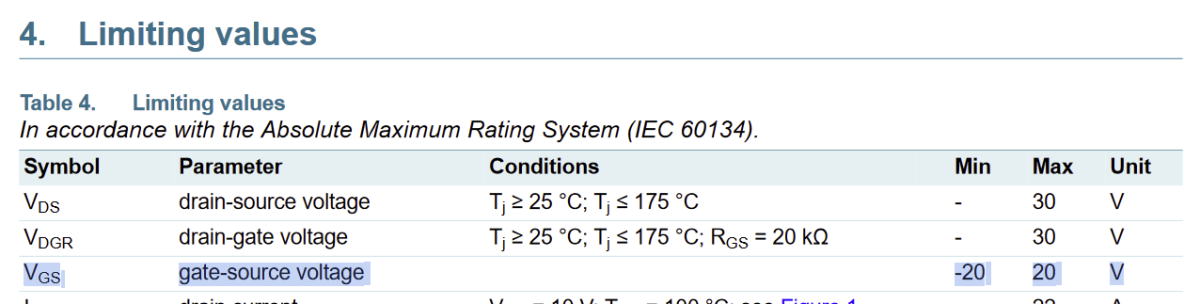

Darnit, I completely forgot about that Limitation, thanks !There should be no need, you can drive the MOSFETs directly from the PCA9685 outputs. Anything more than about 10V is pointless, and, more importantly, 24V is above the maximum Vgs for the MOSFET (and pretty much any MOSFET)

So, just tie the ground from the PWM circuit and the PCA9685 and connect directly.

The pull-down to keep the channel off is fine.

This is fine to run on the perfboard. You can increase the current carrying capacity of a trace by laying solder on top of it for extra insurance.

Not needed. Paralleling devices can be done but unless done carefully one will take the bulk of the load anyway.

I may have missed this from an earlier post, is there anything controlling the current through each LED string?

The Limitation of current is done by the Lamp itself. Normally you just connect the 24V power source and get 100%.

I’ll think about the optocoupling, my paranoia says to use them, especially since I have them lying around. Supplying them with less voltage shouldn’t be a big problem that a few resistors, zener diodes and/or a 5V regulator can’t solve.

Thanks a lot ! I’ll be trying to plan this out on a perfboard with extra solder, even though I have noticed that a propped PCB would both make the current requirement and space usage a lot easier … as @robsworld78 mentioned