Hello Reefers,

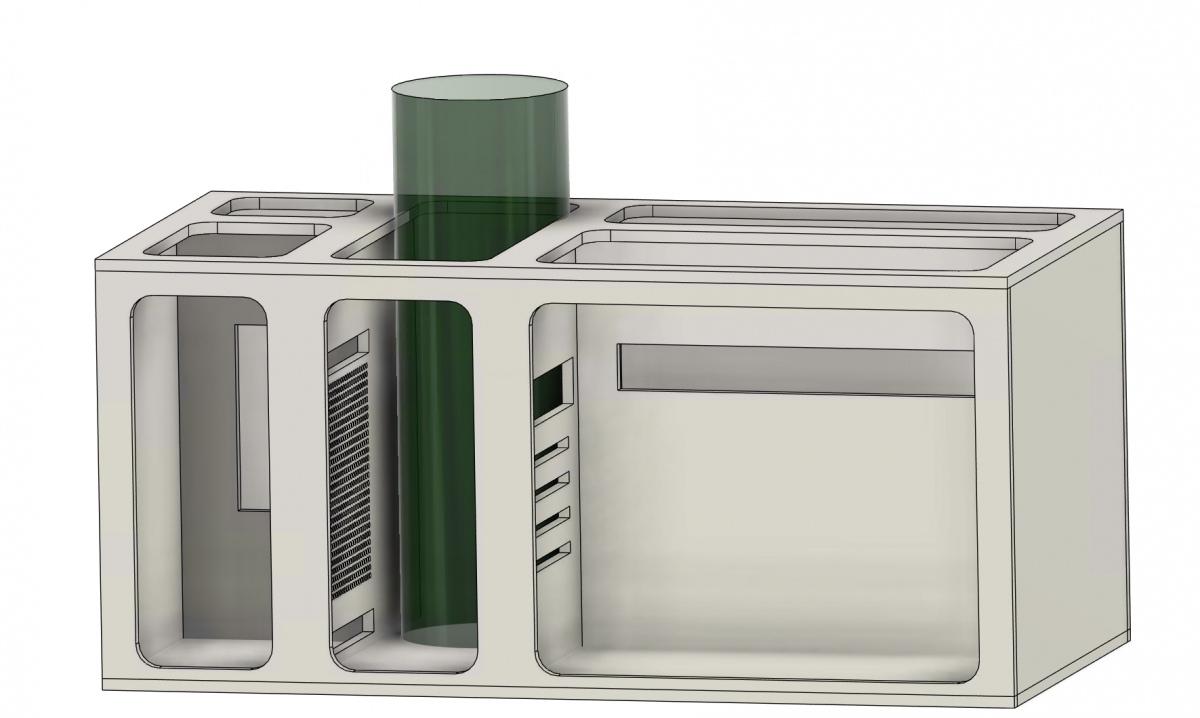

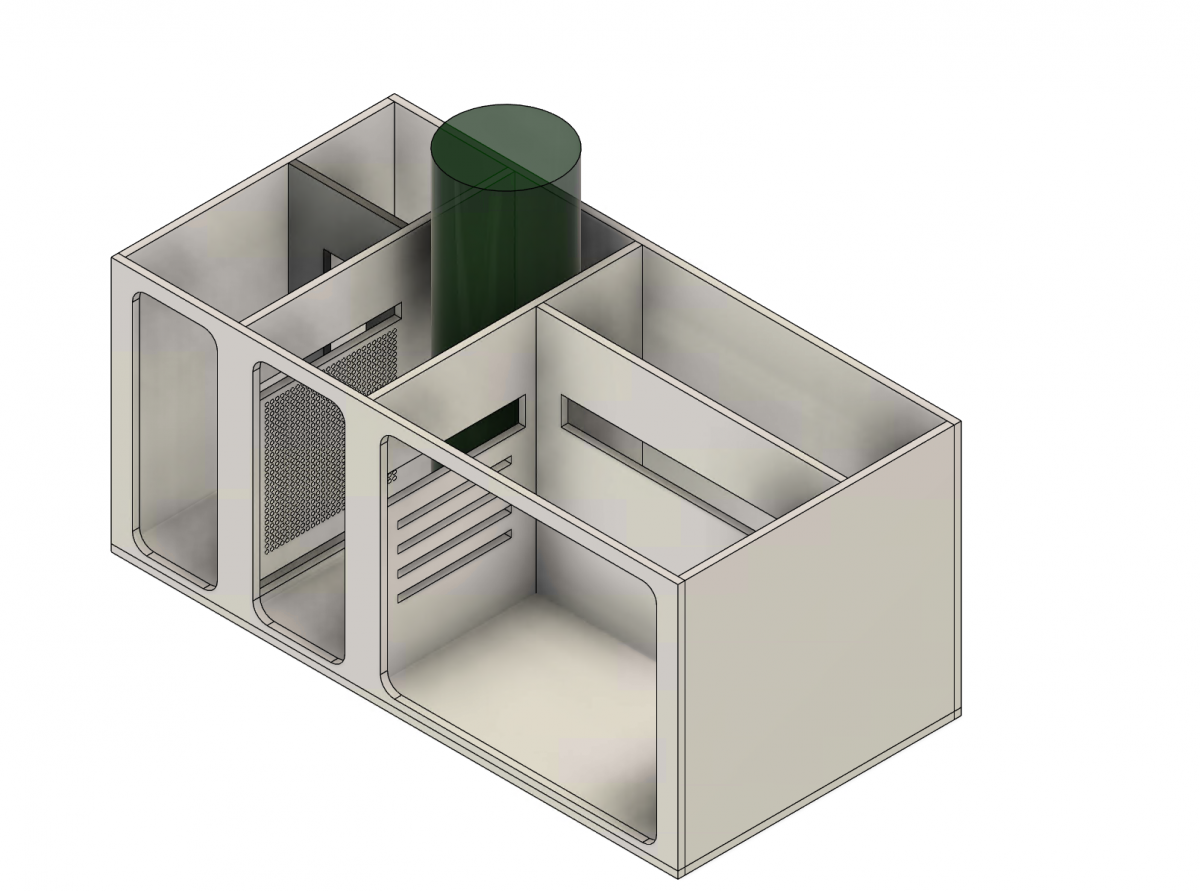

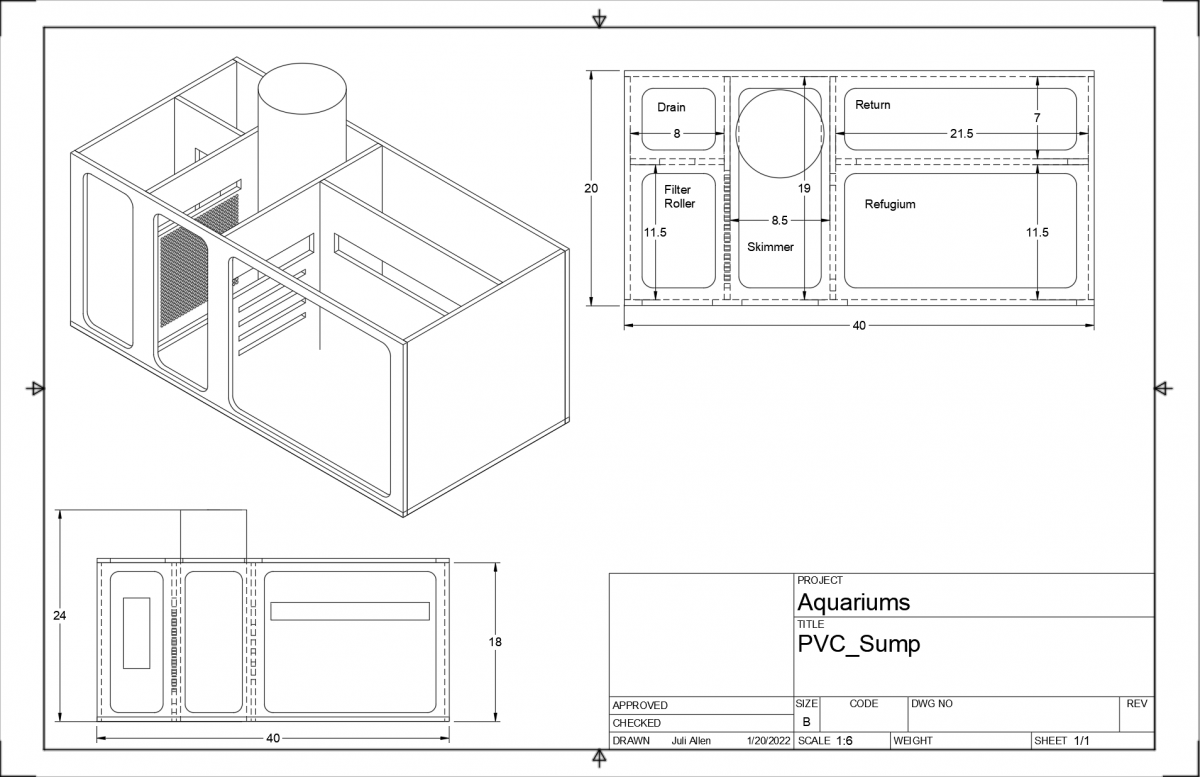

I am planning to build my own sump and figured I could document it here for all to see. I am still in the design phase (Fusion 360) but plan to pick up my material and begin cutting soon. My tank is a 5 foot long 150 gallon from SCA, which means I have a about 55"x 22" of free space inside my stand to work with. As of now I plan to make the sump 40" long, 20" deep and 18" tall.

The majority of the sump will be made from .5" thick white PVC, the rest will be viewing windows made from .25" thick acrylic. This is somewhat for design aesthetics, but also because the PVC is much cheaper and easier to work with.

I have a CNC machine in my garage which I will use to do the cutting of the PVC and Acrylic.

Here are some images to give an idea of my plan.

And here is my Tank Build Thread Build Thread

I am planning to build my own sump and figured I could document it here for all to see. I am still in the design phase (Fusion 360) but plan to pick up my material and begin cutting soon. My tank is a 5 foot long 150 gallon from SCA, which means I have a about 55"x 22" of free space inside my stand to work with. As of now I plan to make the sump 40" long, 20" deep and 18" tall.

The majority of the sump will be made from .5" thick white PVC, the rest will be viewing windows made from .25" thick acrylic. This is somewhat for design aesthetics, but also because the PVC is much cheaper and easier to work with.

I have a CNC machine in my garage which I will use to do the cutting of the PVC and Acrylic.

Here are some images to give an idea of my plan.

And here is my Tank Build Thread Build Thread