I'm interested in an electrical/mechanical failsafe for my dosing pumps, which are controlled a by Reef Angel controller and powered by a DC relay box. I have two dosing pumps, one pumps water through my kalk stirrer and the other runs my ATO. I had a situation the other day where my dosing pump that runs my stirrer came on for no reason. Luckily, I was nearby and knew it was not supposed to be running so I shut it off. I moved the pump to a different relay and changed my programming to accommodate, and It hasn’t happened since, but I want to add a “hard” failsafe. Also, I would like something I could insert between the DC relay box and each pump (e.g. I don't want to move the pumps to an AC relay box because both are about full). Each relay on the DC relay box runs 12VDC at 400 mA max. Is there something I could easily add to restrict the runtime on these two relays such that each pump could run for only so long, or is there maybe a better way to skin this cat?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical/Mechanical Failsafe for Dosing Pumps run by Controller

- Thread starter Crashjack

- Start date

- Tagged users None

you might want to move this to a new thread. I’t would probalby get more traffic there vs this one.

Off hand I don’t know of a ready made solution. Ideas I can think of are:

1. using separate input and output on the reef angel to control the relay and or a solenoid.

2. Creating a simple R-C circuit with a relay that would trigger and shut off after a period of time

3. Using a 555 timer chip to create a circuit.

I’m continuing this here, just to keep it clear...

I don’t have any experience with a Reef Angel controller but from your original description, i’m guessing that this is what you have? At some point, the pump started ‘on its own.’ Without knowing the details of how the system is set up, that would seem to give three possibilities - either the relay box had a bug/glitch and turned on independent of the controller, the controller had a glitch and sent a signal to the relay box when it wasn’t supposed to, or your programing has a bug in it. The 3rd case is the most likely; the first two are the most concerning. How did you shut off the pump when you saw it come on?

First, review your programming. Assuming it’s correct then there’s either a bug in the controller or a bug in the relay box. Neither of those is very comforting because what you’re doing is lookign for a backup because you can’t trust your controller.

First, A relay is simply a magnetic switch. It uses a low-power signal to power an electromagnet that flips a switch. Essentially by flipping a switch you indirectly flip another switch. Most commonly, they are used to allow a low voltage or low power signal to control another higher power line (e.g. a 12V signal from the controller will control the power for a 120V device)

The switch you linked should work, but you have to figure out how send it a signal so it knows when to turn on, and based on your description of your wiring/circuit skills I’m not sure I’d recommend you messing around with 120V power.

Off hand I don’t know of a ready made solution. Ideas I can think of are:

1. using separate input and output on the reef angel to control the relay and or a solenoid.

2. Creating a simple R-C circuit with a relay that would trigger and shut off after a period of time

3. Using a 555 timer chip to create a circuit.

Realize, my electrical experience is almost exclusive to RC planes and helicopters, which is mostly about connectors, wire gauges, and programming. Therefore, I'm pretty much an imbecile as it relates to what I'm trying to do in this situation. I don't really understand #1. I'm familiar with solenoids but don't really understand how to use in this application. I think #2 is what I'm describing utilizing a time delay relay. #3 is likely above my head... if it is something I can buy for less than $1, there is no way I'm going to turn it into something that works.

I did start a thread in the General Equipment forum but got no responses. From what I can piece together something like this is what I need: https://www.ebay.com/itm/MACROMATIC...9946?_trksid=p2349526.m4383.l4275.c1#viTabs_0

The problem is, I don't know the lingo well enough to know exactly what to get or how to wire. What I'm trying to accomplish is simple enough... 12VDC relay 'on' < X minutes, time delay relay remains 'on'. 12VDC relay on = X minutes, time delay relay 'off'. Time delay relay remains 'off' until 12VDC relay turns off and then back 'on'.

I’m continuing this here, just to keep it clear...

I don’t have any experience with a Reef Angel controller but from your original description, i’m guessing that this is what you have? At some point, the pump started ‘on its own.’ Without knowing the details of how the system is set up, that would seem to give three possibilities - either the relay box had a bug/glitch and turned on independent of the controller, the controller had a glitch and sent a signal to the relay box when it wasn’t supposed to, or your programing has a bug in it. The 3rd case is the most likely; the first two are the most concerning. How did you shut off the pump when you saw it come on?

First, review your programming. Assuming it’s correct then there’s either a bug in the controller or a bug in the relay box. Neither of those is very comforting because what you’re doing is lookign for a backup because you can’t trust your controller.

First, A relay is simply a magnetic switch. It uses a low-power signal to power an electromagnet that flips a switch. Essentially by flipping a switch you indirectly flip another switch. Most commonly, they are used to allow a low voltage or low power signal to control another higher power line (e.g. a 12V signal from the controller will control the power for a 120V device)

The switch you linked should work, but you have to figure out how send it a signal so it knows when to turn on, and based on your description of your wiring/circuit skills I’m not sure I’d recommend you messing around with 120V power.

you might want to move this to a new thread. I’t would probalby get more traffic there vs this one.

Off hand I don’t know of a ready made solution. Ideas I can think of are:

1. using separate input and output on the reef angel to control the relay and or a solenoid.

2. Creating a simple R-C circuit with a relay that would trigger and shut off after a period of time

3. Using a 555 timer chip to create a circuit.

I’m continuing this here, just to keep it clear...

I don’t have any experience with a Reef Angel controller but from your original description, i’m guessing that this is what you have? At some point, the pump started ‘on its own.’ Without knowing the details of how the system is set up, that would seem to give three possibilities - either the relay box had a bug/glitch and turned on independent of the controller, the controller had a glitch and sent a signal to the relay box when it wasn’t supposed to, or your programing has a bug in it. The 3rd case is the most likely; the first two are the most concerning. How did you shut off the pump when you saw it come on?

First, review your programming. Assuming it’s correct then there’s either a bug in the controller or a bug in the relay box. Neither of those is very comforting because what you’re doing is lookign for a backup because you can’t trust your controller.

First, A relay is simply a magnetic switch. It uses a low-power signal to power an electromagnet that flips a switch. Essentially by flipping a switch you indirectly flip another switch. Most commonly, they are used to allow a low voltage or low power signal to control another higher power line (e.g. a 12V signal from the controller will control the power for a 120V device)

The switch you linked should work, but you have to figure out how send it a signal so it knows when to turn on, and based on your description of your wiring/circuit skills I’m not sure I’d recommend you messing around with 120V power.

Thanks for the reply! This is what I'm using to power my dosing pumps. I also have (2) of the 120V relay boxes shown in your link, but they are about full, and I would rather not use those relays with DC converters when I already have actual DC relays.

The line of code that operates the relay in question is: if (hour() <=12 || hour() >= 19 ) ReefAngel.DosingPumpRepeat1( Box3_Port1 ); // (REM) Run kalk stirrer dosing pump if <=12:00 pm OR >=7:00 pm. This code pulls values out of internal memory or in other words, I can change dosing time and offset on a cloud interface and save, instead of having to hard code. The only other line that references that relay is: if ( ReefAngel.Params.PH > 851 ) ReefAngel.Relay.Off( Box3_Port1 ); // (REM) FAILSAFE that turns off Kalk Stirrer dosing if tank pH > 8.51.

There are 3 relay statuses shown on the Reef Angel cloud interface. 1) “Auto” - the program is managing the relays, turning on and off with green being on and red being off. 2) “On” - the relay has been manually turned on. 3) “Off” - the relay has been manually turned off. The way this situation presented itself was Auto-green. I guess the only deduction I can make from that is that the relay wasn’t manually turned on.

This issue did occur 4 days after a programming change. After that, I moved the dosing pump to a different relay and changed the code I just listed to “Box3_Port3”, and it hasn’t happened since. This isn’t an uncommon problem with controllers and programmable dosing pumps as a quick search will find all sorts of situations where dosing has gone amuck. In fact, I'm surprised someone hasn't created a simple device for this very reason. I can't imagine that anyone using a controller to manage dosing or anyone using an ATO wouldn’t want to purchase this failsafe. A simple time delay relay with (2) female DC connectors and either a potentiometer that allowed for adjustments up to five or 10 minutes or a series of dip switches that did the same thing, could service 120V with a simple 120VAC/12VDC converter, or it could connect directly to a 12VDC power source like I want to do.

