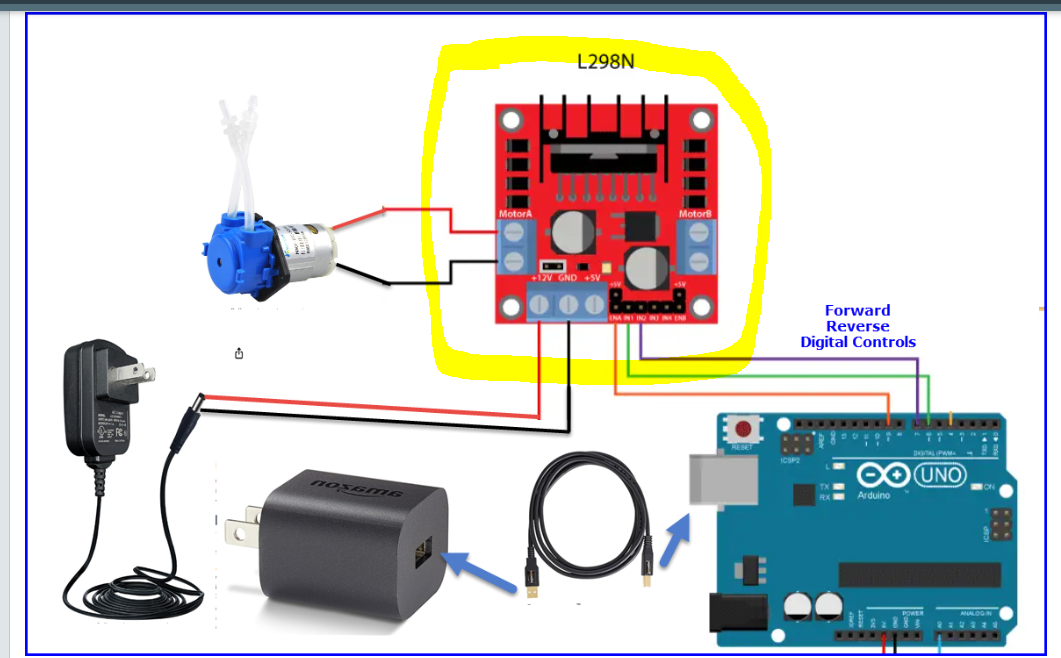

I think it's best to have the Ice Maker as close to feeding area as possible since that keeps the frozen food segement out of cold shorter. If you don't feed often that food will warm up and not be as fresh as the food stored in the bottle. So in my case I've designed a simple Ariduno Controller for two way pump control. Two way allows me to run the pump in reverse after feeding so all food and liquid is returned to the cold bottle. If anyone is interested in the Mini Feed controller design let me know and I'll provide details and code. I used an Ardiuno Uno, and one of these modules and 1 button to program the timing. Same 12 Volt Power Supply to run pump. USB power for the Arduino.

Using the promaable timer is much easier for the rest of you folks.

You simply turn on the pump for just enough time in seconds so food gets drawn from bottle to get to tank. How many seconds is up to you and will decide how big of a portion you want to feed.

I hope this rushed overview is clear.

Let me know what you think and any feedback or questions.

The Feeder is running Perfect. My Sunburst Anthias fish is now getting fatter and is not as shy as in the past. I'm using this feeder (using one pump) and now may add (2nd pump) to feed all 3 of my tanks. The first pump actually feed two tank since The Sunburst Anthias is in a section of my Sump. Some of the food overflow that tank and goes into my sump return section which flows to the 110G office tank.

I've shot the video and need to sitch together the Frozen Feeder Demo ...shouldn't be be long.....It's just shows ice being made, pump pumping and fish eating. These instructions tell how to make one.

This is the setup.

It's pretty simple. You need an Ice Cube Maker like one of these.

Then a Peristaltic (dosing) Pump....like this one. 12 Volt or 6 Volt...Your choice depending on what kind of power supply you have. I use Kamoer brand for quality.

A power supply to run the pump. For the above pump you would need a 12 Volt, 500 miliaAmp AC Adapter. You may have a few kicking around from old electronics. If not you need to purchase on of these.

If you have an Neptune Apex or other smart controller you can turn control things that way. If you don't have a controller then you need a Smart Timer. The timer you need something that can have on and off or duration in seconds, NOT minutes.

