Hi,

I'm still figuring out which Light to buy for my Aquarium and Reef-Pi build, but I want it to be controllable via PWM from Reef-Pi. I therefore need a nice PWM controllable dimmer. I looked up a few threads:

I'm still figuring out which Light to buy for my Aquarium and Reef-Pi build, but I want it to be controllable via PWM from Reef-Pi. I therefore need a nice PWM controllable dimmer. I looked up a few threads:

- DIY led lighting setup

- All in One LED Controller/Dimmer/Driver Project

- Some PCB design ideas for DIY LDD-L driver based builds

- 5-6 channels:

- 1 warm white (prob up to 24V 1,6 A)

- 1 cold white (prob up to 24V 1,6 A)

- 3 RGB (prob. up to 24V 0,25 A each)

- up to ~ 92W in total (from planned LED)

- 24V power supply will come with the light

- I plan to only use non SMD solderable breadboard, since I don't have much equipment and experience yet.

- Advice on the ICs to use ?

- I would like to use IC sockets

- easier to solder and to replace

- Could I use two 1A channels to power the 1,6 A white LEDs ?

- (Or is that a bad Idea since it might fry the second channel if the first dies or something ... ) ?

- Which ICs should I use in your oppinion ?

- What should I watch out for ?

- protection circuits in case something breaks or fries ?

- Bypass Capacitors to limit feedback to the power supply ?

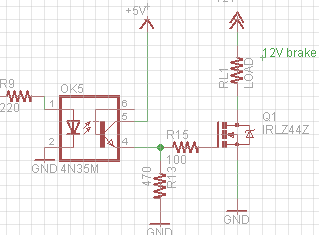

- Optocoupler to isolate the PWM circuit ?

Last edited: