- Joined

- Mar 1, 2019

- Messages

- 140

- Reaction score

- 51

So I'm copying the many guides here and all over the web on aquarium stands. Ive hit a road block, which may or may not be a real issue.

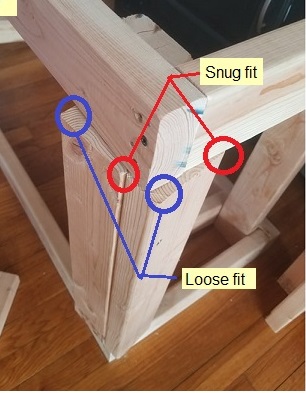

Ive got the frames built, all the wood cut. The uprights dont come out snug on both edges (see picture bellow). Regardless of why*, rebuilding did not help. I watched The King of DIY's video closely, his uprights aren't snug either so maybe it doesnt matter?

It seems important for load distribution, should I use shims? Cut 1/8" styrofoam, or a yoga mat to go between the frame and uprights? wood glue? silicone? or just give up?

*Theories on why this is happening: Maybe The floor itself is too wavey causing the bottom 2x4's frame to very slightly shift (like 0.1mm). Maybe cutting longer 2x4's with a table saw has just enough wobble that the cuts arent quite 90°, more like 89.95°. Maybe construction grade 2x4s are never going to be perfect. Maybe a combo of those things... I cant get a better fit than this with the power tools and workspace I have. So if there isnt a fix, I have to quite.

Ive got the frames built, all the wood cut. The uprights dont come out snug on both edges (see picture bellow). Regardless of why*, rebuilding did not help. I watched The King of DIY's video closely, his uprights aren't snug either so maybe it doesnt matter?

It seems important for load distribution, should I use shims? Cut 1/8" styrofoam, or a yoga mat to go between the frame and uprights? wood glue? silicone? or just give up?

*Theories on why this is happening: Maybe The floor itself is too wavey causing the bottom 2x4's frame to very slightly shift (like 0.1mm). Maybe cutting longer 2x4's with a table saw has just enough wobble that the cuts arent quite 90°, more like 89.95°. Maybe construction grade 2x4s are never going to be perfect. Maybe a combo of those things... I cant get a better fit than this with the power tools and workspace I have. So if there isnt a fix, I have to quite.