That's all you need beside tubing, a bottle, and frozen food.

The setup and run is simple. The ice cube maker makes ice continously to keep it full and food cold. The compartment for the ice is also the source of the water to make the ice. As ice melts that water is again used to make more ice so it's a perpetual ice machine on the same water. You need to find a bottle that fits in the comparment and fill it with water and food. I prefer to melt my forzen food and remove the liquid throught a brine shrimp net before adding the food into the container filled with RO water (pre-chilled). I drilled a hole in the cap of the bottle and then I ran silicone dosing pump tubing from bottle to pump and pump to tank feeding location.

This is the Bottle of Food I use. I use mix of Frozen Brine Shrimp and Mysis.

It's important you have the tubing placed properly into the bottle so it's at the bottom and at the edge of bottle so when bottle is slightly tilted laying in ice the food always is at the tube end. Drilling a hole in the cap of the bottle to be snug helps keeping tubing from shifting out of position. The food will always settle to the bottom of the bottle.

Then push bottle down into ice. Slightly tilted.

Bottle and contents will be kept nice a cold to keep food fresh for a whole week of auto feeding.

I think it's best to have the Ice Maker as close to feeding area as possible since that keeps the frozen food segement out of cold shorter. If you don't feed often that food will warm up and not be as fresh as the food stored in the bottle. So in my case I've designed a simple Ariduno Controller for two way pump control. Two way allows me to run the pump in reverse after feeding so all food and liquid is returned to the cold bottle. If anyone is interested in the Mini Feed controller design let me know and I'll provide details and code. I used an Ardiuno Uno, and one of these modules and 1 button to program the timing. Same 12 Volt Power Supply to run pump. USB power for the Arduino.

Using the promaable timer is much easier for the rest of you folks.

You simply turn on the pump for just enough time in seconds so food gets drawn from bottle to get to tank. How many seconds is up to you and will decide how big of a portion you want to feed.

I hope this rushed overview is clear.

Let me know what you think and any feedback or questions.

Last edited:

WallyB:

Question for you, I see in this new and improved version, you went without a stir plate. Does the lack of a stir plate cause the food at the bottom of the bottle to get concentrated and thus cause clogs in the hoses?

Question for you, I see in this new and improved version, you went without a stir plate. Does the lack of a stir plate cause the food at the bottom of the bottle to get concentrated and thus cause clogs in the hoses?

@Greatreefer, you are 100% correct. In the last design didn't think of tipping the food bottle since it had to be flat to work with the Stir Plate and pellet. This design is better to get all the food to the last drop of water as the bottle drains from the bottom. A stir plate is not needed at all and didn't help clogging, I did that so less food would be drawn each feeding as it was spread out (just before extraction). With this design, the amount of food you extract each feeding can be slightly controlled by how much you tip the bottle. Too much tipped and too much food per feeding (bottle empties quick), too flat and not enough (per feeding), but all will eventually be removed when all water is removed. Take a bit of practice on food, water, and tip angle (and dosing pump duration per feed).WallyB:

Question for you, I see in this new and improved version, you went without a stir plate. Does the lack of a stir plate cause the food at the bottom of the bottle to get concentrated and thus cause clogs in the hoses?

One note: Since I reverse my pump flow with a mini controller, I can actually get the food stirred a bit as air bubbles enter the bottle and cause some stirring. (ie Air bubbles first by REVERSE, then start feeding forward WITH Food and Water). It's not a huge difference but better.

You do have to get the right sizing of the bottle, amount of water, and amount of frozen food. Not too difficult with some guessing. Extra water is better than not enough water. You do need enough water so food can travel the tube length to the tank feeding area. With extra water at some point, all the food will be siphoned out and some spare water left over. Food does not clog if you use the Smaller Mysis, and no issue with brine shrimp. The frozen food thawed and suspended in water is pretty soft. Don't go super thin on the dosing pump tubing, and avoid narrow couplers to joining tubes and all will be fine. (notice I don't use couplers at all, since I use Perstatic tubing from beginning to end, including going through the dosing head). Don't go with chunky food or expect plugging issues, or food left behind.