Regarding a signal to the switch, my understanding is that you can set these devices several ways, one way being that once powered, the device remains on for only a set amount of time. Therefore, if your main relay is set to run for say 30 seconds and your time delay relay is set for 1 minute, the time delay relay will turn-off if it ever receives power for 1 minute, and then it won't turn back on until it receives no power (e.g. main relay turns off). After turning off, when the main relay turns back on, it's business as usual for the time delay relay.

you could probably use one of these. It uses a 12V supply voltage so you could power it directly off the reef angel controller (assuming it doesn't draw too much current) and just have it in line so it would kick on when the pump turns on, then turn off after xx minutes, regardless of whether the reef angel outlet stayed on or not.

***UPDATE***

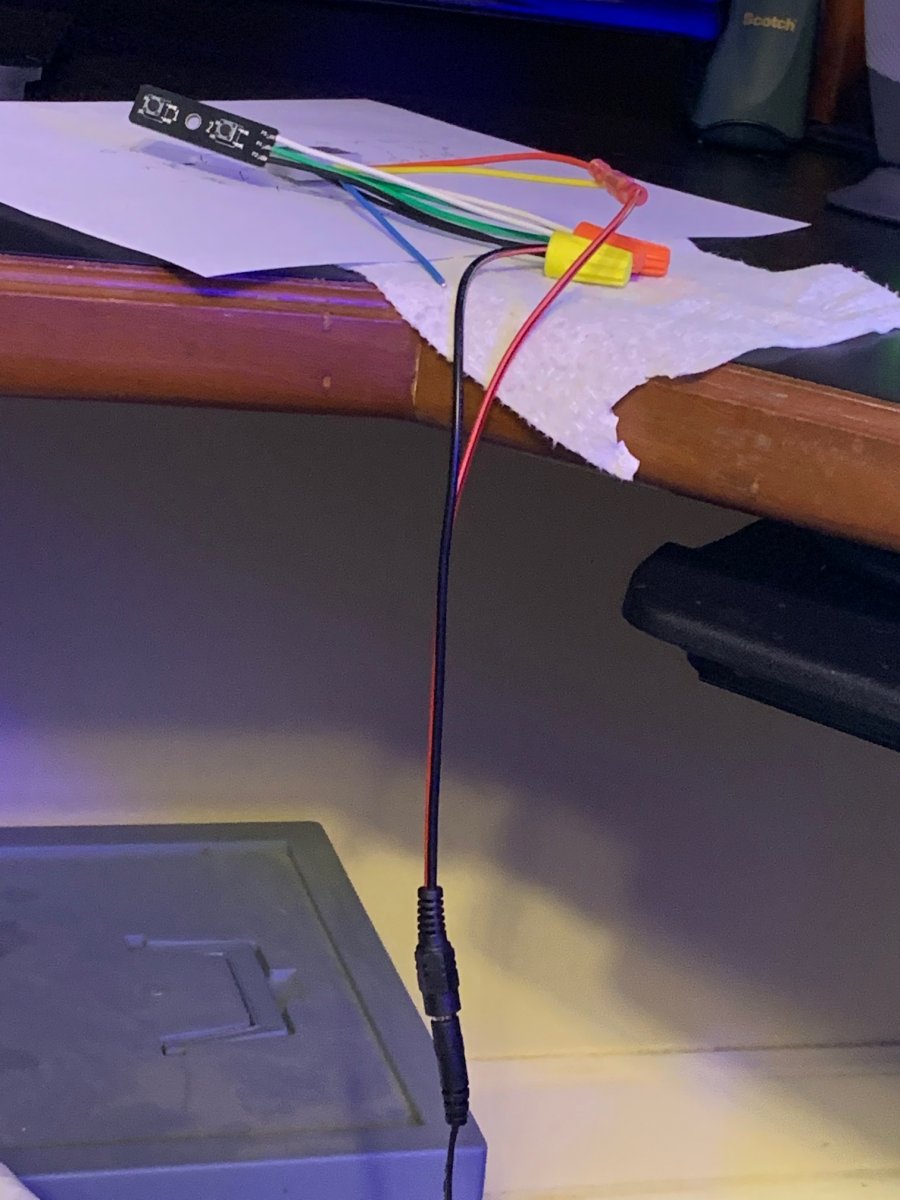

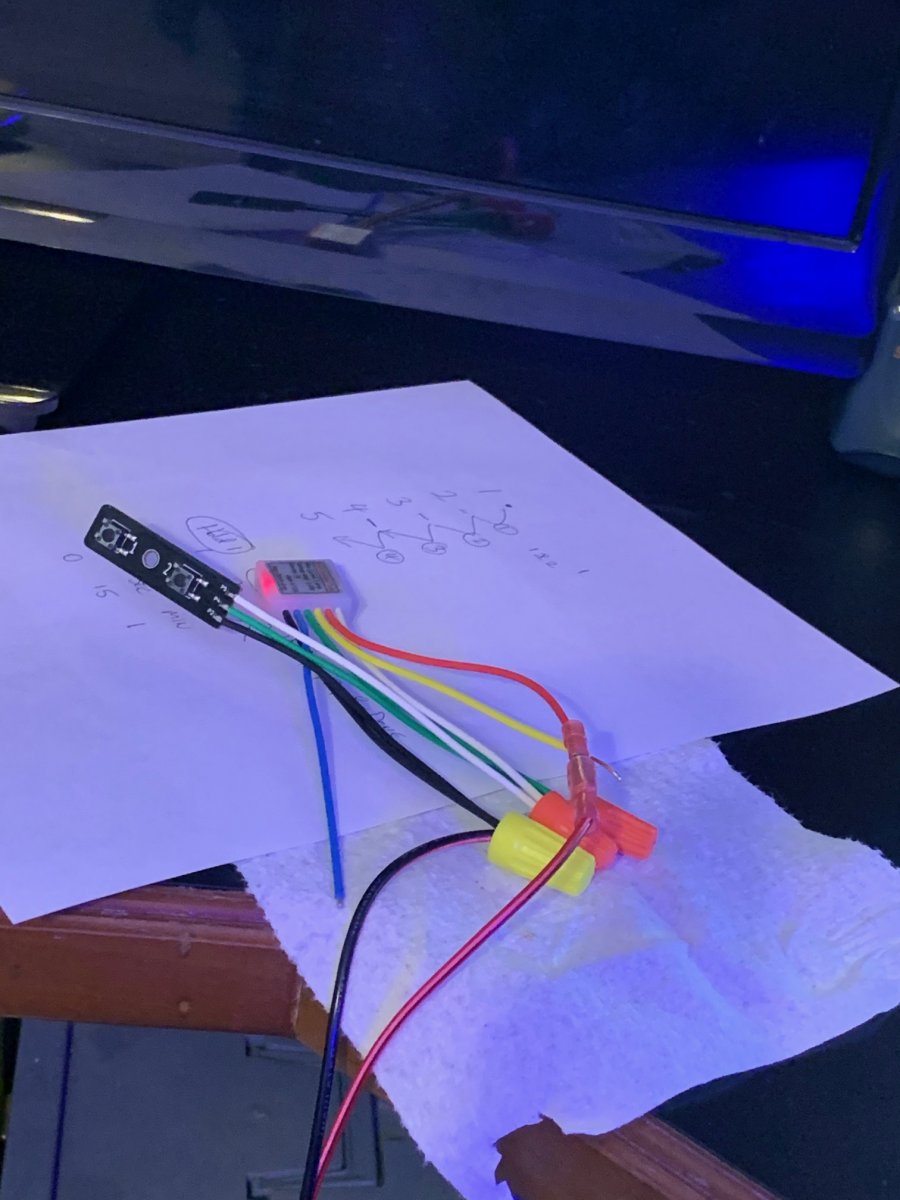

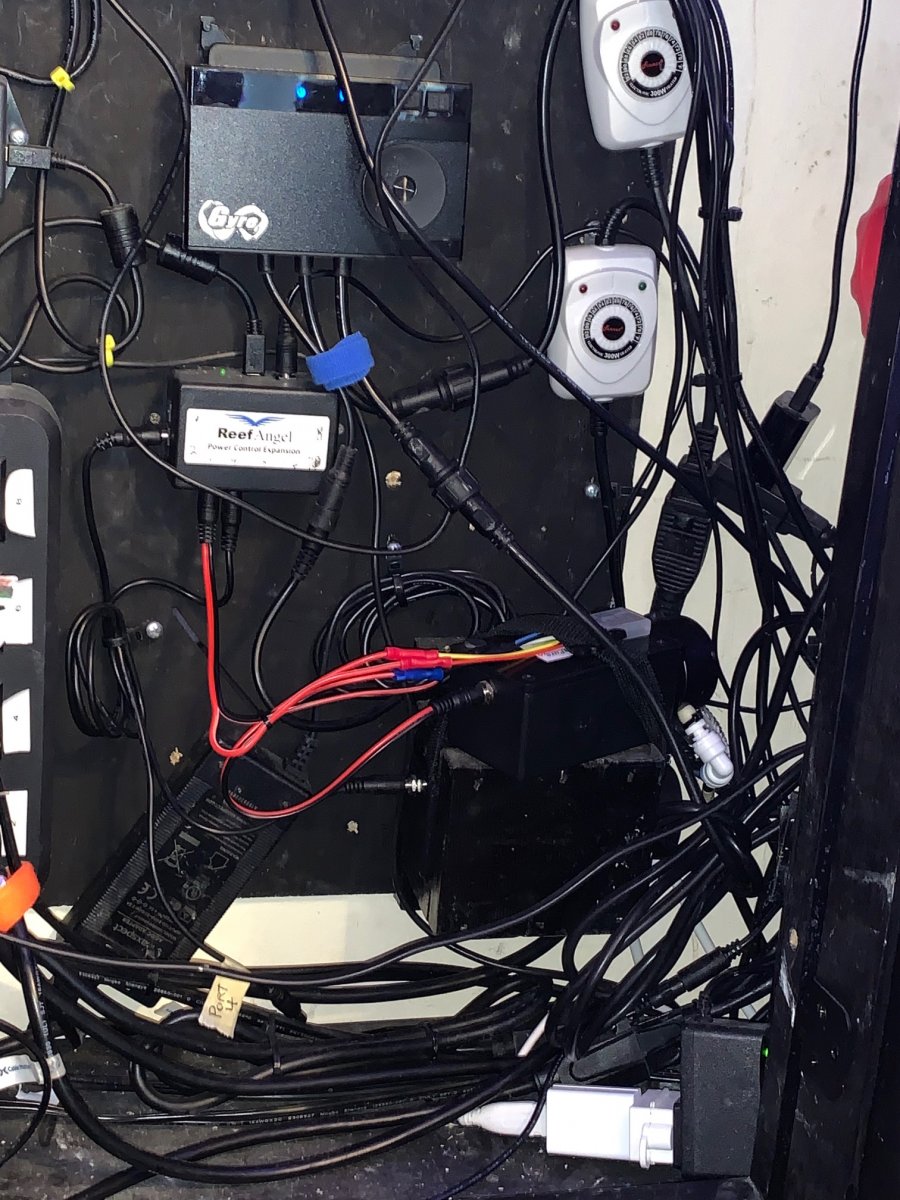

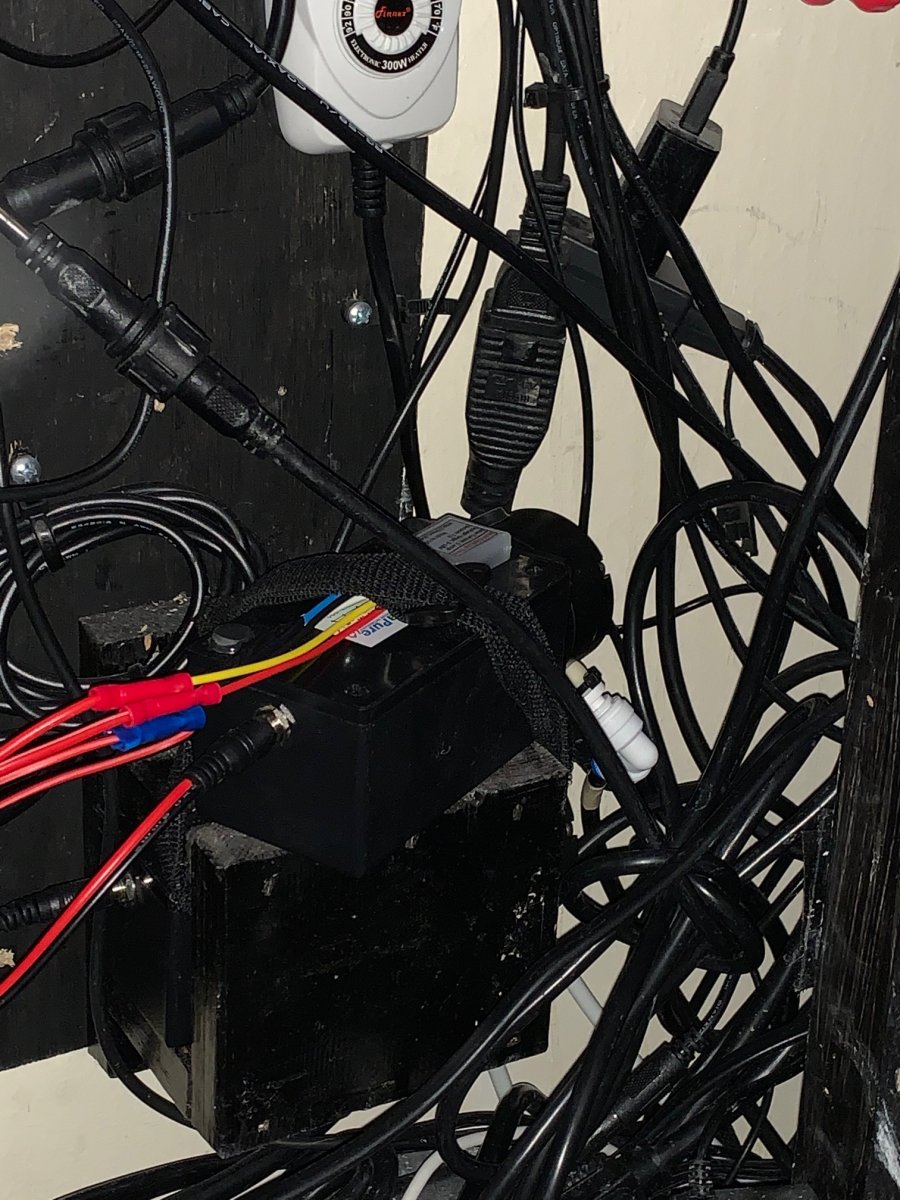

I got my brother in law, who is an electrical engineer, to help me find a solution. We found an inexpensive time delay relay that was small and could run 12V. I've attached some links and pics. I highly recommend, as I had this issue happen again after adding the time delay relays, and my kalk stirrer dosing pump ran for 1 min :15 sec, though the relay was on for 4 hours before I noticed. This time delay relay has Youtube videos and a manual. It does require some learning curve but is an inexpensive way to prevent a disaster.

Multi-Functional Timer

Configuration Board

Programming

Installed

I got my brother in law, who is an electrical engineer, to help me find a solution. We found an inexpensive time delay relay that was small and could run 12V. I've attached some links and pics. I highly recommend, as I had this issue happen again after adding the time delay relays, and my kalk stirrer dosing pump ran for 1 min :15 sec, though the relay was on for 4 hours before I noticed. This time delay relay has Youtube videos and a manual. It does require some learning curve but is an inexpensive way to prevent a disaster.

Multi-Functional Timer

Configuration Board

Programming

Installed

That looks perfect. Did you check to see if you need a flyback diode on the timer? When turned off, motors and other inductive loads can create a voltage spike that can damage some electronics.

From the manual, "A built-in fly-back diode allows for a direct connection of inductive loads."That looks perfect. Did you check to see if you need a flyback diode on the timer? When turned off, motors and other inductive loads can create a voltage spike that can damage some electronics.

Similar threads

- Replies

- 1

- Views

- 131

- Replies

- 18

- Views

- 810

- Replies

- 9

- Views

- 341