So to summarize, the stir plate does help make the food last longer in the bottle to give you more feeding for every fill-up. I learned that more feeding out of a bottle isn't ideal, since even in the cold ice cubes, the thawed food doesn't smell fresh after 5-6 days. Not rotten but not as fresh. You can probably go max 6-7 days of running time on each batch of food refill. Then it's time to replace the content, even if some left over. I have considered adding insulation to maybe make the ice area a bit colder to keep food fresher for longer.

Last edited:

WallyB:

How do you assemble all the parts together?

I assume the doser pump connects to motor drive and then does it branch out to the rasberry PI controller and then connects to power?

Something like below?

How do you assemble all the parts together?

I assume the doser pump connects to motor drive and then does it branch out to the rasberry PI controller and then connects to power?

Something like below?

@Greatreefer,WallyB:

How do you assemble all the parts together?

I assume the doser pump connects to motor drive and then does it branch out to the rasberry PI controller and then connects to power?

Something like below?

Remember as I mentioned you don't need the LN298N motor control module & Ardiuno if don't want bi-direction pump control, or speed control, or two pumps.

You can simply wire things up like this using the Seconds_Timer, 12 Volt AC-Adapter, 2-wires and a pump. This will work to feed using only Forward flow on the dosing pump.

The above is as simplest to get Feeder pump working and various timing intervals.

If you have programming and wiring skills or want to learn you can get more elaborate. It's not super complex but does take some basic understanding of wiring, and programming which can be bit more complex, however tutorials can help you learn.

So, if you want bi-directional (forward & reverse) pump control, then read up on how the LN298N module + Arduino works in this link below. There are sample code instructions as well in this tutorial.

https://howtomechatronics.com/tutor...dc-motor-control-tutorial-l298n-pwm-h-bridge/

The setup will look like this just to give you an idea. This is my setup, except I added a Button to program the forward and backward timing so I can change and adjust, without changing the code ever.

Let me know your thoughts.

Question about the L298N, this boards primary purpose is to reverse the pump so it can flush the line.

Can you hookup multiple pumps to one board or do you have to have one board and one PI per per pump?

Can you hookup multiple pumps to one board or do you have to have one board and one PI per per pump?

Question about the L298N, this boards primary purpose is to reverse the pump so it can flush the line.

Can you hookup multiple pumps to one board or do you have to have one board and one PI per per pump?

First let's get things cleared up. That CONTROLLER BOARD is a Ardiuno UNO, NOT a Raspberry PI. They are very different. You could use a Raspberry PI but then it's a different type of programming language like Python, and much more complex to set-up. The Ardiuno uses a C type programming language.

THIS IS AN ARDIUNO (UNO). There are many models.

THIS is a Raspberry PI. Also many models are available.

I use an ARDUINO since it's quicker and easier to set up and cheaper.

You only need ONE ARDIUNO for the LN298N. (ie, you DO NOT need two ARDIUNO's, and you DO NOT NEED two LN298N's to run two pumps). Each pump can also be run forward and reverse since that is what the LN298N does. The ARDIUNO using digital I/O lines just turns ON/OFF each pump using the LN298N and also set the direction of the pumps (FORWARD or REVERSE).

The LN298N can do (UP TO) two pumps, and all you need is one 12 Volt Power Supply. That's one bonus since you only need One Power Supply (for EACH LN298N). Of course, if you want to run both pumps at the same time you will need a Power Supply to handle both pumps. Power Supply will still be 12 Volts, but it's current rating will have to be Double.

I will be honest. The questions you are asking seem to indicate that you are a novice to mini computer/controller and programming. Nothing wrong with wanting to learn and make a Auto-Feeder, however, you have to do a bit of your own research and learning or else you will quickly be over your head and things will not work out. I don't want you to waste your time, effort, and money and not succeed. I posted the design and extra information to prove it can be done. This is not a full DIY a-z tutorial/Instrucable how to build and code the whole design. Maybe one day I will make an A-Z Instructable and that would require a larger number of people interested in the project.

If you PM me I may point you in the right direction (where to learn more) as I already did and we can discuss privately outside of this thread. This thread would go on for many pages and that never was the intent.

Why don't you go with the "Simple off the Shelf Timer", few wires, pump, One Power Supply and you're done? No programming needed except the Timer and it will come with a manual for that.

Last edited:

Similar threads

- Replies

- 11

- Views

- 292